Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Iec 62040 Fae

Cargado por

nicoreb1Descripción original:

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Iec 62040 Fae

Cargado por

nicoreb1Copyright:

Formatos disponibles

Av.

Carlos Pellegrini N° 460

Luján, Buenos Aires, Argentina

Tel.: + 02323 + 43 5565

Web: www.shitsukesrl.com.ar

@:laboratorio@shitsukesrl.com.ar

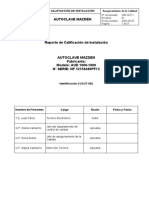

INFORME DE ENSAYO

(Test report)

IEC 62040-1 (Ed. 1): 2008 + A1: 2013

Sistemas de tensión ininterrumpida (UPS)

Parte 1: Requisitos generales y de seguridad para UPS

INFORME DE ENSAYO N°: 48341-1549-83111

Descripción del objeto ensayado .......... : Fuente de alimentación ininterrumpida (UPS).

Marca comercial ....................................... : QMAX.

Modelo ...................................................... : QM-FAE-1KVA.

Fabricante / Importador (+Dirección) ......... : QMAX S.R.L.

Olivieri 235- CABA- Buenos Aires- Argentina.

Características nominales ...................... : Alimentación ~: 1Ø 180-240 VAC; 35-65 Hz; 10 A Max;

Salida~: 1Ø220 VAC; 50 Hz; 1kVA;

Baterías: 8 celdas 12 V/100 Ah (Pb) VRLA; 48 V DC 200 Ah;

Alimentación ―: 36-64 V DC; 25 A.

País de origen .......................................... : Industria Argentina.

Aplicante (+Dirección) ................................. : IRAM

Perú 556, C.A.B.A., Argentina.

Comitente (+Dirección) ................................ : QMAX

Olivieri 235, C.A.B.A., Argentina.

Laboratorio de ensayos .......................... : Shitsuke S.R.L.

Reconocido por Disp. D.N.C.I. Nº .......... : 1045/1999 + 582/2001

Realizó (cargo + firma) ............................ : Germán Somoza

(Experto técnico) ……………………………………

Aprobó (cargo + firma) ............................ : Ing. Guillermo de Gregorio

(Director técnico) ……………………………………

Fecha emisión de informe ...................... : 2018-Ago-21

Laboratorios subcontratados ................. : No se emplearon.

Procedimiento empleado ........................ : El indicado por las normas aplicables.

Métodos no normalizados ...................... : No se aplicaron.

Normas aplicables ................................... : IEC 62040-1 (Ed. 1): 2008 + A1: 2013

Desviaciones ............................................ : No se aplicaron.

Base de Informe ....................................... : IEC62040-1

Fecha y revisión de la base .................... : 2017-May-02 // Rev.: 02

Derechos de propiedad de la base ........ : La base de este documento en blanco preparada por SHITSUKE, podrá ser utilizada

solo con autorización expresa por parte del laboratorio.

Informe N°: 48341-1549-83111 Shitsuke S.R.L.

Página: 1 de 33

Número de sello o lacre Referencia del certificador Fecha de la toma de muestra

02-086262 DC-E-S-4063/002.2 2018-Ago-02

Fecha de realización de los ensayos

Fecha de recepción del objeto

Inicio Finalización

2018-Ago-06 2018-Ago-07 2018-Ago-21

Placa de características y/o fotografía del objeto ensayado

(Imágenes fuera de escala)

Condiciones generales

1. Las posibles formas de identificar un veredicto sobre el resultado de un ensayo o verificación particular

contenida en este informe, es la indicada en la tabla 1.

2. La verificación se efectuará de acuerdo a los criterios y métodos de la norma de referencia establecida por

el organismo de certificación actuante.

3. Cuando los ensayos sean requeridos para un elemento de comercialización en el campo regulado, si de

la inspección y ensayos debiera determinarse otros requisitos no considerados en la lista de

verificaciones técnicas, se incluirá en un anexo dicho requisito o una recomendación al organismo de

certificación actuante o a la autoridad de aplicación del régimen establecido por las resoluciones legales

vigentes aplicables al caso.

4. Cuando no sea autoexplicativo, un resultado NPA tendrá observaciones claras y en lo posible se

adjuntarán imágenes en un anexo.

5. Los componentes certificados no se ensayan salvo expreso pedido por parte del organismo de certificación.

6. No está autorizada la duplicación de este documento si no se expone en su totalidad, salvo autorización

expresa por parte de la dirección del laboratorio.

7. Los datos y resultados contenidos en este informe, sólo se corresponden a la muestra ensayada.

8. La muestra será conservada por el laboratorio durante los 15 días posteriores a la entrega del

informe. Luego de ello, la misma se dispone para su eliminación.

Informe N°: 48341-1549-83111 Shitsuke S.R.L.

Página: 2 de 33

Tabla 1 - Posibles formas de aplicar e identificar un veredicto técnico

Abreviatura Significado Motivo por el cual se aplicó el veredicto

NA NO APLICABLE Capítulo que no se aplica al diseño evaluado.

PA PASA Cumple en forma satisfactoria lo requerido por el capítulo aplicado.

NPA NO PASA No satisface lo requerido por el capítulo aplicado.

Capítulo que, aunque es aplicable, no se lo ensaya por acuerdo con el

NE NO ENSAYADO

certificador o el comitente.

CORRESPONDE Se aplica cuando no se requiere aplicar un veredicto.

XX* Ensayo no acreditado Ensayo no incluido en el alcance de la acreditación del OAA.

#

XX Ensayo sub-contratado Veredicto obtenido con un ensayo subcontratado.

N Veredicto que es acompañado con imágenes anexas, donde N

XX Referencia en anexos

corresponde al número de la ilustración.

Requisitos adicionales no cubiertos por la normativa técnica.

Los ítem 6, 7 y 10 se determinan por ensayos, los restantes se limitan a una inspección visual de su presencia

It Requisitos Observación Veredicto

1 País de origen o Ind. Arg. Industria Argentina PA

2 Fabricante o la marca comercial

Art. 4, 5 y

Ver portada

3 6 Modelo, número de tipo, lote, serie

4 Idioma del marcado Español. PA

Res. 799/99 y 197/04 T L M

Res. 169/18 de

5 Sec. de Art. 14 Los símbolos deberán ser exhibidos en NA

Comercio cada una de las unidades de los

productos alcanzados.

6 No serán aparatos clase 0 o 01 PA

Las personas estarán adecuadamente

7

Anexo II protegidas

PA

Aparatos con tensiones entre 50V y

8

250V

PA

9 Se.C.I. 731/87 Etiquetado de aparatos clase I y clase II. PA

10 Res. 524 S.I.C. y M. Fichas para uso doméstico. PA

Artículo 1 de Disp. 462/2009

11

y Art. 33d) de res. 169/18

Alcanzado por la disposición NO SI N/A

Informe N°: 48341-1549-83111 Shitsuke S.R.L.

Página: 3 de 33

Test item particulars .................................................. :

Equipment mobility .................................................... : [] movable [-] stationary [-] for building-in

Connection to the mains ............................................ : [] pluggable equipment [-] permanent connection

[-] detachable power supply cord

[] non-detachable power supply cord

Operating condition.................................................... : [] continuous

[-] rated operating / resting time:

Access location ......................................................... : [] operator accessible

[-] restricted access location

Over voltage category (OVC) ................................... : [-] OVC I [] OVC II [-] OVC III [-] OVC IV

[-] other:

Mains supply tolerance (%) or absolute mains supply 180-240V

values ........................................................................ :

Tested for IT power systems .................................... : [-] Yes [] No

IT testing, phase-phase voltage (V) .......................... : -

Class of equipment ................................................... : [] Class I [-] Class II

[-] Not classified

Considered current rating (A) ................................... : 10A

Pollution degree (PD) ............................................... : [-] PD 1 [] PD 2 [-] PD 3

IP protection class .................................................... : IP20

Altitude during operation (m) .................................... : -

Altitude of test laboratory (m) ................................... : -

Informe N°: 48341-1549-83111 Shitsuke S.R.L.

Página: 4 de 33

Capitulo Requisito Observación Veredicto

4 GENERAL CONDITIONS FOR TESTS -

4.5 Components -

Comply with IEC 62040-1 or relevant component (see appended table 4.5) PA

standard

1.5.2/RD Evaluation and testing of components PA

1.5.3/RD Thermal controls NA

1.5.4/RD Transformers Componente perteneciente al PA

inversor.

1.5.5/RD Interconnecting cables NA

1.5.6/RD Capacitors bridging insulation Componente perteneciente al PA

inversor.

1.5.7/RD Resistors bridging insulation Componente perteneciente al PA

inversor.

1.5.7.1/RD Resistors bridging functional, basic or supplementary Componente perteneciente al PA

insulation inversor.

1.5.7.2/RD Resistors bridging double or reinforced insulation NA

between a.c. mains and other circuits

1.5.7.3/RD Resistors bridging double or reinforced insulation NA

between a.c. mains and antenna or coaxial cable

1.5.8/RD Components in equipment for IT power systems NA

4.6 Power interface -

1.6.1/RD AC power distribution systems PA

1.6.2/RD Input current (see appended table 4.6) PA

4.6 Neutral conductor PA

1.6.4/RD

4.7 Marking and instructions -

4.7.1 General PA

4.7.2 Power rating PA

Input rated voltage/range (V) ............................ : 180-240 V PA

Input rated current/range (A) ............................ : 10 A PA

Input symbol for nature of supply (d.c.) ........... : NA

Input rated frequency/range (Hz) ..................... : 35-64 Hz PA

Rated short-time withstand current (ICW) or rated ICC 1 kA PA

conditional short-circuit current (ICC)…………..:

1.7.1/RD Number of Input phases and neutral ................ : 1Ø PA

Output rated voltage/range (V) ........................ : 180-240 V PA

Output rated current/range (A) ........................ : 10 A PA

Output rated power factor, (if less than unity, or NA

active power and apparent power or active power

and rated current) ............................................ :

1.7.1/RD Number of output phases and neutral ............. : 1Ø PA

Output rated active power (W) ........................ : NA

Informe N°: 48341-1549-83111 Shitsuke S.R.L.

