Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Pmal 435 HD K 023 2

Cargado por

David Barrenechea0 calificaciones0% encontró este documento útil (0 votos)

35 vistas4 páginasEste documento contiene la hoja de datos para dos transmisores de nivel ultrasónicos (LIT-35932A y LIT-35932B) que miden el nivel en dos tanques (TKZZ-35935A y TKZZ-35935B) como parte de mejoras en el sistema de tratamiento de agua de producción de una planta. La hoja de datos proporciona especificaciones técnicas detalladas de los transmisores como rango de medición, materiales, conexiones, precisión y certificaciones.

Descripción original:

HD

Título original

PMAL-435-HD-K-023-2

Derechos de autor

© © All Rights Reserved

Formatos disponibles

PDF, TXT o lea en línea desde Scribd

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoEste documento contiene la hoja de datos para dos transmisores de nivel ultrasónicos (LIT-35932A y LIT-35932B) que miden el nivel en dos tanques (TKZZ-35935A y TKZZ-35935B) como parte de mejoras en el sistema de tratamiento de agua de producción de una planta. La hoja de datos proporciona especificaciones técnicas detalladas de los transmisores como rango de medición, materiales, conexiones, precisión y certificaciones.

Copyright:

© All Rights Reserved

Formatos disponibles

Descargue como PDF, TXT o lea en línea desde Scribd

0 calificaciones0% encontró este documento útil (0 votos)

35 vistas4 páginasPmal 435 HD K 023 2

Cargado por

David BarrenecheaEste documento contiene la hoja de datos para dos transmisores de nivel ultrasónicos (LIT-35932A y LIT-35932B) que miden el nivel en dos tanques (TKZZ-35935A y TKZZ-35935B) como parte de mejoras en el sistema de tratamiento de agua de producción de una planta. La hoja de datos proporciona especificaciones técnicas detalladas de los transmisores como rango de medición, materiales, conexiones, precisión y certificaciones.

Copyright:

© All Rights Reserved

Formatos disponibles

Descargue como PDF, TXT o lea en línea desde Scribd

Está en la página 1de 4

2 EMITIDO PARA CONSTRUCCIÓN 09/10/2017 JRV ACO LFT

1 EMITIDO PARA CONSTRUCCIÓN 25/07/2016 JRV ACO LFT

0 EMITIDO PARA CONSTRUCCIÓN 22/04/2016 MDT ACO LFT

B EMITIDO PARA APROBACIÓN 04/04/2016 MDT ACO LFT

A EMITIDO PARA APROBACIÓN 15/03/2016 MDT ACO LFT

REV. DESCRIPCION FECHA EJE. REV. APR.

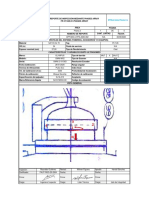

PROYECTO: MEJORAS EN EL SISTEMA DE TRATAMIENTO DE AGUA DE PRODUCCIÓN

TITULO:

Perú Corp. S.A.

TRANSMISORES DE NIVEL TIPO ULTRASÓNICO

P&P FACILITIES DEPARTMENT HOJA DE DATOS

Toda la información contenida en la ESC: DOCUMENTO Nº: REVISION:

presente documentación es

confidencial y de propiedad de PMAL-435-HD-K-023 2

Pluspetrol siendo prohíbida su

N/A

reproducción o copia, total o parcial, REEMPLAZA: Pag: 1 de 4

sin autorización previa.

CLIENTE: PLUSPETROL PERU CORPORATION S.A.

PROYECTO: MEJORAS EN EL SISTEMA DE TRATAMIENTO DE AGUA DE PRODUCCIÓN

TRANSMISORES DE NIVEL TIPO ULTRASÓNICO

HOJA DE DATOS Página

DOCUMENTO N° 2 de 4

Perú Corp. S.A. REV: 2

PMAL-435-HD-K-023

INDEX

Item Tag Service P&ID Page Rev.

001 LIT-35932A Level measurement in the tank TKZZ-35935A PMAL-435-PL-Y-022-H1 03 2

002 LIT-35932B Level measurement in the tank TKZZ-35935B PMAL-435-PL-Y-022-H1 04 2

CLIENTE: PLUSPETROL PERU CORPORATION S.A.

