Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Material Impreso Curso LOGO! - S

Material Impreso Curso LOGO! - S

Cargado por

cesarinarraga0 calificaciones0% encontró este documento útil (0 votos)

12 vistas94 páginasTítulo original

Material Impreso Curso LOGO!_s

Derechos de autor

© © All Rights Reserved

Formatos disponibles

PDF, TXT o lea en línea desde Scribd

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

© All Rights Reserved

Formatos disponibles

Descargue como PDF, TXT o lea en línea desde Scribd

0 calificaciones0% encontró este documento útil (0 votos)

12 vistas94 páginasMaterial Impreso Curso LOGO! - S

Material Impreso Curso LOGO! - S

Cargado por

cesarinarragaCopyright:

© All Rights Reserved

Formatos disponibles

Descargue como PDF, TXT o lea en línea desde Scribd

Está en la página 1de 94

Seite 1

SIMATIC Totally Integrated Automation

Bienvenido

al Mundo de

Totally Integrated Automation!

L

O

G

O

!

L

O

G

O

!

Mdulo Lgico LOGO!

SIMATIC Totally Integrated Automation

Programacin

Descripcin de Funciones

Comunicacin

Caractersticas Generales

Vista Rpida de Funciones

Modelos y Accesorios

Competencia

LogoSoft Comfort V3.1

Visin Global

Aplicaciones Logo!

Novedades 4 Generacin

Contenido LOGO!

Ejemplos de Aplicacin

Seite 2

SIMATIC Totally Integrated Automation

Detalles Tecnolgicos

h

ttp

h

ttp

: / /

: / / w

w

w

w

w

w

.a

d

.

.a

d

.s

ie

m

e

n

s

s

ie

m

e

n

s.d

e

/

.d

e

/lo

g

o

lo

g

o

Web Logo! en Internet

SIMATIC Totally Integrated Automation

Bienvenido

al Mundo de

Totally Integrated Automation!

L

O

G

O

!

L

O

G

O

!

F

Mdulo Lgico LOGO!

Seite 1

SIMATIC Totally Integrated Automation

Usando contactores, rels, temporizadores, rels intermitentes, rels

de impulso de corriente etc.?

Usando mayor espacio que 72x90x55mm para la aplicacin?

Hay una emergencia y se necesita disear rpidamente algo que se

pueda poner en funcionamiento inmediatamente?

Buscando una solucin sencilla para manejar seales y control que

sea flexible y de bajo costo?

LOGO! es la

Respuesta para todas

estas preguntas!

Porqu Usar LOGO!?

SIMATIC Totally Integrated Automation

Precio

Funcionalidad

SIMATIC S7-200

Micro PLC

LOGO!

Mdulo lgico

Rel de tiempo

Contactor-Rel

Posicionamiento de LOGO!

Seite 2

SIMATIC Totally Integrated Automation

Funciones Funciones combinadas con

Contactor / Rel

Multiplicador de contactos

Enclavable

Lgica funcional nica

Rels conmutadores

Adaptables a nivel y

separados elctricamente

del Simatic

Conmutacin de pequeas

cargas unipolares.

Rels temporizados

On retardados:

Para arranques secuenciales de

motors suprimiendo interferencias.

Off retardados:

En paradas de motores

(ventiladores) ,funciones claves :

Estrella tringulo:

Arranque seguro de motores con

intervalos de conmutacin de hasta

50ms.

Multi-funcion:

Flexible para toda aplicacin ,hasta

8 o 16 funciones integradas.

Rels con contactos de accin

positiva:

usados en circuitos de seguridad de

categora 2

rels con contactos de oro

duro en conjunto con PLCs y

contactos de sealizacin para

plcs

Mdulo Lgico

Construccin:

Control de iluminacin

Control de cerradores

Control de ventiladores

Control de accesos

Equipamiento de seguridad

Plantas elevadoras de presin.

Industria:

Bombas/Compresores

Cabinas de control

Control de puertas

Equipos de alimentacin

Plataformas de elevacin

Controles secuenciales

Monitorizacin de nivel

Control de vvulas

Plantas de filtrados

Plantas de extraccin

Equipamiento de transporte

Micro-PLC

Construccin:

Control de elevacin y posicin

Industria:

Mquinas de empaquetar y sunchar

Mquinas textiles

Equipamiento mercante

Equipo para procesos alimenticios

Mquinas de aserrado

Paneles o displays de avisos

Mquinas para procesamiento de

madera

Mquinas de roscado automtico

Prensado y fabricacin de ladrillos

Pintureras

Tratamientos de residuos

Telecontrol

Equipamiento de esterilizacin

Hornos de laboratorios

Mquinas de lavado.

LOGO! Entre Contactores y PLCS

SIMATIC Totally Integrated Automation

F

LOGO! : Qu tiene Incorporado?

Seite 3

SIMATIC Totally Integrated Automation

Casas y

Edificios

Construccin

Industria

LOGO! En Uso : Vista General

SIMATIC Totally Integrated Automation

Control de iluminacin

ej. vidrieras, filasde luminarias

luminarias mviles, Intemperie

luminarias dependientes de la luz

del da

Grupos de luminarias

control de pico de carga.

Monitorizacin

ej. estacionamiento de autos,

sistemas de alarmas, cabinas

Control de acceso

Simulaciones de presencia

Reportes

Control de puertas

portones ,cortinas

ej. Puertas automticas,

Garages, Cabinas

Apertura / cierre de puertas -

elevac./cierre de portones

Indicador lumnico/ Stop&Go

Control temporal

Control de temperatura

Sensores de viento o lluvia.

Irrigacin

ej. viveros, jardines, fuentes

humidificadores dependientes

del tiempo.

Control grupal

Conmutacin de

bombas de agua

Administracin de energa.

Calentadores/

Refrigeradores/

Ventiladores

ej Ventiladores, calenatdores,

acondicionadores de aire.

Control de tiempo y

temperature

Administracin de energa

Sensores de viento y lluvia

tambien se usa en

bombeo de agua

potable, sistemas de

alta presin, etc.

Cul es su necesidad

en la automatizcin

de construcciones ?

LOGO! En Construccin (Privada - Industrial)

Seite 4

SIMATIC Totally Integrated Automation

Control de puertas

y entradas

ej. Portones industriales

Elevacin ,apertura ,cierre

de puertas

Reportes

Dependencias del tiempo

Bombas/

Compresores

ej. agua potable, compresores

de aire

Funciones por turno

Conmutacin dependiente

del nivel

Alarmas a locales centrales

Instalaciones de

transporte

ej. Cintas transportadoras

Control ON/OFF

Inversin de direccin

Contador de unidades

Sistema de llenado

de tanques

ej. bebidas , Granos

Funciones dependientes

del tiempo

Capacidad de contaje de a

unidad

Vigilancia de nivel.

Ambientes especiales

ej. sistemas solares, controles

de energa ,control de rango de

Temperatura ,aplicaciones

mecnicamente extremas.

y tambien en estaciones

de llenados de silos

,control de motores de

elevadores

clavadoras, etc.

Cul es su aplicacin

industrial?

LOGO! Entre Contactores y PLCS

SIMATIC Totally Integrated Automation

En Gabinetes

Dimensiones similares a

interruptores diferenciales

tipo lnea N

Se requieren solo 4 mdulos

unitarios DIN en vez de 7

Almacenamiento

Menor area de depsito

Reduccin del depsito por la

reducida cantidad de

componentes de HW.

menos Accesorios, ej. cables

Menor cantidad de

repuestos

Un slo producto en vez

de varios items

LOGO! : Reduccin de Espacio

Seite 5

SIMATIC Totally Integrated Automation

Confiabilidad en la inversin

producto estandar que puede ser

expandido en cualquier momento

Utilizable con sistemas de bus

estandar AS-Interface

Mas flexibilidad

30 funciones integradas listas

para usar -> 1 Modulo en vez de

varios diferentes

Todos los voltages

- DC12V,AC/DC24V,

AC/DC115/230V)

- Entradas anlogas (0..10V,

0..20mA)

Funcionalidad/Programa

modificable directamente. Via

memoria o va PC

Reduccin de Costos

menos costo de hardware

menos espacio (gabinete, Stock)

mas eficiencia durante el diseo

y puesta en marcha

F

LOGO!: Ventajas para la Industria

SIMATIC Totally Integrated Automation

LOGO!: Ventajas para la Industria

F

Ahorra

Costos

Ahorra

Tiempo

Ahorra

Espacio

Queda

Flexible

Seite 1

SIMATIC Totally Integrated Automation

LOGO! Es...

LOGO! es como un PLC...

LOGO! es mas que un PLC...

LOGO! Es un rel inteligente...

!Conecin con Funciones y ahora

tambin con Ladder.

!Pero no tiene capacidad matemtica

!Capacidad de control y visualizacin.

!Posibilidad de entrada de control

directa en el dispositivo

!Posibilidad de visualizacin directa de

mensajes/variables etc.

!Con salida de 10A

En 1996 Siemens cre una nueva categora de producto con el LOGO!, El Mdulo Lgico

LOGO! Vs PLC: Que es LOGO!?

SIMATIC Totally Integrated Automation

Salida Digital (4, expandiba 16)

Display LCD

En Operacion:

Muestra estado de

entradas/salidas, fecha,

hora etc.