Página: 5 de 33

Capitulo Requisito Observación Veredicto

Output rated apparent power (VA) .................. : 1 kVA PA

Output symbol for nature of supply (d.c.) ........ : NA

Output rated frequency/range (Hz)................... : 50 Hz PA

Ambient operating temperature range (C) ..... : 0-40ºC PA

Manufacturer’s name or trademark or identification QMAX PA

mark ................................................................. :

Type/model or type reference .......................... : QM-FAE-1KVA PA

Symbol for Class II equipment only ................. : NA

Other symbols ................................................. : PA

Certification marks ........................................... : NA

Instructions for units with automatic NA

bypass/maintenance bypass, additional input a.c.

supply, or external batteries, having text "See

installation instructions before connecting to the

supply" ............................................................. :

Rated short-time withstand current or rated 1 kA PA

conditional short-circuit current

4.7.3 Safety instructions PA

4.7.3.1 General PA

4.7.3.2 Installation ........................................................ : PA

Location in a restricted access location only ... : NA

Permanent connector UPS ............................... : NA

Pluggable type A or Pluggable type B UPS .... : PA

4.7.3.3 Operation .......................................................... : PA

4.7.3.4 Maintenance ..................................................... : PA

4.7.3.5 Distribution related backfeed ............................ : PA

4.7.4 Main voltage adjustment ................................. : NA

1.7.4/RD

Methods and means of adjustment; reference to NA

installation instructions .................................... :

4.7.5 Power outlets .................................................... : PA

1.7.5/RD

4.7.6 Fuse identification (marking, special fusing NA

1.7.6/RD characteristics, cross-reference) ..................... :

4.7.7 Wiring terminals NA

1.7.7/RD

1.7.7.1/RD Protective earthing and bonding terminals ...... : NA

1.7.7.2/RD Terminals for a.c. mains supply conductors NA

1.7.7.3/RD Terminals for d.c. mains supply conductors NA

4.7.8 Battery terminals .............................................. : PA

4.7.9 Controls and indicators NA

1.7.8/RD

1.7.8.1/RD Identification, location and marking ................. : NA

1.7.8.2/RD Colours ........................................................... : NA

1.7.8.3/RD Symbols according to IEC 60417 ..................... : NA

Informe N°: 48341-1549-83111 Shitsuke S.R.L.

Página: 6 de 33

Capitulo Requisito Observación Veredicto

1.7.8.4/RD Markings using figures ................................... : NA

4.7.10 Isolation of multiple power sources ................. : NA

1.7.9/RD

4.7.11 IT power systems NA

1.7.2.4/RD

4.7.12 Protection in building installation PA

The UPS manufacturer shall state, as applicable, PA

the rated short-time withstand current or rated

conditional short circuit current.

The installer can then verify that the prospective PA

short-circuit current resulting at the a.c. input

terminals of the unit is equal to or less than the

value declared by the manufacturer.

Irrespective of the UPS being a single unit or a unit PA

in a paralleled system, prospective short-circuit

current

4.7.13 High leakage current (mA) .............................. : Línea: < 2,45 mA PA

5.1/RD Neutro: < 2,45 mA

4.7.14 Thermostats and other regulating devices NA

1.7.10/RD

4.7.15 Language(s) .................................................... :

1.7.2.1/RD

and

1.7.8.1/RD

4.7.16 Durability of markings PA

1.7.11/RD

4.7.17 Removable parts PA

1.7.12/RD

4.7.18 Replaceable batteries PA

1.7.13/RD

4.7.19 Operator access with a tool .............................. : NA

1.7.2.5/RD

4.7.20 Battery PA

Clearly legible information ............................... : PA

Battery type ..................................................... : PA

Nominal voltage of total battery (V) ................. : 48 V DC PA

Nominal capacity of total battery (optional) ..... : 200 Ah PA

Warning label ................................................... : PA

Instructions ...................................................... : PA

2.1.1.5/RD Protection against energy hazards PA

4.7.21 Installation instructions PA

1.7.2.4/RD

5 FUNDAMENTAL DESIGN REQUIREMENTS -

5.1 Protection against electric shock and energy hazards -

5.1.1 Protection for UPS intended to be used in operator PA

2.1.1/RD access areas

2.1.1.1/RD Access to energized parts PA

Informe N°: 48341-1549-83111 Shitsuke S.R.L.

Página: 7 de 33

Capitulo Requisito Observación Veredicto

Test by inspection ........................................... : PA

Test with test finger (Figure 2A) ...................... : PA

Test with test pin (Figure 2B) .......................... : PA

Test with test probe (Figure 2C) ...................... : NA

2.1.1.2/RD Battery compartments PA

2.1.1.3/RD Access to ELV wiring NA

Working voltage (Vpeak or Vrms); minimum

distance through insulation (mm)

2.1.1.4/RD Access to hazardous voltage circuit wiring NA

2.1.1.5/RD Energy hazards ............................................... : NA

2.1.1.6/RD Manual controls NA

2.1.1.7/RD Discharge of capacitors in equipment PA

Measured voltage (V); time-constant (s) .......... : Constante de tiempo <0,7s

2.1.1.8/RD Energy hazards – d.c. mains supply NA

a) Capacitor connected to the d.c. mains supply .. : NA

b) Internal battery connected to the d.c. mains NA

supply .............................................................. :

2.1.1.9/RD Audio amplifiers ............................................... : NA

5.1.2 Protection for UPS intended to be used in service NA

2.1.1.5 c) access areas

/RD

Hazardous energy level NA

5.1.3 Protection for UPS intended to be used in restricted NA

2.1.1.5 c) access areas

/RD

Hazardous energy level NA

5.1.4 Backfeed protection

Shock hazard after de-energization of a.c. input for PA

UPS

Description of the construction ........................ : PA

5.1.5 Emergency switching device PA

5.2 Requirements for auxiliary circuits -

5.2.1 Safety extra low voltage circuit - SELV PA

2.2/RD

2.2.1/RD General requirements PA

2.2.2/RD Voltages under normal conditions (V) ............. : PA

2.2.3/RD Voltages under fault conditions (V) ................. : PA

2.2.4/RD Connection of SELV circuits to other circuits .. : NA

5.2.2 Telephone network voltage circuits - TNV NA

2.3/RD

2.3.1/RD Limits NA

Type of TNV circuits ......................................... :

Informe N°: 48341-1549-83111 Shitsuke S.R.L.

Página: 8 de 33

Capitulo Requisito Observación Veredicto

2.3.2/RD Separation from other circuits and from accessible NA

parts

2.3.2.1/RD General requirements NA

2.3.2.2/RD Protection by basic insulation NA

2.3.2.3/RD Protection by earthing NA

2.3.2.4/RD Protection by other constructions .................... : NA

2.3.3/RD Separation from hazardous voltages NA

Insulation employed ......................................... :

2.3.4/RD Connection of TNV circuits to other circuits NA

Insulation employed ......................................... :

2.3.5/RD Test for operating voltages generated externally NA

Test with test probe (Figure 2C) ...................... : NA

5.2.3 Limited current circuits NA

2.4/RD

2.4.1/RD General requirements NA

2.4.2/RD Limit values

Frequency (Hz) ................................................. :

Measured current (mA) .................................... :

Measured voltage (V) ....................................... :

Measured circuit capacitance (nF or µF) .......... :

2.4.3/RD Connection of limited current circuits to other circuits NA

5.2.4 External signalling circuits NA

3.5/RD

3.5.1/RD General requirements NA

3.5.2/RD Types of interconnection circuits ..................... : NA

3.5.3/RD ELV circuits as interconnection circuits NA

3.5.4/RD Data ports for additional equipment NA

5.2.5 Limited power source NA

2.5/RD

a) Inherently limited output NA

b) Impedance limited output NA

c) Regulating network limited output under normal NA

operating and single fault condition

d) Overcurrent protective device limited output NA

Max. output voltage (V), max. output current (A),

max. apparent power (VA) ............................... :

Current rating of overcurrent protective device (A)

5.3 Protective earthing and bonding -

5.3.1 General PA

2.6/RD Provisions for earthing and bonding PA

2.6.1/RD Protective earthing PA

2.6.2/RD Functional earthing NA

Informe N°: 48341-1549-83111 Shitsuke S.R.L.

Página: 9 de 33

Capitulo Requisito Observación Veredicto

2.6.3/RD Protective earthing and protective bonding PA

conductors

2.6.3.1/RD General PA

2.6.3.2/RD Size of protective earthing conductors PA

2

Rated current (A), cross-sectional area (mm2), 10 A; 2,5 mm

AWG ................................................................. :

2.6.3.3/RD Size of protective bonding conductors PA

2

Rated current (A), cross-sectional area (mm2), 10 A; 2,5 mm

AWG ................................................................. :

2.6.3.4/RD Resistance of earthing conductors and their NA

terminations; resistance (), voltage drop (V), test

current (A), duration (min) ................................ :

2.6.3.5/RD Colour of insulation ........................................... : NA

2.6.4/RD Terminals PA

2.6.4.1/RD General PA

2.6.4.2/RD Protective earthing and bonding terminals PA

Rated current (A), type, nominal thread diameter 10 A; 3,0 mm

(mm) ................................................................. :

2.6.4.3/RD Separation of the protective earthing conductor from PA

protective bonding conductors

2.6.5/RD Integrity of protective earthing PA

2.6.5.1/RD Interconnection of equipment NA

2.6.5.2/RD Components in protective earthing conductors and PA

protective bonding conductors

2.6.5.3/RD Disconnection of protective earth PA

2.6.5.4/RD Parts that can be removed by an operator PA

2.6.5.5/RD Parts removed during servicing PA

2.6.5.6/RD Corrosion resistance PA

2.6.5.7/RD Screws for protective bonding PA

2.6.5.8/RD Reliance on telecommunication network or cable NA

distribution system

5.3.2 Protective earthing PA

2.6.1/RD

2.10/RD Clearances, creepage distances and distances PA

through insulation

4.2/RD Mechanical strength PA

5.2/RD Electric strength PA

5.3.3 Protective bonding PA

5.4 AC and d.c. power isolation -

5.4.1 General PA

3.4/RD Disconnection from the mains supply PA

3.4.1/RD General requirement PA

3.4.2/RD Disconnect devices PA

3.4.3/RD Permanently connected equipment NA

Informe N°: 48341-1549-83111 Shitsuke S.R.L.

