Documentos de Académico

Documentos de Profesional

Documentos de Cultura

104 13479 Mob02918 DSH 420 J 0017 - 2

Cargado por

Roberto Capcha SernaDescripción original:

Título original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

104 13479 Mob02918 DSH 420 J 0017 - 2

Cargado por

Roberto Capcha SernaCopyright:

Formatos disponibles

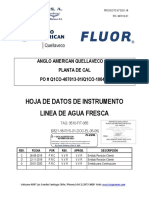

PROYECTO: 13479

EPC - SISTEMA DE BOMBEO DE RELAVES

LINEAS NORTE Y SUR - ELEVACIÓN 4165

ETAPA: INGENIERÍA DE DETALLE - 104

HOJA DE DATOS - DSH

VÁLVULA MARIPOSA ON/OFF - 420-LV-1001

104-13479-MOB02918-ESP-420-J-0013

Líder de disciplina : Carlos Ojeda

Jefe de Ingeniería : Jorge Pinazo

Gerencia de Proyecto : Daniel Peña

VP: Ingeniería & Proyectos

AFE: 13479 CONTRATO: MOB02918

2 27/10/2020 Emitido para construcción COC JPB DPE

1 3/10/2019 Emitido para cotización DS CR LLF

0 12/07/2019 Emitido para cotización DS CR LLF

Rev. Fecha Descripción Por Revisado Aprobado

COMPAÑÍA MINERA ANTAMINA

SISTEMA DE BOMBEO DE RELAVES LÍNEAS NORTE Y SUR - ELEVACIÓN 4165

DATA SHEET

BUTTERFLY VALVE

420-LV-1001

Rev.

