Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Tronadura & Geomecánica

Cargado por

eduardoenrique08289Descripción original:

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Tronadura & Geomecánica

Cargado por

eduardoenrique08289Copyright:

Formatos disponibles

1

LO BUENO....

2

LO MALO....

3

Y LO FEO.

4

CONCEPTOS

GEOMECNICOS

FUNDAMENTALES

5

MODELOS

CONCEPTUALES

BSICOS

6

R(u)

u

MATERIAL ISOTROPO

( ) u u =

o

R R

7

u

MATERIAL ANISOTROPO

R(u)

R

1

R

2

( ) u u

1 2

s s R R R

8

u

MATERIAL DIRECCIONAL

R(u)

R

1

R

2

( ) u u

1 2

s s R R R

9

MATERIAL HOMOGENEO

10

MATERIAL HETEROGENEO

11

MATERIAL CONTINUO

12

MATERIAL DISCONTINUO

13

MATERIAL REAL

6 1.5 m

14

COMPORTAMIENTO

CARGA-DEFORMACION-RESISTENCIA

C

a

r

g

a

Deformacin

ELASTICO

C

a

r

g

a

Deformacin

ELASTO-PLASTICO

C

a

r

g

a

Deformacin

RIGIDO-PLASTICO

C

a

r

g

a

Deformacin

C

a

r

g

a

Deformacin

15

GRANITO MASIVO

UNDERGROUND RESEARCH LABORATORY

PINAWA, MANITOBA

CANADA

ISRM News Journal (1992,93)

Ejemplo Prctico 01.1

CONTINUO

HOMOGENEO

ISOTROPO

LINEALMENTE

ELASTICO

16

GRANITO MASIVO

UNDERGROUND RESEARCH LABORATORY

PINAWA, MANITOBA

CANADA

ISRM News Journal (1992,93)

Ejemplo Prctico 01.2

CONTINUO

HOMOGENEO

ISOTROPO

LINEALMENTE

ELASTICO

17

CALIZAS PLEGADAS

MINA A RAJO ABIERTO

LATINOAMERICA

(1999)

Ejemplo Prctico 01.3

DIscontinuo

ANISOTROPO

NO

ELASTICO

18

CONCEPTOS DE

MACIZO ROCOSO

Y

EFECTOS DE ESCALA

19

250 200 150 100 50 300 0

0.7

0.8

0.9

1.0

1.1

1.2

1.3

1.4

1.5

R

E

S

I

S

T

E

N

C

I

A

U

N

I

A

X

I

A

L

D

E

L

T

E

S

T

I

G

O

R

E

S

I

S

T

E

N

C

I

A

U

N

I

A

X

I

A

L

D

E

U

N

T

E

S

T

I

G

O

D

E

D

I

A

M

E

T

R

O

5

0

m

m

DIAMETRO DEL TESTIGO (mm)

Mrmol

Caliza

Granito

Basalto

Lava Basaltica-Andestica

Gabro

Norita

Diorita cuarcfera

2 . 0

50

50

|

.

|

\

|

=

|

|

.

|

\

|

d UCS

UCS

d

o

20

(a)

(b)

EJEMPLO DE RUPTURA CON CONTROL ESTRUCTURAL QUE IMPIDE CONSIDE-

RAR EL RESULTADO OBTENIDO COMO VALIDO O REPRESENTATIVO DE LA

RESISTENCIA DE LA ROCA INTACTA.

21

TIPOS DE ROCA

Y SUS

PROPIEDADES

22

CLASIFICACION GEOLOGICA:

INTRUSIVAS (Granito / Diorita / Monzonita / Gabro / Diabasa)

Rx IGNEAS

EXTRUSIVAS (Riolita / Dacita / Andesita / Latita / Basalto)

CLASTICAS (Brecha / Conglomerado / Arenisca / Lutitas)

Rx SEDIMENTARIAS

NO CLASTICAS (Caliza / Dolomita / Yeso / Carbn / Coquina)

NO FOLIADAS (Cornalina / Cuarcita / Mrmol / Antracita)

Rx METAMORFICAS ALGO FOLIADAS (Gneiss / Migmatita / Anfibolita / Milonita)

FOLIADAS (Pizarra / Filita / Esquistos)

23

CLASIFICACION GEOTECNICA:

Carbonatos y Sales Solubles Halita / Yeso / Calizas

Micas y Minerales Planos Esquistos

Rx Textura Cristalina Minerales Bandeados Gneiss

Minerales Duros Tamao Uniforme Granito / Diorita / Gabro / Sienita

en una Matriz Fina Basalto / Rioliota

Rocas Muy Cizalladas Milonita / Serpentinita

Cementante Estable Areniscas Siliceas / Limonitas

Cementante algo Soluble Conglomerados & Areniscas Calcticas

Rx Textura Clstica Cementante Soluble Conglomerados & Areniscas Yesferas

Cementante Dbil o Cementacin Incompleta Areniscas Dbiles / Tobas

No Cementadas Areniscas Arcillosas

Duras e Isotrpicas Basaltos

Rx de Grano Duras e Isotropicas (Micro) Anisotrpicas (Macro) Lutitas Cementadas

Muy Fino Duras Anisotrpicas Esquistos / Filitas

Blandas o Tipo Suelo Esquistos / Lutitas / Creta

Rocas Orgnicas Carbn / Esquistos Bituminosos / Coquinas / Turbas

24

PROPIEDADES DE LA ROCA INTACTA:

Porosidad, n (%)

Propiedades Peso Unitario, (ton/m

3

) o (kN/m

3

)

Indice Relaciones de Fase

Degradabilidad

Traccin, TS o o

ci

(MPa)

Resistencia Compresin Uniaxial, UCS o o

ci

(MPa)

Compresin Triaxial, c (MPa) y | (grados)

Propiedades Deformabilidad Velocidad Prop. Ondas, V

P

y V

S

(m/s)

de Ingeniera Mdulos Elsticos, E (GPa) y v

Conductividad Hidrulica

Otras Propiedades

25

RELACIONES DE FASE

Hunt (1984)

26

Pesos Unitarios Tpicos de Algunas Rocas

Roca (ton/m

3

) Roca (ton/m

3

)

Andesitas 2.5 a 2.8 Anfibolitas 2.7 a 3.1

Areniscas 2.0 a 2.8 Basaltos 2.8 a 3.0

Brechas Igneas 2.7 a 2.9 Calizas 1.8 a 2.9

Carbn 0.7 a 2.0 Creta 1.9 a 2.3

Cuarcitas 2.5 a 2.9 Dacitas 2.5 a 2.8

Diabasas 2.6 a 3.0 Dioritas 2.7 a 3.0

Dolomitas 2.7 a 2.9 Esquistos 2.0 a 2.7

Gabros 2.8 a 3.1 Gneiss 2.6 a 2.9

Granitos 2.5 a 2.9 Granodioritas 2.6 a 2.9

Gravas Cementadas 1.9 a 2.1 Hematitas 4.5 a 5.3

Ignimbrita Cinertica 1.4 a 1.8 Ignimbrita Cristalina 2.0 a 2.3

Lutitas 2.0 a 2.8 Mrmol 2.1 a 2.9

Mica-Esquistos 2.5 a 2.9 Mineral de Hierro 4.0 a 5.5

Pizarras 2.5 a 2.8 Prfidos 2.4 a 2.8

Riolitas 2.2 a 2.7 Sal 2.0 a 2.0

Tobas 1.5 a 2.0 Yeso 2.2 a 2.4

27

ENSAYOS TIPICOS PARA DETERMINAR

LA RESISTENCIA DE LA ROCA INTACTA

Compresin Triaxial

- Resistencia al corte

Compresin Uniaxial

- Resistencia uniaxial

- Mdulos elsticos

Traccin Indirecta

- Resistencia en traccin

28

Goodman (1989)

29

Quartz -sericite alteration

P

e

r

c

e

n

t

a

g

e

u

n

i

a

x

i

a

l

c

o

m

p

r

e

s

s

i

v

e

s

t

r

e

n

g

t

h

0

20

40

60

80

100

Porphyry

Andesite

Quartz-monzonite porhpyry

Andesite

Light Moderate Intense Very Intense

30

Table 1:

FIELD ESTIMATES OF UNIAXIAL COMPRESSIVE STRENGTH

Grade

Term

(MPa)

Point Load

Index

(MPa)

Field Estimate of Strength Examples

R6

Extremely

Strong

> 250 > 10

Specimen can only be chipped with a geological

hammer.