Página: 10 de 33

Capitulo Requisito Observación Veredicto

3.4.4/RD Parts which remain energized NA

3.4.5/RD Switches in flexible cords NA

3.4.6/RD Number of poles - single-phase and d.c. equipment PA

3.4.7/RD Number of poles - three-phase equipment NA

3.4.8/RD Switches as disconnect devices NA

3.4.9/RD Plugs as disconnect devices PA

3.4.10/RD Interconnected equipment NA

3.4.11/RD Multiple power sources NA

5.4.2 Disconnect devices PA

5.5 Overcurrent and earth fault protection -

5.5.1 General PA

2.7.3/RD Short-circuit backup protection PA

2.7.4/RD Number and location of protective devices ..... : PA

2.7.5/RD Protection by several devices NA

2.7.6/RD Warning to service personnel .......................... : NA

5.5.2 Basic requirements PA

5.5.3 Battery circuit protection PA

5.5.3.1 Overcurrent and earth fault protection PA

5.5.3.2 Location of protective device PA

5.5.3.3 Rating of protective device PA

5.3.1/RD Protection against overload and abnormal operation (see appended table 8.3) PA

5.5.4 Short-time withstand current PA

5.5.4.1 General PA

5.5.4.2 Modes of operation PA

5.5.4.3 Test procedure PA

5.5.4.3.1 General application PA

5.5.4.3.2 Exemption from testing PA

5.6 Protection of personnel – Safety interlocks -

5.6.1 Operator protection NA

2.8/RD Safety interlocks NA

2.8.1/RD General principles NA

2.8.2/RD Protection requirements NA

2.8.3/RD Inadvertent reactivation NA

2.8.4/RD Fail-safe operation NA

2.8.5/RD Moving parts NA

2.8.6/RD Overriding NA

2.8.7/RD Switches and relays NA

2.8.7.1/RD Contact gaps (mm) .......................................... : NA

Informe N°: 48341-1549-83111 Shitsuke S.R.L.

Página: 11 de 33

Capitulo Requisito Observación Veredicto

2.8.7.2/RD Overload test NA

2.8.7.3/RD Endurance test NA

2.8.7.4/RD Electric strength test NA

2.8.8/RD Mechanical actuators NA

5.6.2 Service person protection NA

5.6.2.1 Introduction NA

5.6.2.2 Covers NA

5.6.2.3 Location and guarding of parts NA

5.6.2.4 Parts on doors NA

5.6.2.5 Component access NA

2.8.3/RD Inadvertent reactivation NA

5.6.2.6 Moving parts NA

5.6.2.7 Capacitor banks NA

5.6.2.8 Internal batteries PA

5.7 Clearances, creepage distances and distances through insulation -

2.10/RD

2.10.1/RD General PA

2.10.1.1/RD Frequency ........................................................ : PA

2.10.1.2/RD Pollution degrees ............................................. : PA

2.10.1.3/RD Reduced values for functional insulation NA

2.10.1.4/RD Intervening unconnected conductive parts NA

2.10.1.5/RD Insulation with varying dimensions NA

2.10.1.6/RD Special separation requirements NA

2.10.1.7/RD Insulation in circuits generating starting pulses NA

2.10.2/RD Determination of working voltage (See appended table 5.7) PA

2.10.2.1/RD General PA

2.10.2.2/RD RMS working voltage PA

2.10.2.3/RD Peak working voltage PA

2.10.3/RD Clearances PA

2.10.3.1/RD General PA

2.10.3.2/RD Mains transient voltages PA

a) AC mains supply ......................................... : PA

b) Earthed d.c. mains supplies ........................ : NA

c) Unearthed d.c. mains supplies .................... : NA

d) Battery operation ......................................... : NA

2.10.3.3/RD Clearances in primary circuits (see appended table 5.7) PA

2.10.3.4/RD Clearances in secondary circuits (see appended table 5.7) PA

2.10.3.5/RD Clearances in circuits having starting pulses NA

2.10.3.6/RD Transients from a.c. mains supply .................. : PA

2.10.3.7/RD Transients from d.c. mains supply .................. : NA

Informe N°: 48341-1549-83111 Shitsuke S.R.L.

Página: 12 de 33

Capitulo Requisito Observación Veredicto

2.10.3.8/RD Transients from telecommunication networks and NA

cable distribution systems ............................... :

2.10.3.9/RD Measurement of transient voltage levels NA

a) Transients from a mains supply NA

For an a.c. mains supply ................................. : NA

For a d.c. mains supply ................................... : NA

b) Transients from a telecommunication network . : NA

2.10.4/RD Creepage distances (see appended table 5.7) PA

2.10.4.1/RD General PA

2.10.4.2/RD Material group and comparative tracking index PA

CTI tests ........................................................... : IIIb

2.10.4.3/RD Minimum creepage distances PA

2.10.5 /RD Solid insulation PA

2.10.5.1/RD General (see appended table 2.10.5.1) NA

2.10.5.2/RD Distances through insulation (see appended table 5.7) PA

2.10.5.3/RD Insulating compound as solid insulation PA

2.10.5.4/RD Semiconductor devices PA

2.10.5.5/RD Cemented joints NA

2.10.5.6/RD Thin sheet material – General PA

2.10.5.7/RD Separable thin sheet material PA

Number of layers (pcs) .................................... :

2.10.5.8/RD Non-separable thin sheet material NA

2.10.5.9/RD Thin sheet material – standard test procedure NA

Electric strength test

2.10.5.10 Thin sheet material – alternative test procedure NA

/RD

Electric strength test

2.10.5.11 Insulation in wound components NA

/RD

2.10.5.12 Wire in wound components NA

/RD

Working voltage ............................................... :

a) Basic insulation not under stress ................ : NA

b) Basic, supplementary, reinforced insulation : NA

c) Compliance with Annex U ........................... : NA

Two wires in contact inside wound component; NA

angle between 45 and 90 ............................. :

2.10.5.13 Wire with solvent-based enamel in wound NA

/RD components

Electric strength test

Routine test NA

2.10.5.14 Additional insulation in wound components NA

/RD

Informe N°: 48341-1549-83111 Shitsuke S.R.L.

Página: 13 de 33

Capitulo Requisito Observación Veredicto

Working voltage ............................................... :

- Basic insulation not under stress .................. : NA

- Supplementary, reinforced insulation ............ : NA

2.10.6/RD Construction of printed boards PA

2.10.6.1/RD Uncoated printed boards NA

2.10.6.2/RD Coated printed boards PA

2.10.6.3/RD Insulation between conductors on the same inner NA

surface of a printed board

2.10.6.4/RD Insulation between conductors on different layers of NA

a printed board

Distance through insulation NA

Number of insulation layers (pcs) .................... : NA

2.10.7/RD Component external terminations PA

2.10.8/RD Tests on coated printed boards and coated NA

components

2.10.8.1/RD Sample preparation and preliminary inspection NA

2.10.8.2/RD Thermal conditioning NA

2.10.8.3/RD Electric strength test

2.10.8.4/RD Abrasion resistance test NA

2.10.9/RD Thermal cycling NA

2.10.10/RD Test for Pollution Degree 1 environment and NA

insulating compound

2.10.11/RD Tests for semiconductor devices and cemented PA

joints

2.10.12/RD Enclosed and sealed parts NA

6 Wiring, connections and supply -

6.1 General PA

6.1.1 Introduction PA

3.1/RD General PA

3.1.1/RD Current rating and overcurrent protection PA

3.1.2/RD Protection against mechanical damage PA

3.1.3/RD Securing of internal wiring PA

3.1.4/RD Insulation of conductors PA

3.1.5/RD Beads and ceramic insulators NA

3.1.6/RD Screws for electrical contact pressure PA

3.1.7/RD Insulating materials in electrical connections NA

3.1.8/RD Self-tapping and spaced thread screws NA

3.1.9/RD Termination of conductors PA

10 N pull test PA

3.1.10/RD Sleeving on wiring NA

6.1.2 Dimensions and rating of busbars and insulated NA

conductors

Informe N°: 48341-1549-83111 Shitsuke S.R.L.

Página: 14 de 33

Capitulo Requisito Observación Veredicto

6.2 Connection to power -

6.2.1 General provisions for connection to power PA

3.2.2/RD Multiple supply connections NA

3.2.3/RD Permanently connected equipment NA

Number of conductors, diameter of cable and

conduits (mm) .................................................. :

3.2.4/RD Appliance inlets NA

3.2.5/RD Power supply cords PA

3.2.5.1/RD AC power supply cords PA

Type ................................................................. : 247 NM 53-C5.