PROYECTO: MEJORAS EN EL SISTEMA DE TRATAMIENTO DE AGUA DE PRODUCCIÓN

TRANSMISORES DE NIVEL TIPO ULTRASÓNICO

HOJA DE DATOS Página

DOCUMENTO N° 3 de 4

Perú Corp. S.A. REV: 2

PMAL-435-HD-K-023

1 Tag No. : LIT-35932A Service : Level measurement in the tank TKZZ-35935A

REVISION

GEN.

2 Fluid Phase : Liquid Fluid : Oily Water Line No : TKZZ-35935A

3 Electrical Area Classification : Class I Div 2 Group D P&ID : PMAL-435-PL-Y-022-H1

4 Process variables Units Min Norm. Max Remarks

5 Temperature °F 55 78.8 133 2

6 Pressure inH2O -1.5 0.6 20 1 2

PROCESS CONDITIONS

7 Vessel Height ft (mm) 34 (10430) 2

8 Fluid Dielectric Constant - 78.5 @77°F 2

9 Level Empty ft (mm) 1.7 (533) 2

10 Level Full ft (mm) 33 (10030) 2

11 Width / Diameter ft (mm) 23 (7000) 2

12 Tank Top Style Cone Roof 2

13 Tank Bottom Style Flat bottom 2

14 Measurement conditions Emulsions migth occur 2

15 Hydrocarbon content 3500ppm 2

16 Tank Material Carbon Steel A36 2

17 Tag No. LIT-35932A 2

18 * Measuring Range 0 - 66 ft 2 2

19 Blocking Distance Max 1 ft (Note 4, 5) 2

20 * Housing Element Material Face Material PVDF By MFR. 2

ELEMENT

21 Vessel Connection ANSI Rating 4" FF (Note 5) 2 150# 2

22 * Element Connection (Note 2) ANSI Rating 4" FF 150# 2

23 * Ultrasonic Cone (Beam Angle) 11º 2 2

24 Temperature Compensation Yes 2

25 Orientation Installation Kit 2

26 2

27 Tag No. LIT-35932A 2

28 * Range Calibration 0 - 66 ft 2 0 - 34 ft 2

29 Indicator Volume Calculation Yes, LCD, eng units (Integral) Yes 2

TRANSMITTER

30 Mounting (Local/Remote) Cable Spec. Requirement Local Shielded 24 to 14 AWG 2

31 Case Material Ingress Protection Painted aluminium 2 IP 68 2 2

32 Electrical Protection Certification/Approval type Eex ia (FISCO) UL Certified for Class I Div. 2 2

33 Power Supply Cable Entries 9 - 32 VDC (loop-powered) 1 2

34 Transmitter Output Accuracy Foundation Fieldbus H1 0.25 % of span 2

35 Electrical Connection 1/2" NPT 2 2

36 2

37 Tag No. N/A 2

SWITCHES

38 Contacts Type N/A 2

39 Rating N/A 2

40 Set At N/A 2

2

41 * Manufacturer Endress + Hauser 2

MISC.

42 * Sensor Model Number -- 2

2

43 * Transmitter Model Number Prosonic M FMU44 2

44 2

NOTES:

1. Instruments shall have FISCO Eex ia IIC T4 Certificated.

2. Instruments shall be provided with advanced diagnosis kit.

3. Each component shall be indentified with it's respective tag number. The nameplates shall be attached with S.S. wire.

4. Field configurable.

5. Instrument shall be installed on 4" RF 150# with nozzle projection 4" from outside vessel to flange face.

6. Transmitters must be immune to EMI/RFI interference.

*: Information to be provided or approved by the manufacturer's representative

CLIENTE: PLUSPETROL PERU CORPORATION S.A.

PROYECTO: MEJORAS EN EL SISTEMA DE TRATAMIENTO DE AGUA DE PRODUCCIÓN

TRANSMISORES DE NIVEL TIPO ULTRASÓNICO

HOJA DE DATOS Página

DOCUMENTO N° 4 de 4

Perú Corp. S.A. REV: 2

PMAL-435-HD-K-023

1 Tag No. : LIT-35932B Service : Level measurement in the tank TKZZ-35935B

REVISION

GEN.