Fresh basalt, chert, diabase, gneiss,

granite, quartzite

R5

Very

Strong

100 - 250 4 - 10

Specimen requires many blows of a geological

hammer to fracture it

Amphibolite, sandstone, basalt, gabbro,

gneiss, granodiorite, peridotite , rhyolite,

tuff

R4 Strong 50 - 100 2 - 4

Specimen requires more than one blow of a

geological hammer to fracture it

Limestone, marble, sandstone, schist

R3

Medium

Strong

25 - 50 1 - 2

Cannot be scraped or peeled with a pocket knife,

specimen can be fractured with a single blow

from a geological hammer

Concete, phyllite, schist, siltstone

R2 Weak 5 - 25

Can be peeled with a pocket knife with difficulty,

shallow indentation made by firm blow with point

of a geological hammer

Chalk, claystone, potash, marl, siltstone,

shale, rocksalt

R1

Very

Weak

1 - 5

Crumbles under firm blows with point of a geo-

logical hammer, can be peeled by a pocket knife

Highly weathered or altered rock, shale

R0

Extremely

Weak

0.25 - 1 Indented by thumbnail Stiff fault gouge

ci

o

Grade according to Brown (1981)

Point load tests on rocks with a uniaxial compressive strength below 25 MPa are likely to yield highly ambiguous results.

31

USO DEL ENSAYO DE CARGA

PUNTUAL PARA ESTIMAR LA

RESISTENCIA EN COMPRESIN

UNIAXIAL DE LA ROCA.

Bieniawski (1984)

32

RESISTENCIA EN COMPRESION TRIAXIAL

Hoek & Brown (1980) Method to estimate the strength

of rock masses

Hoek (1983) Modified the method

Hoek & Brown (1988) Updated the method

Hoek et al. (1992) Modified the method to be applied

to very poor quality rock

Hoek et al. (1995-1998) Developed the GSI index

This paper presents the Hoek-Brown criterion in a form that has been

found practical for surface mines, where rock mass properties are

particularly sensitive to stress relief and blast damage.

33

GENERALIZED HOEK-BROWN CRITERION

, are the maximum and minimum efective stresses at

failure

is the value of the Hoek-Brown parameter m for the

rock mass

, are constants which depend upon the rock mass cha-

racteristics

is the uniaxial compressive strength of the intact rock

pieces

a

ci

b ci

s m

|

|

.

|

\

|

+ + =

o

o

o o o

'

' '

3

3 1

'

1

o

'

3

o

ci

o

b

m

a s

(1)

34

Eq. (1) can be used to generate a series of triaxial test values,

simulating full-scale field tests, and a curve fitting process can be used

to derive an equivalent Mohr envelope given by:

, are material constants

is the normal effective stress

is the tensile strength of the rock mass

'

n

o

tm

o

A B

B

ci

tm n

ci

A

|

|

.

|

\

|

=

o

o o

o t

'

(2)

35

In order to use the Hoek-Brown criterion for estimating the strength of

jointed rock masses, three properties of the rock mass have to be

estimated:

(1) The uniaxial compressive strength of the intact rock

pieces

(2) The value of the Hoek-Brown constant for these intact

rock pieces

(3) The value of the Geological Strength Index GSI for the

rock mass

ci

o

i

m

36

INTACT ROCK PROPERTIES

For the intact rock pieces that make up the rock mass eq. (1) simplifies

to:

The relationship between the principal stresses at failure for a given

rock is defined by two constants, the uniaxial compressive strength

and a constant .

Wherever possible the values of these constants should be determined

by statistical analysis of the results of a set of triaxial tests.

5 0

3

3 1

1

.

'

' '

|

|

.

|

\

|

+ + =

ci

i ci

m

o

o

o o o

(3)

ci

o

i

m

37

Table 2:

VALUES OF THE CONSTANT m

i

FOR INTACT ROCK

NOTE THAT VALUES IN PARENTHESIS ARE ESTIMATES

Rock

Type

Class Group

Texture

Coarse Medium Fine Very Fine

Clastic

Conglomerates (21 3)

Breccias (19 5)

Sandstones 17 4

Siltstones 7 2

Greywackes (18 3)

Claystones 4 2

Shales (6 2)

Marls (7 2)

Non-Clastic

Carbonates Crystalline Limestones (12 3) Sparitic Limestones (10 2) Micritic Limestones (9 2) Dolomites (9 3)

Evaporites Gypsum 8 2 Anhydrite 12 2

Organic Chalk 7 2

Non Foliated Marble 9 3

Hornfels (19 4)

Metasandstone (19 3)

Quartzites 20 3

Slightly Foliated Migmatite (29 3) Amphibolites 26 6

Foliated * Gneiss 28 5 Schists 12 3 Phyllites (7 3) Slates 7 4

Plutonic

Light

Granite 32 3 Diorite 25 5

Granodiorite (29 3)

Dark

Gabbro 27 3

Dolerite (16 5)

Norite 20 5

Hypabyssal Porphyries (20 5) Diabase (15 5) Peridotite (25 5)

Volcanic

Lava

Rhyolite (25 5)

Andesite 25 5

Dacite (25 3)

Basalt (25 5)

Obsidian (19 3)

Pyroclastic Agglomerate (19 3) Breccia (19 5) Tuff (13 5)

I

G

N

E

O

U

S

S

E

D

I

M

E

N

T

A

R

Y

M

E

T

A

M

O

R

P

H

I

C

* For specimens tested normal to bedding or foliation. The value of m

i

will be significantly different if failure occurs along a weakness plane.

38

DETERMINACION DE LOS

MODULOS ELASTICOS.

Lambe & Whitman (1969)

39

RELACIONES ENTRE LOS

MODULOS ELASTICOS.

Hunt (1984)

40

MODULOS DINAMICOS

Hunt (1984)

41

Goodman (1989)

Lambe & Whitman (1969)

42

43

Dowding (1985)

44

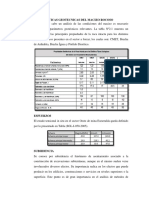

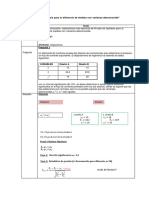

Calculo de las Propiedades de la Roca Intacta:

(1) Realizar ensayos de compresinm uniaxial (5 a 10) para

determinar UCS y los mdulos elsticos E y v.

(2) Realizar ensayos triaxiales para un mnimo de 5 presiones de

confinamiento, y de modo que se alcance ewl 40% al 50% de

UCS. Se recomienda repetir a lo menos una vez cada ensayo

(o sea 2 ensayos x cada presin de confinamiento).

(3) Utilizar estos resultados para determinar los parmetros del

criterio de Hoek-Bown. Se recomienda emplear el software

ROCDATA y usar el mtodo simplex. Deber verificarse que

los resultados son razonables (e.g. m

i

< 36).

Ejemplo Prctico 03.1

45

Ejemplo Prctico 03.2

46

ESTRUCTURAS

Y SUS

PROPIEDADES

47

PARAMETROS GEOMETRICOS

MANTEO

DIRECCION DE MANTEO

TRAZA O EXTENSIN

ESPACIAMIENTO

GAP

48

Mquina de corte directo fija en laboratorio (tomada

de Franklin & Dusseault (1989)).

Mquina de corte directo porttil (tipo Hoek, tomada de

Franklin & Dusseault (1989)).

Ensayo de corte directo in situ sobre planos de

estratificacin, en un talud de reservorio en Grecia

(tomada de Franklin & Dusseault 1989)). Esquema del montaje tpico de un ensayo de corte

directo in situ (tomada de Franklin & Dusseault (1989)).

49

Montaje para la ejecucin

de ensayos de corte

directo sobre estructuras

con un rea expuesta de

unos 400 cm

2

.

50

Estructura despus del ensayo. Estructura antes del ensayo.

51

R

E

S

I

S

T

E

N

C

I

A

R

E

S

I

D

U

A

L

R

E

S

I

S

T

E

N

C

I

A

P

E

A

K

c

p

e

a

k

|

peak

|

res

t

o

n

CONDICION PEAK

CONDICION RESIDUAL

Curva carga-deformacin

para un valor dado del es-

fuerzo normal efectivo.

u

t

c

res

R

E

S

I

S

T

E

N

C

I

A

R

E

S

I

D

U

A

L

R

E

S

I

S

T

E

N

C

I

A

P

E

A

K

c

p

e

a

k

|

peak

|

res

t

o

n

CONDICION PEAK

CONDICION RESIDUAL

Curva carga-deformacin

para un valor dado del es-

fuerzo normal efectivo.

u

t

c

res

RESISTENCIA

52

METODO DE BARTON-BANDIS:

t

MAX

= o tan( |

b

+ JRClog(JCS/o))

t

MAX

= o tan( |

equiv

)

t

MAX

RESISTENCIA AL CORTE

o ESFUERZO NORMAL EFECTIVO

|

b

ANGULO BASICO DE FRICCION (|

b

~ |

r

)

JRC COEFICIENTE DE RUGOSIDAD

JCS RESISTENCIA EN COMPRESION UNIAXIAL

DE LA PARED DE LA ESTRUCTURA

53

54

METODO DE BARTON-BANDIS:

|

equiv

s 70

0.01 s o/JCS s 0.30

ESTRUCTURAS SIN RELLENO

ESTRUCTURAS SIN DESPLAZAMIENTO PREVIO

55

EFECTO DE ESCALA EN LA RESISTENCIA AL

CORTE DE LAS ESTRUCTURAS.