Muiestra mensajes

Para Parametros:

Valor actual

(e.g. Tiempo/valor actual)

Posibilidades de conexin

12 Vdc

24 Vac/Vdc

115 ~ 230 Vac/Vdc

Variante:

Relais (10A, 230 Vac)

Transistor (0,3 A, 12/ 24 Vdc)

Terminales de Alimentacin

Entrada Digital/Analoga: (8 expandible a 24 /

2 expandible a 8)

Interfase PC/Memory Card

Teclado

Posibilidades de conexin

12 Vdc, 24 Vac/Vdc

115 ~ 230 Vac/Vdc

Para ingreso de programa de

control

Usado para ingresar cambio

de parmetros

Para control

Interfase para mdulos de expansin

Visin del Hardware (1)

Seite 2

SIMATIC Totally Integrated Automation

Max. I/O:

24 entradas digitales + 8 entradas analogicas + 16 salidas digitales

Alimentacin

Alimentacin mdulos

de expansion

RUN/STOP

4 salidas

4 entradas 2x4 entradas

Deslizador para conexin elctrica

4 salidas

Visin del Hardware (2)

SIMATIC Totally Integrated Automation

" LOGO! integra todo esto en una sola unidad:

" Controlador Integrado (CPU)

" Controles de Operacin (Interruptor software) y Visualizacin

" Hasta 24 entradas / 16 salidas digitales + 8 entradas analgicas

" Mdulo para esclavo AS-Interface 4DI y 4DO virtuales

" Interface para Mdulo de memoria / Cable para PC

" Programacin directa en LOGO! o va Software en PC.

" EEPROM integrada para guardar el programa en memoria

no voltil, no necesita batera (Proteccin por Password).

" Mdulos de memoria para hacer copias y proteccin Know How.

" Diversos accesorios como: fuente de alimentacin 110/220VAC a

5/12/15/24 o 48VDC, Contactor LOGO! etc.

Todo en una sola Unidad (1)

Seite 3

SIMATIC Totally Integrated Automation

" LOGO! integra todo esto en una sola unidad:

" Alimentacin en 110/220Vac/Vdc; 24Vac/Vdc y 12/24Vdc

" 8 entradas digitales y 4 salidas digitales (Opcin

de 2 entradas anlogas de 0-10Vdc).

" 4 entradas / 4 Salidas digitales virtuales va AS-Interface

" 8 marcas internas (Incluye marca de primer ciclo M8)

" Opcin Con/Sin Display Integrado (Para OEM)

" El Display permite visualizacin de Mensajes; alarmas y

datos de proceso durante el modo RUN.

" Listo para usar: 08 funciones bsicas y 22 funciones especiales

ej. para temporizacin, conteo, reloj, rel de pulsos etc.

" Simulacin grfica Offline del programa (FBD o Ladder)

va LOGO! Soft Comfort V3.1

Todo en una sola Unidad (2)

SIMATIC Totally Integrated Automation

Ancho: 72 mm o 126 mm

Altura : 90 mm o 90 mm

Prof. : 55 mm o 55 mm

01 Conectores de alimentacin

02 Conectores de Entradas

03 Interface PC/Mdulo de memoria

04 Panel de control de operador

05 Panel de visualizacin

06 Conectores de salidas

07 Conector para riel DIN 35mm

1 2

3

4

5

6

7

Diseo e Instalacin

Seite 4

SIMATIC Totally Integrated Automation

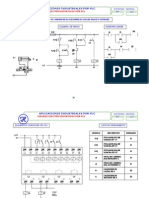

" Alimentacin L1, N (L+, M)

115 / 230 Vac/Vdc

50 / 60 Hz

L1 = 85 ... 253 Vac/Vdc

" Entradas

Entrada I1...I8

Estado 1 > 79 Vac/Vdc

Estado 0 < 40 Vac/Vdc

" Salidas

Salida Q1 ..Q4 (Rel)

LOGO! 230RC / 230RCo

8 entradas

4 salidas

LOGO! 230RC

SIEMENS

ESC OK

Output 4x Rels / 8A

2

Input 6xAC

AC 115/120V

230/240V

X

3 4

I1 I2 I3 I4 I5 I6 L1 N

Q1 Q2 Q3 Q4

L1

N

L1, L2, L3

N

Voltaje de

alimentacin

Cableado Modelo LOGO! 230RC / 230RCo

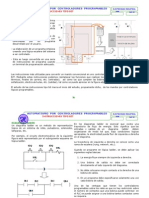

SIMATIC Totally Integrated Automation

" Alimentacin L+, M

12/24 Vdc

L+ = 20,4...28,8 Vdc

10.8...15.6 Vdc

" Entradas

Entrada I1...I6

Estado 1 > 8 Vdc

Estado 0 < 5 Vdc

Entrada I7, I8 (0-10Vdc)

" Salidas

Salida Q1 ..Q4 (Transistor/Rel)

LOGO! 24 / 12/24RC / 12/24RCo

8 entradas

4 salidas

LOGO! 230RC

SIEMENS

ESC OK

Output 4x Rels / 8A

2

Input 6xAC

AC 115/120V

230/240V

X

3 4

I1 I2 I3 I4 I5 I6 L1 N

Q1 Q2 Q3 Q4

L+

M

L1, L2, L3

N

Voltaje de

alimentacin

Cableado Modelo LOGO! 24 / 12/24RC / 12/24RCo

Seite 5

SIMATIC Totally Integrated Automation

" Alimentacin L1, N

24 Vac

L1 = 20,4...26,8 Vac/Vdc

" Entradas

Entrada I1...I8

Estado 1 > 8 Vac/Vdc

Estado 0 < 5 Vac/Vdc

" Salidas

Salida Q1 ..Q4 (Rel)

LOGO! 24RC / 24RCo

8 entradas

4 salidas

LOGO! 230RC

SIEMENS

ESC OK

Output 4x Rels / 8A

2

Input 6xAC

AC 115/120V

230/240V

X

3 4

I1 I2 I3 I4 I5 I6 L1 N

Q1 Q2 Q3 Q4

L+

M

L1, L2, L3

N

Voltaje de

alimentacin

Cableado Modelo LOGO! 24RC / 24RCo

SIMATIC Totally Integrated Automation

Montaje y Cableado (Ejemplo)

N

K2

L1

K2

I : 0. , 1. , 2.

123456789

0123456789

01234

4

Seite 6

SIMATIC Totally Integrated Automation

Instalando y Desinstalando LOGO!

1

3

5

6

Instalando

Montar LOGO! En un riel DIN como sigue:

1. Ubicar el LOGO! Sobre el riel DIN.

2. Girar el LOGO! Alrededor del riel DIN hasta que encaje.

3. Remover la cuvierta del conector localizada en el lado derecho del

LOGO! o del mdulo de expansin.

4. Ubicar el mdulo digital a la derecha del LOGO! (ver

pasos 1 y 2).

5. Deslice el mdulo a la izquierda hacia el LOGO!.

6. Usando un desarmador, presione hacia abajo y mueva el deslizador

integrado a la izquierdat. El mdulo est instalado cuando el deslizador

engancha en su lugar en el LOGO!

Desintalando

Desintalar LOGO! Como sigue:

1. Usando un desarmador, presione abajo y mueva el

deslizador integrado a la derecha.

2. Deslice el mdulo de expansin a la derecha

3. Inserte el desarmador en la grapa de sujecin al riel y tire

girando hacia arriba

4. Gire el mdulo alejandolo del riel DIN.

5. Siga los pasos 3 y 4 para el mdulo LOGO!.

1

2

1

2

3

4

SIMATIC Totally Integrated Automation

Cableando LOGO!

M L+ I1 I2 I3 I4 I5

L1 L+

N M

LOGO! ..... con

Alimentacin DC

LOGO! ..... con

Alimentacin AC

Proteccin con fusibles

Si se desea (recomendado para:

12/24 RC...: 0.8 A

24: 2.0 A

En caso de picos de voltaje, use

varistores (MOV) con un mnimo de 20%

mas de voltaje de trabajo que la tensin nominal

I1 I2 I3 I4 L1 N

Seite 7

SIMATIC Totally Integrated Automation

L1

N

N L1 I1 I2 I3 I4 I5 I6

L3

L2

LOGO! 230 ...

L+

M

M L+ I1 I2 I3 I4 I5 I8

Programa

Ciclo de

Programa

LOGO! 12/24 ...

Conectando las Entradas de LOGO!

Conctar los sensores a las entradas, los sensores incluyen:

pulsadores, switches, sensores fotelctricos etc.

Sensores de Temperatura, presin, o ultrasonido (Beros), etc., con salida de 0-10 V.

Sensores con salida de 0/4 a 20mA

Las entradas estn agrupadas en dos bloques de 4

entradas cada uno. Fases diferentes son posibles slo

entre bloques y no dentro del mismo bloque

Para que LOGO! Detecte un

cambio de estado a 0 o 1, el

estado debe estar presente por lo

menos un ciclo de programa

Las entradas no sn aisladas, por lo tanto requieren de un

mismo potencial de referencia (Masa) de la fuente de

alimentacin

SIMATIC Totally Integrated Automation

Conectando las Salidas de LOGO!

1 2

Q1 Q2

1 2

Q5 Q6

1 2

1 2

DM8...R

Q1 Q2 M M

Q5 Q6 M M

DM8 24

Diferentes cargas pueden ser

conectadas a las salidas e.g.,

Lamparas

Motores

Contactores, etc.