2 Fluid Phase : Liquid Fluid : Oily Water Line No : TKZZ-35935B

3 Electrical Area Classification : Class I Div 2 Group D P&ID : PMAL-435-PL-Y-022-H1

4 Process variables Units Min Norm. Max Remarks

5 Temperature °F 55 78.8 133 2

6 Pressure inH2O -1.5 0.6 20 2 2

PROCESS CONDITIONS

7 Vessel Height ft (mm) 34 (10430) 2

8 Fluid Dielectric Constant - 78.5 @77°F 2

9 Level Empty ft (mm) 1.7 (533) 2

10 Level Full ft (mm) 33 (10030) 2

11 Width / Diameter ft (mm) 23 (7000) 2

12 Tank Top Style Cone Roof 2

13 Tank Bottom Style Flat bottom 2

14 Measurement conditions Emulsions migth occur 2

15 Hydrocarbon content 3500ppm 2

16 Tank Material Carbon Steel A36 2

17 Tag No. LIT-35932B 2

18 * Measuring Range 0 - 66 ft 2 2

19 Blocking Distance Max 1 ft (Note 4, 5) 2

20 * Housing Element Material Face Material PVDF By MFR. 2

ELEMENT

21 Vessel Connection ANSI Rating 4" FF (Note 5) 2 150# 2

22 * Element Connection ANSI Rating 4" FF 150# 2

23 * Ultrasonic Cone (Beam Angle) 11º 2 2

24 Temperature Compensation Yes 2

25 Orientation Installation Kit 2

26 2

27 Tag No. LIT-35932B 2

28 Range Calibration 0 - 66 ft 2 0 - 34 ft 2

29 Indicator Volume Calculation Yes, LCD, eng units (Integral) Yes 2

TRANSMITTER

30 Mounting (Local/Remote) Cable Spec. Requirement Local Shielded 24 to 14 AWG 2

31 Case Material Ingress Protection Painted aluminium 2 IP 68 2 2

32 Electrical Protection Certification/Approval type Eex ia (FISCO) UL Certified for Class I Div. 2 2

33 Power Supply Cable Entries 9 - 32 VDC (loop-powered) 1 2

34 Transmitter Output Accuracy Foundation Fieldbus H1 0.25 % of span 2

35 Electrical Connection 1/2" NPT 2 2

36 2

37 Tag No. N/A 2

SWITCHES

38 Contacts Type N/A 2

39 Rating N/A 2

40 Set At N/A 2

2

41 * Manufacturer Endress + Hauser 2

MISC.

42 * Sensor Model Number -- 2

2

43 * Transmitter Model Number Prosonic M FMU44 2

44 2

NOTES:

1. Instruments shall have FISCO Eex ia IIC T4 Certificated.

2. Instruments shall be provided with advanced diagnosis kit.

3. Each component shall be indentified with it's respective tag number. The nameplates shall be attached with S.S. wire.

4. Field configurable.

5. Instrument shall be installed on 4" RF 150# with nozzle projection 4" from outside vessel to flange face.

6. Transmitters must be immune to EMI/RFI interference.

*: Information to be provided or approved by the manufacturer's representative

También podría gustarte

- Pmal-435-Hd-K-022-2 ObsDocumento8 páginasPmal-435-Hd-K-022-2 ObsDavid BarrenecheaAún no hay calificaciones

- PHTP-PP-4E07-26-103 Rev. A1Documento17 páginasPHTP-PP-4E07-26-103 Rev. A1diegoAún no hay calificaciones

- Ecp Uce 17062 Gma Ib01 0 Mee HD 203 0Documento5 páginasEcp Uce 17062 Gma Ib01 0 Mee HD 203 0Javier Andres Barahona GarciaAún no hay calificaciones

- 104 13479 Mob02918 DSH 420 M 0017 - 3Documento4 páginas104 13479 Mob02918 DSH 420 M 0017 - 3Luis Orlando Gil BancallanAún no hay calificaciones

- Hoja de Datos RociadoresDocumento9 páginasHoja de Datos RociadoresSantos Montero PereiraAún no hay calificaciones

- PHTP-PP-4E08-26-102 Rev. A2Documento18 páginasPHTP-PP-4E08-26-102 Rev. A2diegoAún no hay calificaciones

- PHTP-PP-4E03-26-101 Rev. A2Documento14 páginasPHTP-PP-4E03-26-101 Rev. A2diegoAún no hay calificaciones