56

EL AUMENTO DE LA EXTENSION DE LA ESTRUCTURA PRODU-

CE TRES EFECTOS PRINCIPALES: REDUCE LA RUGOSIDAD, RE-

DUCE LA DILATANCIA, E INCREMENTA EL DESPLAZAMIENTO

NECESARIO PARA MOVILIZAR LA RESISTENCIA PEAK.

57

EFECTO DE ESCALA EN EL PARAMETRO JRC

58

EFECTO DE ESCALA EN EL PARAMETRO JCS

59

0.1 1 10 100 1000 10000 100000

EXTENSION DE LA DISCONTINUIDAD, L (m)

15

20

25

30

35

40

45

50

55

A

N

G

U

L

O

D

E

F

R

I

C

C

I

O

N

(

g

r

a

d

o

s

)

LA SALBANDA ARCILLOSA

SE HACE MUY IMPORTANTE

LA SALBANDA ARCILLOSA

SE HACE MUY IMPORTANTE

Efecto de escala en el valor peak del ngulo de friccin de estructuras de

distinta extensin, conforme con lo valores reseados por Pusch (1997).

60

PROPIEDADES TIPICAS

Joints c = 75 a 150 kPa | = 30

o

a 35

Joints en Roca Argilizada c = 25 a 100 kPa | = 22

o

a 30

Fallas con Salbanda Arcillosa c = 0 a 50 kPa | = 18

o

a 25

Zonas de Falla con Salbanda c = 25 a 75 kPa | = 20

o

a 30

y Roca Brechizada

61

Interpretacin Prctica de la Informacin Geolgica:

(1) Obtener la definicin de dominios estructurales y el patrn

caracterstico de cada dominio: Sets, Orientacin, Trazas,

Espaciamientos, Rellenos, Competencia.

(2) Obtener mapa de estructuras mayores.

(3) Obtener caractersticas de infiltracin de aguas subterrneas.

Ejemplo Prctico 04.1

62

Ejemplo Prctico 04.2: RAJO SUR SUR de DIVISION ANDINA (cortesa Suptcia. Geologa Mina)

63

Ejemplo Prctico 04.3: RAJO SUR SUR de DIVISION ANDINA (cortesa Suptcia. Geologa Mina)

Modos de Falla con Control Estructural

(Hoek & Bray (1981))

64

MACIZOS ROCOSOS

Y SU

CARACTERIZACIN

65

EL PROBLEMA ES DEFINIR UNA CALIFICACION

DE LA COMPETENCIA DEL MACIZO ROCOSO QUE

PERMITA EL ESCALAMIENTO:

Prop. Macizo Rocoso = Fact. Escala Prop. R. I.

RQD

FF

RMR (Bieniawski)

Factor de Escala

RMR (Laubscher)

Q

GSI

66

Ejemplo Prctico 05.1

Modo de Clculo del RQD

(Deere (1989))

67

Indice RMR

Bieniawski (1989)

68

Indice RMR

Laubscher (1996)

69

Rock Mechanics Notes

(Hoek (2000))

70

Rock Mechanics Notes

(Hoek (2000))

71

Rock Mechanics Notes

(Hoek (2000))

72

73

Rock Mechanics Notes

(Hoek (2000))

74

GEOLOGICAL STRENGTH INDEX

The strength of a jointed rock mass depends on the properties of the

intact rock pieces and also upon the freedom of these pieces to slide

and rotate under different stress conditions. This freedom is controlled

by the geometrical shape of the intact rock pieces as well as the

condition of the surfaces separating the pieces. Angular rock pieces

with clean, rough discontinuity surfaces will result in a much stronger

rock mass than one which contains rounded particles surrounded by

weathered and altered material.

The Geological Strength Index (GSI), introduced by Hoek (1994) and

Hoek et al. (1995) provides a system for estimating the reduction in

rock mass strength for different geological conditions.

This system is presented in Table 3, for blocky rock masses, and Table

4 for schistose metamorphic rocks.

75

Table 3:

Characterisation of a blocky rock masses

on the basis of particle interlocking and

discontinuity condition.

After Hoek, Marinos and Benissi (1998).

76

Table 4:

Characterisation of a schistose metamorphic

rock masses on the basis of foliation and

discontinuity condition.

(After M. Truzman, 1999).

77

AL CALIFICAR LA COMPE-

TENCIA DEL MACIZO ROCO-

SO ES PRECISO CONSIDE-

RAR UN RANGO DE VALO-

RES, YA QUE DIFICILMENTE

ESTA CORRESPONDERA A

UN SOLO VALOR.

78

CALIFICACION GEOMECANICA DE MACIZOS ROCOSOS:

- Roca grantica relativamente competente

- Presenta una resistencia en compresin uniaxial de 80 a 120 MPa.

- El ndice RQD se ubica en el rango de 50% a 75%.

- Presenta de 4 a 8 fract./m, las que se observan planas o poco

ondulosas (escala mtrica), y de poca rugosidad (escala

centimtrica).

- Los sistemas estructurales definen bloques de roca con un tamao

tpico del orden de 0.5 m, mayoritariamente con forma cbica.

- El macizo rocoso se encuentre seco.

Ejemplo Prctico 06.1

79

GENERALIZED HOEK-BROWN CRITERION

, are the maximum and minimum efective stresses at

failure

is the value of the Hoek-Brown parameter m for the

rock mass

, are constants which depend upon the rock mass cha-

racteristics

is the uniaxial compressive strength of the intact rock

pieces

a

ci

b ci

s m

|

|

.

|

\

|

+ + =

o

o

o o o

'

' '

3

3 1

'

1

o

'

3

o

ci

o

b

m

a s

(1)

80

Eq. (1) can be used to generate a series of triaxial test values,

simulating full-scale field tests, and a curve fitting process can be used

to derive an equivalent Mohr envelope given by:

, are material constants

is the normal effective stress

is the tensile strength of the rock mass

'

n

o

tm

o

A B

B

ci

tm n

ci

A

|

|

.

|

\

|

=

o

o o

o t

'

(2)

81

In order to use the Hoek-Brown criterion for estimating the strength of

jointed rock masses, three properties of the rock mass have to be

estimated:

(1) The uniaxial compressive strength of the intact rock

pieces

(2) The value of the Hoek-Brown constant for these intact

rock pieces

(3) The value of the Geological Strength Index GSI for the

rock mass

ci

o

i

m

82

The Hoek-Brown failure criterion, which assumes isotropic rock and

rock mass behaviour, should only be applied to those rock masses in

which there are a sufficient number of closely spaced discontinuities,

with similar surface characteristics, that isotropic behaviour involving

failure on multiple discontinuities can be assumed. When the structure

being analysed is large and the block size small in comparison, the

rock mass can be treated as a Hoek-Brown material.

Where the block size is of the same order as that of the structure being

analysed or when one of the discontinuity sets is significantly weaker

than the others, the Hoek-Brown criterion should not be used.

In these cases, the stability of the structure should be analysed by

considering failure mechanisms involving the sliding or rotation of

blocks and wedges defined by intersecting structural features. Figure

2 summarises these statements in a graphical form.

83

Intact Rock

Specimens

USE EQ. 3

One Joint Set

DO NOT USE

HB CRITERION

Many Joints

USE EQ. 1

WITH CAUTION

Heavily Jointed Rock Mass

USE EQ. 1

Two Joint Sets

DO NOT USE

HB CRITERION

Figure 2: Idealised diagram showing the transition from intact to a

heavily jointed rock mass with increasing sample size.

84

Once the Geological Strength Index has been estimated, the

parameters that describe the rock mass strength characteristics, are

calculated as follows:

|

.

|

\

|

=

28 14

100

exp

a

GSI

m m

i b

|

.

|

\

|

=

9 6

100

exp o 0

a

GSI

s

200

65 . 0 o 0.5

GSI

a =

85

For better quality rock masses (GSI > 25), the value of GSI can be

estimated directly from the 1976 version of Bieniawskis RMR, with the

groundwater rating set to 10 (dry) and the adjustment for joint orientation

set to 0 (very favourable). If the 1989 version of Bieniawskis classification

is used, then GSI = RMR

89

- 5 where RMR

89

has the groundwater rating set

to 15 and the adjustment for joint orientation set to zero.