Datasheet N° 104-13479-MOB02918-DSH-420-J-0017 2

1 Tech.Specification 104-13479-MOB02918-ESP-420-J-0013 Equip. No. 420-TKS-1000

2 P&ID Nº, 420-F-20055 2 25/10/20 COC JPB DPE

GENERAL

3 Location TAILINGS PUMPING STATION Altitude 4 300 m a.s.l. 1 3/10/19 D.S.P. C.R.A. L.L.F.

4 Service FILL SEAL WATER TANK Relative humidity 70% 0 12/7/19 D.S.P. C.R.A. L.L.F.

5 Area class UNCLASSIFIED Ambiance temperature -0.1 to 12.0 °C Rev Date: By Appr G.Proy.

6 Line Size/Sched 6" ANSI #150 Line TAG 420-PW-6"-C1E2A-25098 Rev.

PIPE

7 Pipe Material CARBON STEEL Pipe Isolation None 0

8 Units Nominal Maximum

9 Flow Rate m3/h 90 108 0

10 Inlet Pressure psi 110 130 0

11 Pressure Drop psi 110 130 0

12 Operating Temperature °C 6 12 0

PROCESS

13 Operating % Solids % 0 0 0

14 Operating Density kg / l 1 1 0

15 Operating Viscosity cP 1 1 0

16 Yield stress Pa 0 57 Manufacturer TBD 0

17 Fluid & Fluid phase WATER / LIQUID 58 Model N° TBD 0

18 Design Press. Design Temp. 130 psi 15 °C 59 Tag N° 420-HYO-LV-1001 0

SOLENOID VALVE

19 60 420-HYC-LV-1001 0

20 Manufacturer N/A 61 Type TBD 0

21 Model N° TBD 62 When De-Energize Valve CLOSE 0

22 Size & ANSI Class 6" ANSI #150 63 Quantity TWO 0

23 Max. Pressure Max. Temp. 130 psi 12 °C 64 Coil Rating / Power Supply NEMA 4 / 120 VAC 0

24 Body Type WAFER 65 Coil Conect Pneumatic conn. TERMINAL STRIP 3/8" NPTF (TBC) 0

VALVE BODY

25 Body / Bonnet Material CAST C.S. per ASTM A216 Gr. WCB 66 Manufacturer TBD 0

26 Liner Material / ID N/A 67 Model N° TBD 0

27 End Connect: Flg / Serie / Class ASME B16.5 FF / TBD / CLASS 150 68 Tag N° 420-ZSC-LV-1001 1

69

SWITCHES / TRANSMITTER

28 Bolting Material STEEL 420-ZSO-LV-1001 0

29 End Ext / Material N/A 70 Type Quantity LIMIT SWITCH (MECH) TWO 0

30 Flow to Open / Close OPEN 71 Calibration Open / Close OPEN: NO CLOSE: NO 0

31 Flow Direcction FORWARD 72 Rating (Amps/Volt/Hz.) 2 A, 120 VAC, 60 Hz, NEMA 4 0

32 Packing Material / Type N/A 73 Actuation points / contacts OPEN/CLOSE, SPDT 0

33 Port Type FULL PORT 74 Power supply N/A 0

34 Port Size Rated Travel 6" N/A 75 Switching position 0 & 100% 0

35 Seal Material / Liner PTFE 76 Fieldbus N/A 0

VALVE TRIM

36 Retainer Mat. Gasket Mat STEEL TBD 77 Advanced Diagnostics N/A 0

37 Rated CV / FL / XT N/A 78 PID Controller N/A 0

38 Disc Material DISC / A351 SS CF3M 79 Manufacturer TBD 0

39 Seat Material Ring Mat. BUNA N BUNA N 80 Model N° TBD 0

AIR SET

40 Cage / Guide Material N/A 81 Set Pressure YES 0

41 Stem Material 316 SS 82 Filter Gauge YES, REMOVE 20 microm. YES 0

42 83 Option LUBRICATOR, INCLUDED 0

43 Manufacturer Model N° N/A TBD 84 Pressure Test REQUIRED 0

44 Type SCOTCH YOKE, ROTARY (90°) 85 ANSI / FCI Leakage Class TBD 0

TESTS

45 Size Eff. Area N/A N/A 86 Non Destructive Examination TBD 0

46 On/Off or Modulating ON/OFF 87 0

47 Operating Speed 20 DEG/SEC 88 Air Failure Valve REQUIRED 0

ACCESSORIES

48 Actuator Orient. VERTICAL UP 89 Device Description REQUIRED 0

ACTUATOR

49 Handwheel Type TBD 90 Electric Junction Box MOUNTED ON THE VALVE 0

50 Available Air Supply: Min to Max 85 TO 124 psi 91 0

51 Bench Range: Min to Max. N/A 92 0

52 Action: ATO / ATC Fail Position OPEN / CLOSE LAST POSITION 93 Manufacturer QUADRAPOWER NOTE 5 1

94

PURCHASE

53 Min Req Press. MAWP 80 psi TBD Model N° 0

54 Motive Power Power Supply N/A N/A 95 P. O. N° Item N° 0

55 Power/Control Cable Connection N/A 96 Serial N° 0

56 Operating Principle DOUBLE-ACTING 97 Electrical Aproval 1

98 1. AFFIX ENGRAVED SS TAG TO VALVE, SOLENOIDS, SWITCHES AND JUNCTION BOX

99 2. PRESSURE DROP DESCRIBES THE DROP OVER THE TOTAL SYSTEM (REF. LINE 11).

100 3. NUMBER OF UNITS TO PROVIDE 1 UNIT

101 4. CONTROL STATION WILL BE PROVIDED BY OTHERS

NOTES

102 5. MANUFACTURER AND MODEL ARE REFERENTIAL

103 6. TBD: TO BE DEFINED BY VENDOR

104 7. TBC: TO BE CONFIRMED BY VENDOR

105 8. N/A: NOT APPLY

2/2

También podría gustarte

- Manual de Operacion Sal Fase2Documento145 páginasManual de Operacion Sal Fase2cristhian ayanome100% (2)

- Ejercicios Automatismos ElectricosDocumento2 páginasEjercicios Automatismos ElectricosJonatan García Gómez0% (1)