LOGO! con

salida de transistor

LOGO! con

salidas de rel

Max. Corriente de conmutacin es 0.3 A por salida

Max. Corriente de conmutacin es 10A / 5A para salida de mdulo de

expansin

Seite 8

SIMATIC Totally Integrated Automation

" Aprobacin : VDE 0631, IEC 1131, UL , CSA, y FM

" Supresin de RI segn : EN 55011 (Lmite clase B)

" Grado de proteccin : IP 20

(max. 95 % de humedad)

" Temperatura de operacin : 0 to +55C

(En cualquier posicin!)

" Aprobado para aplicaciones de uso marino

# American Bureau of Shipping

# Bureau Veritas

# Det Norske Veritas

# Germanischer Lloyd

# Lloyds Register of Shipping

55C

0C

B B

Condiciones Ambientales para LOGO!

Seite 1

SIMATIC Totally Integrated Automation

! Antes:

! Ahora:

!1

L1

N

No1

No2

No3

L1

S1

L1

L1

L1

S1

N

Cableado Standard vs LOGO!

SIMATIC Totally Integrated Automation

La funcin Co se usa para conectar las entra-

das y salidas o los diferentes niveles de voltaje

a los bloques.

Seleccin:

X

I1 I24

Q1 Q16

hi lo

B01

Q1

&

I5

X

I1

X

I1

I2

I3

I4

I5

I6

Q1

Q2

Q3

Q4

hi

lo

Conectores (Co)

M1 M8

Marcas: M1...M8, Incluye marca

de primer ciclo (M8)

Sin conexin, Entrada no usada.

Constantes: hi=1; lo=0.

Salidas: Q1...Q16.

Entradas: I1...I24. (En algunos modelos

hay 02 analgicas de 0-10V)

AI1 AI8

Salidas: AI1...AI8.

Seite 2

SIMATIC Totally Integrated Automation

8 Funciones Bsicas Integradas (GF)

AND OR NOT

NAND NOR XOR

&

&

!1

!1

1

=1

&"

AND flanco

NAND flanco

&#

SIMATIC Totally Integrated Automation

22 Funciones Especiales Integradas (SF)

ON Delay

Trg

T

OFF Delay

Trg

R

T

Generador de Pulsos

En

T

No1

No2

No3

Contador UP/Down

R

Cnt

Dir

Par

+/-

On Delay con Memoria

Trg

R

T

R

En

Ral

Par

h

Contador de Horas

Trg

T

One Shot

Toggle

Trg

R

Par

Rel Autoenclavado

S

R

Par

RS

Fre

Par

Switch de Umbral

Generador de pulsos

Asncrono

En

Inv

Par

Reloj Semanal

Seite 3

SIMATIC Totally Integrated Automation

22 Funciones Especiales Integradas (SF)

Trg

Par

EN

Par

Pulso Aleatorio

Trg

T

Switch Off Intermitente

Switch Confortable

Trg

T

One Shot Disparado

. por Flanco

Ax

Par

Q

A

Trigger Anlogo

En

P

Par

Q

..

..

Mostrar Mensajes

A

Ax

Ay

Par

Q

Comparador Anlogo

Trg

Par

On / Off Delay Switch Anual

No

MM

DD

F

Switch Software

En

Par

Q

Seite 1

SIMATIC Totally Integrated Automation

LOGO! Pure LOGO! Basic

12/24RCo

24o (Trans)

12/24RC

24 (Trans) 24

24RCo (Vac)

230RCo (Vac/Vdc)

24RC (Vac)

230RC (Vac/Vdc) 230R (Vac/Vdc)

LOGO! : Variedad de Modelos

LOGO! DM8 LOGO! AM2

LOGO! ASI

12/24R

0-10Vdc / 0/4-20ma

AS-Interfac / EIB

Pt100 (-50...200C)

24R (Vac/Vdc)

SIMATIC Totally Integrated Automation

LOGO! : Mdulos Base

LOGO!Pure LOGO!Basic

LOGO! 24o 6ED1052-2CC00-0BA3

LOGO! 12/24RCo 6ED1052-2MD00-0BA3

LOGO! 24RCo 6ED1052-2HB00-0BA3

LOGO! 230RCo 6ED1052-2FB00-0BA3

LOGO! 24 6ED1052-1CC00-0BA3

LOGO! 12/24RC 6ED1052-1CC00-0BA3

LOGO! 24RC 6ED1052-1CC00-0BA3

LOGO! 230RC 6ED1052-1CC00-0BA3

Seite 2

SIMATIC Totally Integrated Automation

LOGO! : Mdulo de Expansin Digital

DM8 230R 6ED1055-1FB00-0BA0

! Alimentacin 120/230Vac/Vdc

! 4DI 120/230Vac/Vdc

! 4DO Rele@5A cada uno

! max. 20A cada mdulo

DM8 24 6ED1055-1CB00-0BA0

! Alimentacin 24Vdc

! 4DI 24Vdc

! 4DO Transistor 0.3A

DM8 12/24R 6ED1055-1MB00-0BA0

! Alimentacin 12/24Vdc

! 4DI 12/24Vdc

! 4DO Rele@5A cada uno

! max. 20A cada mdulo

DM8 24R 6ED1055-1HB00-0BA0

! Alimentacin 24Vac/Vdc

! 4DI 24Vac/Vdc

! 4DO Rele@5A cada uno

! max. 20A cada mdulo

SIMATIC Totally Integrated Automation

LOGO! : Mdulo Expansin Anloga

AM2 6ED1055-1MA00-0BA0

! Alimentacin 12/24Vdc

! 2AI 0..10V o 0/4...20ma

! Resolucin: 10 bit

! Tiempo de muestreo: 50ms

! Alimentacin de Sensor: No tiene

AM2 Pt100 6ED1055-1MD00-0BA0

! Alimentacin 12/24Vdc

! 2AI Pt100 (-50...200C)

! Tiempo de muestreo: 50ms

Seite 3

SIMATIC Totally Integrated Automation

LOGO! : Mdulo de Comunicacin

AS-Interface 3RK1400-0CE10-0AA2

! Alimentacin 12/24Vdc

! Protocolo: AS-Interface (Esclavo)

! 4DI + 4DO Virtuales

Konnex (EIB) En Preparacin

! Alimentacin 12/24Vdc

! Protocolo: EIB Instabus

! 24DI + 16DO + 8AI

ASi

SIMATIC Totally Integrated Automation

LOGO!

12/24RCo

LOGO!

24RCo

LOGO!

230RCo

LOGO!

12/24RC

LOGO!

24

LOGO!

24RC

LOGO!

230RC

Entradas

Entradas analgicas

6

2 (0 to 10 V)

6

2 (0 to 10 V)

8

-

8

-

8

-

8

-

Tensin de entrada

Rango permitido

Seal 0

Seal 1

6

2 (0 to 10 V)

12/24 Vdc

12 Vdc:

10,8 V - 15,6 Vdc

24 Vdc:

20,4 V - 28,8 Vdc

max. 5 Vdc

min. 8 Vdc

24 Vac

20,4 a

26,4 Vac

max. 5 Vac

min. 12 Vac

115/230 Vac/Vdc

85 a

265 Vac/Vdc

max. 40 Vac/Vdc

min. 79 Vac/Vdc

12/24 Vdc

12 V:

10,8 V - 15,6 Vdc

24 V:

20,4 V - 28,8 Vdc

max. 5 Vdc

min. 8 Vdc

24 Vdc

20,4 V - 28,8 Vdc

max. 5 Vdc

min. 8 Vdc

24 Vac

20,4 V a

26,4 Vac

max. 5 Vac

min. 12 Vac

115/230 Vac/Vdc

85 a

265 Vac/Vdc

max. 40 Vac/Vdc

min. 79 Vac/Vdc

Corriente de entrada 1,5 mA 12 Vdc

2,5 mA 24 Vdc

2,5 mA 0,08 mA 1,5 mA 12 Vdc

2,5 mA 24 Vdc

1,5 mA 2,5 mA 0,08 mA

Salidas 4 relays 4 relays 4 relays 4 relays 4 Transistor 4 relays 4 relays

Corriente permanente

10A Carga resistiva

3A Carga inductiva

10A Carga resistiva

3A Carga inductiva

10A Carga resistiva

3A Carga inductiva

10A Carga resistiva

3A Carga inductiva

10A Carga resistiva

3A Carga inductiva

10A Carga resistiva

3A Carga inductiva

0,3 A

Proteccion contra

cortocircuito

Se requiere fusible

externo

Se requiere fusible

externo

Se requiere fusible

externo

Se requiere fusible

externo

Se requiere fusible

externo

Se requiere fusible

externo

Electrnica (~ 1A)

Frecuencia de conmutacin 2 Hz carga resistiva

0,5 Hz carga inductiva

2 Hz carga resistiva

0,5 Hz carga inductiva

2 Hz carga resistiva

0,5 Hz carga inductiva

2 Hz carga resistiva

0,5 Hz carga inductiva

2 Hz carga resistiva

0,5 Hz carga inductiva

2 Hz carga resistiva

0,5 Hz carga inductiva

10 Hz

Dispacin de potencia 0,1 bis 1,2 W (12 V)

0,2 bis 1,6 W (24 V)

0,1 to 1,2 W (12 V)

0,2 to 1,6 W (24 V)

0,3 - 1,8 W 0,3 - 1,8 W 1,1 to 3,5 W (115 V)

2,3 to 4,6 W (230 V)

1,1 to 3,5 W (115 V)

2,3 to 4,6 W (230 V)

0,2 to 0,5 W

Reloj integrado/ reserva 8/typ. 80 h 8/typ. 80 h 8/typ. 80 h 8/typ. 80 h 8/typ. 80 h 8/typ. 80 h -

Cables de conexin 2 x 1,5 mm

2

, 1 x 2,5 mm

2

Dimensiones 72 (4TE) x 90 x 55mm (BxHxT)

LOGO! Basic: Datos Tcnicos

LOGO!

