Documentos de Académico

Documentos de Profesional

Documentos de Cultura

MSS Me Fab 00001 - 2

MSS Me Fab 00001 - 2

Cargado por

Guillermo GutierrezTítulo original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

MSS Me Fab 00001 - 2

MSS Me Fab 00001 - 2

Cargado por

Guillermo GutierrezCopyright:

Formatos disponibles

REQUEST FOR QUOTATION MECHANICAL

SCOPE PIPING / STRUCTURAL / I&E

3293171-MSS-ME-FAB-00001 “Patines de Medición de Hidrocarburos para la Medición de Turbosina //

SEDENA

Revision 2 –03-25-2021– Page 1 of 26 Project ID: PA 3293171

REQUEST FOR QUOTATION

MECHANICAL SCOPE PIPING /

STRUCTURAL / I&E

Patines de Medición de Hidrocarburos para la Medición de Turbosina.

3293171-MSS-ME-FAB-00001

End Customer: SEDENA

End Customer Reference Number: XXXX-X-XXXX-XX

Document File Name: 3293171-MSS-ME-FAB-00001_2

Document Status: For Use

Authorizations

Name Function Signature

Developed By: Jesús González Technical Lider

Reviewed By: Pedro González Technical Manager

Released By: Omar Mora Project Maganer

Distribution

Name Company Name Company

Emerson Automation Solutions – Internal and Proprietary

Template No. 3293171-MSS-ME-FAB-00001, Revision 0, Date 16-mar-21

REQUEST FOR QUOTATION MECHANICAL

SCOPE PIPING / STRUCTURAL / I&E

3293171-MSS-ME-FAB-00001 “Patines de Medición de Hidrocarburos para la Medición de Turbosina //

SEDENA

Revision 2 –03-25-2021– Page 2 of 26 Project ID: PA 3293171

Revision History

Rev Status Description Date Developed By Reviewed By

A Issued Internal Review 07/12/2020 Jesús González Pedro González

B Issued Internal Review 15/01/2021 Jesús González Pedro González

C Issued Internal Review 16/03/2021 Jesús González Pedro González

0 Issued For quotation 16/03/2021 Jesús González Pedro González

1 Issued For quotation 23/03/2021 Omar Mora Omar Mora

2 Issued For quotation 25/03/2021 Jesús González Pedro González

Reference Documents

Document Number Document Title

3293171-MSS-ME-DWG-00001 Diagrama de Tuberías e Instrumentación Patín de Salida a Plataforma

3293171-MSS-ME-DWG-00002 Diagrama de Tuberías e Instrumentación Descargaderas Aeropuerto

3293171-MSS-ME-DWG-00003 Diagrama de Tuberías e Instrumentación Llenaderas Aeropuerto

3293171-MSS-ME-DWG-00004 Diagrama de Tuberías e Instrumentación Llenadera BAM

3293171-MSS-ME-DWG-00005 Diagrama de Tuberías e Instrumentación Patín Bidireccional BAM

3293171-MSS-ME-DWG-00006 Diagrama de Tuberías e Instrumentación Medición Banco de Pruebas

3293171-MSS-IE-DWG-00001 Arquitectura General Patín de Salida a Plataforma

3293171-MSS-IE-DWG-00002 Arquitectura General Descargaderas Aeropuerto

3293171-MSS-IE-DWG-00003 Arquitectura General Llenaderas Aeropuerto

3293171-MSS-IE-DWG-00004 Arquitectura General Llenadera BAM

3293171-MSS-IE-DWG-00005 Arquitectura General Patín Bidireccional BAM

3293171-MSS-IE-DWG-00006 Arquitectura General Medición Banco de Pruebas

3293171-MSS-ME-DWG-00007 Arreglo General Patín de Salida a Plataforma

3293171-MSS-ME-DWG-00008 Arreglo General Descargaderas Aeropuerto

3293171-MSS-ME-DWG-00009 Arreglo General Llenaderas Aeropuerto

3293171-MSS-ME-DWG-00010 Arreglo General Llenadera BAM

3293171-MSS-ME-DWG-00011 Arreglo General Patín Bidireccional BAM

3293171-MSS-ME-DWG-00012 Arreglo General Medición Banco de Pruebas

3293171-MSS-ME-PROC-00001 Especificación General de Pintura

3293171-MSS-QY-ITP-00002 Plan de Inspección y Pruebas

NRF-032-PEMEX-2012 Especificación de Materiales de Tuberías T-A04T1

NA Especificación Técnica de los Sistemas de Medición

Emerson Automation Solutions – Internal and Proprietary

Template No. 3293171-FSS-ME-FAB-00001, Revision 0, Date 16-mar-21

REQUEST FOR QUOTATION MECHANICAL

SCOPE PIPING / STRUCTURAL / I&E

3293171-MSS-ME-FAB-00001 “Patines de Medición de Hidrocarburos para la Medición de Turbosina //

SEDENA

Revision 2 –03-25-2021– Page 3 of 26 Project ID: PA 3293171

Contents

1. INTRODUCTION ____________________________________________________ 5

2. DEFINITIONS _______________________________________________________ 6

3. GENERAL PROJECT INFORMATION ___________________________________ 6

4. GENERAL NOTES __________________________________________________ 6

5. SCOPE OF SUPPLY _________________________________________________ 6

5.1. Supply of Airport Truck Loading Metering System Skids (Tag: PM-1310 / PM-1320).6

5.2. Supply of Airport Truck Unloading Metering Systems (Tag: PM-1210 / PM-1220 /

PM-1230 / PM-1240 / PM-1250 / PM-1260 / PM-1270 / PM-1280) ______________ 8

5.3. Supply of Jet Fuel Pipeline Metering System (Tag: PM-1100)__________________ 9

5.4. Supply of MAB Truck Loading Metering System (Tag: PM-2500) ______________ 11

5.5. Supply of MAB Truck Loading / Unloading Metering System (Tag PM-2600) _____ 12

5.6. Supply of Refueling Truck Calibration Metering System (Tag PM-1400) _________ 14

6. Engineering Scope _________________________________________________ 15

7. GENERAL PROJECT REQUIREMENTS ________________________________ 15

7.1. Quality Assurance _________________________________________________ 15

7.2. Order Progress ____________________________________________________ 15

7.3. Deviations _________________________________________________________ 16

7.3.1. Pre-Order _________________________________________________________ 16

7.3.2. Post-Order ________________________________________________________ 16

7.4. General Notes _____________________________________________________ 16

8. MATERIALS PROVIDED BY SUPPLIER ________________________________ 19

9. DOCUMENTATION PROVIDED BY SUPPLIER ___________________________ 19

9.1. Fabrication Schedule (MS Project or MS Excel) _________________________ 19

9.2. Weekly Fabrication Progress Report __________________________________ 19

Emerson Automation Solutions – Internal and Proprietary

Template No. 3293171-FSS-ME-FAB-00001, Revision 0, Date 16-mar-21

REQUEST FOR QUOTATION MECHANICAL

SCOPE PIPING / STRUCTURAL / I&E

3293171-MSS-ME-FAB-00001 “Patines de Medición de Hidrocarburos para la Medición de Turbosina //

SEDENA

Revision 2 –03-25-2021– Page 4 of 26 Project ID: PA 3293171

9.3. Supplier Procedures _______________________________________________ 19

9.4. Supplier Qualifications _____________________________________________ 20

9.5. Fabrication Drawings (As Built) ______________________________________ 20

9.6. Fabrication Reports ________________________________________________ 20

10. LIST OF APPLICABLE DRAWINGS____________________________________ 21

11. END USER SPECIFICATIONS ________________________________________ 24

12. PRICING SUMMARY ________________________________________________ 25

13. APPLICABLE SPECIFICATIONS ______________________________________ 26

Emerson Automation Solutions – Internal and Proprietary

Template No. 3293171-FSS-ME-FAB-00001, Revision 0, Date 16-mar-21

REQUEST FOR QUOTATION MECHANICAL

SCOPE PIPING / STRUCTURAL / I&E

3293171-MSS-ME-FAB-00001 “Patines de Medición de Hidrocarburos para la Medición de Turbosina //

SEDENA

Revision 2 –03-25-2021– Page 5 of 26 Project ID: PA 3293171

1. INTRODUCTION

Emerson Process Management request your quotation for the supply of materials, labour for the

mechanical, Electrical & Instrumentation, transportation and site services scope associated with the

Metering System´s supply for Aeropuerto Internacional Felipe Ángeles as per the drawings,

specifications and information contained in this Request for Quotation (RFQ) related to project:

Patines de Medición de Hidrocarburos para la Medición de Turbosina, executed by SEDENA.

These Metering ytems have been designed according to international codes and local Mexican

regulations. It is extremely important to comply with all requirements presented in this document,

especially those associated to QAQC scope due to local Mexican requirements which are very

rigorous about documentation to be provided by fabricators.

All documentation provided by the Supplier should be in native language: Spanish.

All documents requested in this RFQ are mandatory, qualifications and / or exceptions to this RFQ

must be duly identified and advised in writing with your quotation.