2

Rated current (A), cross-sectional area (mm²), AWG 10 A; 2,50 mm

.......................................................................... :

3.2.5.2/RD DC power supply cords NA

3.2.6/RD Cord anchorages and strain relief PA

Mass of equipment (kg), pull (N) .................... : > 4kg; 100 N

Longitudinal displacement (mm) ..................... : < 1,4 mm

3.2.7/RD Protection against mechanical damage PA

3.2.8/RD Cord guards NA

Diameter or minor dimension D (mm); test mass (g)

.......................................................................... :

Radius of curvature of cord (mm) ..................... :

6.2.2 Means of connection ....................................... : PA

More than one supply connection ................... : NA

6.3 Wiring terminals for external power conductors -

3.3/RD Wiring terminals for connection of external NA

conductors

3.3.1/RD Wiring terminals NA

3.3.2/RD Connection of non-detachable power supply cords NA

3.3.3/RD Screw terminals NA

3.3.4/RD Conductor sizes to be connected NA

Rated current (A), cord/cable type, cross-sectional

area (mm2) ....................................................... :

3.3.5/RD Wiring terminal sizes NA

Rated current (A), type, nominal thread diameter

(mm) ................................................................ :

3.3.6/RD Wiring terminal design NA

3.3.7/RD Grouping of wiring terminals NA

3.3.8/RD Stranded wire NA

7 Physical requirements –

7.1 Enclosure PA

Informe N°: 48341-1549-83111 Shitsuke S.R.L.

Página: 15 de 33

Capitulo Requisito Observación Veredicto

7.2 Stability -

4.1/RD

Angle of 10 PA

Test force PA

7.3 Mechanical strength -

4.2/RD

4.2.1/RD General PA

4.2.2/RD Steady force test, 10 N

4.2.3/RD Steady force test, 30 N PA

4.2.4/RD Steady force test, 250 N PA

4.2.5/RD Impact test PA

Fall test PA

Swing test PA

4.2.6/RD Drop test; height (mm) ..................................... : NA

4.2.7/RD Stress relief test

4.2.8/RD Cathode ray tubes NA

Picture tube separately certified ...................... :

4.2.9/RD High pressure lamps NA

4.2.10/RD Wall or ceiling mounted equipment; force (N) . : NA

7.4 Construction details -

7.4.1 Introduction PA

4.3.1/RD Edges and corners PA

4.3.2/RD Handles and manual controls; force (N) ........... : NA

4.3.3/RD Adjustable controls NA

4.3.4/RD Securing of parts PA

4.3.5/RD Connection by plugs and sockets NA

4.3.7/RD Heating elements in earthed equipment NA

4.3.11/RD Containers for liquids or gases NA

4.4/RD Protection against hazardous moving parts NA

4.4.1/RD General NA

4.4.2/RD Protection in operator access areas ................ : NA

4.4.3/RD Protection in restricted access locations ......... : NA

4.4.4/RD Protection in service access areas NA

4.5/RD Thermal requirements PA

4.5.1/RD General PA

4.5.2/RD Temperature tests PA

Normal load condition per Annex L ................. : NA

4.5.3/RD Temperature limits for materials PA

4.5.4/RD Touch temperature limits PA

4.5.5/RD Resistance to abnormal heat ........................... : (see appended table 7.4) PA

Informe N°: 48341-1549-83111 Shitsuke S.R.L.

Página: 16 de 33

Capitulo Requisito Observación Veredicto

7.4.2 Openings PA

7.4.3 Gas Concentration PA

7.4.4 Equipment movement NA

7.5 Resistance to fire -

4.7/RD

4.7.1/RD Reducing the risk of ignition and spread of flame PA

Method 1, selection and application of components NA

wiring and materials

Method 2, application of all of simulated fault (see appended table 8.3) PA

condition tests El producto posee una cubierta

íntegramente metálica

4.7.2/RD Conditions for a fire enclosure PA

4.7.2.1/RD Parts requiring a fire enclosure PA

4.7.2.2/RD Parts not requiring a fire enclosure PA

4.7.3/RD Materials NA

4.7.3.1/RD General NA

4.7.3.2/RD Materials for fire enclosures NA

4.7.3.3/RD Materials for components and other parts outside NA

fire enclosures

4.7.3.4/RD Materials for components and other parts inside fire NA

enclosures

4.7.3.5/RD Materials for air filter assemblies NA

4.7.3.6/RD Materials used in high-voltage components NA

7.6 Battery location -

7.6.1 Battery location and installation PA

7.6.2 Accessibility and maintainability PA

7.6.3 Distance PA

7.6.4 Case insulation PA

7.6.5 Wiring PA

7.6.6 Electrolyte spillage PA

7.6.7 Ventilation PA

7.6.8 Charging voltage PA

7.7 Temperature rise -

4.5/RD Thermal requirements PA

4.5.1/RD General PA

4.5.2/RD Temperature tests (see appended table 7.7) PA

Normal load condition per Annex L ................. : NA

4.5.3/RD Temperature limits for materials PA

4.5.4/RD Touch temperature limits PA

4.5.5/RD Resistance to abnormal heat ........................... : PA

Informe N°: 48341-1549-83111 Shitsuke S.R.L.

Página: 17 de 33

Capitulo Requisito Observación Veredicto

8 Electrical requirements and simulated abnormal conditions -

8.1 General provisions for earth leakage -

5.1.1/RD General PA

5.1.7/RD Equipment with touch current exceeding 3,5 mA NA

8.2 Electric strength -

5.2/RD

5.2.1/RD General (see appended table 8.2) PA

5.2.2/RD Test procedure (see appended table 8.2) PA

8.3 Abnormal operating and fault conditions -

8.3.1 General PA

5.3.1/RD Protection against overload and abnormal operation (see appended table 8.3) PA

5.3.2/RD Motors (see appended Annex B) NA

5.3.3/RD Transformers (see appended Annex C) PA

5.3.4/RD Functional insulation ......................................... : PA

5.3.5/RD Electromechanical components NA

5.3.9/RD Compliance criteria for abnormal operating and fault PA

conditions

8.3.2 Simulation of faults PA

8.3.3 Conditions for tests PA

9 Connection to telecommunication networks -

6/RD

6.1/RD Protection of telecommunication network service persons, and users of other equipment -

connected to the network, from hazards in the equipment

6.1.1/RD Protection from hazardous voltages NA

6.1.2/RD Separation of the telecommunication network from NA

earth

6.1.2.1/RD Requirements NA

Supply voltage (V) ........................................... :

Current in the test circuit (mA) ....................... :

6.1.2.2/RD Exclusions ....................................................... : NA

6.2/RD Protection of equipment users from overvoltages on telecommunication networks -

6.2.1/RD Separation requirements NA

6.2.2/RD Electric strength test procedure NA

6.2.2.1/RD Impulse test NA

6.2.2.2/RD Steady-state test NA

6.2.2.3/RD Compliance criteria NA

6.3/RD Protection of the telecommunication wiring system from overheating -

Max. output current (A) .................................... :

3.5/RD Interconnection of equipment -

3.5.1/RD General requirements NA

3.5.2/RD Types of interconnection circuits ..................... : NA

Informe N°: 48341-1549-83111 Shitsuke S.R.L.

Página: 18 de 33

Capitulo Requisito Observación Veredicto

3.5.3/RD ELV circuits as interconnection circuits NA

3.5.4/RD Data ports for additional equipment NA

2.1.3/RD Protection in restricted access locations NA

2.3.1/RD Limits NA

Type of TNV circuits ......................................... :

2.3.2/RD Separation from other circuits and from accessible NA

parts

2.3.2.1/RD General requirements NA

2.3.2.2/RD Protection by basic insulation NA

2.3.2.3/RD Protection by earthing NA

2.3.2.4/RD Protection by other constructions .................... : NA

2.3.3/RD Separation from hazardous voltages NA

Insulation employed ......................................... :

2.3.4/RD Connection of TNV circuits to other circuits NA

Insulation employed ......................................... :

2.3.5/RD Test for operating voltages generated externally NA

2.6.5.8/RD Reliance on telecommunication network or cable NA

distribution system

2.10.3.3/RD Clearances in primary circuits NA

2.10.3.4/RD Clearances in secondary circuits NA

2.10.4/RD Creepage distances NA

2.10.4.1/RD General NA

2.10.4.2/RD Material group and comparative tracking index NA

CTI tests ........................................................... :

2.10.4.3/RD Minimum creepage distances NA

M/RD ANNEX M, CRITERIA FOR TELEPHONE RINGING SIGNALS (see 2.3.1/RD) -

M.1/RD Introduction NA

M.2 /RD Method A NA

M.3/RD Method B NA

M.3.1/RD Ringing signal NA

M.3.1.1/RD Frequency (Hz) ................................................ :

M.3.1.2/RD Voltage (V) ....................................................... :

M.3.1.3/RD Cadence; time (s), voltage (V) ......................... :

M.3.1.4/RD Single fault current (mA) .................................. :

M.3.2/RD Tripping device and monitoring voltage .......... : NA

M.3.2.1/RD Conditions for use of a tripping device or a

monitoring voltage

M.3.2.2/RD Tripping device NA

M.3.2.3/RD Monitoring voltage (V) ..................................... : NA

A/RD Annex A, Tests for resistance to heat and fire -

Informe N°: 48341-1549-83111 Shitsuke S.R.L.