24o

6

2 (0 to 10 V)

24 Vdc

24 Vdc:

20,4 V - 28,8 Vdc

max. 5 Vdc

min. 8 Vdc

4 Transistor

0,3A

Electrnica (~ 1A)

10 Hz

0,2 to 0,5 W

Seite 4

SIMATIC Totally Integrated Automation

LOGO! DM8

12/24R

LOGO! DM8

230R

LOGO! DM8

24

LOGO! AM2 LOGO! FM1

AS-I

Entradas

Entradas analgicas

4

-

4

-

-

2 (Pt100: -50...200C)

4 (DI Virtual AS-I)

-

Tensin de entrada

Rango permitido

Seal 0

Seal 1

4

-

12/24 Vdc

12 Vdc:

10,8 V - 15,6 Vdc

24 Vdc:

20,4 V - 28,8 Vdc

max. 5 Vdc

min. 8 Vdc

115/230 Vac/Vdc

85 a

265 Vac/Vdc

max. 40 Vac/Vdc

min. 79 Vac/Vdc

24 Vdc

20,4 V - 28,8 Vdc

max. 5 Vdc

min. 8 Vdc

12/24 Vdc

12 Vdc:

10,8 V - 15,6 Vdc

24 Vdc:

20,4 V - 28,8 Vdc

Comsumo: 25...50ma

Corriente de entrada 1,5 mA 12 Vdc

2,5 mA 24 Vdc

0,08 mA 1,5 mA -

Salidas 4 relays 4 relays 4 Transistor - 4 (DO Virtual AS-I)

Corriente permanente

10A Carga resistiva

3A Carga inductiva

10A Carga resistiva

3A Carga inductiva

0,3 A

Proteccion contra

cortocircuito

Se requiere fusible

externo

Se requiere fusible

externo

No Aislamiento

Galvnico

Electrnica (~ 1A)

Frecuencia de conmutacin 2 Hz carga resistiva

0,5 Hz carga inductiva

2 Hz carga resistiva

0,5 Hz carga inductiva

10 Hz

Dispacin de potencia 0,1 bis 1,2 W (12 Vdc)

0,2 bis 1,8 W (24 Vdc)

12Vdc: 0,3 - 0.6 W

24Vdc: 0,6 - 1.2 W

1,1 to 3,5 W (115 Vac)

2,3 to 4,6 W (230 Vac)

0.5 a 1.8 W (115 Vdc)

1.2 a 2.4 W (230 Vdc)

0,8 to 1.1 W

Cables de conexin 2 x 1,5 mm

2

, 1 x 2,5 mm

2

Dimensiones 36 (4TE) x 90 x 55mm (BxHxT)

LOGO! Basic: Datos Tcnicos

12Vdc: 0,3 - 0.6 W

24Vdc: 0,6 - 1.2 W

12/24 Vdc

12 Vdc:

10,8 V - 15,6 Vdc

24 Vdc:

20,4 V - 28,8 Vdc

Comsumo: 25...50ma

LOGO! AM2

-

2 (0-10Vdc / 0/4-20ma)

12/24 Vdc

12 Vdc:

10,8 V - 15,6 Vdc

24 Vdc:

20,4 V - 28,8 Vdc

Comsumo: 25...50ma

-

-

No Aislamiento

Galvnico

12Vdc: 0,3 - 0.6 W

24Vdc: 0,6 - 1.2 W

LOGO! DM8

24R

4

-

24 Vac/Vdc

20,4 V - 28,8 Vac/Vdc

max. 5 Vdc

min. 8 Vdc

1,5 mA

4 relays

10A Carga resistiva

3A Carga inductiva

Se requiere fusible

externo

2 Hz carga resistiva

0,5 Hz carga inductiva

1,1 to 3,5 W (115 Vac)

2,3 to 4,6 W (230 Vac)

0.5 a 1.8 W (115 Vdc)

1.2 a 2.4 W (230 Vdc)

SIMATIC Totally Integrated Automation

LOGO! PC-Cable

Para la transferencia del programa

PC <-> LOGO!

LOGO! Manual

Information detallada

Ejemplos de aplicacin

LOGO! Power

Transforma los 120V/230V AC de la red

a la tensin requerida

LOGO! Prom

Copia multiples Cards

Dscarga PC a Cards

LOGO! Contact

En 2 Variantes

(DC 24 V, AC 230 V)

Dimensiones compactas

36 x 72 x 55 mm (BxHxT)

Maniobra directa de cargas resistivas hasta

20A y motores hasta 4KW (8.4A)

LOGO! : Variedad de Accesorios

LOGO! Panel

Para montaje de LOGO! en puerta de Armario

IP65 con Tapa / IP30 sin tapa

LOGO! Mdulos de programa

Amarillo: Copia

Rojo: Know-How Protection y Copia

Seite 5

SIMATIC Totally Integrated Automation

Mdulo de contactos capaz de maniobrar hasta 20A (AC1)

LOGO!Contact LOGO!Contact

230 24

!Dimensiones 36 x 72 x 55 mm 36 x 72 x 55 mm

!Tensin operativa AC 230 V DC 24 V

!Corriente nominal 20 A resistiva, 20 A resistiva,

8,4 A inductiva. 8,4 A inductiva,

4kW Motores 4 k W Motores

LOGO! Contact : Contactor para LOGO!

SIMATIC Totally Integrated Automation

Fuente de alimentacin regulada para LOGO!24.. and LOGO! 12..

LOGO!Power 1.3 / 2.5 (24Vdc) 1.9 / 4.5 (12Vdc)

!Dimensiones 72/126 x 90 x 55 mm 72/126 x 72 x 55 mm

!Tensin de entrada AC 85...264V AC 85...264V

!Tensin de salida DC 24V DC 12V

!Corriente vlida 1.3/2.5Amp. 1.9/4.5Amp.

!Proteccin por corto circuito si si

Se ofrecen tambien las siguientes tensiones:

5 Vdc 3.0 / 6.3Amp.

15 Vdc 1.85 / 4.0Amp.

48 Vdc 0.65 / 1.25Amp.

LOGO! Power : Alimentacin para LOGO!

Seite 6

SIMATIC Totally Integrated Automation

LOGO! : Kit de Montaje en Panel Frontal

F

6AG1057-1AA00-0AA0

Protecin IP65 con Panel de Plexigls

Proteccin IP30 sin Panel de Plaxigls

Tamao (AnchoxAlturaxProf) 79x95x57mm

SIMATIC Totally Integrated Automation

LOGO! Prom : Hacer copias del Know How

F

Copiado de LOGO! A Memory cards

" via PC con LOGO!Soft Comfort

" via una Memory Card Maestra

Seite 1

SIMATIC Totally Integrated Automation

Nueva Generacin

LOGO!

3.0

LOGO! 4 Generacin (0BA3)

SIMATIC Totally Integrated Automation

3-hilos-serial- IO 3-hilos-serial- IO

Maestro

Esclavo Tipo 1 Esclavo Tipo 2

LOGO! ..0BA3 : Mdulos de Expansin

Seite 2

SIMATIC Totally Integrated Automation

Adjuste de Tiempo Automtico : Verano / Invierno

! EU, US, GB, ninguno etc.

Men en vez de 2 y 3 teclas al mismo tiempo

Proteccin por Password

! 10 caracteres

! Los Parmetros pueden ser modificados

Retentividad para OHC en conjunto con Card Red

Valor Actual del OHC puede ser mostrado en el Software (V3.1)

! Esto es importante para LOGO! sin display

El rango I/O completo puede ser usado con cualquier tipo de LOGO!

Funcionalidad de display mejorada.

LOGO! ..0BA3 : Mejoras en el Firmware

SIMATIC Totally Integrated Automation

Soporta los Sistemas Operativos:

! Win 95/98/2000/ME/NT 4.0

! MAC-OS X

! Linux (min. V2.2.12 and glibc V2.1.2)

Nueva Funcin Especial

! Funcin Switch Software (Interruptor/Pulsador)

Soporta una nueva Funcionalidad del Password

! Chequea el password en caso de Upload

Posibilidad de abrir mas de un proyecto al mismo tiempo (MDI)

Ajustes para simulacin se almacenan con el archivo de programa

Programacin Ladder como opcin (LOGO!Soft Comfort V3.1)

LOGO!Soft Confort V3.1 : Caractersticas Adicionales

F

Seite 1

SIMATIC Totally Integrated Automation

! Antes:

! Ahora:

!1

L1

N

No1

No2

No3

L1

S1

L1

L1

L1

S1

N

Cableado Standard vs LOGO!

SIMATIC Totally Integrated Automation

LOGO! Respuesta a Power ON

Whether a program is stored in the internal LOGO! memory

Whether a program module is inserted

Program in the

program

module or

program in the

internal

memory

LOGO!

No Program

Press ESC

No program in the

program module

and no program in

the internal

memory

SIEMENS

LOGO!

Program

PC/Card..

Clock..

Start

>

If there is a program in the

program module, it is

automatically copied to the

internal LOGO! memory. Any

program already present in the

internal LOGO! memory is

overwritten.