All queries relating to this bid are to be directed in writing as follows:

Technical Query:

To: Omar Mora – Project Manager, Flow Systems and Solutions Mexico

omar.mora@emerson.com

+52-5548008201

Commercial Query:

To: Karla Umana – Sr. Buyer – Procurement Costa Rica

karla.umana@Emerson.com

Emerson and/or our customer’s inspection representatives reserve the right to inspect the works

during the progress of the tasks. Final inspection requirements will be defined and agreed between

Emerson and the successful Supplier at contract award / KOM (Kick off Meeting)

Any award made under this RFQ will be subject to Emerson Terms & Conditions. The Supplier is

required to confirm his acceptance of the T & C’s. Any exception to the T & C’s will be reviewed during

the evaluation of the bid.

Thank you in advance for your timely response to this request for quotation.

Yours truly,

Jesús González

Technical PM

Emerson – Flow System and Solutions

Emerson Automation Solutions – Internal and Proprietary

Template No. 3293171-FSS-ME-FAB-00001, Revision 0, Date 16-mar-21

REQUEST FOR QUOTATION MECHANICAL

SCOPE PIPING / STRUCTURAL / I&E

3293171-MSS-ME-FAB-00001 “Patines de Medición de Hidrocarburos para la Medición de Turbosina //

SEDENA

Revision 2 –03-25-2021– Page 6 of 26 Project ID: PA 3293171

2. DEFINITIONS

“Company” means Emerson.

“Supplier” means the company awarded to supply the goods under this purchase

order.

“Purchase Order” means this document and any other document listed herein and shall

constitute the entire agreement between the parties.

“Goods” means the materials, equipment or spare parts to be supplied.

“Party” means either the Company or the Supplier individually and Parties shall mean

the Company and the Supplier.

3. GENERAL PROJECT INFORMATION

General Scope of supply as follow:

Airport Truck Loading Metering Systems - 2 bays / 1 position per bay.

Airport Truck Unloading Metering Systems - 4 bays / 2 positions per bay.

Jet Fuel Pipeline Metering System - 1 skid (1+1) with expansion capabilities.

MAB Truck Loading Metering System - 1 bay / 1 position per bay.

MAB Truck Loading / Unloading Metering System - 1 bay / 1 position per bay.

Refueling Truck Calibration Metering System – 1 Meter Tube.

4. GENERAL NOTES

Spools shall comply with all the engineering information approved by customer.

5. SCOPE OF SUPPLY

The supply of materials, labour for the mechanical, Electrical & Instrumentation, transportation

and site services scope associated with the Metering System´s supply for Aeropuerto

Internacional Felipe Ángeles. All works shall be carried out, strictly, in accordance with the

information contained within this document.

The scope includes:

5.1. Supply of Airport Truck Loading Metering System Skids (Tag: PM-1310 / PM-1320).

2 bays / 1 position per bay: Each Skid shall be provided with 1 stream of 4” Coriolis meters

(CMF300) to ensure the best overall optimum performance.

Equipment & Material to quote:

Supply of all major and minor piping fabrication material according ASME B31.4 and

customer piping class.

Supply of all pipe mechanical material like flanges, elbows, tees, reductions, stud, nuts,

blinds and other indicated in the engineering and specs.

Supply all small valves, minor or equal to 2”.

Supply of all structural material, including all lifting lugs and spreaded bar if required.

Emerson Automation Solutions – Internal and Proprietary

Template No. 3293171-FSS-ME-FAB-00001, Revision 0, Date 16-mar-21

REQUEST FOR QUOTATION MECHANICAL

SCOPE PIPING / STRUCTURAL / I&E

3293171-MSS-ME-FAB-00001 “Patines de Medición de Hidrocarburos para la Medición de Turbosina //

SEDENA

Revision 2 –03-25-2021– Page 7 of 26 Project ID: PA 3293171

Supply of all gaskets for all flanged connections (all sizes) for pipes, equipment and

instrument connections.

Supply of all gaskets, studs & nuts for tie poins connetions.

Supply all isolation kit material required for CS-SS flanged connections (all sizes) for

equipment and instruments.

Supply all pipe supports isolation material and u-bolts required for all sizes.

Supply of all electrical material.

Supply all instrumentation material. Included all instrumentation supports material

required.

Supply of all grounding material terminal connections for structural skid.

Supply all instruments nameplates and systems nameplates required.

Supply of 4” 150# basket strainer, ASME Stamp (Qty 2).

Supply of 4” 150# swing check valves (Qty 2).

Supply of all mounting bracket for coupling valves and actuator.

Supply of TBs for all JBs.

Pipe fabrication labor.

Structural fabrication labor.

Labor for piping, equipments & instrumentation installation.

Labor for all electrical & instrumentation material installation.

Labor for coupling bracket to valves and actuator.

Supplier must paint all pipes, structural material, strainers, valves, actuators and

labelling as per indicated in the engineering.

Instrumentation installation shall be as per indicated in engineering.

Assambly & disassembly activities for Pre-FAT and FAT.

Red lines drawings shall be also submitted by fabricator.

Technical assistance during Pre-FAT and FAT. Manufacturer must consider all

material and human resources for those activities execution.

Disassembly labor for transportation.

Packing and marking for transportation.

Manouver and services transportation.

Technical assistance and resources during all activities at site: manouver and

mechanical and electrical installation (hoisting equipment shall be considered).

Manufacturer must consider all equipments and tools to excecuted the works.

Supply of anchoring system according engineering.

Installation of anchoring system according engineering.

Touch up paint.

Testing:

o Visual Inspection

o NDE: radiographic, Dye penetrant.

o Dimensional (including wall thickness)

o Paint application (adhesion test, wall thickness).

o Hydrostatic tests

Emerson Automation Solutions – Internal and Proprietary

Template No. 3293171-FSS-ME-FAB-00001, Revision 0, Date 16-mar-21

REQUEST FOR QUOTATION MECHANICAL

SCOPE PIPING / STRUCTURAL / I&E

3293171-MSS-ME-FAB-00001 “Patines de Medición de Hidrocarburos para la Medición de Turbosina //

SEDENA

Revision 2 –03-25-2021– Page 8 of 26 Project ID: PA 3293171

o Pnematic test.

o All additional test as per indicated in ITP.

All Documentation as described in Section 9.

China, India, Turkey and Ukraine material wont be acceptable. Only certificate of origin

of countries with commercial commitments with Mexico will be acceptable.

5.2. Supply of Airport Truck Unloading Metering Systems (Tag: PM-1210 / PM-1220 / PM-1230 /

PM-1240 / PM-1250 / PM-1260 / PM-1270 / PM-1280)

4 bays / 2 positions per bay: Each skid shall be provided with 1 streams of 4” Coriolis meters

(CMF300) to ensure the best overall optimum performance.

Equipment & Material to quote:

Supply of all major and minor piping fabrication material according ASME B31.4 and

customer piping class.

Supply of all pipe mechanical material like flanges, elbows, tees, reductions, stud,

nuts, blinds and other indicated in the engineering and specs.

Supply all small valves, minor or equal to 2”.

Supply of all structural material, including all lifting lugs and spreaded bar, if required.

Supply of all gaskets for all flanged connections (all sizes) for pipes, equipment and

instrument connections.

Supply of all gaskets, studs & nuts for tie poins connections.

Supply all isolation kit material required for CS-SS flanged connections (all sizes) for

equipment and instruments.

Supply all pipe supports isolation material and u-bolts required for all sizes.

Supply of all electrical material.

Supply all instrumentation material. Included all instrumentation supports material

required.

Supply of all grounding material terminal connections for structural skid.

Supply all instruments nameplates and systems nameplates required.

Supply of 4” 150# basket strainer, ASME Stamp (Qty 8).

Supply of 4” 150# air eliminator w/ electronic head with two position switchs, ASME

Stamp (Qty 8).

Supply of 4” 150# swing check valves (Qty 8).

Supply of hight pressure switch (Qty 8).

Supply of all mounting bracket for coupling valves and actuator.

Supply of TBs for all JBs.

Supply grating material as per engineering.

Pipe fabrication labor.

Structural fabrication labor.

Labor for piping, equipments & instrumentation installation.

Labor for all electrical & instrumentation material installation.

Labor for coupling bracket to valves and actuator.

Labor for pump installation.

Emerson Automation Solutions – Internal and Proprietary

Template No. 3293171-FSS-ME-FAB-00001, Revision 0, Date 16-mar-21

REQUEST FOR QUOTATION MECHANICAL

SCOPE PIPING / STRUCTURAL / I&E

3293171-MSS-ME-FAB-00001 “Patines de Medición de Hidrocarburos para la Medición de Turbosina //

SEDENA

Revision 2 –03-25-2021– Page 9 of 26 Project ID: PA 3293171

Supplier must paint all pipes, structural material, air eliminator, strainers, valves,

actuators and labelling as per indicated in the engineering.

Instrumentation installation shall be as per indicated in engineering.

Assembly & disassembly activities for Pre-FAT and FAT.

Red lines drawings shall be also submitted by fabricator.

Technical assistance during Pre-FAT and FAT. Manufacturer must consider all

material and human resources for those activities execution.

Disassembly labor for transportation.

Packing and marking for transportation.

Manouver and services transportation.

Technical assistance and resources during all activities at site: manouver, mechanical

and electrical installation (hoisting equipment shall be considered). Manufacturer must

consider all equipments and tools to excecuted the works.

Supply of anchoring system according engineering.