For very poor quality rock masses the value of RMR is very difficult to

estimate and the balance between the ratings no longer gives a reliable

basis for estimating rock mass strength. Consequently, Bieniawskis RMR

classification should not be used for estimating the GSI values for poor

quality rock masses (RMR < 25) and the GSI charts should be used

directly.

86

DEFORMATION MODULUS

Serafim and Pereira (1983) proposed a relationship between the in situ

modulus of deformation and Bieniawskis RMR. This relationship is based

upon back analysis of dam foundation deformations and it has been found

to work well for better quality rocks. However, for many of the poor quality

rocks it appears to predict deformation modulus values that are too high.

Based upon practical observations and back analysis of excavation

behaviour in poor quality rock masses, the following modification to

Serafim and Pereiras equation is proposed for:

|

.

|

\

|

=

40

10

10

100

GSI

ci

m

E

o

(12)

87

Figure 5: Deformation modulus versus Geological Strength Index GSI.

Geological Strength Index GSI

0 10 20 30 40 50 60 70 80 90 100

D

e

f

o

r

m

a

t

i

o

n

m

o

d

u

l

u

s

E

-

G

P

a

0

20

40

60

80

100

120

140

160

180 o

ci

= 100 MPa

o

ci

= 50 MPa

o

ci

= 30MPa

o

ci

= 15 MPa

o

ci

= 10 MPa

o

ci

= 5 MPa

o

ci

= 1MPa

88

Note that GSI has been substituted for RMR in this equation and that the

modulus E

m

is reduced progressively as the value of falls below 100.

This reduction is based upon the reasoning that the deformation of better

quality rock masses is controlled by the discontinuities while, for poorer

quality rock masses, the deformation of the intact rock pieces contributes

to the overall deformation process.

Based upon measured deformations, eq. 12 appears to work reasonably

well in those cases where it has been applied. However, as more field

evidence is gathered it may be necessary to modify this relationship.

89

MODULO DE DEFORMABILIDAD:

E = |E

SEISMIC

(Deere et al. (1967)).

E = 2RMR - 100 (RMR > 50, Bieniawski (1978)

E = 10

((RMR 10)/40)

(Serafim & Pereira (1983))

E

MIN

= 10log(Q)

E

MEAN

= 25log(Q) (Barton (1983))

E

MAX

= 40log(Q)

90

1.0

0.8

0.6

0.4

0.2

0.0

1.0 0.8 0.6 0.4 0.2 0.0

|

V

FIELD

/ V

LAB

, RQD

91

STRESS RELAXATION

When the rock mass adjacent to a tunnel wall or a slope is excavated, a

relaxation of the confining stresses occurs and the remaining material

is allowed to expand in volume or to dilate.

This has a profound influence on the strength of the rock mass since,

in jointed rocks, this strength is strongly dependent upon the

interlocking between the intact rock particles that make up the rock

mass.

As far as the authors are aware, there is very little research evidence

relating the amount of dilation to the strength of a rock mass. One set

of observations that gives an indication of the loss of strength

associated with dilation is derived from the support required to

stabilize tunnels. Sakurai (1983) suggested that tunnels in which the

strain, defined as the ratio of tunnel closure to tunnel diameter,

exceeds 1% are likely to suffer significant instability unless adequately

supported.

92

This suggestion was confirmed in observations by Chern et al. (1998)

who recorded the behavior of a number of tunnels excavated in Taiwan.

They found that all of those tunnels that exhibited strains of greater

than 1 to 2% required significant support. Tunnels exhibiting strains as

high as 10% were successfully stabilized but the amount of effort

required to achieve this stability increased in proportion to the amount

of strain.

While it is not possible to derive a direct relationship between rock

mass strength and dilation from these observations, it is possible to

conclude that the strength loss is significant.

93

An unconfined surface that has deformed more than 1 or 2% (based

upon Sakurais definition of strain) has probably reached residual

strength in which all of the effective cohesive strength of the rock

mass has been lost.

While there are no similar observations for rock slopes, it is reasonable

to assume that a similar loss of strength occurs as a result of dilation.

Hence, a 100 m high slope which has suffered a total crest displace-

ment of more than 1 m (i.e. more than 1% strain) may start to exhibit

significant signs of instability as a result of loss of strength of the rock

mass.

94

BLAST DAMAGE

Blast damage results in a loss of rock mass strength due to the

creation of new fractures and the wedging open of existing fractures by

the penetration of explosive gasses.

In the case of very large open pit mine blasts, this damage can extend

as much as 100 m behind the final row of blast holes.

In contrast to the strength loss due to stress relaxation or dilation,

discussed in the previous section, it is possible to arrive at an

approximate quantification of the strength loss due to blast damage.

This is because the blast is designed to achieve a specific purpose

which is generally to produce a fractured rock mass that can be

excavated by means of a given piece of equipment.

95

Figure 6 presents a plot of 23 case histories of excavation by digging,

ripping and blasting published by Abdullatif and Cruden (1983). These

case histories are summarised in Table 5. The values of GSI are

estimated from the data contained in the paper by Abdullatif and

Cruden while the rock mass strength values were calculated assuming

an average slope height of 15 m.

These examples shows that rock masses can be dug, obviously with

increasing difficulty, up to GSI values of about 40 and rock mass

strength values of about 1 MPa.

Ripping can be used up to GSI values of about 60 and rock mass

strength values of about 10 MPa, with two exceptions where heavy

equipment was used to rip strong rock masses.

Blasting was used for GSI values of more than 60 and rock mass

strengths of more than about 15 MPa.

96

Table 5:

Summary of methods used to excavate rock masses with a range of uniaxial compressive strength values,

based on data published by Abdullatif and Cruden (1983).

GSI

Rock Mass Strength, o

CM

( MPa )

Excavation Method

85 86 Blasting

85 117 Blasting

77 64 Blasting

77 135 Blasting

77 84 Blasting

76 54 Blasting

71 35 Blasting

69 15 Blasting

68 17 Blasting

68 30 Blasting

67 42 Ripping by D9L bulldozer

67 33 Ripping by D9L bulldozer

58 2.4 Ripping by track loader

57 9.5 Ripping by 977L track loader

51 0.8 Ripping by track loader

42 1.2 Digging by 977L track loader

40 0.5 Digging by wheel loader

34 0.5 Digging by hydraulic face shovel

25 0.3 Digging by 977L track loader

25 0.2 Digging by wheel loader

24 0.2 Digging by hydraulic backhoe

19 0.1 Digging by D9 bulldozer

19 0.1 Digging by 977L track loader

97

Figure 6: Plot of rock mass strength versus GSI for different excavation methods, after

Abdullatif and Cruden (1983).

Geological Strength Index GSI

0 10 20 30 40 50 60 70 80 90 100

R

o

c

k

m

a

s

s

s

t

r

e

n

g

t

h

o

c

i

-

M

P

a

0.1

1

10

100

Excavation method

Dig

Rip

Blast

98

Consider the case of an open pit slope excavated in granodiorite. The

uniaxial compressive strength of the intact rock is o

ci

= 60 MPa and the

Geological Strength Index is GSI = 55. For granodiorite, Table 2 gives

the value of m

i

= 30. Substitution of these values into the spreadsheet

given in the appendix, for a single 18 m high bench, gives a rock mass

strength o

cm

= 5.7 MPa. In order to create conditions for easy digging,

the blast is designed to reduce the GSI value to below 40 and/or the

rock mass strength to less than 1 MPa. In this case the controlling

parameter is the rock mass strength and the spreadsheet given in the

appendix shows that the GSI value has to be reduced to about 22 on

order to achieve this rock mass strength.

In another example of a 15 m high slope in weak sandstone, the

compressive strength of the intact rock is o

ci

= 10 MPa, m

i

= 17 and

GSI = 60. These values give a rock mass strength o

cm

= 1.4 MPa and

this is reduced to 0.7 by reducing the GSI to 40. Hence, in this case,

both the conditions for efficient digging in this soft rock are satisfied

by designing the blast to give a GSI value of 40.

99

Figure 7 summarizes the conditions for a muckpile that can be dug

efficiently and the blast damaged rock mass that lies between the

digging limit and the in situ rock mass. The properties of this blast

damaged rock mass will control the stability of the slope that remains

after digging of the muckpile has been completed.

Figure 7: Diagrammatic representation of the transition between the in situ

rock mass and blasted rock that is suitable for digging.