- Inspeccion Visual Linea 1715Documento5 páginasInspeccion Visual Linea 1715alex salasAún no hay calificaciones

- Inspeccion Visual Linea 1716Documento5 páginasInspeccion Visual Linea 1716alex salasAún no hay calificaciones

- Manual de Operacion Sal Fase2Documento145 páginasManual de Operacion Sal Fase2cristhian ayanome100% (2)

- Limpieza Mecanica Chilelr RTHD 4 - EspumadosDocumento6 páginasLimpieza Mecanica Chilelr RTHD 4 - EspumadosrefrigeracionintegralyservicioAún no hay calificaciones

- Listado de Lineas Cintas CalefactorasDocumento3 páginasListado de Lineas Cintas CalefactorasMauricioAún no hay calificaciones

- Formato Reporte Diario JulioDocumento14 páginasFormato Reporte Diario JulioManuel Alexander Mejía Castrillón0% (1)

- 6480 15 029 01 LP DM HD 002 CaoDocumento5 páginas6480 15 029 01 LP DM HD 002 CaoandradaingAún no hay calificaciones

- HD 002gp0727a 590 07 1002 - 0Documento3 páginasHD 002gp0727a 590 07 1002 - 0KEVIN ISRAEL GUILLEN MOLLINEDOAún no hay calificaciones

- PHTP-PP-4E17-26-102 Rev. A1Documento11 páginasPHTP-PP-4E17-26-102 Rev. A1diegoAún no hay calificaciones

- Inspeccion Visual Linea 1711Documento5 páginasInspeccion Visual Linea 1711alex salasAún no hay calificaciones

- Inspeccion Visual Linea 1714Documento5 páginasInspeccion Visual Linea 1714alex salasAún no hay calificaciones

- Inspeccion Visual Linea 1713Documento5 páginasInspeccion Visual Linea 1713alex salasAún no hay calificaciones

- Caminata Work To Go DC 200Documento3 páginasCaminata Work To Go DC 200Lizeth IsidroAún no hay calificaciones

- Inspeccion Visual Linea 1712Documento5 páginasInspeccion Visual Linea 1712alex salasAún no hay calificaciones

- Li-002gp0878a-570-07-4003 - 0 Li Lista de CablesDocumento4 páginasLi-002gp0878a-570-07-4003 - 0 Li Lista de CablesRicardoAún no hay calificaciones

- PHTP-PP-4E16-26-101 Rev. A2Documento26 páginasPHTP-PP-4E16-26-101 Rev. A2diegoAún no hay calificaciones

- Gap SegmentaciónDocumento5 páginasGap SegmentaciónJuan Manuel Luna GonzalezAún no hay calificaciones

- PTX5918 - It - Acumulador - Cierre Lower Pipe RamDocumento3 páginasPTX5918 - It - Acumulador - Cierre Lower Pipe RamCamilo MartinezAún no hay calificaciones

- 2123JSDM12251TEN34216ER0Documento2 páginas2123JSDM12251TEN34216ER0Jose Carlos Rios IbarraAún no hay calificaciones

- 104 13479 Mob02918 DSH 420 M 0018 - 3Documento4 páginas104 13479 Mob02918 DSH 420 M 0018 - 3Luis Orlando Gil BancallanAún no hay calificaciones

- Reporte de Balanceo Carton FinalDocumento2 páginasReporte de Balanceo Carton Finaljairo enrique silva rAún no hay calificaciones

- Reporte de Mantenimiento de Grupo Electrógeno (Respaldo Eléctrico)Documento3 páginasReporte de Mantenimiento de Grupo Electrógeno (Respaldo Eléctrico)Gustavo RobertAún no hay calificaciones

- Ppona-Da-001 HRDocumento8 páginasPpona-Da-001 HRDomingo OropezaAún no hay calificaciones

- 104 13479 Mob02918 DSH 420 J 0015 - 3Documento15 páginas104 13479 Mob02918 DSH 420 J 0015 - 3Roberto Capcha SernaAún no hay calificaciones

- 3958 S030i VD 21 003 1Documento3 páginas3958 S030i VD 21 003 1Camilo AyalaAún no hay calificaciones

- Procedimiento Cambio de Spools Sistema Inyección Bombas 16P-3541 A 16P-3553Documento9 páginasProcedimiento Cambio de Spools Sistema Inyección Bombas 16P-3541 A 16P-3553Luisa Fernanda Vega HernandezAún no hay calificaciones