Installation of anchoring system according engineering.

Touch up paint.

Testing:

o Visual Inspection

o NDE: radiographic, Dye penetrant.

o Dimensional (including wall thickness)

o Paint application (adhesion test, wall thickness).

o Hydrostatic tests

o Pnematic test.

o All additional test as per indicated in ITP.

All Documentation as described in Section 9.

China, India, Turkey and Ukraine material wont be acceptable. Only certificate of

origin of countries with commercial commitments with Mexico will be acceptable.

5.3. Supply of Jet Fuel Pipeline Metering System (Tag: PM-1100)

Meter system shall be provided with (1 + 1 spare) x 100%-meter runs with expansion

capabilities, 24” headers. Coriolis has 10” streams utilizing Coriolis meters (CMFHC3) to

ensure the best overall optimum performance.

Equipment & Material to quote:

Supply of all major and minor piping fabrication material according ASME B31.4 and

customer piping class.

Supply of all pipe mechanical material like flanges, elbows, tees, reductions, stud,

nuts, blinds and other indicated in the engineering and specs.

Supply all small valves, minor or equal to 2”.

Supply of all structural material, including all lifting lugs and spreaded bar, if required.

Supply of all gaskets for all flanged connections (all sizes) for pipes, equipment and

instrument connections.

Supply of all gaskets, studs & nuts for tie poins connections.

Emerson Automation Solutions – Internal and Proprietary

Template No. 3293171-FSS-ME-FAB-00001, Revision 0, Date 16-mar-21

REQUEST FOR QUOTATION MECHANICAL

SCOPE PIPING / STRUCTURAL / I&E

3293171-MSS-ME-FAB-00001 “Patines de Medición de Hidrocarburos para la Medición de Turbosina //

SEDENA

Revision 2 –03-25-2021– Page 10 of 26 Project ID: PA 3293171

Supply all isolation kit material required for CS-SS flanged connections (all sizes) for

equipment and instruments.

Supply all pipe supports isolation material and u-bolts required for all sizes.

Supply of all electrical material.

Supply all instrumentation material. Included all instrumentation supports material

required.

Supply of all grounding material terminal connections for structural skid.

Supply all instruments nameplates and systems nameplates required.

Supply grating material as per engineering.

Supply of 10” 150# basket strainer, ASME Stamp (Qty 2).

Supply of 10” 150# swing check valves (Qty 1).

Supply of all internal components and wiring for flow computer enclosure installation

(Qty 1).

Supply of 24” orifice plate (Qty 1).

Supply of all mounting bracket for coupling valves and actuator.

Supply of TBs for all JBs.

Supply of grating material as per engineering.

Pipe fabrication labor.

Structural fabrication labor.

Labor for piping, equipments & instrumentation installation.

Labor for all electrical & instrumentation material installation.

Labor for coupling bracket to valves and actuator.

Supplier must paint all pipes, structural material, strainers, valves, actuators and

labelling as per indicated in the engineering.

Instrumentation installation shall be as per indicated in engineering.

Assembly & disassembly activities for Pre-FAT and FAT.

Red lines drawings shall be also submitted by fabricator.

Technical assistance during Pre-FAT and FAT. Manufacturer must consider all

material and human resources for those activities execution.

Disassembly labor for transportation.

Packing and marking for transportation.

Manouver and services transportation.

Technical assistance and resources during all activities at site: manouver, mechanical

and electrical installation (hoisting equipment shall be considered). Manufacturer must

consider all equipments and tools to excecuted the works.

Supply of anchoring system according engineering.

Installation of anchoring system according engineering.

Touch up paint.

Testing:

o Visual Inspection

o NDE: radiographic, Dye penetrant.

o Dimensional (including wall thickness)

Emerson Automation Solutions – Internal and Proprietary

Template No. 3293171-FSS-ME-FAB-00001, Revision 0, Date 16-mar-21

REQUEST FOR QUOTATION MECHANICAL

SCOPE PIPING / STRUCTURAL / I&E

3293171-MSS-ME-FAB-00001 “Patines de Medición de Hidrocarburos para la Medición de Turbosina //

SEDENA

Revision 2 –03-25-2021– Page 11 of 26 Project ID: PA 3293171

o Paint application (adhesion test, wall thickness).

o Hydrostatic tests

o Pnematic test.

o All additional test as per indicated in ITP.

All Documentation as described in Section 9.

China, India, Turkey and Ukraine material wont be acceptable. Only certificate of

origin of countries with commercial commitments with Mexico will be acceptable.

5.4. Supply of MAB Truck Loading Metering System (Tag: PM-2500)

1 bay / 1 position per bay: Skid shall be provided with 4” stream utilizing Coriolis meter to

ensure the best overall optimum performance.

Equipment & Material to quote:

Supply of all major and minor piping fabrication material according ASME B31.4 and

customer piping class.

Supply of all pipe mechanical material like flanges, elbows, tees, reductions, stud, nuts,

blinds and other indicated in the engineering and specs.

Supply all small valves, minor or equal to 2”.

Supply of all structural material, including all lifting lugs and spreaded bar if required.

Supply of all gaskets for all flanged connections (all sizes) for pipes, equipment and

instrument connections.

Supply of all gaskets, studs & nuts for tie poins connetions.

Supply all isolation kit material required for CS-SS flanged connections (all sizes) for

equipment and instruments.

Supply all pipe supports isolation material and u-bolts required for all sizes.

Supply of all electrical material.

Supply all instrumentation material. Included all instrumentation supports material

required.

Supply of all grounding material terminal connections for structural skid.

Supply all instruments nameplates and systems nameplates required.

Supply of 4” 150# basket strainer, ASME Stamp (Qty 1).

Supply of 4” 150# swing check valves (Qty 1).

Supply of all mounting bracket for coupling valves and actuator.

Supply of TBs for all JBs.

Pipe fabrication labor.

Structural fabrication labor.

Labor for piping, equipments & instrumentation installation.

Labor for all electrical & instrumentation material installation.

Labor for coupling bracket to valves and actuator.

Supplier must paint all pipes, structural material, strainers, valves, actuators and

labelling as per indicated in the engineering.

Instrumentation installation shall be as per indicated in engineering.

Assambly & disassembly activities for Pre-FAT and FAT.

Emerson Automation Solutions – Internal and Proprietary

Template No. 3293171-FSS-ME-FAB-00001, Revision 0, Date 16-mar-21

REQUEST FOR QUOTATION MECHANICAL

SCOPE PIPING / STRUCTURAL / I&E

3293171-MSS-ME-FAB-00001 “Patines de Medición de Hidrocarburos para la Medición de Turbosina //

SEDENA

Revision 2 –03-25-2021– Page 12 of 26 Project ID: PA 3293171

Red lines drawings shall be also submitted by fabricator.

Technical assistance during Pre-FAT and FAT. Manufacturer must consider all

material and human resources for those activities execution.

Disassembly labor for transportation.

Packing and marking for transportation.

Manouver and services transportation.

Technical assistance and resources during all activities at site: manouver and

mechanical and electrical installation (hoisting equipment shall be considered).

Manufacturer must consider all equipments and tools to excecuted the works.

Supply of anchoring system according engineering.

Installation of anchoring system according engineering.

Touch up paint.

Testing:

o Visual Inspection

o NDE: radiographic, Dye penetrant.

o Dimensional (including wall thickness)

o Paint application (adhesion test, wall thickness).

o Hydrostatic tests

o Pnematic test.

o All additional test as per indicated in ITP.

All Documentation as described in Section 9.

China, India, Turkey and Ukraine material wont be acceptable. Only certificate of origin

of countries with commercial commitments with Mexico will be acceptable.

5.5. Supply of MAB Truck Loading / Unloading Metering System (Tag PM-2600)

1 bay / 1 position per bay: Shall be provided 4” stream utilizing Coriolis meters to ensure the

best overall optimum performance.

Equipment & Material to quote:

Supply of all major and minor piping fabrication material according ASME B31.4 and

customer piping class.

Supply of all pipe mechanical material like flanges, elbows, tees, reductions, stud, nuts,

blinds and other indicated in the engineering and specs.

Supply all small valves, minor or equal to 2”.

Supply of all structural material, including all lifting lugs and spreaded bar if required.

Supply of all gaskets for all flanged connections (all sizes) for pipes, equipment and

instrument connections.

Supply of all gaskets, studs & nuts for tie poins connetions.

Supply all isolation kit material required for CS-SS flanged connections (all sizes) for

equipment and instruments.

Supply all pipe supports isolation material and u-bolts required for all sizes.

Supply of all electrical material.

Emerson Automation Solutions – Internal and Proprietary

Template No. 3293171-FSS-ME-FAB-00001, Revision 0, Date 16-mar-21

REQUEST FOR QUOTATION MECHANICAL

SCOPE PIPING / STRUCTURAL / I&E

3293171-MSS-ME-FAB-00001 “Patines de Medición de Hidrocarburos para la Medición de Turbosina //

SEDENA

Revision 2 –03-25-2021– Page 13 of 26 Project ID: PA 3293171

Supply all instrumentation material. Included all instrumentation supports material

required.

Supply of all grounding material terminal connections for structural skid.

Supply all instruments nameplates and systems nameplates required.