SIEMENS

Seite 2

SIMATIC Totally Integrated Automation

LOGO! Respuesta a Power ON

LOGO! Estado previo al Power OFF

Si una desconexin ocurre mientras el programa era entrado, el progrma se borra una vez

que se recobra la tensin

Antes de Power OFF Despus de Power ON

En mode edicin

LOGO!

Q1

SIEMENS

LOGO!

No Program

Press ESC

SIEMENS

Antes de Power OFF

En modo RUN

Despus de Power ON

LOGO!

I : 0. , 1. , 2.

123456789

0123456789

01234

SIEMENS

LOGO!

I : 0. , 1. , 2.

123456789

0123456789

01234

SIEMENS

SIMATIC Totally Integrated Automation

Operando la Unidad LOGO!

Tenemos diseado un circuito y queremos ingresarlo al

LOGO! Cul es el procedimiento?

Conectar el LOGO! A la alimentacin y conectarla.

El siguiente display aparece.

.

Presione ESC para accesar al men princiapal

LOGO!

OK ESC

No Program

Press ESC

SIEMENS

LOGO!

OK ESC

Program ..

PC / Card ..

Clock ..

Start

>

SIEMENS

Seite 3

SIMATIC Totally Integrated Automation

Men Principal / Men Programa

In the first position of the first line, you see a >.

Using the keys, you move the > up and down.

Move the > to Program

and press . LOGO! switches to the program menu.

OK

In addition, you can move the > up and down

using the keys.

Move the > to Edit Prg and

press the key.

LOGO! now displays the first output (Q1).

OK

Using the keys, you can select the other

outputs (Q1, Q2, Q3, etc.).

When entering your circuit, take into account the following

rules ....

LOGO! 12/24 RC

OK ESC

Program ..

PC / Card ..

Clock ..

Start

>

LOGO! 12/24 RC

OK ESC

Edit Prg

Prg Name

Clear Prg

Password

>

OK ESC

Q1

SIEMENS

SIEMENS

SIEMENS

LOGO!

SIMATIC Totally Integrated Automation

Reglas de Operacin de LOGO! (1)

1. Always enter a circuit from the output to

the input.

2. You can connect one output to more than

one input.

3. However, you cannot connect an output to a input

preceding it in the same path (no feedback loops).

I

I1

Q

Q1

Q

Q1

&

I1

>

I2

&

Q1

Q

Q2

&

I1

Seite 4

SIMATIC Totally Integrated Automation

Reglas de Operacin de LOGO! (2)

4. If the cursor appears as an underscore (_), you can move it using the keys:

Q1 B01 Q1 B01 Q1

B02

B01

I1

x

&

Q1

B02

B01

I1

x

&

B01

B02

I3

1

SIMATIC Totally Integrated Automation

Reglas de Operacin de LOGO! (3)

Use to accept the selection

Use to go back one step

OK

OK

Q1 BF

Q1 SF

Q1 Co

Q1

B01

&

Q1

B01

&

Q1

B01

>1

OK Q1

B01

&

OK

Q1

B01

& Co

Q1

B01

& x

OK

Q1

B01

&

I1

5. If the cursor appears as a (solid block), you can use the

keys to select a connector (Co), a basic function (BF), or a special function (SF).

ESC

Seite 5

SIMATIC Totally Integrated Automation

Programa Inicial

Refer to the following parallel circuit containing two switches.

Switch S1 and switch S2 switch the load.

The parallel circuit of S1 and S2 is an

OR operation in LOGO!, because

S1 or S2 switches on the output.

>1

I1

I2

x

Q1

S1 S2

K1

K1

E1

v

SIMATIC Totally Integrated Automation

Cableado

Switch S1 acts on input I1 and switch S2

acts on input I2. The load is connected at

relay Q1.

You now enter the program (from the

output to the input!). To start, LOGO!

displays output Q1.

Below the Q of Q1, you see an

underscore (_). We refer to the

underscore as a cursor. The cursor

indicates your current location in the

program.

L1

N

S1

LOGO! 12/24 RC

OK ESC

Q1

I1 I2 I3 I4 I5 I6 L1 N

Q1 Q2 Q3 Q4

S2

L

N

SIEMENS

I7 I8

Seite 6

SIMATIC Totally Integrated Automation

Ingresando un Programa (1)

Now, press the key. The cursor

moves to the left.

The cursor indicates your location in the

program. You enter the first block (the OR

block) at this location.

Change to editing mode by pressing . OK

The cursor now appears as a solid block

Now, use the keys to select one of

the following:

Connector (Co)

Basic function (BF)

Special function (SF)

LOGO! 12/24 RC

OK ESC

Q1

LOGO! 12/24 RC

OK ESC

Q1

LOGO!

OK ESC

Q1 Co

SIEMENS

SIEMENS

SIEMENS

SIMATIC Totally Integrated Automation

Ingresando un Programa (2)

Select the basic function using (GF) and confirm

with .

The first block on the list of basic functions (BF) is

the AND block.

Now use the keys to select one of the

following:

OK

AND

AND (Edge)

NAND

NAND (Edge)

OR

NOR

XOR

NOT

Select the OR block ( >1 ) and confirm with .

OK

LOGO! 12/24 RC

OK ESC

Q1 BF

LOGO! 12/24 RC

OK ESC

Q1

B01

&

LOGO!

OK ESC

Q1

B01

>1

SIEMENS

SIEMENS

SIEMENS

Seite 7

SIMATIC Totally Integrated Automation

Ingresando un Programa (3)

You have entered the first block. Each block that

you enter has a block number (B01). Now all you

have to do is connect the inputs of the block

(B01).

Press the key. OK

The cursor now appears as a solid block

Now, use the keys to select from the

following:

Connector (Co)

Basic function (BF)

Special function (SF)

Select connector (Co) and confirm with .

OK

The first element in the list (Co) is an x, which

is the character for input not used. Select input

I1 using the keys.

Confirm the selection with . OK

LOGO! 12/24 RC

OK ESC

Q1

B01

>1

LOGO! 12/24 RC

OK ESC

Q1

B01

>1 Co

LOGO!

OK ESC

Q1

B01

>1 I1

SIEMENS

SIEMENS

SIEMENS

SIMATIC Totally Integrated Automation

Ingresando un Programa (4)

Now connect input I2 to the input of the OR

block. You already know the procedure for this:

1. Change to editor mode with

2. Select the Co list with

3. Accept the Co list with

4. Select I2 with

5. Accept I2 with

OK

OK

OK

We do not need the last input of the OR block for

this program. In a LOGO! program, we designate

an unused input with an x. You now know the

principle behind doing this:

1. Change to editor mode with

2. Select the Co list with

3. Accept the Co list with

4. Select x with

5. Accept x with

OK

OK

OK

OK ESC

Q1

B01

>1 I1

SIEMENS

LOGO! 12/24 RC

OK ESC

Q1

B01

>1 I1

I2

SIEMENS

LOGO!

OK ESC

Q1

B01

>1 I1

I2

x

SIEMENS

Seite 8

SIMATIC Totally Integrated Automation

Arrancando un Programa

Now, all inputs of the block are connected.

LOGO! considers the program to be complete.

LOGO! jumps back to output Q1.

If you still want to view your initial program, you can move

the cursor through the program

using the keys.

In order to be able to start the program, you must

return to the main menu using the

key.

ESC

Using the keys, move the cursor to

Start and confirm with the

key.

OK

LOGO! 12/24 RC

OK ESC

Q1 B01

OK ESC

Edit Prg

Prg Name

Clear Prg

Password

>

LOGO! 12/24 RC

LOGO!

OK ESC

Program ..

PC / Card ..

Clock ..

Start

>

SIEMENS

SIEMENS

SIEMENS

However, we now leave the program entering

step and return to the program menu

using the key. ESC

SIMATIC Totally Integrated Automation

LOGO! En Modo RUN

LOGO! displays the following in RUN mode:

Input states:

State of input I = 1

State of input I = 0

1

1

Output states:

State of output Q = 1

State of output Q = 0

1

1

Refer to our example below:

If switch S1 is closed, input I1 is energized and the state of input I1 = 1.

The LOGO! program determines the output states.

In this example, the state of output Q1 = 1.

If the state of Q1 = 1, LOGO! enables relay Q1 and the load at Q1 is energized.

L1

S1

=1

S2

=0

I :0.,1.,2.

23456789

0123456789

01234

N

Q1

=1

Mo 09:00

06.21.01

1

Q :0.,1.

23456789

0123456

1

The window on the left shows the time of day

and the date.

The window in the center shows the input states

(I1 to I9; I10 to I19; I20 to I24).

The window on the right shows the output

states (Q1 to Q9; Q10 to Q16)

Seite 9

SIMATIC Totally Integrated Automation

Asignando Parametros en LOGO! (1)

Assigning parameters of functions:

You can assign the following:

Time delays of time functions

Switching times for timer switches

Threshold for a counter

Monitoring interval of an elapsed time counter

On and off thresholds for the threshold switch

By assigning parameters, we mean the assignment of parameters of

functions.

You can assign parameters in the following operating modes:

Programming

Parameter assignment

You reach parameter assignment mode by pressing the

key in RUN mode, placing the cursor on Set Param,

and confirming with the key. OK

ESC

LOGO! 12/24 RC

LOGO!

OK ESC

I :0.,1.,2.

123456789

0123456789

01234

SIEMENS

LOGO! 12/24 RC

LOGO!