- 20-RG-005-03 HolidayDocumento3 páginas20-RG-005-03 HolidayFausto Enrique Alvarez BaqueroAún no hay calificaciones

- App MXC Utpa 2020 002Documento5 páginasApp MXC Utpa 2020 002THE JAMPAún no hay calificaciones

- Mi Manual de InstalacionDocumento12 páginasMi Manual de InstalacionJeyson ArdilaAún no hay calificaciones

- Areaciones 23-24oct23 NocturnoDocumento7 páginasAreaciones 23-24oct23 NocturnoOscar ZeladaAún no hay calificaciones

- Ppixa Gas FG 4570Documento74 páginasPpixa Gas FG 4570emilio mendez olveraAún no hay calificaciones

- Informe PDV-88Documento16 páginasInforme PDV-88Alexander AgostiniAún no hay calificaciones

- DVZ AH TMDB F.63420 IC A 102 - Rev 0Documento2 páginasDVZ AH TMDB F.63420 IC A 102 - Rev 0Alcántara JorgeAún no hay calificaciones

- Formato Me RSPDocumento25 páginasFormato Me RSPLuis Rogelio Martinez MateosAún no hay calificaciones

- Proforma 6429 - Septico 3b DTRT 200, Creativa, Aura, JHGDocumento4 páginasProforma 6429 - Septico 3b DTRT 200, Creativa, Aura, JHGCarlitosMBAún no hay calificaciones

- 01 Manual de Operacion PVTDocumento61 páginas01 Manual de Operacion PVTincaurco100% (2)

- Protocolo MeggerDocumento1 páginaProtocolo MeggerFelipe CamusAún no hay calificaciones

- Huanzala - As - 2021Documento3 páginasHuanzala - As - 2021qqweaAún no hay calificaciones

- It Oacs 423 RM 18553 - BuenaventuraDocumento3 páginasIt Oacs 423 RM 18553 - BuenaventuraOscar André Campos SalasAún no hay calificaciones

- Informe N21294Documento17 páginasInforme N21294hernangAún no hay calificaciones

- HD 002gp0727a 550 07 1011 - 0Documento4 páginasHD 002gp0727a 550 07 1011 - 0KEVIN ISRAEL GUILLEN MOLLINEDOAún no hay calificaciones

- Filtro CoalescedorDocumento2 páginasFiltro CoalescedorMiriam Torres Torres100% (1)

- Ppis-540-Li-K-201-B ObsDocumento3 páginasPpis-540-Li-K-201-B Obsremoto.015Aún no hay calificaciones

- Paquete de Tratamiento de Aguas Negras Pa-660 y Pa-661 STDN RM-H-006Documento406 páginasPaquete de Tratamiento de Aguas Negras Pa-660 y Pa-661 STDN RM-H-006Adrian Ivan Lopez100% (1)

- 249-28900-Ma-117-0021 Levantamiento de PotencialesDocumento37 páginas249-28900-Ma-117-0021 Levantamiento de Potencialesjorge martinezAún no hay calificaciones

- Evaluación Técnica Valvulas de ControlDocumento11 páginasEvaluación Técnica Valvulas de ControlJorge LemusAún no hay calificaciones

- PV-6398 - Telefonica - Mtto Mayor MG2 - Core Barinas - Marzo 2018Documento15 páginasPV-6398 - Telefonica - Mtto Mayor MG2 - Core Barinas - Marzo 2018Willians Alexander Mendoza QuilelliAún no hay calificaciones

- Cierre de Ciclo Combinado 4+1: A-Evangelista S.ADocumento6 páginasCierre de Ciclo Combinado 4+1: A-Evangelista S.Acarlos monicoAún no hay calificaciones

- Listado (21010)Documento3 páginasListado (21010)Saul Ernesto Ramos RivasAún no hay calificaciones

- 1 Ppixa-P-Fa 1501 VT - OkDocumento7 páginas1 Ppixa-P-Fa 1501 VT - OkElena Rosales RosadoAún no hay calificaciones

- Reporte PTDocumento5 páginasReporte PTGuillermo Antonio Piña CurielAún no hay calificaciones