Supply of 4” 150# basket strainer, ASME Stamp (Qty 1).

Supply of 4” 150# air eliminator w/ electronic head with two position switchs, ASME

Stamp (Qty 1).

Supply of 4” 150# swing check valves (Qty 4).

Supply of hight pressure switch (Qty 1).

Supply of all mounting bracket for coupling valves and actuator.

Supply of TBs for all JBs.

Supply of grating material as per engineering.

Pipe fabrication labor.

Structural fabrication labor.

Labor for piping, equipments & instrumentation installation.

Labor for all electrical & instrumentation material installation.

Labor for coupling bracket to valves and actuator.

Supplier must paint all pipes, structural material, strainers, valves, actuators and

labelling as per indicated in the engineering.

Instrumentation installation shall be as per indicated in engineering.

Assambly & disassembly activities for Pre-FAT and FAT.

Red lines drawings shall be also submitted by fabricator.

Technical assistance during Pre-FAT and FAT. Manufacturer must consider all

material and human resources for those activities execution.

Disassembly labor for transportation.

Packing and marking for transportation.

Manouver and services transportation.

Technical assistance and resources during all activities at site: manouver and

mechanical and electrical installation (hoisting equipment shall be considered).

Manufacturer must consider all equipments and tools to excecuted the works.

Supply of anchoring system according engineering.

Installation of anchoring system according engineering.

Touch up paint.

Testing:

o Visual Inspection

o NDE: radiographic, Dye penetrant.

o Dimensional (including wall thickness)

o Paint application (adhesion test, wall thickness).

o Hydrostatic tests

o Pnematic test.

o All additional test as per indicated in ITP.

All Documentation as described in Section 9.

Emerson Automation Solutions – Internal and Proprietary

Template No. 3293171-FSS-ME-FAB-00001, Revision 0, Date 16-mar-21

REQUEST FOR QUOTATION MECHANICAL

SCOPE PIPING / STRUCTURAL / I&E

3293171-MSS-ME-FAB-00001 “Patines de Medición de Hidrocarburos para la Medición de Turbosina //

SEDENA

Revision 2 –03-25-2021– Page 14 of 26 Project ID: PA 3293171

China, India, Turkey and Ukraine material wont be acceptable. Only certificate of origin

of countries with commercial commitments with Mexico will be acceptable.

5.6. Supply of Refueling Truck Calibration Metering System (Tag PM-1400)

1 skid: 4” Meter run for Test System to be used for truck calibration.

Equipment & Material to quote:

Supply of all major and minor piping fabrication material according ASME B31.4 and

customer piping class.

Supply of all pipe mechanical material like flanges, elbows, tees, reductions, stud,

nuts, blinds and other indicated in the engineering and specs.

Supply all small valves, minor or equal to 2”.

Supply of all gaskets for all flanged connections (all sizes) for pipes, equipment and

instrument connections.

Supply of all gaskets, studs & nuts for tie poins connections.

Supply all isolation kit material required for CS-SS flanged connections (all sizes) for

equipment and instruments.

Supply all pipe supports isolation material and u-bolts required for all sizes.

Supply of all electrical material.

Supply all instrumentation material. Included all instrumentation supports material

required.

Supply all instruments nameplates and systems nameplates required.

Supply of 4” 150# basket strainer, ASME Stamp (Qty 1).

Supply of 4” 150# swing check valves (Qty 1).

Supply of all internal components and wiring for flow computer enclosure installation

(Qty 1).

Supply of all mounting bracket for coupling valves and actuator.

Supply of TBs for all JBs.

Pipe fabrication labor.

Labor for piping, equipments & instrumentation installation.

Labor for all electrical & instrumentation material installation.

Labor for coupling bracket to valves and actuator.

Supplier must paint all pipes, structural material, strainers, valves, actuators and

labelling as per indicated in the engineering.

Instrumentation installation shall be as per indicated in engineering.

Assembly & disassembly activities for Pre-FAT and FAT.

Red lines drawings shall be also submitted by fabricator.

Technical assistance during Pre-FAT and FAT. Manufacturer must consider all

material and human resources for those activities execution.

Disassembly labor for transportation.

Packing and marking for transportation.

Manouver and services transportation.

Emerson Automation Solutions – Internal and Proprietary

Template No. 3293171-FSS-ME-FAB-00001, Revision 0, Date 16-mar-21

REQUEST FOR QUOTATION MECHANICAL

SCOPE PIPING / STRUCTURAL / I&E

3293171-MSS-ME-FAB-00001 “Patines de Medición de Hidrocarburos para la Medición de Turbosina //

SEDENA

Revision 2 –03-25-2021– Page 15 of 26 Project ID: PA 3293171

Technical assistance and resources during all activities at site: manouver, mechanical

and electrical installation (hoisting equipment shall be considered). Manufacturer must

consider all equipments and tools to excecuted the works.

Touch up paint.

Testing:

o Visual Inspection

o NDE: radiographic, Dye penetrant.

o Dimensional (including wall thickness)

o Paint application (adhesion test, wall thickness).

o Hydrostatic tests

o Pnematic test.

o All additional test as per indicated in ITP.

All Documentation as described in Section 9.

China, India, Turkey and Ukraine material wont be acceptable. Only certificate of

origin of countries with commercial commitments with Mexico will be acceptable.

Notes:

• Airport truck unloading systems are meant to operate for single and / or double tank trucks.

• Other systems are meant to operate with single tank trucks.

• MAB: Military Air Base

6. Engineering Scope

Fabrication Drawings.

Red Lines Drawings.

Quality Dossier.

7. GENERAL PROJECT REQUIREMENTS

7.1. Quality Assurance

The Supplier shall have a Quality System that has been documented and verified by

the Company.

If Supplier complies with the standard ISO 9001, then verification of the quality

system is not required by the Company.

Supplier shall identify in their quotation, level of approval held.

Alternatively, the Supplier may be subject to evaluation by the Company whether

ISO is certified or not.

Supplier shall provide certified inspector level II or III for all test execution. Results

interpretation will be executed only by certified inspector level III.

7.2. Order Progress

To establish clear lines of communication between both parties, contract review

meeting (order award) shall take place at an agreed date. The meeting shall

encompass, as a minimum, but not limited to, the following:

Review of purchase order requisition scope, schedule and requirements.

Emerson Automation Solutions – Internal and Proprietary

Template No. 3293171-FSS-ME-FAB-00001, Revision 0, Date 16-mar-21

REQUEST FOR QUOTATION MECHANICAL

SCOPE PIPING / STRUCTURAL / I&E

3293171-MSS-ME-FAB-00001 “Patines de Medición de Hidrocarburos para la Medición de Turbosina //

SEDENA

Revision 2 –03-25-2021– Page 16 of 26 Project ID: PA 3293171

Review of attached order specifications (Client & industry specifications, as

applicable).

Allocation of project personnel and contact details.

Communication protocol.

Reporting requirements.

Inspection requirements.

Site access.

7.3. Deviations

7.3.1. Pre-Order

The Supplier shall state in his quotation that items quoted are in full compliance with the

requirements of this Material Requisition. Where the Subcontractor advises any

exception or deviation with the stated conditions of this Material Requisition, full details

of the exception or deviation shall be provided.

Changes to the specification proposed by the Supplier, which may improve installation,

operation, maintenance, or economy of fabrication of the equipment may be considered,

by providing the excellent performance and safety of the equipment. Any proposed

changes shall be itemized in the Supplier’s quotation.

7.3.2. Post-Order

No deviations from this material requisition will be allowed unless approved in writing by

the Company.

Where the Supplier cannot comply with the stated conditions of this material requisition,

the Subcontractor shall clearly identify with a concession request, the alternative solution

for the Purchaser's review. The concession request and the waiver (if granted) shall be

included in the equipment data book.

7.4. General Notes

Delivery Date for testing: Works must be completed by June 11th 2021.

Preliminary work schedule needs to be presented along with quoting, indicating

resources, number of crews, labor days, labor hours per day, among others to comply

with the delivery date.

The supplier shall comply deliver the Goods in strict compliance of the instructions,

specifications, standards and quality requirements of the company and the best standards

and practices of the industry.

The supplier shall deliver the Goods on the date agreed for purchased specifications. The

no compliance of the delivering on the contractual date shall entitle the company to apply

the agreed penalties and to cancel the Purchased order without prior notification to the

supplier.

All delivery of Goods shall be with a delivery note issued by the supplier, which shall refer

to the purchase order number and contain the detailed quantities and descriptions of the

delivery Goods.

During manufacturing process, the supplier shall allow the company to inspect the Goods

at any time. Such inspections shall not release the supplier from any liability arising

through fabrication.

The goods shall be delivered properly package according to the type of materials and

shall be identified with the purchase order number and shall contain the warnings and

indications for handling in case of fragile or hazardous materials.

Emerson Automation Solutions – Internal and Proprietary

Template No. 3293171-FSS-ME-FAB-00001, Revision 0, Date 16-mar-21

REQUEST FOR QUOTATION MECHANICAL

SCOPE PIPING / STRUCTURAL / I&E

3293171-MSS-ME-FAB-00001 “Patines de Medición de Hidrocarburos para la Medición de Turbosina //

SEDENA

Revision 2 –03-25-2021– Page 17 of 26 Project ID: PA 3293171

The supplier shall include any lifting equipment required to load the Goods on trucks for

shipping.