Página: 19 de 33

Capitulo Requisito Observación Veredicto

A.1/RD Flammability test for fire enclosures of movable NA

equipment having a total mass exceeding 18 kg,

and of stationary equipment (see 4.7.3.2/RD)

A.1.1/RD Samples............................................................ :

Wall thickness (mm) ......................................... :

A.1.2/RD Conditioning of samples; temperature (C) ..... : NA

A.1.3/RD Mounting of samples ....................................... : NA

A.1.4/RD Test flame (see IEC 60695-11-3) NA

Flame A, B, C or D .......................................... :

A.1.5/RD Test procedure NA

A.1.6/RD Compliance criteria NA

Sample 1 burning time (s) ................................ :

Sample 2 burning time (s) ................................ :

Sample 3 burning time (s) ................................ :

A.2/RD Flammability test for fire enclosures of movable equipment having a total mass not -

exceeding 18 kg, and for material and components located inside fire enclosures (see

4.7.3.2/RD and 4.7.3.4/RD)

A.2.1/RD Samples, material ............................................. :

Wall thickness (mm) ......................................... :

A.2.2/RD Conditioning of samples; temperature (°C) ..... : NA

A.2.3/RD Mounting of samples ....................................... : NA

A.2.4/RD Test flame (see IEC 60695-11-4) NA

Flame A, B or C ............................................... :

A.2.5/RD Test procedure NA

A.2.6/RD Compliance criteria NA

Sample 1 burning time (s) ................................ :

Sample 2 burning time (s) ................................ :

Sample 3 burning time (s) ................................ :

A.2.7/RD Alternative test acc. to IEC 60695-11-5, cl. 5 and 9 NA

Sample 1 burning time (s) ................................ :

Sample 2 burning time (s) ................................ :

Sample 3 burning time (s) ................................ :

A.3/RD Hot flaming oil test (see 4.6.2/RD) NA

A.3.1/RD Mounting of samples NA

A.3.2/RD Test procedure NA

A.3.3/RD Compliance criterion NA

Informe N°: 48341-1549-83111 Shitsuke S.R.L.

Página: 20 de 33

Capitulo Requisito Observación Veredicto

B/RD Annex B, Motor tests under abnormal conditions (see 4.7.2.2/RD and 5.3.2/RD) -

B.1/RD General requirements NA

Position ............................................................ :

Manufacturer ................................................... :

Type ................................................................. :

Rated values ................................................... :

B.2/RD Test conditions NA

B.3/RD Maximum temperatures NA

B.4/RD Running overload test NA

B.5/RD Locked-rotor overload test NA

Test duration (days) ........................................ :

Electric strength test: test voltage (V) .............. :

B.6/RD Running overload test for d.c. motors in secondary NA

circuits

B.6.1/RD General NA

B.6.2/RD Test procedure NA

B.6.3/RD Alternative test procedure NA

B.6.4/RD Electric strength test; test voltage (V) ............. : NA

B.7/RD Locked-rotor overload test for d.c. motors in NA

secondary circuits

B.7.1/RD General NA

B.7.2/RD Test procedure NA

B.7.3/RD Alternative test procedure NA

B.7.4/RD Electric strength test; test voltage (V) ............. : NA

B.8/RD Test for motors with capacitors NA

B.9/RD Test for three-phase motors NA

B.10/RD Test for series motors NA

Operating voltage (V) ...................................... :

C/RD Annex C, Transformers (see 1.5.4/RD and 5.3.3/RD) -

Position ............................................................ : -

Manufacturer ................................................... : -

Type ................................................................. : -

Rated values .................................................. : -

Method of protection ......................................... : -

C.1/RD Overload test NA

C.2/RD Insulation NA

Protection from displacement of windings ........ : NA

D/RD Annex D, Measuring instruments for touch current tests (see 5.1.4/RD) -

D.1/RD Measuring instrument PA

Informe N°: 48341-1549-83111 Shitsuke S.R.L.

Página: 21 de 33

Capitulo Requisito Observación Veredicto

D.2/RD Alternative measuring instrument NA

E/RD Annex E, Temperature rise of a winding (see 1.4.13/RD) -

F/RD Annex F, Measurements of clearances and PA

creepage distance (see 2.10/RD and Annex G/RD)

G/RD Annex G, Alternative method for determining minimum clearances -

G.1/RD Clearances -

G.1.1/RD General -

G.1.2/RD Summary of the procedure for determining minimum clearances -

G.2/RD Determination of mains transient voltage (V) -

G.2.1/RD AC mains supply ............................................. : -

G.2.2/RD Earthed d.c. mains supplies ............................ : -

G.2.3/RD Unearthed d.c. mains supplies ........................ : -

G.2.4/RD Battery operation ............................................. : -

G.3/RD Determination of telecommunication network NA

transient voltage (V) ........................................ :

G.4/RD Determination of required withstand voltage (V) NA

G.4.1/RD Mains transients and internal repetitive peaks : NA

G.4.2/RD Transients from telecommunication networks . : NA

G.4.3/RD Combination of transients NA

G.4.4/RD Transients from cable distribution systems NA

G.5/RD Measurement of transient voltages (V) NA

a) Transients from a mains supply NA

For an a.c. mains supply NA

For a d.c. mains supply NA

b) Transients from a telecommunication network NA

G.6/RD Determination of minimum clearances ............ : NA

H Annex H, Guidance on protection against ingress of water and foreign objects -

(see IEC 60529)

I Annex I, Backfeed protection test -

I.1 General PA

I.2 Test for pluggable UPS PA

I.3 Test for permanently connected UPS NA

I.4 Load-induced change of reference potential PA

I.5 Solid-state backfeed protection NA

(see clause 7.1-7.5 of IEC 62040-2 and clause 7.1-

7.2 of IEC 62040-3)

Informe N°: 48341-1549-83111 Shitsuke S.R.L.

Página: 22 de 33

Capitulo Requisito Observación Veredicto

J/RD Annex J, Table of electrochemical potentials (see 2.6.5.6/RD) -

Metal(s) used ................................................... :

K/RD Annex K, Thermal controls (see 1.5.3/RD and 5.3.8/RD) -

K.1/RD Making and breaking capacity NA

K.2 /RD Thermostat reliability; operating voltage (V) .... : NA

K.3/RD Thermostat endurance test; operating NA

voltage (V) ....................................................... :

K.4/RD Temperature limiter endurance; operating voltage NA

(V) .................................................................... :

K.5/RD Thermal cut-out reliability NA

K.6/RD Stability of operation NA

L Annex L, Reference loads -

L.1 General PA

L.2 Reference resistive load PA

L.3 Reference inductive-resistive load

L.4 Reference capacitive-resistive loads PA

L.5 Reference non-linear load PA

L.5.1 Test method PA

L.5.2 Connection of the non-linear reference load

M Annex M, Ventilation of battery compartments -

M.1 General PA

M.2 Normal conditions PA

M.3 Blocked conditions PA

M.4 Overcharge conditions PA

N Annex N, Minimum and maximum cross-sections of copper conductors suitable for -

connection (see 6.3)

U/RD Annex U, Insulated winding wires for use without interleaved insulation -

(see 2.10.5.4/RD)

V/RD Annex V, AC POWER DISTRIBUTION SYSTEMS (see 1.6.1/RD) -

V.1/RD Introduction PA

V.2/RD TN power distribution systems NA

Informe N°: 48341-1549-83111 Shitsuke S.R.L.

Página: 23 de 33

2.10.5.1 TABLE: Distance through insulation measurements NA

Distance through insulation (DTI) at/of: U peak U r.m.s. Test Required DTI

(V) (V) voltage DTI (mm)

(V) (mm)

– – – – – –

Supplementary information: -

4.5 TABLE: List of critical components PA

Listado de componentes de seguridad, para la vigilancia periódica de la certificación por marca de

conformidad.

Tildar cuando el elemento deba mantener ensayos de vigilancia.

Certificaciones

Un Elemento Marca, modelo, fabricante, origen y características técnicas X

obtenidas

Ficha de

- 1 Richi; INDUSTRIA ARGENTINA; 250 V; 10 A~; Nº103.273. 3 -

alimentación.

2

Cordón de ARGENPLAS S.A.; INDUSTRIA ARGENTINA; 300/ 500 V; 3 x 2,50 mm ;

- 1 3 -

alimentación. 247 NM 53-C5.

1 Prensa cable. BSC; 3/4 “ - -

Interruptor Schneider Electric; DomA32; 230 V~; 3000 3, C32; Merlin Gerin;

- 3 3; 2 -

termomagnético. Made in BULGARIA; YY181432.

Interruptor Schneider Electric; DomB2; Type AC; ~; 230 V~; 30 mA; 25A; 16790; PEC;

- 1 3 -

diferencial. made in SPAIN; E1805-&; LINE4.EE18051; SCPD FUS 50A Gg.

Indicador ELITRON; Indicador Luminoso; Alimentación 220 Vca; Elibet S.A.; Ind. Arg.;

2 - -

luminoso. L2; V220.

- 3 Toma corriente. 10 A; 250 V; INDUSTRIA ARGENTINA; Cambre. 3 -

Marca N° Marca N° Marca N° Marca N° Marca N° Marca N° Marca N°

GS 1 ULC 8 BSI 15 SISIR 22 - 29 (Israel) 36 USNC 43

VDE 2 DEMCO 9 KEMA 16 SEMKO 23 INTI 30 (India) 37 (Yugosl) 44

IRAM 3 AEE 10 IIRS 17 SEV 24 UCIEE 31 (Islandia) 38 (Hungría) 45

SAA 4 UNE 11 IMQ 18 NFPA 25 (China) 32 (Korea) 39 (Polonia) 46

OVE 5 SETI 12 UTE 19 26 EZU 33 (Rusia) 40 ENEC 47

CEBEC 6 BEAB 13 JIS 20 UL 27 ASTA 34 (Slovenia) 41 48

CSA 7 BSI 14 NEMKO 21 28 (Grecia) 35 (Slovakia) 42 49

Los símbolos o sellos que identifican a cada certificador, se referencian en VD-012-02

X: Marcar cuando exista evidencia documental objetiva que dicho elemento está certificado. La evidencia se encuentra en nuestro poder.

Informe N°: 48341-1549-83111 Shitsuke S.R.L.

Página: 24 de 33

4.5 TABLE: List of critical components PA

Listado de componentes de seguridad, para la vigilancia periódica de la certificación por marca de

conformidad.