100

The thickness D of the blast damaged zone will depend upon the design

of the blast. Based upon experience, the authors suggest that the

following approximate relationships can be used as a starting point in

judging the extent of the blast damaged zone resulting from open pit

mine production blasting:

Large production blast, confined and with litle or no control D = 2.0 to 2.5 H

Production blast with control but blasting to a free face D = 1.0 to 1.5 H

Production blast, confined but with some control, e.g. one or more

buffer rows

D = 1.0 to 1.2 H

Production blast with some control, e.g. one or more buffer rows,

and blasting to a free face

D = 0.5 to 1.0 H

Carefully controlled poduction blast with a free face D = 0.3 to 0.5 H

101

EN LA PRACTICA SE ESTA UTILIZANDO CADA VEZ MAS EL METODO DE

HOEK & BROWN, CON LAS CONSIDERACIONES SIGUIENTES:

SE DETERMINAN LOS PARAMETROS m

i

Y o

ci

EN BASE A UNA

CUIDADOSA INTERPRETACION DE LOS RESULTADOS DE ENSAYOS

TRIAXIALES SOBRE TESTIGOS DE ROCA INTACTA (USUALMENTE

UTILIZANDO ROCKDATA).

SE DETERMINA EL RANGO DE VALORES PROBABLES PARA EL INDICE GSI

(USUALMENTE 15 A 20 PUNTOS).

SE DETERMINA EL RANGO DE PRESIONES DE CONFINAMIENTO Y SI SE

TRATA DE UN MACIZO BIEN TRABADO O NO.

SE ESTIMA LA INCERTEZA ASOCIADA A CADA PARAMETRO Y SU POSIBLE

FUNCION DE DISTRIBUCION.

SE EVALUAN LAS PROPIEDADES DEL MACIZO ROCOSO UTI-LIZANDO LA

METODOLOGIA PROPUESTA POR HOEK (1998,99).

102

PROBLEMAS :

EL METODO NO SIEMPRE ES APLICABLE.

SE DEFINE UNA RESISTENCIA ISOTROPICA.

PARA MACIZOS MASIVOS Y COMPETENTES EL METODO

DEBE APLICARSE EN FORMA FLEXIBLE.

PARA MACIZOS DE MALA CALIDAD GEOTECNICA, POBRE-

MENTE TRABADOS Y POCO CONFINADOS EL METODO

PUEDE SOBREVALUAR LA RESISTENCIA.

EN EL CASO DE ROCAS ESQUISTOSAS O FOLIADAS EL

METODO DEBE APLICARSE MUY CUIDADOSAMENTE.

103

ZONIFICACIN

GEOTECNICA

104

Ejemplo Prctico 07.1: ZONIFICACIN GEOTECNICA

DE MINA CHUQUICAMATA EN

TERMINOS DEL INDICE GSI

(cortesa Suptcia. Ingeniera Geotcnica)

BLOCKY ROCK MASS + FAIR TO GOOD JOINT CONDITION

BLOCKY ROCK MASS + FOOR JOINT CONDITION

VERY BLOCKY ROCK MASS + GOOD JOINT CONDITION

VERY BLOCKY ROCK MASS + FAIR TO POOR JOINT CONDITION

BLOCKY AND SEAMY ROCK MASS + FAIR TO GOOD JOINT CONDITION

BLOCKY AND SEAMY ROCK MASS + POOR TO VERY POOR JOINT CONDITION

CRUSHED ROCKS MASS + FAIR JOINT CONDITION

CRUSHED ROCKS MASS + POOR TO VERY POOR JOINT CONDITION

105

Ejemplo Prctico 07.2: ZONIFICACIN GEOTECNICA RAJO SUR SUR de DIVISION ANDINA EN TERMINOS DEL

INDICE GSI (cortesa Suptcia. Geologa Mina)

106

Ejemplo Prctico 07.3: ZONIFICACION GEOTECNICA DEL II PANEL DE LA MINA

RIO BLANCO EN TERMINOS DEL INDICE RMR

(cortesa Suptcia. Geologa Mina, Divisin Andina)

107

Ejemplo Prctico 07.4: ZONIFICACION GEOTECNICA DEL SECTOR DON LUIS EN TERMINOS DEL INDICE RMR

(cortesa Suptcia. Geologa Mina, Divisin Andina)

108

RUPTURA DE LA ROCA

Y DEL MACIZO ROCOSO

109

Esquema que ilustra la trituracin de la roca y la generacin de nuevas fracturas

debido a una tronadura (tomada de Hagan et al. (1978)).

110

111

MANUAL DE PERFORACION Y VOLADURA DE ROCAS, Lpez et al. (1994), IGME

112

MANUAL DE PERFORACION Y VOLADURA DE ROCAS, Lpez et al. (1994), IGME

Mecanismo de Ruptura por Flexin

113

EFECTO DE LAS PROPIEDADES

DE LA ROCA INTACTA

114

Peso Unitario Energa Requerida

Atenuacin

Porosidad Trituracin

% Finos

Friccin Interna Atenuacin

Resistencia Energa Requerida

115

EFECTO DE LAS

CARACTERISTICAS DEL

MACIZO ROCOSO

116

MANUAL DE PERFORACION Y VOLADURA DE ROCAS, Lpez et al. (1994), IGME

PRECAUCION !

BLOCOSIDAD Y RESISTENCIA DEL BLOQUE TIPICO

117

MANUAL DE PERFORACION Y VOLADURA DE ROCAS, Lpez et al. (1994), IGME

HETEROGENEIDADES

118

BLASTING TECHNOLOGY, Sen (1995), UNSW Press

HETEROGENEIDADES

119

MANUAL DE PERFORACION Y VOLADURA DE ROCAS, Lpez et al. (1994), IGME

HETEROGENEIDADES

120

EFECTO DE LAS

ESTRUCTURAS

121

BLASTING PRINCIPLES FOR OPEN PIT MINING, Hustrulid, W. (1999), A. A. Balkema

122

BLASTING PRINCIPLES FOR OPEN PIT MINING, Hustrulid, W. (1999), A. A. Balkema

123

BLASTING PRINCIPLES FOR OPEN PIT MINING

Hustrulid, W. (1999)

A. A. Balkema

MANUAL DE PERFORACION Y VOLADURA DE ROCAS

Lpez et al. (1994)

IGME

124

125

126

TRONADURABILIDAD

DEL MACIZO ROCOSO

(ROCK MASS BLASTABILITY)

127

( ) H SGI JPO JPS RMD BI

2

1

+ + + + =

Indice de Tronadurabilidad de Lylli (1986):

BI Indice de tronadurabilidad

RMD Descripcin del macizo rocoso

JPS Espaciamiento de las estructuras

JPO Orientacin de las estructuras

SGI Influencia del peso especfico

H Dureza de la roca

128

129

Prediccin de la Fragmentacin Cunningham (1983,87):

X Tamao medio de los fragmentos (cm)

A Factor que depende el tipo de roca

8 para rocas de resistencia media

10 para rocas duras algo fisuradas

13 para rocas duras muy fisuradas

Q

e

Masa de explosivo (kg)

S

ANFO

Potencia del explosivo respecto al ANFO

30 / 19

6 / 1 8 . 0

_

115

|

|

.

|

\

|

=

ANFO

e

S

Q K A X

130

( ) HF RDI JF RMD A 06 . 0 + + + =

RMD Descripcin del macizo rocoso

JPS Espaciamiento de las estructuras verticales

JPA Angulo de inclinacin de las estructuras

RDI Influencia de la densidad de la roca

HF Factor asociado a la dureza de la roca

JPA JPS + = JF

131

132

DAOS INDUCIDOS

EN EL

MACIZO ROCOSO

133

134

135

RMR

DAO

= C

B

RMR

136

137

138

139

140

141

EFECTOS

DINAMICOS

142

143

144

BLAST VIBRATION MONITORING AND CONTROL, Dowding, C. (1985), Prentice-Hall

145

BLAST VIBRATION MONITORING AND CONTROL, Dowding, C. (1985), Prentice-Hall

146

147

BLAST VIBRATION MONITORING AND CONTROL

Dowding, C. (1985)

Prentice-Hall

148

P

V

PPV

= c

P

V

E PPV

= o

149

RMR

DAO

= C

B

RMR

150

BLASTING PRINCIPLES FOR OPEN PIT MINING, Hustrulid, W. (1999), A. A. Balkema

151

MANUAL DE PERFORACION Y VOLADURA DE ROCAS, Lpez et al. (1994), IGME

152

Hendron (1977)

153

BLASTING PRINCIPLES FOR OPEN PIT MINING, Hustrulid, W. (1999), A. A. Balkema

154

BLASTING PRINCIPLES FOR OPEN PIT MINING, Hustrulid, W. (1999), A. A. Balkema

155

Cortesa Grupo Geotcnico DMDIC

0

200

400

600

800

1000

1200

0 5 10 15 20 25 30 35

Distancia desde la carga, (m)