The receipt of the Goods by the company does not mean the final acceptance of the

same. The Goods shall be subject to further inspection and the company shall be entitled

to claim for defects and the supplier will be obligated to make the related replacement

and repairs.

Materials provided by the Company (free issue materials):

ITEM DESCRIPCIÓN CANTIDAD

1 Loading Arm 8

2 Loading Arm 2

3 10" Ball Valve - Inlet 2

4 4" Ball Valve 19

5 4" Ball Valve (with Electric Actuator) 10

6 4" Electric Actuator for Ball Valve 10

7 Electric Actuator for 4" DBB Plug Valve 7

8 4" DBB Plug Valve (with Electric 7

Actuator)

9 10" DBB Plug Valve 5

10 4" DBB Plug Valve 10

11 Actuator for 10" Flow Control Valve 3

12 10"Flow Control Valve 3

13 Thermal Relief Valve 26

16 Differential Pressure Indicator 24

Transmitter

17 Manifold 24

18 Pressure Indicator Transmitter Model 1 16

19 Pressure Indicator Transmitter Model 2 2

20 Manifold 38

22 10" Coriolis Flow Element 2

23 4" Coriolis Flow Element 13

24 Coriolis Flow Transmitter 15

26 Pressure Indicator 20

27 Temperature Indicator Transmitter 15

With RTD & Thermowell

28 Temperature Indicator with 15

Thermowell

29 Test Thermowell 16

30 Digital Control Valve, two steps 12

31 Orifice Plate 1

32 Densitometer 1

Emerson Automation Solutions – Internal and Proprietary

Template No. 3293171-FSS-ME-FAB-00001, Revision 0, Date 16-mar-21

REQUEST FOR QUOTATION MECHANICAL

SCOPE PIPING / STRUCTURAL / I&E

3293171-MSS-ME-FAB-00001 “Patines de Medición de Hidrocarburos para la Medición de Turbosina //

SEDENA

Revision 2 –03-25-2021– Page 18 of 26 Project ID: PA 3293171

33 Preset Controller W/ touchscreen 12

34 Flow Computer 2

38 Grounding Verification System 12

39 Overfill Prevention Control Monitor 4

40 Junction Boxes 12

42 Power Panel Distribution 2

42 Quick Connection Hose 2

43 HMI System 1

45 Emergency Push Button 12

Emerson Automation Solutions – Internal and Proprietary

Template No. 3293171-FSS-ME-FAB-00001, Revision 0, Date 16-mar-21

REQUEST FOR QUOTATION MECHANICAL

SCOPE PIPING / STRUCTURAL / I&E

3293171-MSS-ME-FAB-00001 “Patines de Medición de Hidrocarburos para la Medición de Turbosina //

SEDENA

Revision 2 –03-25-2021– Page 19 of 26 Project ID: PA 3293171

8. MATERIALS PROVIDED BY SUPPLIER

All material listed in section 5.

9. DOCUMENTATION PROVIDED BY SUPPLIER

9.1. Fabrication Schedule (MS Project or MS Excel)

The fabrication schedule is mandatory for the quote presentation; the schedule should

include (not limited to) the following items with corresponding duration:

Manufacturing Engineering.

Manufacturing & manouver procedures submission.

Material requisition.

Piping fabrication (marking, cutting, welding).

NDE for piping.

Piping painting.

Hydrotest (indicate if will be performed in one assembly or various, per skid).

Pneumatic Test. Assembly completed.

Structural fabrication (marking, cutting, welding).

NDE for structure (it is needed estimated dates in order to notify the end user).

Structure painting.

Major valves painting.

Skid assembly for inspection.

Pre FAT.

FAT.

Skid disassembly for transportation.

Packing.

Delivery.

9.2. Weekly Fabrication Progress Report

The Fabrication Report should be presented in a weekly basis, every Friday morning. This

report is very important to keep track of the fabrication schedule, present queries and

clarification notes and notify any potential risk for the completion of this work.

The report should be presented including the fabrication schedule tasks, presenting the

progress during the past week and works to be carry on the next week.

Along with the written report, picture to support the progress needs to be included. During the

assembly phase, it is requested to show as first picture a general view of the skid.

9.3. Supplier Procedures

All activities to be performed within the scope of this supply require to be supported by a

procedure. As minimum, the following procedures need to be submitted:

Welding Procedure Specification (WPS), CWI signed.

Welding Reports, CWI Signed.

Visual Inspection Procedure, Signed by Level 3.

Dye Penetrant Inspection (DPI) Procedure, Signed by Level 2.

Radiographic Testing (RT) Procedure.

Hydrotest Procedure, Signed by Level 3. Per local regulations, hydrotest duration is 4

hours.

Emerson Automation Solutions – Internal and Proprietary

Template No. 3293171-FSS-ME-FAB-00001, Revision 0, Date 16-mar-21

REQUEST FOR QUOTATION MECHANICAL

SCOPE PIPING / STRUCTURAL / I&E

3293171-MSS-ME-FAB-00001 “Patines de Medición de Hidrocarburos para la Medición de Turbosina //

SEDENA

Revision 2 –03-25-2021– Page 20 of 26 Project ID: PA 3293171

Hydrotest Report, Signed by Level 2.

Piping Fabrication Procedure.

Structural Fabrication Procedure.

Others as required.

All procedures will be approved by customer quality engineering.

9.4. Supplier Qualifications

All qualification should be presented specifically for the scope of this supply. Qualifications

should correspond to signatures to be found in fabricated materials and reports.

Procedure Qualification Record (PQR).

Welder Procedure Qualification (WPQ).

NDE Qualifications.

9.5. Fabrication Drawings (As Built)

Once the fabrication is done, as built drawings and fabrication traceability drawings should

be submitted.

Spool and structure markup drawings.

Red Lines for FAT support.

Weld Maps.

Material Traceability*.

*The material traceability drawing/map/document should include those materials to be

supplied by the Company and listed in sections 7.

9.6. Fabrication Reports

These reports have high importance for the end user QAQC review and control, in this sense

is very important to submit accordingly.

Material test reports, for all piping and structural material. Including welding material.

Welds visual inspection reports. Should include reference to the weld number or ID.

NDE reports. The NDE qualification should correspond to the technician signing these reports.

Dimensional reports (including pipe wall thickness).

Hydrotest charts and reports. For this report is required to include the spool arrangement

drawing tested and calibration certificates for the instruments used in the test.

Paint reports. Is very important to consider tests and certification documents requested in the

paint specification document provided. If the paint application is performed in batches, each

report should include the spools or structures ID´s.

Certificate and datasheet of coatings/paints.

Certificate of material used for sand blast.

Measurement of surface profile of blasted clean steel SP-5 (SSPC).

Dry film thickness measurement.

Adherence test per ASTM D-3359

Assembly Torque Reports. Required for those flanged joint to be supplied assembled.

Blow system report.

Final Inspection Release Reports.

Notes:

Emerson Automation Solutions – Internal and Proprietary

Template No. 3293171-FSS-ME-FAB-00001, Revision 0, Date 16-mar-21

REQUEST FOR QUOTATION MECHANICAL

SCOPE PIPING / STRUCTURAL / I&E

3293171-MSS-ME-FAB-00001 “Patines de Medición de Hidrocarburos para la Medición de Turbosina //

SEDENA

Revision 2 –03-25-2021– Page 21 of 26 Project ID: PA 3293171

I. All documentation will need to be provided to the Company in order to release payment

for the “Testing and Documentation” item associated to the order.

II. All documents shall be presented separately per skid; combination of

documents/reports in one unified document is not accepted.

III. A final data book per location, with all listed documentation above should be provided.

One original copy needs to be provided to the Company.

10. LIST OF APPLICABLE DRAWINGS

No Document Title Document No. Sht. Rev.

1. Diagrama de Tuberías e Instrumentación Patín de Salida a

Plataforma

2. Diagrama de Tuberías e Instrumentación Descargaderas

Aeropuerto

3. Diagrama de Tuberías e Instrumentación Llenaderas

Aeropuerto

4. Diagrama de Tuberías e Instrumentación Llenadera BAM

5. Diagrama de Tuberías e Instrumentación Patín

Bidireccional BAM

6. Diagrama de Tuberías e Instrumentación Medición Banco

de Pruebas

7. Arquitectura General Patín de Salida a Plataforma

8. Arquitectura General Descargaderas Aeropuerto

9. Arquitectura General Llenaderas Aeropuerto

10. Arquitectura General Llenadera BAM

11. Arquitectura General Patín Bidireccional BAM

12. Arquitectura General Medición Banco de Pruebas

13. Arreglo General Patín de Salida a Plataforma

14. Arreglo General Descargaderas Aeropuerto

15. Arreglo General Llenaderas Aeropuerto

16. Arreglo General Llenadera BAM

17. Arreglo General Patín Bidireccional BAM

18. Arreglo General Medición Banco de Pruebas

19.

Diagrama Unifilar Patín de Salida a Plataforma

20.

Diagrama Unifilar Descargaderas Aeropuerto

21.