- 605000M-MTO-LR-WI-000001 Calibración de Los Pilotos Del Panel Baker Rev1Documento4 páginas605000M-MTO-LR-WI-000001 Calibración de Los Pilotos Del Panel Baker Rev1JhonPaul TarazonaAún no hay calificaciones

- Simulación Metodo MontecarloDocumento21 páginasSimulación Metodo MontecarloDavid BarrenecheaAún no hay calificaciones

- Consumo de Energía y Eficiencia EnergéticaDocumento17 páginasConsumo de Energía y Eficiencia EnergéticaDavid BarrenecheaAún no hay calificaciones

- Pmal-435-Hd-K-024-1 ObsDocumento4 páginasPmal-435-Hd-K-024-1 ObsDavid BarrenecheaAún no hay calificaciones

- Caso de Exito - G6 MallDocumento8 páginasCaso de Exito - G6 MallDavid BarrenecheaAún no hay calificaciones

- Centrales SolaresDocumento17 páginasCentrales SolaresDavid BarrenecheaAún no hay calificaciones

- Caso de Éxito (Grupo 3) ShefieldDocumento11 páginasCaso de Éxito (Grupo 3) ShefieldDavid BarrenecheaAún no hay calificaciones

- Pmal 435 HD K 024 1Documento4 páginasPmal 435 HD K 024 1David BarrenecheaAún no hay calificaciones

- Pmal-435-Hd-K-023-2 ObsDocumento4 páginasPmal-435-Hd-K-023-2 ObsDavid BarrenecheaAún no hay calificaciones

- Pmal-435-Hd-K-021-0 ObsDocumento4 páginasPmal-435-Hd-K-021-0 ObsDavid BarrenecheaAún no hay calificaciones

- Pmal 435 HD K 022 2Documento8 páginasPmal 435 HD K 022 2David BarrenecheaAún no hay calificaciones

- Pmal 435 HD K 021 0Documento4 páginasPmal 435 HD K 021 0David BarrenecheaAún no hay calificaciones

- Accesorios en Lineas ExistentesDocumento1 páginaAccesorios en Lineas ExistentesDavid BarrenecheaAún no hay calificaciones

- Sim20211 TA1 JachDocumento10 páginasSim20211 TA1 JachDavid BarrenecheaAún no hay calificaciones

- Academia Grundfos NFPA 20 Nov 26 PDFDocumento159 páginasAcademia Grundfos NFPA 20 Nov 26 PDFDavid BarrenecheaAún no hay calificaciones

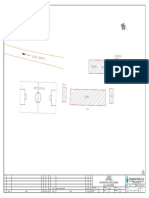

- Plano de Ubicacion de Oleoductos Por Tramos (LT 8)Documento1 páginaPlano de Ubicacion de Oleoductos Por Tramos (LT 8)David BarrenecheaAún no hay calificaciones

- Bat 5 y 9Documento10 páginasBat 5 y 9David BarrenecheaAún no hay calificaciones

- NFPA 14 (2007) - EspañolDocumento55 páginasNFPA 14 (2007) - EspañolOctavio Martinez Manjarrez86% (7)

- 04-08055504 - 11-G-LD-001-A (Lista de Documentos)Documento22 páginas04-08055504 - 11-G-LD-001-A (Lista de Documentos)David BarrenecheaAún no hay calificaciones

- DIBOND Specialities Brochure ESDocumento12 páginasDIBOND Specialities Brochure ESDavid Torregrosa FuentesAún no hay calificaciones

- Sesiones 1° - TV - Semana 19Documento10 páginasSesiones 1° - TV - Semana 19Marysol Valdiviezo ZapataAún no hay calificaciones

- Laboratorio # 3 Construccion de Un Circuito Eléctrico ParaleloDocumento3 páginasLaboratorio # 3 Construccion de Un Circuito Eléctrico Paraleloyency89100% (4)

- Entrevista Sobre Ansiedad FCO MOYADocumento6 páginasEntrevista Sobre Ansiedad FCO MOYAfrancisco moyaAún no hay calificaciones

- Contrato Privado-Revisores UrbanosDocumento3 páginasContrato Privado-Revisores UrbanosLaura CaychoAún no hay calificaciones

- Medina Et Al. 2015. Aves y Mamíferos Páramo de RabanalDocumento14 páginasMedina Et Al. 2015. Aves y Mamíferos Páramo de RabanalWilderson MedinaAún no hay calificaciones