- Ecp Uce 17062 Gma Ib01 0 Mee HD 203 0Documento5 páginasEcp Uce 17062 Gma Ib01 0 Mee HD 203 0Javier Andres Barahona GarciaAún no hay calificaciones

- Pipíng & Stress Analysis Ref - Sofware Caesar II. 06-09-2017 Autor - Ing R L Morard - U T N 1Documento16 páginasPipíng & Stress Analysis Ref - Sofware Caesar II. 06-09-2017 Autor - Ing R L Morard - U T N 1Oswaldo Guerra100% (1)

- Mq13-407013-01-Dst-In-9321-18-Rys-01-Doc-El-05-08 - 1 Cert - DDocumento3 páginasMq13-407013-01-Dst-In-9321-18-Rys-01-Doc-El-05-08 - 1 Cert - DJhonatan RodriguezAún no hay calificaciones

- Submittal INTENSITY - Paquete Comercial Solo Frio On-Off, 220VDocumento5 páginasSubmittal INTENSITY - Paquete Comercial Solo Frio On-Off, 220VLucero CamposAún no hay calificaciones

- Hoja de Datos RociadoresDocumento9 páginasHoja de Datos RociadoresSantos Montero PereiraAún no hay calificaciones

- 104 13479 Mob02918 DSH 420 J 0016 - 2Documento2 páginas104 13479 Mob02918 DSH 420 J 0016 - 2Roberto Capcha SernaAún no hay calificaciones

- 104 13479 Mob02918 DSH 420 J 0015 - 3Documento15 páginas104 13479 Mob02918 DSH 420 J 0015 - 3Roberto Capcha SernaAún no hay calificaciones

- 104 13479 Mob02918 DSH 320 M 0001 - 1Documento2 páginas104 13479 Mob02918 DSH 320 M 0001 - 1Luis Orlando Gil BancallanAún no hay calificaciones

- 104 13479 Mob02918 DSH 420 M 0018 - 3Documento4 páginas104 13479 Mob02918 DSH 420 M 0018 - 3Luis Orlando Gil BancallanAún no hay calificaciones

- 104 13479 Mob02918 DSH 420 M 0017 - 3Documento4 páginas104 13479 Mob02918 DSH 420 M 0017 - 3Luis Orlando Gil BancallanAún no hay calificaciones

- dATOS ARRANCADORES SUAVESDocumento8 páginasdATOS ARRANCADORES SUAVESRobinsonContrerasMAún no hay calificaciones

- R Ip Dar 001Documento1 páginaR Ip Dar 001Cristian GonzalezAún no hay calificaciones

- 104 13479 Mob02918 DSH 420 M 0016 - 1Documento11 páginas104 13479 Mob02918 DSH 420 M 0016 - 1Luis Orlando Gil BancallanAún no hay calificaciones

- MQ13 407013 01 DST in 9321 18 Rys 01 Doc El 05 06 - 0 DDocumento4 páginasMQ13 407013 01 DST in 9321 18 Rys 01 Doc El 05 06 - 0 DJhonatan Rodriguez100% (1)

- Test PressureDocumento1 páginaTest PressureLizz EstradaAún no hay calificaciones

- I GII GIO 631 104140 HD I 302 0 Transmisor de TemperaturaDocumento6 páginasI GII GIO 631 104140 HD I 302 0 Transmisor de TemperaturaMartin DanzeAún no hay calificaciones

- MQ13 407013 01 DST in 9321 18 Rys 01 Doc El 05 18 - 0 DDocumento4 páginasMQ13 407013 01 DST in 9321 18 Rys 01 Doc El 05 18 - 0 DJHONATAN RODRIGUEZ VENTOAún no hay calificaciones

- FT-LAC 920-EsDocumento1 páginaFT-LAC 920-EsRogelio Raul Medina RodriguezAún no hay calificaciones