Diagrama Unifilar Llenaderas Aeropuerto

Emerson Automation Solutions – Internal and Proprietary

Template No. 3293171-FSS-ME-FAB-00001, Revision 0, Date 16-mar-21

REQUEST FOR QUOTATION MECHANICAL

SCOPE PIPING / STRUCTURAL / I&E

3293171-MSS-ME-FAB-00001 “Patines de Medición de Hidrocarburos para la Medición de Turbosina //

SEDENA

Revision 2 –03-25-2021– Page 22 of 26 Project ID: PA 3293171

22.

Diagrama Unifilar Llenadera BAM

23.

Diagrama Unifilar Patín Bidireccional BAM

24.

Diagrama Unifilar Medición Banco de Pruebas

25.

Típicos de Instalación de Instrumentos

26.

Diagramas de Conexionado Eléctrico

27.

Isométricos de Tuberías Patín de Salida a Plataforma

28.

Isométricos de Tuberías Descargaderas Aeropuerto

29.

Isométricos de Tuberías Llenaderas Aeropuerto

30.

Isométricos de Tuberías Llenadera BAM

31.

Isométricos de Tuberías Patín Bidireccional BAM

32.

Isométricos de Tuberías Medición Banco de Pruebas

33.

Detalle de Estructuras Patín de Salida a Plataforma

34.

Detalle de Estructuras Descargaderas Aeropuerto

35.

Detalle de Estructuras Llenaderas Aeropuerto

36.

Detalle de Estructuras Llenadera BAM

37.

Detalle de Estructuras Patín Bidireccional BAM

38.

Rotulado de Tuberías y Estructuras

39.

Detalle de Placas de Identificación de Instrumentos

40.

Ruta de Tubería Conduit Patín de Salida a Plataforma

41.

Ruta de Tubería Conduit Descargaderas Aeropuerto

42.

Ruta de Tubería Conduit Llenaderas Aeropuerto

43.

Ruta de Tubería Conduit Llenadera BAM

44.

Ruta de Tubería Conduit Patín Bidireccional BAM

45.

Ruta de Tubería Conduit Medición Banco de Pruebas

46. Cédula de Cableado y Tubería Conduit Patín de Salida a

Plataforma

47. Cédula de Cableado y Tubería Conduit Descargaderas

Aeropuerto

48. Cédula de Cableado y Tubería Conduit Llenaderas

Aeropuerto

Emerson Automation Solutions – Internal and Proprietary

Template No. 3293171-FSS-ME-FAB-00001, Revision 0, Date 16-mar-21

REQUEST FOR QUOTATION MECHANICAL

SCOPE PIPING / STRUCTURAL / I&E

3293171-MSS-ME-FAB-00001 “Patines de Medición de Hidrocarburos para la Medición de Turbosina //

SEDENA

Revision 2 –03-25-2021– Page 23 of 26 Project ID: PA 3293171

49.

Cédula de Cableado y Tubería Conduit Llenadera BAM

50. Cédula de Cableado y Tubería Conduit Patín Bidireccional

BAM

51. Cédula de Cableado y Tubería Conduit Medición Banco de

Pruebas

52. Diagrama de Cableado Interno Gabinete de Control Patín

de Salida a Plataforma

53. Disposición de Equipos y Accesorios Gabinete de Control

Patín de Salida a Plataforma

54. Distribución de Fuerza AC/DC Gabinete de Control Patín

de Salida a Plataforma

55. Diagrama de Comunicación Gabinete de Control Patín de

Salida a Plataforma

56.

Layout UCL Descargaderas Aeropuerto

57. Diagrama de Cableado de Tarjetas UCL Descargaderas

Aeropuerto

58.

Layout UCL Llenaderas Aeropuerto

59. Diagrama de Cableado de Tarjetas UCL Llenaderas

Aeropuerto

60.

Layout UCL Llenaderas BAM

61.

Diagrama de Cableado de Tarjetas UCL Llenaderas BAM

62.

Layout UCL Patín Bidireccional BAM

63. Diagrama de Cableado de Tarjetas UCL Patín

Bidireccional BAM

64. Diagrama de Cableado Interno Gabinete de Control

Medición Banco de Pruebas

65. Disposición de Equipos y Accesorios Gabinete de Control

Medición Banco de Pruebas

66. Distribución de Fuerza AC/DC Gabinete de Control

Medición Banco de Pruebas

67. Diagrama de Comunicación Gabinete de Control Medición

Banco de Pruebas

68. Diagrama de Cableado Interno Gabinete de Control Patín

de Salida a Plataforma

69. Disposición de Equipos y Accesorios Gabinete de Control

Patín de Salida a Plataforma

70. Distribución de Fuerza AC/DC Gabinete de Control Patín

de Salida a Plataforma

71. Diagrama de Comunicación Gabinete de Control Patín de

Salida a Plataforma

72.

Layout UCL Descargaderas Aeropuerto

73. Diagrama de Cableado de Tarjetas UCL Descargaderas

Aeropuerto

74.

Layout UCL Llenaderas Aeropuerto

75. Diagrama de Cableado de Tarjetas UCL Llenaderas

Aeropuerto

Emerson Automation Solutions – Internal and Proprietary

Template No. 3293171-FSS-ME-FAB-00001, Revision 0, Date 16-mar-21

REQUEST FOR QUOTATION MECHANICAL

SCOPE PIPING / STRUCTURAL / I&E

3293171-MSS-ME-FAB-00001 “Patines de Medición de Hidrocarburos para la Medición de Turbosina //

SEDENA

Revision 2 –03-25-2021– Page 24 of 26 Project ID: PA 3293171

76.

Layout UCL Llenaderas BAM

77.

Diagrama de Cableado de Tarjetas UCL Llenaderas BAM

78.

Layout UCL Patín Bidireccional BAM

79. Diagrama de Cableado de Tarjetas UCL Patín

Bidireccional BAM

80. Diagrama de Cableado Interno Gabinete de Control

Medición Banco de Pruebas

81. Disposición de Equipos y Accesorios Gabinete de Control

Medición Banco de Pruebas

82. Distribución de Fuerza AC/DC Gabinete de Control

Medición Banco de Pruebas

83. Diagrama de Comunicación Gabinete de Control Medición

Banco de Pruebas

84. Protocolo de Pruebas de Aceptación en Fábrica (FAT)

85. Protocolo de Pruebas de Aceptación en Sitio (SAT)

11. END USER SPECIFICATIONS

No Document Title Document No. Sht. Rev.

1 Especificación Técnica de los Sistemas de Medición. 54 A

Emerson Automation Solutions – Internal and Proprietary

Template No. 3293171-FSS-ME-FAB-00001, Revision 0, Date 16-mar-21

REQUEST FOR QUOTATION MECHANICAL

SCOPE PIPING / STRUCTURAL / I&E

3293171-MSS-ME-FAB-00001 “Patines de Medición de Hidrocarburos para la Medición de Turbosina //

SEDENA

Revision 2 –03-25-2021– Page 25 of 26 Project ID: PA 3293171

12. PRICING SUMMARY

Total PriceTotal

Metering Systems 5.1 5.2 5.3 5.4 5.5 5.6

(USD)

Fabrication Dossier

Piping Material Supply

Mechanical & Piping Labor

Mechanical Material Supply

Structural Material Supply

Structural Labor

Electrical & Instrumentation Material

Supply

Electrical & Instrumentation Labor

Paint & Touch up paint (all material

requested)

Strainer, Check Valves Supply

Gas Separator Supply

Pressure Switch supply

Pre FAT, FAT, Packing and

shipment labor

Site works: Manouver (Hoisting

equipment shall be considered),

Installation & transportation)

Sub Totals

Total

Emerson Automation Solutions – Internal and Proprietary

Template No. 3293171-FSS-ME-FAB-00001, Revision 0, Date 16-mar-21

REQUEST FOR QUOTATION MECHANICAL

SCOPE PIPING / STRUCTURAL / I&E

3293171-MSS-ME-FAB-00001 “Patines de Medición de Hidrocarburos para la Medición de Turbosina //

SEDENA

Revision 2 –03-25-2021– Page 26 of 26 Project ID: PA 3293171

13. APPLICABLE SPECIFICATIONS

If any conflict exists between documents listed in the requisition, resolution and/or interpretation

precedence shall be obtained in writing from PURCHASER before proceeding with design /

manufacture.