Tildar cuando el elemento deba mantener ensayos de vigilancia.

Certificaciones

Un Elemento Marca, modelo, fabricante, origen y características técnicas X

obtenidas

QMAX; Invesor- Cargador Serie FC; Industria Argentina; QMAX S.R.L.;

Olivieri 235- CABA- Buenos Aires- Argentina;

ESPECIFICACION DEL INVERSOR

Modelo QM-1048FC-C

Tensión Entrada DC –

Corriente Entrada DC 25 A

Potencia Salida AC 1000 VA

1 Inversor. - -

Tensión Salida AC 220 Vac~ 50 Hz

ESPECIFICACION DEL CARGADOR

Tensión Entrada AC 180-240 Vac; 35-65 Hz

Corriente Entrada AC Cargador 15 A+ 15 A Max de Paso

Potencia Salida DC 20 A

Tensión Salida DC 36-64 Vdc

Nº SERIE 3141514314

VISIÓN; 6FM100PL-X; 12 V 100 AH; VALVE REGULATED LEAD ACID

BATTERY; CONSTANT VOLTAGE CHARGE; CYCLE USE: 14,4 – 14,7 V;

8 Batería. - -

STANDBY USE: 13,2-13,8 V; INITIAL CURRENT: LESS THAN 30 A; MADE

IN CHINA.

Cableado

- PVC - -

interno.

Marca N° Marca N° Marca N° Marca N° Marca N° Marca N° Marca N°

GS 1 ULC 8 BSI 15 SISIR 22 - 29 (Israel) 36 USNC 43

VDE 2 DEMCO 9 KEMA 16 SEMKO 23 INTI 30 (India) 37 (Yugosl) 44

IRAM 3 AEE 10 IIRS 17 SEV 24 UCIEE 31 (Islandia) 38 (Hungría) 45

SAA 4 UNE 11 IMQ 18 NFPA 25 (China) 32 (Korea) 39 (Polonia) 46

OVE 5 SETI 12 UTE 19 26 EZU 33 (Rusia) 40 ENEC 47

CEBEC 6 BEAB 13 JIS 20 UL 27 ASTA 34 (Slovenia) 41 48

CSA 7 BSI 14 NEMKO 21 28 (Grecia) 35 (Slovakia) 42 49

Los símbolos o sellos que identifican a cada certificador, se referencian en VD-012-02

X: Marcar cuando exista evidencia documental objetiva que dicho elemento está certificado. La evidencia se encuentra en nuestro poder.

4.6 TABLE: Electrical data (in normal conditions) PA

U (V) I (A) Irated (A) P (W) Fuse # Ifuse (A) Condition/status

180 10,35 10 - - 32* Funcionamiento normal a 180 V

240 10,20 10 - - 32* Funcionamiento normal a 240 V

Supplementary information:

* interruptor témomagnetico.

Informe N°: 48341-1549-83111 Shitsuke S.R.L.

Página: 25 de 33

5.7 TABLE: Clearance and creepage distance measurements PA

Clearance (cl) and creepage U peak U r.m.s. Required cl cl Required cr cr

distance (cr) at/of/between: (V) (V) (mm) (mm) (mm) (mm)

Functional:

Partes activas de diferente 339 240 ≥ 1,46 > 1,89 ≥ 2,4 > 3,12

polaridad

Basic / supplementary:

Partes activas y partes 339 240 ≥ 2,0 > 2,6 ≥ 2,4 > 3,12

accesibles

Reinforced:

Circuito primario y circuito 542 326 ≥ 4,69 > 6,09 ≥ 4,69 > 6,09

secundario

Partes activas y partes 339 240 ≥ 4,0 > 5,2 ≥ 4,0 > 5,2

accesibles

Supplementary information: -

7.4 TABLE: Ball pressure test of thermoplastic parts PA

Allowed impression diameter (mm) .................. : 2 mm

Part Test temperature Impression diameter

(°C) (mm)

Interruptor termomagnético 125 -

Interruptor diferencial. 125 -

Indicador luminoso 125 < 1,4 mm

Toma corriente. 125 -

Inversor 125 < 1,4 mm

Supplementary information:

*Componente certificado y utilizado de acuerdo a sus características nominales

Informe N°: 48341-1549-83111 Shitsuke S.R.L.

Página: 26 de 33

7.7 TABLE: Temperature test PA

Supply voltage (V) ........................... : 254

Ambient Tmin (C) ............................. : 21,7

Ambient Tmax (C) ............................ : 21,9

Maximum measured temperature T of part/at:: T (C) Allowed Tmax (C)

Cordón de alimentación 30,2 50

Interruptor termomagnético 45.2 –

Interruptor diferencial. 42,7 –

Indicador luminoso. 24,8 –

Toma corriente. 38,9 –

Batería. 48,7 –

Partes accesibles 23,8 45

Rincón de ensayo 24,0 90

Supplementary information:

1

* : Componente montado sobre el circuito impreso principal.

2

* : Clasificación mínima otorgada por no tener clase marcada

Temperature T of winding: t1 (°C) R1 () t2 (°C) R2 () T (C) Allowed Insulation

Tmax (C) class

- - - - - - - -

Supplementary information: -

8.2 TABLE: Electric strength tests, impulse tests and voltage surge tests PA

Test voltage applied between: Voltage shape Test voltage Breakdown

(AC, DC, (V) Yes / No

impulse, surge)

Functional:

- - - -

Basic / supplementary:

Partes activas y partes accesibles AC 1500 No

Reinforced:

Partes activas y partes accesibles AC 3000 No

Supplementary information:-

Informe N°: 48341-1549-83111 Shitsuke S.R.L.

Página: 27 de 33

8.3 TABLE: Abnormal operating and fault conditions PA

Ambient temperature (°C) ..................................... : 20,5ºC

Power source for EUT: Manufacturer, model/type, output -

rating ...................................................................... :

Component No. Fault Supply voltage Fuse # Fuse current Observation

(V) (A)

Carga de los Sobre carga / 254 - No se generan

32 *

tomacorriente. Cortocircuito riesgos

Falla del inversor. Desconexión / 254 - No se generan

32 *

Cortocircuito riesgos

Supplementary information:

* interruptor témomagnetico.

Informe N°: 48341-1549-83111 Shitsuke S.R.L.

Página: 28 de 33

Imágenes para ilustrar características constructivas (Imágenes fuera de escala).

Informe N°: 48341-1549-83111 Shitsuke S.R.L.

Página: 29 de 33

Imágenes para ilustrar características constructivas (Imágenes fuera de escala).

Informe N°: 48341-1549-83111 Shitsuke S.R.L.

Página: 30 de 33

Imágenes para ilustrar características constructivas (Imágenes fuera de escala).

Informe N°: 48341-1549-83111 Shitsuke S.R.L.

Página: 31 de 33

Imágenes para ilustrar características constructivas (Imágenes fuera de escala).

Informe N°: 48341-1549-83111 Shitsuke S.R.L.

Página: 32 de 33

Imágenes para ilustrar características constructivas (Imágenes fuera de escala).

FIN DEL DOCUMENTO

Informe N°: 48341-1549-83111 Shitsuke S.R.L.

Página: 33 de 33

También podría gustarte

- Mantenimiento correctivo de instalaciones frigoríficas. IMAR0108De EverandMantenimiento correctivo de instalaciones frigoríficas. IMAR0108Aún no hay calificaciones

- Informe de Ensayo: Sistema Conductivo de Carga para Vehículos Eléctricos - Parte 1: Requisitos GeneralesDocumento15 páginasInforme de Ensayo: Sistema Conductivo de Carga para Vehículos Eléctricos - Parte 1: Requisitos GeneralesRoger Valenzuela HuamanAún no hay calificaciones

- Organización y ejecución del montaje de instalaciones frigoríficas. IMAR0108De EverandOrganización y ejecución del montaje de instalaciones frigoríficas. IMAR0108Aún no hay calificaciones

- Bandeja Metálica para AutoservicioDocumento11 páginasBandeja Metálica para AutoservicioMaricarmen Canayo PanaifoAún no hay calificaciones

- Operaciones de mecanizado por medios automáticos. FMEE0208De EverandOperaciones de mecanizado por medios automáticos. FMEE0208Aún no hay calificaciones

- Deu 04 15 3195Documento65 páginasDeu 04 15 3195Felipe Andres Lizana BastiasAún no hay calificaciones

- Guía de instalación en locales de características especialesDe EverandGuía de instalación en locales de características especialesAún no hay calificaciones

- Coa Va23-002339Documento2 páginasCoa Va23-002339CAMILO AVILAAún no hay calificaciones

- Guía para La CertificaciónDocumento18 páginasGuía para La CertificaciónFury RiosAún no hay calificaciones

- Simplex 4098 Detector Application Manual - En.esDocumento64 páginasSimplex 4098 Detector Application Manual - En.esRAFAEL ROJAS VACAAún no hay calificaciones

- Guía para La Certificación IACSADocumento20 páginasGuía para La Certificación IACSAIgnacio DiazAún no hay calificaciones

- Bodtrak - II Manual de UsuarioDocumento46 páginasBodtrak - II Manual de UsuariokoloristaAún no hay calificaciones

- Documento de Control de Calidad Rev 0. Fecha: 06-Jun-08 Hoja No. 1 de 1 Forma No.: S2000-FOR-Q50-005-017Documento2 páginasDocumento de Control de Calidad Rev 0. Fecha: 06-Jun-08 Hoja No. 1 de 1 Forma No.: S2000-FOR-Q50-005-017Jorge Dario Jarrin VivarAún no hay calificaciones

- LE14188A 0000 0430 ESP 00051 - Rev0Documento62 páginasLE14188A 0000 0430 ESP 00051 - Rev0a20184850Aún no hay calificaciones