- Planos - de - Piezas 15Documento1 páginaPlanos - de - Piezas 15Leandro Rame ValenciaAún no hay calificaciones

- 19120-2020-EST-07-004 Torque Pernos Tranformador Celda A Zocalo 201Documento4 páginas19120-2020-EST-07-004 Torque Pernos Tranformador Celda A Zocalo 201Enrique MirandaAún no hay calificaciones

- Chamber Tup VT ExternaDocumento22 páginasChamber Tup VT Externabrianda canteAún no hay calificaciones

- Estrangulador de Fondo VenturiDocumento20 páginasEstrangulador de Fondo Venturiregina camachoAún no hay calificaciones

- 2.5 STRADDLE PACKER SP10 SERIES Data SheetDocumento2 páginas2.5 STRADDLE PACKER SP10 SERIES Data SheetNosthbeer H. VelasquezAún no hay calificaciones

- Inspeccion Visual Linea 1711Documento5 páginasInspeccion Visual Linea 1711alex salasAún no hay calificaciones

- Certificado de Calidad Tuberia Hdpe 355Documento2 páginasCertificado de Calidad Tuberia Hdpe 355Cesar Augusto Marrufo UrteagaAún no hay calificaciones

- Inspeccion Visual Linea 1712Documento5 páginasInspeccion Visual Linea 1712alex salasAún no hay calificaciones

- Inspeccion Visual Linea 1713Documento5 páginasInspeccion Visual Linea 1713alex salasAún no hay calificaciones

- Inspeccion Visual Linea 1714Documento5 páginasInspeccion Visual Linea 1714alex salasAún no hay calificaciones

- FA-1102-DESCARGA BLOQUEADA (API 520 Gas) PDFDocumento11 páginasFA-1102-DESCARGA BLOQUEADA (API 520 Gas) PDFljherediaAún no hay calificaciones

- Protocolo 2Documento1 páginaProtocolo 2joel rodolfo alberto haroAún no hay calificaciones

- TEMPLADORESDocumento24 páginasTEMPLADORESLuisAún no hay calificaciones

- 4501195778-LIS-MC-001-R0 - Listado de Equipos MecanicosDocumento4 páginas4501195778-LIS-MC-001-R0 - Listado de Equipos MecanicosroroAún no hay calificaciones

- Protocolo 4Documento2 páginasProtocolo 4joel rodolfo alberto haroAún no hay calificaciones

- 6480 15 029 01 LP DM MC 014 CaoDocumento41 páginas6480 15 029 01 LP DM MC 014 CaoandradaingAún no hay calificaciones

- Ecp Uce 17062 Gma Id05 0 Ins HD 103 1Documento3 páginasEcp Uce 17062 Gma Id05 0 Ins HD 103 1jonathan julian sanchezmondragonAún no hay calificaciones

- Planos - de - Piezas 21Documento1 páginaPlanos - de - Piezas 21Leandro Rame ValenciaAún no hay calificaciones

- DICKSON LAC 950 SLF-EsDocumento1 páginaDICKSON LAC 950 SLF-EsJan Carlos Pampa VaraAún no hay calificaciones

- Programa InstalacionDocumento14 páginasPrograma InstalacionMiguel SalazarAún no hay calificaciones

- Normal - Cav-16 - Mando Final Delantero Izquierdo - 14-11-20Documento1 páginaNormal - Cav-16 - Mando Final Delantero Izquierdo - 14-11-20johnAún no hay calificaciones

- 10102-C-ET-714-0.doc Especificación Técnica de CTBDocumento8 páginas10102-C-ET-714-0.doc Especificación Técnica de CTBHoracio AndradaAún no hay calificaciones

- Aldec G2 70 Partes - Centrífuga de ALFA LAVALDocumento76 páginasAldec G2 70 Partes - Centrífuga de ALFA LAVALruben bautistaAún no hay calificaciones

- INSPECCION VISUAL MesasDocumento1 páginaINSPECCION VISUAL Mesasalex salasAún no hay calificaciones