In case of conflict, the order of precedence shall be:

I. End User Specifications and Drawings

II. Emerson Drawings

III. This Requisition

IV. Applicable Industry Codes and Standards

Emerson Automation Solutions – Internal and Proprietary

Template No. 3293171-FSS-ME-FAB-00001, Revision 0, Date 16-mar-21

También podría gustarte

- Stock, procesos y dirección de operaciones: Conoce y gestiona tu fábricaDe EverandStock, procesos y dirección de operaciones: Conoce y gestiona tu fábricaCalificación: 4 de 5 estrellas4/5 (3)

- Operaciones de mecanizado por medios automáticos. FMEE0208De EverandOperaciones de mecanizado por medios automáticos. FMEE0208Aún no hay calificaciones

- Especificacion Tecnica Especificacion Te PDFDocumento27 páginasEspecificacion Tecnica Especificacion Te PDFPablo José Delgado CarrasquelAún no hay calificaciones

- Examen TeoricoDocumento5 páginasExamen TeoricoFabian CifuentesAún no hay calificaciones

- Rediseño del laboratorio de soldadura de la Universidad UTEDe EverandRediseño del laboratorio de soldadura de la Universidad UTEAún no hay calificaciones

- ASME B31.3 P.2.0371.01 (Español)Documento202 páginasASME B31.3 P.2.0371.01 (Español)Juan Felipe Dioses Alban89% (9)

- Pets - Montaje de Estructuras MetalicasDocumento58 páginasPets - Montaje de Estructuras MetalicasVladimir damaso de la cruz100% (17)

- Aga 9Documento41 páginasAga 9Guillermo Gutierrez75% (4)

- 2182-PCOM-MEC-005-Rev. 00 - Proc. Gral Maquinas A SoldarDocumento8 páginas2182-PCOM-MEC-005-Rev. 00 - Proc. Gral Maquinas A SoldarVidal ChoqueAún no hay calificaciones

- CATÁLOGO de PRODUCTOS Soportes Eléctricos de AluminioDocumento72 páginasCATÁLOGO de PRODUCTOS Soportes Eléctricos de AluminioGuillermo GutierrezAún no hay calificaciones

- Análisis del proceso de barrido en motores de dos tiempos pequeña cilindradaDe EverandAnálisis del proceso de barrido en motores de dos tiempos pequeña cilindradaAún no hay calificaciones

- Organización y desarrollo del montaje de tuberías. FMEC0108De EverandOrganización y desarrollo del montaje de tuberías. FMEC0108Calificación: 5 de 5 estrellas5/5 (1)

- P.3.0341.03 FAbricacion de Presas Metalicas para LodosDocumento43 páginasP.3.0341.03 FAbricacion de Presas Metalicas para LodosAnacarmenlopezlopez100% (3)

- Procedimiento de Secado Edicion 3 PDFDocumento350 páginasProcedimiento de Secado Edicion 3 PDFJuan Torres100% (2)

- IluminaciónDocumento9 páginasIluminaciónPanchito666Aún no hay calificaciones

- Hc20ec1 002 Ocs 1620 e Tec Pen004 - RBDocumento54 páginasHc20ec1 002 Ocs 1620 e Tec Pen004 - RBRicardo Alejandro Oyarce Armijo100% (1)

- SST-PRO-CYM-045 - PETS Preparación de Superficie, Aplicación y Resanes de Pintura (Pets+Iperc)Documento27 páginasSST-PRO-CYM-045 - PETS Preparación de Superficie, Aplicación y Resanes de Pintura (Pets+Iperc)DERECK AUGUSTO VEGA GONZALESAún no hay calificaciones

- ETG-C.2.04 170314 Levantamientos Topograficos Líneas y SseeDocumento8 páginasETG-C.2.04 170314 Levantamientos Topograficos Líneas y SseeEduardoAún no hay calificaciones

- Bases Tecnicas CO-25 - 2023 Movimiento de Tierra Proyectos DCN-DGM-PZN 2024-2026Documento32 páginasBases Tecnicas CO-25 - 2023 Movimiento de Tierra Proyectos DCN-DGM-PZN 2024-2026vernon paredesAún no hay calificaciones

- C008-001076-04-QAC-PO-0003-02 - RSC - TSK Touch Up NO PDFDocumento52 páginasC008-001076-04-QAC-PO-0003-02 - RSC - TSK Touch Up NO PDFPatricia CastroAún no hay calificaciones

- B2 Manual de Construccion de Redes de Distribución PDFDocumento23 páginasB2 Manual de Construccion de Redes de Distribución PDFluciana :DAún no hay calificaciones

- Vil-Proc-Mec-12 Tramo-I Rev. 003 Procedimiento Tramo1 22072022Documento29 páginasVil-Proc-Mec-12 Tramo-I Rev. 003 Procedimiento Tramo1 22072022Hector ChiroqueAún no hay calificaciones

- Acero Calmado 04Documento9 páginasAcero Calmado 04Guillermo GutierrezAún no hay calificaciones

- Mbdp05 0000 Pem Ist 002 - C Anexo B Listado de SistemasDocumento20 páginasMbdp05 0000 Pem Ist 002 - C Anexo B Listado de SistemasClaudio Nicolas Pizarro EspinozaAún no hay calificaciones

- PEMEX - Normas para TuberíasDocumento202 páginasPEMEX - Normas para TuberíasEmmanuel Cervantes Velázquez100% (1)

- Procedimiento de Señalización Y Seguridad Vial: Construcción de Canal Revestido Tramo 6 (Paquete C.6)Documento23 páginasProcedimiento de Señalización Y Seguridad Vial: Construcción de Canal Revestido Tramo 6 (Paquete C.6)cesarAún no hay calificaciones

- Procedimiento de Tronadura Rev.8 01-10-21 (1) (1) Con ComentariosDocumento73 páginasProcedimiento de Tronadura Rev.8 01-10-21 (1) (1) Con ComentariosAlfredo Rojas100% (1)

- Estudio de Conexión PCH 9MW PDFDocumento9 páginasEstudio de Conexión PCH 9MW PDFCami FCAún no hay calificaciones

- 02070-GEN-QUA-GYM-02-220 Rev.2 Procedimiento de Pruebas Neumáticas en TuberíasDocumento22 páginas02070-GEN-QUA-GYM-02-220 Rev.2 Procedimiento de Pruebas Neumáticas en TuberíasunimillaAún no hay calificaciones

- MC-SERVI-FEM-PLT_INSPCN_CJN_3411-BX-03.Rev.BDocumento20 páginasMC-SERVI-FEM-PLT_INSPCN_CJN_3411-BX-03.Rev.BMarco Hector ChavezAún no hay calificaciones

- T05GUX05 (Incluye Adenda)Documento15 páginasT05GUX05 (Incluye Adenda)jamp2627Aún no hay calificaciones

- Procedimiento de Señalización Y Seguridad Vial: Construcción de Canal Revestido Tramo 6 (Paquete C.6)Documento23 páginasProcedimiento de Señalización Y Seguridad Vial: Construcción de Canal Revestido Tramo 6 (Paquete C.6)cesarAún no hay calificaciones

- 2513013-100-019-P-01-01-00-Rv-A (Aecuo.000.12.00.dti.1.p001.bdd) Rev - Oag 01.09.13Documento67 páginas2513013-100-019-P-01-01-00-Rv-A (Aecuo.000.12.00.dti.1.p001.bdd) Rev - Oag 01.09.13Omar GraterolAún no hay calificaciones

- Desvíos en Fabricación de SpoolsDocumento1 páginaDesvíos en Fabricación de Spoolsaleyzar1315Aún no hay calificaciones

- MPM GPR CC 1020100322 000 S Po 001 - 0Documento71 páginasMPM GPR CC 1020100322 000 S Po 001 - 0Marck KollAún no hay calificaciones

- Coordinación de Protecciones - BISA-13221-21-3-2100-24-MCL-006 - 0Documento27 páginasCoordinación de Protecciones - BISA-13221-21-3-2100-24-MCL-006 - 0Franklin Mendoza100% (1)

- UNI-OCC-PE-19 - PROCEDIMIENTO DE CONFORMACIÓN DE VÍAS Y SEÑALIZACIÓN - SE PLANICIE 220.500kV 21.04.23Documento18 páginasUNI-OCC-PE-19 - PROCEDIMIENTO DE CONFORMACIÓN DE VÍAS Y SEÑALIZACIÓN - SE PLANICIE 220.500kV 21.04.23Gian SPAún no hay calificaciones

- 103Documento16 páginas103iCOLAB - Gte IngenieriaAún no hay calificaciones

- CA3 - Automatización Sistema de BombeoDocumento8 páginasCA3 - Automatización Sistema de BombeoLuis ZapanaAún no hay calificaciones

- 26148-223-V206-CB00-00074 - Procedimiento Señalero de Obras - Native Rev.02Documento20 páginas26148-223-V206-CB00-00074 - Procedimiento Señalero de Obras - Native Rev.02Ricardo Rodríguez IribarrenAún no hay calificaciones

- Plano ElectricoDocumento24 páginasPlano ElectricoEDUAR ANTONIO BUITRAGO CONTRERASAún no hay calificaciones

- V-101946-0507-0344 2 Status 1Documento72 páginasV-101946-0507-0344 2 Status 1JESUS HUAMANIAún no hay calificaciones

- DP200 00 2el Pro 0001 R0Documento13 páginasDP200 00 2el Pro 0001 R0ANDRES CABRERAAún no hay calificaciones

- Maed 03 04 Manual para El Calculo de Redes de AlcantarilladoDocumento53 páginasMaed 03 04 Manual para El Calculo de Redes de AlcantarilladotaticguarinAún no hay calificaciones

- Especificacion Tecnica para PipelineDocumento21 páginasEspecificacion Tecnica para Pipelinejuanjo3abAún no hay calificaciones

- Especificacion Tecnica DemolicionesDocumento13 páginasEspecificacion Tecnica Demolicionesjuanjo3abAún no hay calificaciones

- Memoria de Cálculo Fundaciones y TanquillasDocumento46 páginasMemoria de Cálculo Fundaciones y TanquillasMiguel A. Martinez PAún no hay calificaciones

- Tme Ssoma XX Pets PC3 0003 - 2Documento32 páginasTme Ssoma XX Pets PC3 0003 - 2Robert Bazán PrinceAún no hay calificaciones