OK ESC

Stop

Set Param

Set Clock

Set Name

>

SIEMENS

SIMATIC Totally Integrated Automation

Asignando Parametros en LOGO! (2)

When the setting for the required block has been made, press

the key. The cursor jumps to the first parameter

to be modified. You can now modify the value using the

keys.

OK

When the setting for the required value has been made,

press the key. The cursor jumps to the block

number. Using the keys, you can select the

next block to be changed, and so on.

OK

Select a block:

In parameter assignment mode, select the appropriate block

using the keys.

LOGO! 12/24 RC

OK ESC

B01:Par

Lim=005

Cnt=000000

LOGO! 12/24 RC

LOGO! 12/24 RC

OK ESC

B04: T

T = 5.0s

Ta=0.0s

LOGO! 12/24 RC LOGO! 12/24 RC

LOGO!

OK ESC

B07: T

T = 8.0s

Ta=0.0s

SIEMENS

SIEMENS

SIEMENS

Seite 10

SIMATIC Totally Integrated Automation

Asignando Parametros en LOGO! (3)

ESC

Use the key to return to the menu.

ESC Use the key to return to RUN mode.

LOGO! 12/24 RC LOGO! 12/24 RC

LOGO!

OK ESC

B07: T

T = 8.0s

Ta=0.0s

SIEMENS

LOGO! 12/24 RC

LOGO!

OK ESC

Stop

Set Param

Set Clock

Set Name

>

SIEMENS

LOGO! 12/24 RC

LOGO!

OK ESC

I :0.,1.,2.

123456789

0123456789

01234

SIEMENS

SIMATIC Totally Integrated Automation

Function RE

Basic function 0 0 0 0

ON delay 1 1 1 0

OFF delay 2 1 1 0

Impulse relay 1 1 1 0

Pulse relay

1)

0 1 0 0

Pulse relay

2)

0 0 0 1

Clock 6 2 0 0

Latching relay

1)

0 1 0 0

Latching relay

2)

0 0 0 1

Clock-pulse generator 1 1 1 0

Latching ON delay 2 1 1 0

Counter

1)

2 2 0 0

Counter

2)

2 0 0 2

Operating hours counter 2 0 0 4

Trigger 3 3 1 0

1)

LOGO! - sin remanencia

2)

LOGO! - con remanencia

Temporizadores (Timer)

Set Points (Par)

Valores Actuales (RAM)

RE Remanencia

Memoria Disponible en LOGO!

F

Seite 1

SIMATIC Totally Integrated Automation

Conectores

Funciones Generales

F

Funciones Especiales-a

Funciones Especiales-b

Descripcin Detallada de Funciones

SIMATIC Totally Integrated Automation

Funciones Bsicas (BF)

AND AND

(Edge)

NAND NAND

(Edge)

OR NOR XOR NOT

Funciones

Bsicas

Seite 2

SIMATIC Totally Integrated Automation

(BF) Operacin Lgica AND

The state of the AND output = 1 only if the state of all

inputs = 1.

An unconnected input pin in this block is automatically

assigned state = 1.

Input 2 Input 3 Output

0 0 0 0

0 0 1 0

0 1 0 0

0 1 1 0

1 0 0 0

1 0 1 0

1 1 0 0

1 1 1 1

Tabla Lgica para bloque AND:

&

S1

S2

x

H1

AND

S1

S2

H1

Referring to the circuit diagram, it can be seen that lamp H1

illuminates only if S1 and S2 are both closed. There is a dependency

between the input and output states.

The circuit shown on the right is referred to as an AND logic

operation.

This means that switches S1 and S2 must be energized in order for

lamp H1 to illuminate.

Symbolically, this operation is represented by .

Input 1

Circuito serie con cantactos NO

SIMATIC Totally Integrated Automation

(BF) Operacin Lgica OR

The state of the OR output =1 if the state of at least one input

= 1. An unconnected input pin in this block is automatically

assigned state = 0.

Input 2 Input 3 Output

0 0 0 0

0 0 1 1

0 1 0 1

0 1 1 1

1 0 0 1

1 0 1 1

1 1 0 1

1 1 1 1

Logic Table for OR Block:

>

S3

S4

x

H2

OR

For lamp H2 to illuminate, switch S3 or S4 must be closed. This

dependency of the output state on the input states is referred to as

an OR logic operation.

This means that at least one of the two switches--S3 or S4--must

be closed in order for lamp H2 to illuminate.

The symbol for this operation is

Input 1

S3 S4

H2

Parallel circuit with normally

open contacts

Seite 3

SIMATIC Totally Integrated Automation

(BF) AND con Evaluacin de Flanco

The state of the output of the AND with edge evaluation

operation = 1 only if the state of all inputs = 1 and the state

of at least one input during the previous cycle = 0.

An unconnected input pin in this block is automatically

assigned state = 1.

&

S1

S2

S3

H2

AND with edge evaluation

S1

S2

S3

H2

S1

S2

H2

S3

Electromechanical counter

5 1 6 0

SIMATIC Totally Integrated Automation

(BF) Operacin Lgica NAND

The state of the NAND (Not AND) output = 0 only if the

state of all inputs = 1.

An unconnected input pin in this block is automatically

assigned state = 1.

Logic Table for NAND Block:

&

S1

S2

x

H2

NAND (Not AND)

Referring to the circuit diagram, it can be seen that lamp H2 is always

illuminated, unless all of the switches are activated.

The circuit shown on the right is referred to as a NAND (Not And)

logic operation.

This means that switches S1, S2, and S3 must be activated in order

for lamp H2 not to be illuminated.

The symbol for this operation is .

Input 2 Input 3 Output

0 0 0 1

0 0 1 1

0 1 0 1

0 1 1 1

1 0 0 1

1 0 1 1

1 1 0 1

1 1 1 0

Input 1

Parallel circuit with

normally closed contacts

S1 S3 S3

H2

Seite 4

SIMATIC Totally Integrated Automation

(BF) NAND con Evaluacin e Flanco

S1

S2

S3

H2

The state of the output of the NAND (Not And) with edge

evaluation operation = 1 only if the state of at least one

input = 0 and the state of all inputs during the previous

cycle = 1.

An unconnected input pin in this block is automatically

assigned state = 1.

&

S1

S2

S3

H2

NAND with edge evaluation

Electromechanical counter

S1 S3 S3

H2

5 1 6 0

SIMATIC Totally Integrated Automation

(BF) Operacin Lgica NOR

The state of the NOR (Not OR) output = 1 only if the state

of all inputs = 0. As soon as any input is switched on (state

= 1), the output is switched off.

An unassigned input pin in this block is automatically

assigned state = 0.

NOR (Not OR)

S1

S2

H1

Referring to the circuit diagram, it can be seen that lamp H1 is

illuminated only if normally closed switches S1 and S2 are not

activated.

The circuit diagram shown on the right is referred to as a NOR (Not

OR) logic operation.

This means that if at least one of the switches S1 or S2 is activated,

lamp H1 is not illuminated.

The symbol for this operation is .

Input 2 Input 3 Output

0 0 0 1

0 0 1 0

0 1 0 0

0 1 1 0

1 0 0 0

1 0 1 0

1 1 0 0

1 1 1 0

Logic Table for AND Block:

Input 1

Series circuit with normally

closed switches

>1

S1

S2

x

H1

Seite 5

SIMATIC Totally Integrated Automation

(BF) Operacin Lgica XOR

The state of the XOR (Exclusive OR) output = 1 if the

state of the inputs is different.

An unconnected input pin in this block is automatically

assigned state = 0.

XOR (Exclusive OR)

S1

S2

H1

Referring to the circuit diagram, it can be seen that lamp H1 is not

illuminated only if all of the switches are activated.

The circuit diagram on the right is referred to as an XOR (Exclusive

OR) logic operation.

This means that if either switch S1 or switch S2 is activated, lamp H1

will illuminate.

The symbol for this operation is .

Logic Table for XOR Block:

Input 2 Output

0 0 0

0 1 1

1 0 1

1 1 0

Input 1 =1

S1

S2

H1

SIMATIC Totally Integrated Automation

(BF) Operacin Lgica NOT

The state of the output = 1 if the input = 0, that is, NOT inverts

the input state. One advantage of the NOT operation is that

normally closed contacts are no longer needed for LOGO! A

normally open contact is used and is converted to a normally

closed contact with the NOT operation.

An unconnected input pin in this block is automatically assigned

state = 1.

NOT (Exclusive OR)

1

S1 H1

Referring to the circuit diagram, it can be seen that lamp H1 is only

illuminated if switch S1 is not activated.

The circuit diagram on the right implements a NOT logic operation.

The symbol for this operation is .

S1

Logic Table for NOT Block:

Output

0 1

1 0

Input 1

H1

K1

Seite 6

SIMATIC Totally Integrated Automation

Funciones Especiales

Funciones

Especiales

On-Delay

Off-Delay

On/Off Delay

Retentive On-Delay

Latching Relay

Pulse Relay

Internal Time-Delay Relay

Edge-Triggered Internal

Time-Delay Relay

Weekly Timer

Yearly Timer

Up/Down Counter

Elapsed Time Counter

Clock Pulse

Generator

Pulse Relay

Random Generator

Threshold Switch

Staircase Lighting

Time Delay

Multifunction Switch

Message Text

Analog Threshold Switch

Analog Comparator

Softkey

SIMATIC Totally Integrated Automation

(SF) On-Delay

Function Description:

If the state at input Trg changes from 0 to 1, the timer starts running. If the state at input Trg =1 for a sufficient amount of time,

the output is set to 1 once time T expires. There is a delay in switching on the output as compared to the input. The output is reset

to 0 if the state at input Trg = 0.