- W87165 Suministro de Repuestos para Planta de Tratamiento de AguasDocumento8 páginasW87165 Suministro de Repuestos para Planta de Tratamiento de Aguasandresprando777Aún no hay calificaciones

- 6480 15 029 01 LP DM MC 013 CaoDocumento48 páginas6480 15 029 01 LP DM MC 013 CaoandradaingAún no hay calificaciones

- Inspeccion Visual Linea 1716Documento5 páginasInspeccion Visual Linea 1716alex salasAún no hay calificaciones

- 97309b Manual Central AC PLUS Ref 4410 V07 - 15Documento77 páginas97309b Manual Central AC PLUS Ref 4410 V07 - 15Joaquin Poblet JimenezAún no hay calificaciones

- 21 4 Itc DS 00003 0Documento2 páginas21 4 Itc DS 00003 0Lizz CabelloAún no hay calificaciones

- Inspeccion Visual Sistema Motriz 026 - 1Documento1 páginaInspeccion Visual Sistema Motriz 026 - 1alex salasAún no hay calificaciones

- Pmal 435 HD K 023 2Documento4 páginasPmal 435 HD K 023 2David BarrenecheaAún no hay calificaciones

- Inspeccion Visual Linea 1715Documento5 páginasInspeccion Visual Linea 1715alex salasAún no hay calificaciones

- L01 6410 EMEC DS 0072 - 00 - c1Documento2 páginasL01 6410 EMEC DS 0072 - 00 - c1Gustavo BerbergiAún no hay calificaciones

- Inspeccion Visual Sistema Motriz 026 - 2Documento1 páginaInspeccion Visual Sistema Motriz 026 - 2alex salasAún no hay calificaciones

- 4195 Tchi e SP 000 001Documento14 páginas4195 Tchi e SP 000 001Ricardo OjedaAún no hay calificaciones

- Home Gao23611Documento217 páginasHome Gao23611J MANCERAAún no hay calificaciones

- Reporte Dimensional de Medicion de ProductosDocumento2 páginasReporte Dimensional de Medicion de ProductosRosita Flores MartínezAún no hay calificaciones

- Facest 2013 Rep Fac 2020 RBDocumento7 páginasFacest 2013 Rep Fac 2020 RBAdolfolui TRAún no hay calificaciones

- Detalle AscensorDocumento9 páginasDetalle AscensorFer Fernández LuisAún no hay calificaciones

- 2123JSDM12251TEN34216ER0Documento2 páginas2123JSDM12251TEN34216ER0Jose Carlos Rios IbarraAún no hay calificaciones

- Conceptos Básicos y Ejemplos de Sistemas DistribuidosDocumento11 páginasConceptos Básicos y Ejemplos de Sistemas DistribuidosFabricio OrtizAún no hay calificaciones

- Instalacion Eléctrica de Una Casa o Vivienda. Aprende FacilmenteDocumento25 páginasInstalacion Eléctrica de Una Casa o Vivienda. Aprende FacilmenteOCHA OCHAAún no hay calificaciones

- 8.3 - Ejercicios Propuestos de Lineas LargasDocumento2 páginas8.3 - Ejercicios Propuestos de Lineas LargasNico UrunagaAún no hay calificaciones

- KENNEDY SSEE 05ENE2023-Layout2-1Documento1 páginaKENNEDY SSEE 05ENE2023-Layout2-1Vite Estrada SilvanaAún no hay calificaciones

- PLANTILLA 2021 - 2 Montaje de LLTTDocumento14 páginasPLANTILLA 2021 - 2 Montaje de LLTTLuis Miguel ContrerasAún no hay calificaciones

- Universidad Del Valle Ingenieria Mecanica Diseño MecanicoDocumento4 páginasUniversidad Del Valle Ingenieria Mecanica Diseño MecanicoJUAN FELIPE URIBE CIFUENTESAún no hay calificaciones