- Propuesta 3Documento9 páginasPropuesta 3Claudio Valenzuela YañezAún no hay calificaciones

- ResumenDocumento2 páginasResumenTheKillerGoat 3003Aún no hay calificaciones

- Desfase de Tuberías en Llegadas A Equipo 3310-Ay-305Documento1 páginaDesfase de Tuberías en Llegadas A Equipo 3310-Ay-305aleyzar1315Aún no hay calificaciones

- Informe N 20 - Japa - Informe Tableros Generales Proveido 380Documento26 páginasInforme N 20 - Japa - Informe Tableros Generales Proveido 380Jose Luis Velasco CruzAún no hay calificaciones

- Descripcion Del Diseño de FuncionalDocumento8 páginasDescripcion Del Diseño de FuncionalDianaMartínezAún no hay calificaciones

- 105-18028-Mob00922-Pln-430-G-0001 JRGDocumento28 páginas105-18028-Mob00922-Pln-430-G-0001 JRGDayana AnculliAún no hay calificaciones

- P 2 0227 04 Diseno e Instalacion de Sistemas Electricos enDocumento25 páginasP 2 0227 04 Diseno e Instalacion de Sistemas Electricos entristanxp80Aún no hay calificaciones

- Estudio de Tensiones de Operación 2022 (ETO 2022)Documento36 páginasEstudio de Tensiones de Operación 2022 (ETO 2022)Rickert Villanueva Coz100% (1)

- Memori Üa de Ca Ülculo Correa COR528 - NPTIV - Rev. A - MSE9Documento31 páginasMemori Üa de Ca Ülculo Correa COR528 - NPTIV - Rev. A - MSE9Cristobal JimenezAún no hay calificaciones

- Proyecto TurboDocumento15 páginasProyecto TurboSebastian Gordillo67% (3)

- Trabajo de Campo-EjemploDocumento29 páginasTrabajo de Campo-EjemploMax C. GarayAún no hay calificaciones

- ASME B31 3 P 2 0371 01 EspanolDocumento202 páginasASME B31 3 P 2 0371 01 EspanolDavid EnríquezAún no hay calificaciones

- Licitacion Cochemotores CAF 593Documento19 páginasLicitacion Cochemotores CAF 593enelSubteAún no hay calificaciones

- Especificaciones Técnicas Proyecto Eléctrico GalpónDocumento48 páginasEspecificaciones Técnicas Proyecto Eléctrico GalpónRichard Santana100% (1)

- Alcance MMProject Concrete RevBDocumento13 páginasAlcance MMProject Concrete RevBPedro LopezAún no hay calificaciones

- 290-TUB-PO-11 Preparacion de Superficie y Aplicacion de RecubrimientosDocumento22 páginas290-TUB-PO-11 Preparacion de Superficie y Aplicacion de RecubrimientosbladimirAún no hay calificaciones

- Catálogo Dixon Bayco Dry Bulk Carga SecaDocumento44 páginasCatálogo Dixon Bayco Dry Bulk Carga SecaGuillermo GutierrezAún no hay calificaciones

- Equivalencia MaterialesDocumento1 páginaEquivalencia MaterialesGuillermo GutierrezAún no hay calificaciones

- Catalogi Gassoinox 2016 - LR2 1Documento28 páginasCatalogi Gassoinox 2016 - LR2 1Guillermo GutierrezAún no hay calificaciones

- Equivalencia MaterialesDocumento1 páginaEquivalencia MaterialesGuillermo GutierrezAún no hay calificaciones

- MS 02 312Documento7 páginasMS 02 312Guillermo GutierrezAún no hay calificaciones

- Cátalogo Válv. Bola T 16 Walworth 1500Documento1 páginaCátalogo Válv. Bola T 16 Walworth 1500Guillermo GutierrezAún no hay calificaciones

- Anillos GrafoilDocumento1 páginaAnillos GrafoilGuillermo GutierrezAún no hay calificaciones

- Válvulas de Aguja Con Bonete Integral: SS-1RS4-RDDocumento1 páginaVálvulas de Aguja Con Bonete Integral: SS-1RS4-RDGuillermo GutierrezAún no hay calificaciones

- T D01T1 PDFDocumento5 páginasT D01T1 PDFGuillermo GutierrezAún no hay calificaciones

- Grupo de Gas 11a-01 PDFDocumento1 páginaGrupo de Gas 11a-01 PDFGuillermo GutierrezAún no hay calificaciones

- Catálogo 17.4 PH 01 PDFDocumento4 páginasCatálogo 17.4 PH 01 PDFGuillermo GutierrezAún no hay calificaciones

- Pixma MP750 PDFDocumento3 páginasPixma MP750 PDFJherson RojasAún no hay calificaciones

- Fundamento Teórico Fisica MedicionesDocumento4 páginasFundamento Teórico Fisica Medicionesfredy ronaldAún no hay calificaciones

- AEW Semana 11Documento4 páginasAEW Semana 11Juan Adolfo Nicasio SantillanAún no hay calificaciones

- Redes Por Su Grado de DifusiónDocumento3 páginasRedes Por Su Grado de DifusiónSebastian Saltos100% (2)

- Tecnologias Moviles El Camino A La UbicuidadDocumento7 páginasTecnologias Moviles El Camino A La Ubicuidadcarlosgg_1Aún no hay calificaciones

- Memoria Calculo - Mercado - AbastosDocumento4 páginasMemoria Calculo - Mercado - Abastosrichard ramón abanto ruizAún no hay calificaciones

- Mat Ciclo 5 Unid1 Radianes y Sexagesimales Resumen Ejercicios 3Documento4 páginasMat Ciclo 5 Unid1 Radianes y Sexagesimales Resumen Ejercicios 3CESAR DAVID ARROYO CRISMATAún no hay calificaciones

- Presentación 1Documento60 páginasPresentación 1Luis Enrique100% (1)

- 01 Teoría de ErroresDocumento9 páginas01 Teoría de ErroresLEYDER VELASCO GUZAMNAún no hay calificaciones

- Blog Pandorafms Org Es Nosql Vs SQL Diferencias y Cuando EleDocumento15 páginasBlog Pandorafms Org Es Nosql Vs SQL Diferencias y Cuando EleAndresVeraHAún no hay calificaciones

- DNS Dinámica Con BINDDocumento4 páginasDNS Dinámica Con BINDaalejosdAún no hay calificaciones

- Comparativo Técnico Lifan x60 y OtrasDocumento10 páginasComparativo Técnico Lifan x60 y OtrasMauricio Carvallo G.Aún no hay calificaciones

- FORMULASDocumento4 páginasFORMULASDiego Manuel Zapata Asencios100% (1)

- Central Telefonica SkyphoneDocumento22 páginasCentral Telefonica SkyphoneMery TurpoAún no hay calificaciones

- Taller Ejercicios Estimacion de Incertidumbre PDFDocumento5 páginasTaller Ejercicios Estimacion de Incertidumbre PDFanpipe19Aún no hay calificaciones

- PasantiasDocumento8 páginasPasantiasYENIREESAún no hay calificaciones

- Botones Básicos en Cuadro de Herramientas Visual BasicDocumento3 páginasBotones Básicos en Cuadro de Herramientas Visual BasicHabid Parada GarciaAún no hay calificaciones

- Manual de Servicios Web Api - SIRE - Compras v6Documento122 páginasManual de Servicios Web Api - SIRE - Compras v6Diana MagalyAún no hay calificaciones

- Estandar Oficiales Cableado EstructuradoDocumento116 páginasEstandar Oficiales Cableado EstructuradoITSPPIngenieros100% (1)

- Ado 2.5Documento19 páginasAdo 2.5Masvec 107Aún no hay calificaciones

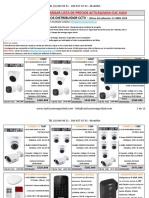

- Precios Distribuidor TacticasenseguridadDocumento13 páginasPrecios Distribuidor TacticasenseguridadGlen Castañeda MiraAún no hay calificaciones

- Anticorrupcion y Etica EmpresarialDocumento26 páginasAnticorrupcion y Etica EmpresarialAlex Sucar LeguizamonAún no hay calificaciones

- Fichas TecnicasDocumento15 páginasFichas Tecnicasalan britoAún no hay calificaciones

- Tablas de Actualizacion OtaDocumento4 páginasTablas de Actualizacion OtaingyormanlealAún no hay calificaciones

- Guía Calibración 5Documento13 páginasGuía Calibración 5Jenifer Carvajal CruzAún no hay calificaciones

- Instalacion Servidor LemppDocumento3 páginasInstalacion Servidor LemppJhonathan VillegasAún no hay calificaciones

- Cafco Spray Film WB 4 - C-Tds-Es - 08-18Documento2 páginasCafco Spray Film WB 4 - C-Tds-Es - 08-18joseAún no hay calificaciones

- S11 - HTML-CSS-JavaScript PDFDocumento49 páginasS11 - HTML-CSS-JavaScript PDFJavier ZuñigaAún no hay calificaciones

- Ejercicios Estimación de BayesDocumento2 páginasEjercicios Estimación de BayesClaudia Elisa Orihuela LagunaAún no hay calificaciones