K

g

d

e

A

n

f

o

o

E

q

u

i

v

a

l

e

n

t

e

p

o

r

R

e

t

a

r

d

o

Vp = 127 mm/seg

Vp = 381 mm/seg

Vp = 635 mm/seg

Collahuasi

Ext. Collahuasi

156

Cortesa Grupo Geotcnico DMDIC

157

CONSTRUCTION VIBRATIONS

Dowding, C. (1996), Prentice-Hall

158

CONSTRUCTION VIBRATIONS

Dowding, C. (1996), Prentice-Hall

159

TRONADURAS

CONTROLADAS

160

MANUAL DE PERFORACION Y VOLADURA DE ROCAS, Lpez et al. (1994), IGME

161

BLASTING PRINCIPLES FOR OPEN PIT MINING, Hustrulid, W. (1999), A. A. Balkema

162

BLASTING PRINCIPLES FOR OPEN PIT MINING, Hustrulid, W. (1999), A. A. Balkema

163

Cortesa Grupo Geotcnico DMDIC

RESULTADOS DE PRE-CORTE EN IGNIMBRITA

164

Cortesa Grupo Geotcnico DMDIC

DISEO DE LA TRONADURA DE PRE-CORTE EN IGNIMBRITA

Banco Doble de 30 m, Tiros de 61/2

165

Cortesa Sr. Luis Olivares, Suptcia. Ingeniera Geotcnica Divisin Chuquicamata

Tronaduras Controladas en Roca Cuarzo-Serictica

TRONADURA : 127 A N1 + Precorte

EXPANSION : 28 N

FECHA TRONADURA : 21 de Septiembre de 2000

FECHA PRECORTE : 21 de Septiembre de 2000

PALA : 093

NUMERO DE TIROS : 70 (6 1/2 produccin)

61 (6 1/2 precorte)

ALTURA BANCO : 26 m

MALLA PERFORACION : 6 x 6 m (produccin en 6 1/2)

6 x 3 (buffer en 6 1/2)

2,0 m (Espaciamiento Precorte)

SECUENCIA DE SALIDA : Hacia el Rajo

RETARDOS : Entre filas 130 ms

Entre tiros produccin 35 ms

Entre tiros buffer 17 ms

TONELAJE A REMOVER : 124.000 Ton (c/q)

EXPLOSIVO : 27.300 Kg

FACTOR DE CARGA : 220 (gr/Ton)

DENSIDAD DE CARGA : 0,58 (Kg/m^2)

DISEO PERFIL

26 m

1 m(p)

0 m(p)

80

1 m

6 m

6 m

3 m

2 m (espaciamiento precorte)

LP

DISEO PLANTA

PERFORACION EN 6-1/2 PRECORTE EN 6-1/2

TRONADURA : 127 A N1 + Precorte

EXPANSION : 28 N

FECHA TRONADURA : 21 de Septiembre de 2000

FECHA PRECORTE : 21 de Septiembre de 2000

PALA : 093

NUMERO DE TIROS : 70 (6 1/2 produccin)

61 (6 1/2 precorte)

ALTURA BANCO : 26 m

MALLA PERFORACION : 6 x 6 m (produccin en 6 1/2)

6 x 3 (buffer en 6 1/2)

2,0 m (Espaciamiento Precorte)

SECUENCIA DE SALIDA : Hacia el Rajo

RETARDOS : Entre filas 130 ms

Entre tiros produccin 35 ms

Entre tiros buffer 17 ms

TONELAJE A REMOVER : 124.000 Ton (c/q)

EXPLOSIVO : 27.300 Kg

FACTOR DE CARGA : 220 (gr/Ton)

DENSIDAD DE CARGA : 0,58 (Kg/m^2)

DISEO PERFIL

26 m

1 m(p)

0 m(p)

80

1 m

DISEO PERFIL

26 m

1 m(p)

0 m(p)

80

1 m

6 m

6 m

3 m

2 m (espaciamiento precorte)

LP

DISEO PLANTA

PERFORACION EN 6-1/2 PRECORTE EN 6-1/2

6 m

6 m

3 m

2 m (espaciamiento precorte)

LP

DISEO PLANTA

PERFORACION EN 6-1/2 PRECORTE EN 6-1/2

166

Cortesa Sr. Luis Olivares, Suptcia. Ingeniera Geotcnica Divisin Chuquicamata

TRONADURA : 114 A N3 + Precorte

EXPANSION : 28 N

FECHA TRONADURA : 13 de Octubre de 2000

PALA : 093

NUMERO DE TIROS : 98 (6 1/2 produccin)

56 (6 1/2 A 75 Precorte)

ALTURA BANCO : 26 - 27 m

MALLA PERFORACION : 6,0 x 6,0 m (produccin en 6 1/2)

6,0 x 3,0 (buffer en 6 1/2)

1,5 m (Espaciamiento Precorte)

SECUENCIA DE SALIDA : Hacia el Rajo

RETARDOS : Entre filas 42 ms

Entre tiros produccin 0 - 17 ms

Entre tiros buffer 17 ms

TONELAJE A REMOVER : 178.000 Ton (c/q)

EXPLOSIVO : 35.100 Kg

FACTOR DE CARGA : 197 (gr/Ton)

DENSIDAD DE CARGA : 0.74 (Kg/m^2)

6 m

6 m

3 m

1,5 m

LP

DISEO PLANTA

DISEO PERFIL

26 m

1 m (p)

0 m (p)

75

1 m

TRONADURA : 114 A N3 + Precorte

EXPANSION : 28 N

FECHA TRONADURA : 13 de Octubre de 2000

PALA : 093

NUMERO DE TIROS : 98 (6 1/2 produccin)

56 (6 1/2 A 75 Precorte)

ALTURA BANCO : 26 - 27 m

MALLA PERFORACION : 6,0 x 6,0 m (produccin en 6 1/2)

6,0 x 3,0 (buffer en 6 1/2)

1,5 m (Espaciamiento Precorte)

SECUENCIA DE SALIDA : Hacia el Rajo

RETARDOS : Entre filas 42 ms

Entre tiros produccin 0 - 17 ms

Entre tiros buffer 17 ms

TONELAJE A REMOVER : 178.000 Ton (c/q)

EXPLOSIVO : 35.100 Kg

FACTOR DE CARGA : 197 (gr/Ton)

DENSIDAD DE CARGA : 0.74 (Kg/m^2)

6 m

6 m

3 m

1,5 m

LP

DISEO PLANTA

6 m

6 m

3 m

1,5 m

LP

DISEO PLANTA

DISEO PERFIL

26 m

1 m (p)

0 m (p)

75

1 m

DISEO PERFIL

26 m

1 m (p)

0 m (p)

75

1 m

Tronaduras Controladas en Roca Cuarzo-Serictica

167

CONCLUSIONES

Basados en la caracterizacin geotcnica y estructural de esta unidad geotcnica, la cual presenta una

competencia media y considerando que corresponde a un material de carcter masivo, la condicin estructural

NO afecta en forma importante el resultado de la tronadura en la Orientacin Norte-Sur del rajo, es que podemos

efectuar pre-cortes con alta inclinacin, incluso alcanzando valores de 80. Para el caso de la orientacin Este-

Oeste (Sector Norte), la inclinacin del pre-corte debe ser 70, dada la condicin de Falla Plana.

El especiamiento del pre-corte utilizado corresponde a 2 metros para una inclinacin de 80 y dimetro 6-1/2, y

la densidad de carga para ste corresponde a 0.58 Kg/m

2

. Para el caso de espaciamientos de 1.5 metros e

inclinado a 75 la densidad de carga corresponde a 0.78 Kg/m

2

. Por lo tanto, la densidad de carga para un diseo

de pre-corte debe considerar estos rangos utilizados.

De las 2 tronaduras analizadas, las cuales corresponden a las mejores resultados obtenidos en esta unidad

geotcnica, se utilizaron valores de Factores de Carga que variaron entre 180 a 220 gramos por tonelada.

Respecto de la secuencia de salida de las tronaduras, el resultado en cuanto a desplazamiento de la pila y dao

indica que debe iniciarse hacia el rajo utilizando 130 ms entre filas, 35 ms entre los tiros de produccin y 17 ms

entre los tiros buffer.

El diseo de la perforacin consider 3 filas de 6-1/2 para ambas tronaduras y se obtuvieron muy buenos

resultados tanto en los parmetros geotnicos, de planificacin y operacionales, como pudimos observar en las

grficas presentadas. Por otro lado el resultado visual es claro, el cual propone que la utilizacin de este tipo de

tronaduras es la que se debe emplear para lograr cumplir con el diseo geotcnico de taludes y adems ver

oportunidades de mejoras en el negocio minero de Chuquicamata.

Cortesa Sr. Luis Olivares, Suptcia. Ingeniera Geotcnica Divisin Chuquicamata

Tronaduras Controladas en Roca Cuarzo-Serictica

168

Mount Rushmore Memorial, South Dakota, USA. Esculpido por G. Borglum

entre 1927 y 1941 (6.5 aos de trabajo efectivo). Cada cabeza tiene unos 18 m.