- ET 0201818 2 0000 607 0001 - Rev.0 PDFDocumento19 páginasET 0201818 2 0000 607 0001 - Rev.0 PDFsandra gomelskyAún no hay calificaciones

- RT-IEC 60335-2-15 2002 Hervidores, CafeterasDocumento65 páginasRT-IEC 60335-2-15 2002 Hervidores, CafeterasFelipe Andres Lizana BastiasAún no hay calificaciones

- 180 Ing 001 39 06 09 001 - 0Documento24 páginas180 Ing 001 39 06 09 001 - 0Elmer QuispeAún no hay calificaciones

- CIN-0007P-CLI-ET-0001-A Especificaciones Tecnicas.Documento44 páginasCIN-0007P-CLI-ET-0001-A Especificaciones Tecnicas.enyel monteroAún no hay calificaciones

- 1.3 Iq AutoclaveDocumento9 páginas1.3 Iq Autoclavegeraldin huarcaya rodriguezAún no hay calificaciones

- Epm. CM - 00898 Cable OpticoDocumento20 páginasEpm. CM - 00898 Cable OpticoFabian GomezAún no hay calificaciones

- Condiciones Técnica Revisadas 16.06.2022Documento39 páginasCondiciones Técnica Revisadas 16.06.2022Joel CixAún no hay calificaciones

- SOP Dispensette ESDocumento17 páginasSOP Dispensette ESadrimtzc13Aún no hay calificaciones

- (Proced. Precom. Area 500Documento19 páginas(Proced. Precom. Area 500Pablo Andrés senaAún no hay calificaciones

- ISO Registro de Fabricacion de Soportes MetalicosDocumento1 páginaISO Registro de Fabricacion de Soportes MetalicosLuis Enrique Yanallaye ArandaAún no hay calificaciones

- 180 Ing 001 39 06 08 001 - 0Documento14 páginas180 Ing 001 39 06 08 001 - 0Elmer QuispeAún no hay calificaciones

- VPP 1001 03 CS 0001 0000 J CD 00001 (00P)Documento37 páginasVPP 1001 03 CS 0001 0000 J CD 00001 (00P)Pablo CancinoAún no hay calificaciones

- Guia Precision Exactitud EmeraldDocumento18 páginasGuia Precision Exactitud Emeralddfpl_24Aún no hay calificaciones

- Polipasto de Palanca ManualDocumento68 páginasPolipasto de Palanca Manualsergio blandon l100% (1)

- Ec-3521 Inversiones #AsignacionDocumento10 páginasEc-3521 Inversiones #AsignacionSara RuizAún no hay calificaciones

- Capitulo1 Materias Primas - UnlockedDocumento4 páginasCapitulo1 Materias Primas - UnlockedAlexis MartínezAún no hay calificaciones

- COmisionamientoDocumento43 páginasCOmisionamientowilyAún no hay calificaciones

- Criterio de Diseño - Estandar - 2003Documento35 páginasCriterio de Diseño - Estandar - 2003hoke-14100% (1)

- Operation 31200766 05-03-12 ANSI SpanishDocumento168 páginasOperation 31200766 05-03-12 ANSI SpanishJorge GarciaAún no hay calificaciones

- 7.2 Etg Tic H.chala 21-08-2016 OkDocumento99 páginas7.2 Etg Tic H.chala 21-08-2016 OkjimvelbAún no hay calificaciones

- Certificado Aprobacion Sec Tuberia Rigida-1250Documento3 páginasCertificado Aprobacion Sec Tuberia Rigida-1250Felipe Hidalgo GonzálezAún no hay calificaciones

- NTC Iso Iec 17065 2013Documento15 páginasNTC Iso Iec 17065 2013John Jairo Gomez CastellanosAún no hay calificaciones

- Paycheck1234 TechMan - En.esDocumento47 páginasPaycheck1234 TechMan - En.es- M I L T O N - - G. -AAún no hay calificaciones

- 5277.CO - PC.05-I - Instrumentación y Control PDFDocumento13 páginas5277.CO - PC.05-I - Instrumentación y Control PDFLuis SantillanAún no hay calificaciones

- Certificado de Equipo Intrinsicamente Seguro.Documento26 páginasCertificado de Equipo Intrinsicamente Seguro.cvalencial702Aún no hay calificaciones

- IVIZIONDocumento158 páginasIVIZION- M I L T O N - - G. -AAún no hay calificaciones

- Protocolo de Calificacion Funcional Tapadora para Tapas Pilfer RP28Documento6 páginasProtocolo de Calificacion Funcional Tapadora para Tapas Pilfer RP28pablo710Aún no hay calificaciones

- Trampas Envio y ReciboDocumento14 páginasTrampas Envio y Reciboaquilesanchez100% (1)

- IA - LA - Delegate Exercise Booklet v2Documento20 páginasIA - LA - Delegate Exercise Booklet v2Librería bazar KOSITAS SHOPPAún no hay calificaciones

- Informe de Homologación de La Unidad G1 de La C.H. YanangoDocumento80 páginasInforme de Homologación de La Unidad G1 de La C.H. Yanangoalberto.rojasAún no hay calificaciones

- Manual Flygt 4680Documento28 páginasManual Flygt 4680victorAún no hay calificaciones

- Requisitos para Iluminación Decorativa 2014019069Documento6 páginasRequisitos para Iluminación Decorativa 2014019069Ramiro OrtegaAún no hay calificaciones

- Guardacabos No. 01526Documento2 páginasGuardacabos No. 01526Lizeth Sanchez0% (1)

- Informe de MacrografiaDocumento15 páginasInforme de MacrografiaJohannita Tdt SolisAún no hay calificaciones

- Ic-Reg-011 CertificadoDocumento2 páginasIc-Reg-011 CertificadoTransportes Marson sasAún no hay calificaciones

- iSED Manual Del OperadorDocumento50 páginasiSED Manual Del OperadorMiriam GarcíaAún no hay calificaciones

- ER2 Owners Manual .125 A 5T Manual PolipastoDocumento96 páginasER2 Owners Manual .125 A 5T Manual PolipastoAngel Liang MundooAún no hay calificaciones

- Copia de Pipeta NPDocumento21 páginasCopia de Pipeta NPjoseAún no hay calificaciones

- PDF Informe 13 Instrumentacion Industrial DLDocumento33 páginasPDF Informe 13 Instrumentacion Industrial DLjuancitoAún no hay calificaciones

- NTC 5926-2Documento30 páginasNTC 5926-2Luis Angel100% (3)

- Plan de Calibración de Equipos VCA - 13.09.2018 - Rev.000Documento8 páginasPlan de Calibración de Equipos VCA - 13.09.2018 - Rev.000Alvaro CamposAún no hay calificaciones

- 180 Ing 001 39 06 08 002 - 0Documento27 páginas180 Ing 001 39 06 08 002 - 0Elmer QuispeAún no hay calificaciones

- Solicitud de Certificación de Artefactos Eléctricos de SeguridadDocumento3 páginasSolicitud de Certificación de Artefactos Eléctricos de SeguridadClaudio Valencia MarínAún no hay calificaciones

- Manual de Usuario Centurion 905-2150-006 Rev B PDFDocumento206 páginasManual de Usuario Centurion 905-2150-006 Rev B PDFJuan Luis Teodoro RamírezAún no hay calificaciones

- Ext Eku1qaehiqzjbrasjsn6Documento5 páginasExt Eku1qaehiqzjbrasjsn6Jennifer LizarazoAún no hay calificaciones

- 2.5.2 Eett - SeñaleticasDocumento23 páginas2.5.2 Eett - SeñaleticasDanitzaAún no hay calificaciones

- 0202 0012cataargtecnicoz11 21 4Documento52 páginas0202 0012cataargtecnicoz11 21 4nicoreb1Aún no hay calificaciones

- Manual Zeta Czerweny ImpresiónDocumento2 páginasManual Zeta Czerweny Impresiónnicoreb1Aún no hay calificaciones

- Manual Periféricas QBDocumento2 páginasManual Periféricas QBnicoreb1Aún no hay calificaciones

- Son Los Libros Más Caros de Editorial SpringerDocumento3 páginasSon Los Libros Más Caros de Editorial Springernicoreb1100% (1)

- Módulo 1 - Curso Inteligencia Emocional-1Documento35 páginasMódulo 1 - Curso Inteligencia Emocional-1nicoreb1Aún no hay calificaciones

- 01 PCM600 - Introducción - Mendoza - 1507Documento31 páginas01 PCM600 - Introducción - Mendoza - 1507nicoreb1100% (1)

- 3M Caja HerramientasDocumento1 página3M Caja Herramientasnicoreb1Aún no hay calificaciones

- Masilla para CalafatearDocumento1 páginaMasilla para Calafatearnicoreb1Aún no hay calificaciones

- Manual Emdr Fin de Semana 2Documento211 páginasManual Emdr Fin de Semana 2Lorena Cano Sola100% (1)

- FISICADocumento3 páginasFISICAJessica Barrera0% (1)

- Alu Stock GA3 Presentacion - e - IndiceDocumento10 páginasAlu Stock GA3 Presentacion - e - IndiceCPAún no hay calificaciones

- 3.4 Medidas de Tendencia CentralDocumento13 páginas3.4 Medidas de Tendencia CentralCarlos SolanoAún no hay calificaciones

- Evaluación Final MATEMÁTICAS AARÓN 2A OKDocumento7 páginasEvaluación Final MATEMÁTICAS AARÓN 2A OKpamela ojedabarriaAún no hay calificaciones

- Reto 7-2Documento1 páginaReto 7-2LUIS ALFONSOAún no hay calificaciones

- 1-1 Fundamentacion de ModaDocumento30 páginas1-1 Fundamentacion de Modaliliana arandaAún no hay calificaciones