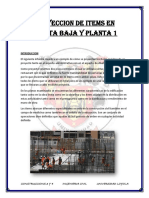

- Proyeccion de Items en Planta Baja y Planta 1Documento6 páginasProyeccion de Items en Planta Baja y Planta 1Daniel AguilarAún no hay calificaciones

- Descargar Civil 3D 2020 FullDocumento3 páginasDescargar Civil 3D 2020 FullBruno Richard Blanco AlarconAún no hay calificaciones

- 3 La Estructura en Las Organizaciones EducativasDocumento3 páginas3 La Estructura en Las Organizaciones Educativasfatima REYESAún no hay calificaciones

- PlaneaciónDocumento4 páginasPlaneaciónJORGE ZAID AGUILAR MARTINEZAún no hay calificaciones

- Guia de Ejercicios Resueltos y PropuestosDocumento31 páginasGuia de Ejercicios Resueltos y PropuestosMartin Alejandro25% (4)

- Com Uri Vasai Z Morales 17Documento12 páginasCom Uri Vasai Z Morales 17Eduardo Asinc BenitesAún no hay calificaciones

- Ecología PDocumento64 páginasEcología PIvette Guadalupe Reyes LópezAún no hay calificaciones

- SEMANA 9 3 Años A CUIDAR NUESTRO CUERPODocumento18 páginasSEMANA 9 3 Años A CUIDAR NUESTRO CUERPOSONIA ELIZABETH CONFORME VILLAMARAún no hay calificaciones

- Tecnica ReticulocitosDocumento6 páginasTecnica Reticulocitoshermes david palestina perezAún no hay calificaciones

- Clave # Descripción Cantidad U.M. P.U Total Modelo: Chapas Y Maderas Importadas S.A de C.VDocumento1 páginaClave # Descripción Cantidad U.M. P.U Total Modelo: Chapas Y Maderas Importadas S.A de C.VAriasAún no hay calificaciones

- Microcontroladores (Pic) .3Documento17 páginasMicrocontroladores (Pic) .3FRANCISCO ORTEGA GARZONAún no hay calificaciones

- Seguridad en Telnet y HTTPDocumento48 páginasSeguridad en Telnet y HTTPm_lesli_2012Aún no hay calificaciones

- Energías Renovables en México y El MundoDocumento11 páginasEnergías Renovables en México y El MundoMario Eduardo Muñoz MéridaAún no hay calificaciones

- Aportes A Las Relaciones HumanasDocumento26 páginasAportes A Las Relaciones HumanasSandra Milena ZAPATA BEDOYAAún no hay calificaciones

- Mod 3 Proceso Gerencial de Informacion y Toma de Decisiones PDFDocumento18 páginasMod 3 Proceso Gerencial de Informacion y Toma de Decisiones PDFRicardo InquillaAún no hay calificaciones

- Problemas de Métodos NuméricosDocumento6 páginasProblemas de Métodos NuméricosDavid Fernando Villanueva LlontopAún no hay calificaciones

- 3 - GALLETAS BÁSICAS DULCES y SALADASDocumento11 páginas3 - GALLETAS BÁSICAS DULCES y SALADASGaby DiazAún no hay calificaciones

- Carta MR - Burger 2023Documento9 páginasCarta MR - Burger 2023dbr4q84g4gAún no hay calificaciones

- Actividad Repaso BencenoDocumento6 páginasActividad Repaso Bencenop7kcpb56zfAún no hay calificaciones

- Strip MallDocumento16 páginasStrip MallMiguel AngelAún no hay calificaciones

- Sílabo MOOC Gestión de Reclamos - 2021Documento7 páginasSílabo MOOC Gestión de Reclamos - 2021Daleus JbbAún no hay calificaciones

- Adn y Su AlimentacionDocumento4 páginasAdn y Su Alimentacionpierdonne100% (2)

- Universidad Nacional San Agustín de Arequipa Ensayo AvanceDocumento7 páginasUniversidad Nacional San Agustín de Arequipa Ensayo AvanceCintiaAún no hay calificaciones

- Teach Me To Live - Alannah CarbonneauDocumento345 páginasTeach Me To Live - Alannah Carbonneauyomara narvaezAún no hay calificaciones