If the state at input Trg changes back to 0 before time T expires, the timer is reset.

The expired timer is reset after a power failure.

Referring to the circuit diagram, it can be seen that the motor starts

running only after the set time delay expires.

This function is referred to as an on-delay.

This means that the motor is switched on after a set time delay.

The symbol for this function is .

S1

K1

K1

M

Diagram:

Trg

Q

Ta

T T

(Timer active)

Seite 7

SIMATIC Totally Integrated Automation

(SF) Off-Delay

Referring to the circuit diagram, it can be seen that the motor

is switched off only after the set time delay expires.

This function is referred to as an off-delay.

This means that the motor is switched of after a set time

delay.

The symbol for this function is .

Function Description

If the state at input Trg = 1, the state at output Q switches immediately to 1. If the state at input Trg changes from 1 to 0, the

timer in LOGO! is activated and the output state is retained. When the timer reaches the value set using T (Ta =T), the state at

output Q is reset to 0.

If the input Trg is switched on and off again, time Ta is restarted.

Time Ta and the output are reset using input R (reset) before time T expires.

(Timer active)

S1

K1

K1

M

Diagram:

Trg

Q

Ta

T

R

T

SIMATIC Totally Integrated Automation

(SF) On/Off-Delay

Referring to the circuit diagram, it can be seen:

If S1 is closed, contact K1 closes after a time delay and the

motor runs.

If S1 is opened, contact K2 opens after a time delay and the

motor stops.

S1

K1

K1

M K2

K2

This function is referred to as an on/off delay. This means

that the motor is switched on and off after a set time delay.

The symbol for this function is .

Function Description

If the state at input Trg changes from 0 to 1, time TH runs. If the state at input Trg remains 1, the output is set to 1

once the time TH expires.

If the input state changes back to 0, time TL runs. If the state at input Trg remains 0 for the duration of time TL, the output is set

to 0 once time TL expires.

Trg

TL

Q

TH

Diagram:

Seite 8

SIMATIC Totally Integrated Automation

(SF) On-Delay Retentivo

Function Description:

If the state at input Trg changes from 0 to 1, the current time Ta starts running. When time Ta reaches time T,

the state at output Q is set to 1. Output Q is reset to 0 only when the state at input R = 1.

Further switching actions at input Trg have no influence on output Q.

Referring to the circuit diagram, it can be seen that motor M runs

after a set time delay following activation of momentary-contact

pushbutton S1. Momentary-contact pushbutton S2 (normally

closed) causes the motor to switch off again.

This function is referred to as a retentive on-delay.

The symbol for this operation is .

S2

K1

K2

M

S1 K1 K1

K2

Trg

R

Ta

Q

T

Diagram:

SIMATIC Totally Integrated Automation

(SF) Rel con Auto-enclavamiento

Referring to the circuit diagram, it can be seen that coil K1 is energized

with momentary-contact pushbutton S1, causing maintained-contact

switch K1 to close (latching).

This function is referred to as a latching relay.

The symbol for this operation is .

S2

K1 M

S1 K1 K1

K2

Diagram:

S

R

Q

Function Description

Output Q is set by means of input S; output Q is reset by means of a second input R.

Seite 9

SIMATIC Totally Integrated Automation

(SF) Rel de Pulso (Toggle)

Function Description

Each time that the state at input Trg changes from 0 to 1, output Q changes its state,

i.e., the output is switched on or off. The state of the latching relay is set to 0 using input R.

Referring to the circuit diagram, it can be seen that lamp H1 can be

switched on and off with momentary-contact pushbuttons S1 or S2.

This function is referred to as a pulse relay.

This means that lamp H1 is switched on and off by a brief pulse in

S1 or S2, respectively.

The symbol for this operation is .

K1

S1 K1 S2

H1

Diagram:

Trg

R

Q

SIMATIC Totally Integrated Automation

(SF) Intervalo-Delay Rel/Salida de Pulso

Referring to the circuit diagram, it can be seen that lamp H1 is

illuminated only if maintained-contact switch S1 is closed, but at

most for the time period set on timer T1.

The symbol for this operation is .

T1

S1

H1

T1

Diagram:

Trg

Ta

Q

Function Description

If the state at input Trg = 1, the state at output Q immediately switches to 1. Simultaneously, the current time Ta

starts in LOGO!, and the output setting is retained. When Ta reaches the value set using T

(Ta =T), the state at output Q is reset to 0 (pulse output).

If the state at input Trg changes from 1 to 0 before the specified time expires, the state at the output also changes immediately from 1

to 0.

Seite 10

SIMATIC Totally Integrated Automation

(SF) Intervalo delay Rel por Flanco

T1

S1

H1

T1

T1

Diagram:

Trg

Ta

Q

T T

Referring to the circuit diagram, it can be seen that lamp H1

illuminates for a period of time set in timer T1 when maintained-

contact switch S1 is activated.

The symbol for this operation is .

Function Description

If the state at input Trg = 1, the state at output Q switches to 1. Simultaneously, time Ta starts. When time Ta

reaches the value set using T (Ta=T), the state at output Q is reset to 0 (pulse output).

If the state at input Trg changes back from 0 to 1 before the specified time expires (retriggering), time Ta is reset

and the output remains switched on.

SIMATIC Totally Integrated Automation

(SF) Temporizador Semanal

The output is controlled by means of an assignable on and

off date. Any combination of weekdays is supported. Active

weekdays are selected by removing inactive weekdays.

Wednesday

Monday

Function Description

Each weekly timer has three cams which can be used

to assign parameters for each time window. The on

and off times are specified using the cams.

Cam1

Cam2

Cam3

Lu Ma Vi Ju Sa Mi On Do Off

07 : 30 16 05

08 : 00 12 00

10 : 00 12 30

Seite 11

SIMATIC Totally Integrated Automation

(SF) Termporizador Anual

Function Description

Each yearly timer has an on and off time. The yearly timer

switches the output on at a specified on time and switches it off

at a specified off time. The off date identifies the day when the

output is to be reset to 0.

Jan Feb Mar Apr May Jun Jul Aug Sep Oct Nov Dec

On May 10 Off Oct 20

SIMATIC Totally Integrated Automation

(SF) Contador Up/Down

Referring to the circuit diagram, it can be seen that the time pulse is

generated with maintained-contact switch S1. Maintained-contact

switch S2 determines whether the counter counts up or down. If

the counter content has a value >= 10, the lamp is switched on.

Function Description

For every rising edge at input Cnt, the internal counter counts up by

one (Dir = 0) or down by one (Dir = 1). If the internal counter value

is equal to or greater than the value specified using Par, output Q is

set to 1.

The internal counter value and the output can be reset to 0 using

input R.

As long as R = 1, the output is 0, and pulses at input Cnt are not

counted.

C1

S1

S2

+ -

>=5

H1 Q

R

Par

Dir

Cnt

Diagram:

Q

R

Contador

Dir

Cnt

2

3

2

1

0

4

3

5

6 6

5

3

1

4

2

3

0

5

4

Seite 12

SIMATIC Totally Integrated Automation

(SF) Contador de Horas de Operacin

Function Description

The elapsed time counter monitors input En. As long as the value at this input = 1,

LOGO! quantifies elapsed time OT and the remaining residual time MN. LOGO! indicates the times in parameter assignment

mode. If the remaining residual time MN = 0, output Q is set to 1. The reset input R is used to reset

output Q and to set the counter for the residual time to the specified value MI. Internal counter OT resumes counting.

The reset input Ral is used to reset output Q and to set the counter for the residual time MN to the specified value MI.

The internal counter OT is reset to 0.

1

2

3

4

3

2

1

0

MN = MI

MN = 0

Q

Ral

En

3

2

1

0

R

OT

SIMATIC Totally Integrated Automation

(SF) Generador de Pulsos Simtrico

Referring to the circuit diagram, it can be seen that lamp H1 flashes

with a pulse time set using a clock pulse generator when

maintained-contact switch S1 is activated.

The symbol for this operation is .

Function Description

Parameter T is used to specify the length of the on and off time.

En (Enable) is used to switch the clock pulse generator on. The clock pulse generator sets the output to 1 for time T,

and then to 0 for time T, and so on, until EN = 0 at the input.

The time T specified must be > 0.1 seconds at all times.

G

H1 S1

Diagram:

En

Q

T T

Seite 13

SIMATIC Totally Integrated Automation

(SF) Generador de Pulsos Asncrono

The pulse form of the output can be modified by means of the

assignable pulse/pause ratio.

The symbol for this function is .

Function Description

Pulse length and pause length can be set by means of parameters. The time base can be divided into seconds,

minutes, or hours. Both parameters have the same time basis, and a different setting is not possible. Input Inv causes

the output to be inverted if the block is enabled by means of EN.

Diagram:

En

Q

Pulse length/Pause length

Inv

SIMATIC Totally Integrated Automation

(SF) Generador Aleatorio

Function Description

If input En changes from 0 to 1, a random time of between 0 and 10 seconds is started. If En =1 for at least the

duration of the on-delay time, the output is set to 0 when the on-delay time expires. If the state at input En changes

back to 0 before the on-delay time expires, the time is reset.