- Tarea II - Tarea III - Hormonas y PersonalidadDocumento16 páginasTarea II - Tarea III - Hormonas y PersonalidadHenrry Antigua GonzalezAún no hay calificaciones

- Calificar BarajitasDocumento2 páginasCalificar BarajitasStefany OlvarellosAún no hay calificaciones

- Analisis MatematicoDocumento12 páginasAnalisis MatematicoVeronica Martina Cacha Espinoza0% (1)

- Aplicaciones de Funciones RealesDocumento13 páginasAplicaciones de Funciones Realesedith70% (10)

- Dinámica LinealDocumento3 páginasDinámica LinealjobishAún no hay calificaciones

- Plan de Respuesta Ante Emergencias FaeDocumento44 páginasPlan de Respuesta Ante Emergencias FaeFernando Calvo MontañoAún no hay calificaciones

- Practica 4 Rectificacion ContinúaDocumento16 páginasPractica 4 Rectificacion ContinúaAlfredo TlapaleAún no hay calificaciones

- Elogio de La FilosofiaDocumento4 páginasElogio de La FilosofiaPatricia KingsleighAún no hay calificaciones

- Sintesis y Caracterizacion N - (Morfolina-4-Carbotiol) BenzamidaDocumento14 páginasSintesis y Caracterizacion N - (Morfolina-4-Carbotiol) BenzamidaCarmen RosaAún no hay calificaciones

- Tecnica de Conteo 1Documento4 páginasTecnica de Conteo 1Lizeth RodriguezAún no hay calificaciones

- Historia 1 MDocumento3 páginasHistoria 1 MDanielaAún no hay calificaciones

- Concepto: Propiedades Y CaracteristicasDocumento13 páginasConcepto: Propiedades Y CaracteristicasHEIDY CRISTEL AYALA TRUJILLOAún no hay calificaciones

- Guia de La Exploracion Ecografica Del Corazon FetalDocumento38 páginasGuia de La Exploracion Ecografica Del Corazon FetalAldo RdzAún no hay calificaciones

- Experiencias Sobre Medidas Laboratorio 1 ADocumento4 páginasExperiencias Sobre Medidas Laboratorio 1 AMaría De Lujan VillarruelAún no hay calificaciones

- Durante El TLCANDocumento9 páginasDurante El TLCANMiliisiitha GomesAún no hay calificaciones

- Alimentación SaludableDocumento2 páginasAlimentación SaludableYeisson ChavezAún no hay calificaciones

- Cap 8Documento12 páginasCap 8clinthonAún no hay calificaciones

- Proceso de Embutido de MetalesDocumento1 páginaProceso de Embutido de Metalesdavid_valdez_83Aún no hay calificaciones

- Air Alert III Eriksmith #11Documento8 páginasAir Alert III Eriksmith #11Carlos FloresAún no hay calificaciones

- Investigación de Ecuaciones Diferenciales Series de Fourier (Función Impar) .Documento11 páginasInvestigación de Ecuaciones Diferenciales Series de Fourier (Función Impar) .Luis Miguel Pineda100% (1)

- Epistemología de La IntrospecciónDocumento3 páginasEpistemología de La IntrospecciónIrene KremerAún no hay calificaciones

- Capital Cultural y Comunicación PedagógicaDocumento6 páginasCapital Cultural y Comunicación PedagógicaJHONJIMMY CASTANEDARENDONAún no hay calificaciones

- Arias Maris - Tesis Sobre Una Teoria Critica de Los Derechos HumanosDocumento23 páginasArias Maris - Tesis Sobre Una Teoria Critica de Los Derechos HumanosJesus BlancoAún no hay calificaciones

- Influencia. La psicología de la persuasiónDe EverandInfluencia. La psicología de la persuasiónCalificación: 4.5 de 5 estrellas4.5/5 (14)

- Ciencia de datos: La serie de conocimientos esenciales de MIT PressDe EverandCiencia de datos: La serie de conocimientos esenciales de MIT PressCalificación: 5 de 5 estrellas5/5 (1)

- Inteligencia artificial: Lo que usted necesita saber sobre el aprendizaje automático, robótica, aprendizaje profundo, Internet de las cosas, redes neuronales, y nuestro futuroDe EverandInteligencia artificial: Lo que usted necesita saber sobre el aprendizaje automático, robótica, aprendizaje profundo, Internet de las cosas, redes neuronales, y nuestro futuroCalificación: 4 de 5 estrellas4/5 (1)

- 7 tendencias digitales que cambiarán el mundoDe Everand7 tendencias digitales que cambiarán el mundoCalificación: 4.5 de 5 estrellas4.5/5 (87)

- Sistema de gestión lean para principiantes: Fundamentos del sistema de gestión lean para pequeñas y medianas empresas - con muchos ejemplos prácticosDe EverandSistema de gestión lean para principiantes: Fundamentos del sistema de gestión lean para pequeñas y medianas empresas - con muchos ejemplos prácticosCalificación: 4 de 5 estrellas4/5 (16)

- Excel y SQL de la mano: Trabajo con bases de datos en Excel de forma eficienteDe EverandExcel y SQL de la mano: Trabajo con bases de datos en Excel de forma eficienteCalificación: 1 de 5 estrellas1/5 (1)

- EL PLAN DE MARKETING EN 4 PASOS. Estrategias y pasos clave para redactar un plan de marketing eficaz.De EverandEL PLAN DE MARKETING EN 4 PASOS. Estrategias y pasos clave para redactar un plan de marketing eficaz.Calificación: 4 de 5 estrellas4/5 (51)

- Cultura y clima: fundamentos para el cambio en la organizaciónDe EverandCultura y clima: fundamentos para el cambio en la organizaciónAún no hay calificaciones

- Clics contra la humanidad: Libertad y resistencia en la era de la distracción tecnológicaDe EverandClics contra la humanidad: Libertad y resistencia en la era de la distracción tecnológicaCalificación: 4.5 de 5 estrellas4.5/5 (117)

- Inteligencia artificial: Una exploración filosófica sobre el futuro de la mente y la concienciaDe EverandInteligencia artificial: Una exploración filosófica sobre el futuro de la mente y la concienciaAna Isabel Sánchez DíezCalificación: 4 de 5 estrellas4/5 (3)

- Guía de aplicacion de la ISO 9001:2015De EverandGuía de aplicacion de la ISO 9001:2015Calificación: 5 de 5 estrellas5/5 (3)

- GuíaBurros Microsoft Excel: Todo lo que necesitas saber sobre esta potente hoja de cálculoDe EverandGuíaBurros Microsoft Excel: Todo lo que necesitas saber sobre esta potente hoja de cálculoCalificación: 3.5 de 5 estrellas3.5/5 (6)

- El Mom Test: Cómo Mantener Conversaciones con tus Clientes y Validar tu Idea de Negocio Cuando Todos te MientenDe EverandEl Mom Test: Cómo Mantener Conversaciones con tus Clientes y Validar tu Idea de Negocio Cuando Todos te MientenCalificación: 5 de 5 estrellas5/5 (8)

- Excel para principiantes: Aprenda a utilizar Excel 2016, incluyendo una introducción a fórmulas, funciones, gráficos, cuadros, macros, modelado, informes, estadísticas, Excel Power Query y másDe EverandExcel para principiantes: Aprenda a utilizar Excel 2016, incluyendo una introducción a fórmulas, funciones, gráficos, cuadros, macros, modelado, informes, estadísticas, Excel Power Query y másCalificación: 2.5 de 5 estrellas2.5/5 (3)

- Ciberseguridad: Una Simple Guía para Principiantes sobre Ciberseguridad, Redes Informáticas y Cómo Protegerse del Hacking en Forma de Phishing, Malware, Ransomware e Ingeniería SocialDe EverandCiberseguridad: Una Simple Guía para Principiantes sobre Ciberseguridad, Redes Informáticas y Cómo Protegerse del Hacking en Forma de Phishing, Malware, Ransomware e Ingeniería SocialCalificación: 4.5 de 5 estrellas4.5/5 (11)

- Cómo ser una Persona más Sociable: Aprende a hablar con cualquiera sin temor e incrementa por completo tu inteligencia socialDe EverandCómo ser una Persona más Sociable: Aprende a hablar con cualquiera sin temor e incrementa por completo tu inteligencia socialCalificación: 4.5 de 5 estrellas4.5/5 (34)

- Agile: Una guía para la Gestión de Proyectos Agile con Scrum, Kanban y LeanDe EverandAgile: Una guía para la Gestión de Proyectos Agile con Scrum, Kanban y LeanCalificación: 5 de 5 estrellas5/5 (1)

- Scrum Las Estrategias del Juego: Es Póker, No AjedrezDe EverandScrum Las Estrategias del Juego: Es Póker, No AjedrezCalificación: 5 de 5 estrellas5/5 (1)

- Crear una web desde cero. Paso a paso con Joomla!. 2ª Edición Actualizada: Gráficos y diseño webDe EverandCrear una web desde cero. Paso a paso con Joomla!. 2ª Edición Actualizada: Gráficos y diseño webCalificación: 4.5 de 5 estrellas4.5/5 (2)

- La función del envase en la conservación de alimentos.De EverandLa función del envase en la conservación de alimentos.Calificación: 5 de 5 estrellas5/5 (3)

- Python Paso a paso: PROGRAMACIÓN INFORMÁTICA/DESARROLLO DE SOFTWAREDe EverandPython Paso a paso: PROGRAMACIÓN INFORMÁTICA/DESARROLLO DE SOFTWARECalificación: 4 de 5 estrellas4/5 (13)

- Toma de decisiones en las empresas: Entre el arte y la técnica: Metodologías, modelos y herramientasDe EverandToma de decisiones en las empresas: Entre el arte y la técnica: Metodologías, modelos y herramientasAún no hay calificaciones