- Expo SeguridadDocumento17 páginasExpo SeguridadMario ZegarraAún no hay calificaciones

- Informe Ac AcDocumento13 páginasInforme Ac AcJuan RamosAún no hay calificaciones

- Ficha Tecnica Tuberia de Acero Cold RolledDocumento7 páginasFicha Tecnica Tuberia de Acero Cold RolledJONATHAN PATIÑO LOPEZAún no hay calificaciones

- Peritaje Planta de Beneficio ViterboDocumento9 páginasPeritaje Planta de Beneficio ViterboCésar GarcíaAún no hay calificaciones

- Trabajo de Fin de Grado Ingeniería Civil: Autor: Iván Megías Muñoz Tutor: Gabriel Chamorro SosaDocumento553 páginasTrabajo de Fin de Grado Ingeniería Civil: Autor: Iván Megías Muñoz Tutor: Gabriel Chamorro SosaCristian SuarezAún no hay calificaciones

- Hoja de Calculo de Albañileria - CCIDocumento35 páginasHoja de Calculo de Albañileria - CCIMario OlorteguiAún no hay calificaciones

- 10-11-2021-10 Planillla de Cuadrillas DiariasDocumento3 páginas10-11-2021-10 Planillla de Cuadrillas DiariasGiovanny DEVIA RODRIGUEZAún no hay calificaciones

- RDT ReferenciaDocumento6 páginasRDT ReferenciaNet WalkerAún no hay calificaciones

- Diodo Zener y Sus AplicacionesDocumento3 páginasDiodo Zener y Sus AplicacionesJorge EspinosaAún no hay calificaciones

- Capitulo 5 Vigas T Diseño Problemas 9-11Documento15 páginasCapitulo 5 Vigas T Diseño Problemas 9-11JACK ANTHONY APACCLLA HUAMANAún no hay calificaciones

- Proyecto ProductivoDocumento5 páginasProyecto ProductivoJose Arteta SalasAún no hay calificaciones

- F2IIc-C9 (Sem 9) Uft1.3Documento17 páginasF2IIc-C9 (Sem 9) Uft1.3Luisana Leon martinezAún no hay calificaciones

- Examen Final Upn 2021 IIDocumento2 páginasExamen Final Upn 2021 IILuis Gustavo Gonzales VelasquezAún no hay calificaciones

- Taller Del Modulo 2Documento5 páginasTaller Del Modulo 2MauricioAún no hay calificaciones

- Diseño IsometricoDocumento1 páginaDiseño IsometricoPaquito JoséAún no hay calificaciones

- Insa 12 Ins 14 1 0 PDFDocumento77 páginasInsa 12 Ins 14 1 0 PDFFrankCapraAún no hay calificaciones

- Cotizacion Pozo A TierraDocumento1 páginaCotizacion Pozo A TierraonanAún no hay calificaciones

- Presupuesto de Biodigestores LaqDocumento3 páginasPresupuesto de Biodigestores LaqYhon Eliot Leon SAún no hay calificaciones

- Taller 3 Circuitos en ParaleloDocumento3 páginasTaller 3 Circuitos en ParaleloJuan Francisco Gamboa MarínAún no hay calificaciones

- Pre-Informe - Resistencia Interna de Una PilaDocumento10 páginasPre-Informe - Resistencia Interna de Una PilaAndres Felipe Salazar RamirezAún no hay calificaciones

- Lineas Electricas de Diferente Tension en Estructura Comun multitensionRPTD12Documento3 páginasLineas Electricas de Diferente Tension en Estructura Comun multitensionRPTD12Jean Paul Alexander Opazo ArceAún no hay calificaciones

- Cotizacion HerramientasDocumento4 páginasCotizacion Herramientasjose rodrigo sayco bernedo100% (1)

- Tutorial Basico Del PCB WizardDocumento11 páginasTutorial Basico Del PCB WizardAnibal Castro EguisAún no hay calificaciones