National Geographic, Oct. 1956 / Encyclopaedia Britannica

169

Goodman, R. (1989):

INTRODUCTION TO ROCK MECHANICS

2

nd

ed., J. Wiley & Sons

La cubierta de roca degradada

por intemperizacin se removi

mediante tronaduras controla-

das (dinamita).

A medida que se obtena la for-

ma deseada se disminua el es-

paciamiento entre tiros y el fac-

tor de carga.

Las ltimas pulgadas se remo-

vieron me-diante perforacin y

cincelado.

170

ASPECTOS GEOMECNICOS

DE LA TRONADURA EN

MINAS SUBTERRNEAS

171

1918, Minas de carbn en USA,

preparando una tronadura.

National Geographic, Nov. 1918

172

Cavidad generada en sal por una explosin nuclear de 3.1 KT, a una

profundidad de unos 360 m, en Nuevo Mexico, USA.

Judd (1964)

173

Tronaduras controladas de excelente calidad en el desarrollo del Nivel 240 del

Underground Research Laboratory, en granito masivo (Manitoba, CANADA).

Martin & Simmons (1992)

174

Holmberg et al. (2001)

175

Holmberg et al. (2001)

176

Holmberg et al. (2001)

177

Holmberg et al. (2001)

178

Holmberg et al. (2001)

179

Holmberg et al. (2001)

180

Holmberg et al. (2001)

181

Holmberg et al. (2001)

182

Holmberg et al. (2001)

183

Holmberg et al. (2001)

184

Punto de apoyo

A

1

A

2

Avance de la socavacin

Transmisin de carga

(concentracin de esfuerzos)

Zona de daos y fracturas

(produce dilatancia, lo que carga la caja)

Galera del Nivel de Produccin

Material

quebrado

También podría gustarte

- 02 Fortificacion 2017 PDFDocumento42 páginas02 Fortificacion 2017 PDFDiego CastroAún no hay calificaciones

- Complemento de FortificaciónDocumento11 páginasComplemento de FortificaciónLisbenny RamosAún no hay calificaciones

- Tronadura en Mineria SubterraneaDocumento34 páginasTronadura en Mineria SubterraneaVictor Ajsdalks Y Algo Mas100% (2)

- Cut and FillDocumento36 páginasCut and FillOscar Esquivel TraslaviñaAún no hay calificaciones

- Clase de Pernos1-INICIO12SETDocumento17 páginasClase de Pernos1-INICIO12SETFERNANDITO5900% (1)

- Minado Por Tajos LargosDocumento39 páginasMinado Por Tajos LargosJC ChinchayAún no hay calificaciones

- Tarea 2 - Equipos de Perforación Mienría Superficial y SubterráneaDocumento13 páginasTarea 2 - Equipos de Perforación Mienría Superficial y SubterráneaBRENDA ALEXANDRA HUACARPUMA PEREZAún no hay calificaciones

- Fortificación Con Marcos Pernos y MallasDocumento17 páginasFortificación Con Marcos Pernos y MallasJavier Orellana50% (2)

- Mineria SubteDocumento18 páginasMineria Subtebastian farayAún no hay calificaciones

- Instructivo Fortificación Con Madera ListoDocumento3 páginasInstructivo Fortificación Con Madera ListoEdu ContrerasAún no hay calificaciones

- Tarea Marco Geologico El TenienteDocumento6 páginasTarea Marco Geologico El TenienteCristian Segura BidermannAún no hay calificaciones

- FORTIFICACIONDocumento14 páginasFORTIFICACIONPANIC FFAún no hay calificaciones

- 03.check List Actividades AcuñaduraDocumento1 página03.check List Actividades AcuñaduraWladimir CollaoAún no hay calificaciones

- Resumen Cut and FillDocumento4 páginasResumen Cut and FillMiguel Angel Painenahuel GarcesAún no hay calificaciones

- Inacap Evaluacion Nº2 Taller MineroDocumento35 páginasInacap Evaluacion Nº2 Taller MineroSebastián MuñozAún no hay calificaciones

- Metodos de Explotacion SubterraneoDocumento30 páginasMetodos de Explotacion Subterraneovanabrudh75% (4)

- Geomecanica Basíca 3Documento127 páginasGeomecanica Basíca 3YOLE JORDY PONTE MORILLOAún no hay calificaciones

- Refuerzos EstructuralesDocumento12 páginasRefuerzos EstructuralesLk PetersenAún no hay calificaciones

- SHOTCRETEDocumento11 páginasSHOTCRETEjesusAún no hay calificaciones

- Transporte en Mina A Cielo AbiertoDocumento22 páginasTransporte en Mina A Cielo AbiertoCristhian Candela Olivares0% (1)

- Perforación LivianaDocumento120 páginasPerforación LivianaRich M100% (1)

- Tesis - Analisis Geologico Geomecanico PDFDocumento132 páginasTesis - Analisis Geologico Geomecanico PDFisaacAún no hay calificaciones

- Clasificación Geomecánica de Las RocasDocumento4 páginasClasificación Geomecánica de Las RocasSonicthe JrAún no hay calificaciones

- Taller de Gestion Minera Caso N°3 - Room (A)Documento3 páginasTaller de Gestion Minera Caso N°3 - Room (A)Carlos CorreaAún no hay calificaciones

- Mineria Cielo AbiertoDocumento73 páginasMineria Cielo AbiertoLaurencio PåvêlAún no hay calificaciones

- Interventoría de Túneles - SICH PDFDocumento72 páginasInterventoría de Túneles - SICH PDFAna Tividad Mosquera GomezAún no hay calificaciones

- AcuñaduraDocumento32 páginasAcuñaduraLeopoldo P. ValenzuelaAún no hay calificaciones

- Contruccion de Accesos A Interior LM1B4T2R0-20191114Documento98 páginasContruccion de Accesos A Interior LM1B4T2R0-20191114ALEXY MARTI OBREGON GIRONAún no hay calificaciones

- Anexo C Descripcion Metodo de Explotacion ADocumento33 páginasAnexo C Descripcion Metodo de Explotacion ADaniel Manrique100% (1)

- 6 Fortificacion Sub PDFDocumento46 páginas6 Fortificacion Sub PDFJuan Ignacio Castro VarasAún no hay calificaciones

- Room and PillarDocumento17 páginasRoom and PillarRD GianAún no hay calificaciones

- Tipos de SostenimientoDocumento3 páginasTipos de SostenimientoEdwin Mejia ReyesAún no hay calificaciones

- Geomecanica El TenienteDocumento3 páginasGeomecanica El Tenientekevin rojasAún no hay calificaciones

- Geomecanica Basica y FortificacionDocumento84 páginasGeomecanica Basica y FortificacionKatterinne Meza Diaz100% (1)

- 5.estandar Corte y Relleno Con Camaras y Pilares en RealceDocumento3 páginas5.estandar Corte y Relleno Con Camaras y Pilares en Realceinghelsias15Aún no hay calificaciones

- Explotacion MineraDocumento11 páginasExplotacion Minerahammjosen100% (1)

- Estallido de RocaDocumento8 páginasEstallido de RocaDayanaBarajasAún no hay calificaciones

- 11 UDA Cut and Fill MDocumento131 páginas11 UDA Cut and Fill MMatias MerchanAún no hay calificaciones

- Parametros o Factores Que Intervienen en El Diseño de Voladura de Rocas en TunelesDocumento8 páginasParametros o Factores Que Intervienen en El Diseño de Voladura de Rocas en TunelesMarco Medina CarranzaAún no hay calificaciones

- Hundimiento de BloquesDocumento30 páginasHundimiento de BloquesYordi Aguilar BuguñaAún no hay calificaciones

- Rampas Mineria SubterraneaDocumento17 páginasRampas Mineria SubterraneaFranz Jhonatan Hilares Alvarez100% (1)

- Manual Sostenimiento Anclajes Varillas Fierro Barras Cemento Resina Cables Malla Cintas Fibra AceroDocumento62 páginasManual Sostenimiento Anclajes Varillas Fierro Barras Cemento Resina Cables Malla Cintas Fibra AceroHenry CrsAún no hay calificaciones

- CimbrasDocumento71 páginasCimbrasJenifer CustodioAún no hay calificaciones

- SostenimientoDocumento50 páginasSostenimientoBrayan Kevin Sauñe HuamanAún no hay calificaciones

- Trabajo de Fortificación en MinasDocumento51 páginasTrabajo de Fortificación en Minasarisnel1262Aún no hay calificaciones

- Optimización de La Voladura-Mina La Virgen PDFDocumento157 páginasOptimización de La Voladura-Mina La Virgen PDFJulio Enrique Laguna EspinozaAún no hay calificaciones