If input En changes from 1 to 0, a random time (off-delay time) of between 0 and 15 seconds is started. If En = 0 for

at least the duration of the off-delay time, the output is set to 0 once the off-delay time expires. If the state at input En

changes to 1 before the off-delay time expires, the time is reset.

The random generator switches the output on or off within an

assignable time.

The symbol for this function is .

Diagram:

En

Q

Maximum On-Delay/Maximum Off-Delay

Q

Seite 14

SIMATIC Totally Integrated Automation

(SF) Switch de Umbral de Frecuencia

The output is switched on and off depending on two assignable

frequencies.

The symbol for this function is .

Function Description

The threshold switch measures the signals at input Fre. The pulses are detected over an assignable time period

(peak time). If during the peak time, the measured values are greater than the upper threshold value, output Q

switches on. Output Q switches off again when the measured values are less than the lower threshold value.

SWOn is the on threshold. The permitted range is 0000 to 9999.

SWOff is the off threshold. The permitted range is 0000 to 9999.

Peak time is the time interval during which the pulses at Fre are measured. The permitted range is 0.05 seconds

to 99.95 seconds.

Diagram:

Fre

Q

Ventana

Fre > SWOn Fre > SWoff Fre < SWOff

Fre =12 Fre = 5 Fre = 3 Fre = 5

Fre < SWOn

SIMATIC Totally Integrated Automation

(SF) Delay Alumbrado de Escalera

An assignable time runs following an input pulse (edge

triggering). The output is reset after the time expires. An

early shutdown warning is issued 15 seconds before the

time expires.

The symbol for this function is .

Function Description

If the state at input Trg changes from 0 to 1, the current time Ta runs and output Q is set to 1. Fifteen seconds

before Ta reaches time T, output Q is reset to 0 for 1 second.

If Ta reaches time T, output Q is reset to 0.

Further switching actions at input Trg while Ta is running resets Ta (retrigger option).

Diagram:

Ta

Trg

Q

T (Off-delay)

1 s

15 s

Seite 15

SIMATIC Totally Integrated Automation

(SF) Switch Multifuncin

Switch with two different functions:

Pulse switch with off-delay

Switch (steady light)

The symbol for this function is .

Function Description

If the state at input Trg changes from 0 to 1, output Q is set to 1. If input Trg changes back to 0 before the steady

light time expires, the output is reset to 0 after a time delay of 5 seconds.

If the state at input Trg changes from 0 to 1 and remains 1 for at least 20 seconds, the steady light function is enabled

and output Q is switched on for the duration. Further switching actions from 0 to 1 and back to 0 at input Trg causes

output Q to switch off.

Diagram:

Q

Trg

5 s >20 s

SIMATIC Totally Integrated Automation

SIEMENS

(SF) Message Text

Display of an assigned message text in RUN mode.

The symbol for this function is .

Function Description

If the input state changes from 0 to 1, the appropriate message text is output on

the display during RUN mode. If the input state changes from 1 to 0, the message

text is removed. If more than one message text has been triggered with En=1, the

highest priority message is displayed.

It is possible using the keys to toggle between the standard display and

the message text display. If acknowledge message is selected, the

corresponding message text is removed only after pressing a button on LOGO!,

provided En = 0.

LOGO

OK ESC

1

2 3 4

I : 0. , 1. , 2.

123456789

0123456789

01234

Motor on

in 2 min

01:15 m

Alarm!

Pressure

in %

95.0

Seite 16

SIMATIC Totally Integrated Automation

(SF) Switch de Umbral Anlogo

Function Description

The output is switched off if the analog value exceeds an assignable on threshold.

The output is switched off if the analog value is less than an assignable off

threshold (hysteresis).

The function reads analog value AI1 or AI2. The offset parameter is then added to

the analog value. This value is then multiplied by the gain parameter.

If this value exceeds the on

threshold (SW!),

output Q is set to 1.

Q is reset to 0 if the value falls b

low the off threshold (SW").

Note: In the effective range,

the minimum and maximum

must be assigned the same

ones digit.

Diagram

Pinout

SIMATIC Totally Integrated Automation

(SF) Comparador Anlogo

Function Description

This function generates the difference between the analog values Ax and Ay. The offset

parameter is then added to the difference. The difference is then multiplied by the gain parameter.

If the difference of this value exceeds the assigned threshold, output Q is set to 1.

Output Q is reset to 0 if the valued falls below the threshold again.

Diagram

Pinout

Seite 17

SIMATIC Totally Integrated Automation

(SF) Softkey

Function Description

This logic function works like a mechanical momentary-contact pushbutton or a maintained-contact switch.

If input En is set and the switch parameter is switched to On and confirmed with OK in parameter

assignment mode, the output is switched on. Whether the function was configured as a maintained-contact

switch or a momentary-contact pushbutton is irrelevant.

The output is reset to 0 in the following three cases:

If the state at input En changes from 1 to 0.

If the function was configured as a momentary-contact push-

button and a cycle has run since it was switched on.

If the Switch parameter was switched to Off and confirmed

with OK in parameter assignment mode.

Diagram

Q

En

Par

Pinout

Seite 1

SIMATIC Totally Integrated Automation

Interfase bien conocida tipo Windows

! Menus contextuales, Smbolos etc.

Programacin confortable

! En Bolque de Funciones (FBD) o Escalera (Ladder)

Programacin usando Drag and Drop

! Pruebe el Programa en pantalla - directamente

en la PC

Simulacin del programa

! con el estado de cada funcin (en color)

Impresin Profesional y funcin de documentacin

Seleccin del equipo

! (0BA0, 0BA1, 0BA2, 0BA3 con chequeo de

capacidad de funcin)

LOGO!Soft Confort V3.1 Caractersticas

SIMATIC Totally Integrated Automation

Inicio Rpido con LOGO! Soft Comfort V3.1

Barra de Ttulo

Barra de Men

Barra de Smbolos

Barra de Herramientas

Status bar

Ventana de Mensajes

Etiqueta de Progrma

Seite 2

SIMATIC Totally Integrated Automation

Funciones de Ayuda (1)

El Help es activado usando el

comando Help -> Content . Se

puede encontrar informacin

adicional ordenada por temas en el

directorio Contenido

Haciendo clik en un

tema de interes, se

obtiene informacin

detallada a ese respecto

SIMATIC Totally Integrated Automation

Funciones de Ayuda (2)

Que es esto? Puede ser accesado

por medio del men contextual

(click con boton derecho del

mouse) para cada funcin

Seite 3

SIMATIC Totally Integrated Automation

Funciones de Ayuda (3)

Que es esto? Se activa tambin

usando el comando Help -> Whats

This? . Los objetos sobre los cuales

se desea ayuda se apuntan con el

mouse

SIMATIC Totally Integrated Automation

Funciones de Ayuda (4)

Usando el comando Help -> Update

Center, se puede instalar leguajes

adicionales, Upgrades y sevice packs

del programa

Seite 4

SIMATIC Totally Integrated Automation

Ttulo

Lista de Menu

Barra de herramientas n conos

Modo seleccionar para modificar

Texto libre para comentarios

adicionales

Para una mejor vista , separar las

interconexiones

Trazado de las lneas de interconexin

Mostrar Conectores (Co)

Mostrar funciones generales (GF)

Mostrar funciones especiales (SF)

Simulacin offline

Standard-Windows

PC -> LOGO!

LOGO! -> PC!

LOGO!Soft Confort: Botones

SIMATIC Totally Integrated Automation

Rango de

Medida

Ganancia (1 - 1000)

Offset -999

+999

Umbral

Dependiendo del

rango de medida

Cuadro : Comparador Anlogo

Seite 5

SIMATIC Totally Integrated Automation

4 Lneas

Prioridad

Edicin de

Texto

Seleccin de

Bloque Seleccin de

Parmetro

Cuadro : Mensajes

SIMATIC Totally Integrated Automation

Seleccin de

7 Das

Hora de

Encedido

Hora de

Apagado

Leva 1,2,3

Cuadro : Reloj Semanal

Seite 6

SIMATIC Totally Integrated Automation

Fondo

Color High

Color Low

Sleccin de color

Vista previa

Cuadro : Personalizacin de Colores

SIMATIC Totally Integrated Automation

Seleccon de

pulsador

Valor min./max.

Para simulacin

de frecuencia

Valor min./max.

Para simulacin

anloga

Cuadro : Parmetro de Simulacin

Seite 7

SIMATIC Totally Integrated Automation

Ventana de

mensajes

Simulador

Anlogo

Azul = Low

Rojo = High

Valor Actual

Prioridad

Simulacin Offline

SIMATIC Totally Integrated Automation

Logo de la Empresa : Impresin Profesional

Seite 8

SIMATIC Totally Integrated Automation

Vista Previa de Impresin

SIMATIC Totally Integrated Automation

Men Rpido con Botn derecho del Mouse

Seite 9

SIMATIC Totally Integrated Automation

Pgina1, B55

Pgina2, Marca 1

Funcin Unir / Desunir Conexin

SIMATIC Totally Integrated Automation

Seleccionar Hardware

F

Seite 1

SIMATIC Totally Integrated Automation

Comunicacin

LOGO!

LOGO!: COMUNICACIN

SIMATIC Totally Integrated Automation

Comunicacin de Campo

Comunicacin de Campo Comunicacin de Campo

PROCESS FIELD BUS

Comunicacin de Datos

Comunicacin de Datos Comunicacin de Datos

PROCESS FIELD BUS

PROCESS FIELD BUS

net net net

Comunicacin - IT