- Fortificacion Hormigon ProyectadoDocumento18 páginasFortificacion Hormigon Proyectadocamila francisca yañez floresAún no hay calificaciones

- Exposicion Final Tajo LargoDocumento48 páginasExposicion Final Tajo Largoalexander019450% (2)

- Proyecto N°4Documento59 páginasProyecto N°4Betho Bavestrello100% (2)

- VULCAN MejoraDocumento17 páginasVULCAN MejoraJoan Robert ArpitaAún no hay calificaciones

- Geomecanica Presentacion 1Documento34 páginasGeomecanica Presentacion 1Claudio LechugaAún no hay calificaciones

- Informe CaseronesDocumento23 páginasInforme CaseronesIvan HormazabalAún no hay calificaciones

- Memorias de Mina Teniente: Episodio IDe EverandMemorias de Mina Teniente: Episodio IAún no hay calificaciones

- 6 - Excavabilidad Del TerrenoDocumento23 páginas6 - Excavabilidad Del TerrenoDilson Loaiza CruzAún no hay calificaciones

- Elementos de Mecanica de RocasDocumento77 páginasElementos de Mecanica de RocasFrancisco Javier Zepeda Iribarren0% (2)

- Sesion No. 02-Clasificación de Macizos Rocosos-2016-IIDocumento27 páginasSesion No. 02-Clasificación de Macizos Rocosos-2016-IIRicardoACumbreAún no hay calificaciones

- Clase 5 Sustancia RocosaDocumento27 páginasClase 5 Sustancia RocosaFranco Ezequiel GarciaAún no hay calificaciones

- 7 Hoek Brown Modificado Macizos Fracturados 1992Documento8 páginas7 Hoek Brown Modificado Macizos Fracturados 1992Roger Mendoza DelgadoAún no hay calificaciones

- Elementos de Mecanica de RocasDocumento78 páginasElementos de Mecanica de RocasrolosvAún no hay calificaciones

- Catálogo Instructivo de las Colecciones MineralógicasDe EverandCatálogo Instructivo de las Colecciones MineralógicasAún no hay calificaciones

- Clase 06-Criterios de FortificacionDocumento22 páginasClase 06-Criterios de Fortificacioneduardoenrique08289Aún no hay calificaciones

- Capitulo N°4 - HundibilidadDocumento21 páginasCapitulo N°4 - Hundibilidadeduardoenrique08289Aún no hay calificaciones

- Clase 06-Criterios de FortificacionDocumento22 páginasClase 06-Criterios de Fortificacioneduardoenrique08289Aún no hay calificaciones

- Capitulo N°2 - Siniestros GeomecánicosDocumento14 páginasCapitulo N°2 - Siniestros Geomecánicoseduardoenrique08289100% (1)

- Clase 06 Fragmentacion de Roca para El Manejo de MaterialesDocumento36 páginasClase 06 Fragmentacion de Roca para El Manejo de Materialeseduardoenrique08289Aún no hay calificaciones

- 201104081930460.BAI Tecnica de VoladuraDocumento20 páginas201104081930460.BAI Tecnica de Voladuraeduardoenrique08289Aún no hay calificaciones

- CURSO GeomecanicaDocumento184 páginasCURSO Geomecanicaeduardoenrique0828996% (27)

- Fundamentos Teoricos de TronaduraDocumento23 páginasFundamentos Teoricos de Tronaduraeduardoenrique082890% (1)

- Curso de Tronadura RT AaDocumento308 páginasCurso de Tronadura RT Aaeduardoenrique08289100% (1)

- Manejo de Explosivos en Las Operaciones MinerasDocumento217 páginasManejo de Explosivos en Las Operaciones MinerasMary Fernanda Gonzalez Aranguren100% (4)

- Variables Controlables de TronaduraDocumento14 páginasVariables Controlables de Tronaduraeduardoenrique08289100% (3)

- Seguridad en El Uso de ExplosivosDocumento27 páginasSeguridad en El Uso de Explosivoseduardoenrique08289Aún no hay calificaciones

- Resumen Capitulo 1 Gerencia EstratégicaDocumento11 páginasResumen Capitulo 1 Gerencia EstratégicaDavid CastilloAún no hay calificaciones

- Trabajo de Investigacion de Mercado Com 350Documento9 páginasTrabajo de Investigacion de Mercado Com 350Katherine SosaAún no hay calificaciones

- 004 MendenhallDocumento60 páginas004 Mendenhalltukytutuky60% (5)

- Trabajo Final Estadística OficialDocumento32 páginasTrabajo Final Estadística OficialGabriela SaucedoAún no hay calificaciones

- Prueba de HipótesisDocumento3 páginasPrueba de HipótesismariaAún no hay calificaciones

- Medición Del Aprendizaje OrganizacionalDocumento19 páginasMedición Del Aprendizaje Organizacionalyenifer BarriosAún no hay calificaciones

- P - Castro Jones 065.1 - 19Documento11 páginasP - Castro Jones 065.1 - 19peprlucho100% (1)

- Introducci N A La Teor A de DecisionesDocumento11 páginasIntroducci N A La Teor A de Decisionesellioth1Aún no hay calificaciones

- Yadira SoteldoDocumento102 páginasYadira Soteldovilmary Beatriz Hernandez lopezAún no hay calificaciones

- Educación - La PsicomotricidadDocumento288 páginasEducación - La Psicomotricidadpepeluzu100% (1)

- Norma Apa Informe Fundamento de Investigacion IDocumento32 páginasNorma Apa Informe Fundamento de Investigacion ICRISTHIAN JUAN DE DIOS GASTELO CHANTAAún no hay calificaciones

- Julia George Trabajo Final EconometriaDocumento22 páginasJulia George Trabajo Final EconometriaMariaAún no hay calificaciones

- Tarea 6-7 Clasificacion y Valoracion de Puesto Carmela MarisolDocumento12 páginasTarea 6-7 Clasificacion y Valoracion de Puesto Carmela MarisolLoida Perez ReyesAún no hay calificaciones

- Investigación Mixta. Qué Es y Tipos Que ExistenDocumento7 páginasInvestigación Mixta. Qué Es y Tipos Que ExistenJosé Luis ElizarrarazAún no hay calificaciones

- Estudio de Prospección de Mercado de Empresas de InserciónDocumento65 páginasEstudio de Prospección de Mercado de Empresas de InserciónObservatorio de Economía SolidariaAún no hay calificaciones

- Diapositivas de Seminario de Investigación Científica IDocumento21 páginasDiapositivas de Seminario de Investigación Científica IEdén Sarmiento CelisAún no hay calificaciones

- NTC 5660Documento21 páginasNTC 5660Luis MateusAún no hay calificaciones

- Proceso de InvestigacionDocumento25 páginasProceso de InvestigacionAngel Capichi LunaAún no hay calificaciones

- Comunicaciones Analisis - Rendimiento - DeportivoDocumento67 páginasComunicaciones Analisis - Rendimiento - DeportivoYahiAún no hay calificaciones

- Tesis FinalDocumento77 páginasTesis FinalLa Merced Sangarará - AcomayoAún no hay calificaciones

- Consolidado Investigación UtplDocumento120 páginasConsolidado Investigación UtplLenin NavarreteAún no hay calificaciones

- Ejemplo 6 Quiebre OriginalDocumento2 páginasEjemplo 6 Quiebre Originalkarl marticorenaAún no hay calificaciones

- Examen CenevalDocumento4 páginasExamen CenevalSalvador SierraAún no hay calificaciones

- 1 Practica - Organización e Interpretación de Datos O15 AMYDocumento4 páginas1 Practica - Organización e Interpretación de Datos O15 AMYMaytea ApaAún no hay calificaciones

- Examen - (AAB02) Cuestionario 2 - Responda El Cuestionario EVA 2 Sobre Las Pruebas de La PersonalidadDocumento5 páginasExamen - (AAB02) Cuestionario 2 - Responda El Cuestionario EVA 2 Sobre Las Pruebas de La Personalidadisrael idrovoAún no hay calificaciones

- Efectos en EspanolDocumento18 páginasEfectos en EspanolElizabeth NarvaezAún no hay calificaciones

- Estimación de La Posición de Un Robot de Configuración Ackerman Usando FE de KalmanDocumento9 páginasEstimación de La Posición de Un Robot de Configuración Ackerman Usando FE de KalmanOscar Giraldo CastilloAún no hay calificaciones

- Guion PH DM Con Varianza DesconocidaDocumento4 páginasGuion PH DM Con Varianza DesconocidaLuis Alberto Rondoy CarhuapomaAún no hay calificaciones

- Habilidades Basicas de Pensamiento ResumenDocumento3 páginasHabilidades Basicas de Pensamiento ResumenElver GalargaAún no hay calificaciones