Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Formosa Formolene LB1810E2

Cargado por

yolanda sofia restan causilTítulo original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Formosa Formolene LB1810E2

Cargado por

yolanda sofia restan causilCopyright:

Formatos disponibles

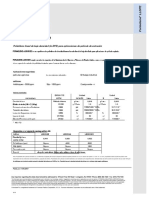

Formolene® LB1810E2

Linear Low Density Polyethylene (LLDPE) Resin for Film Extrusion Applications

Formolene® LB1810E2 is a butene based linear low density polyethylene copolymer designed for blown film

applications.

Formolene® LB1810E2 meets all requirements of the U.S. Food and Drug Administration as specified in 21

CFR 177.1520, covering safe use of polyolefin articles intended for direct food contact.

Suggested Applications:

Agricultural Films Industrial Liners Industrial Packaging Garment Bags

Additives:

Antiblock – 5000 ppm Slip – 1500 ppm Processing Aid – No

Nominal Values

ASTM TEST ENGLISH SI

PROPERTY METHOD Unit Value Unit Value

Base Density Internal Method g/cm3 0.918 g/cm3 0.918

Melt Index (190 C, 2.16 kg) D1238 g/10 min 1.0 g/10 min 1.0

Tensile Strength at Yield D882 psi 1550/1600* MPa 10.7/11.0*

Tensile Strength at Break D882 psi 5300/3900* MPa 36.5/26.9*

Tensile Elongation at Break D882 % 580/690* % 580/690*

Dart Impact D1709A g 90 g 90

Elmendorf Tear Strength D1922 g 170/320* g 170/320*

* MD/TD

Available in the following additive packages:

Additive LB1810B LB1810A LB1810E2

Density (g/cm3)

0.918 0.920 0.922

ASTM D792

Antiblock (ppm) None 4000 5000

Slip (ppm) None None 1500

Processing aid None None None

Special High Antioxidant Additives talc based Additives talc based

Note: Film properties are based on 1.0 mil (25 μm) thickness blown film produced with a 2.5:1 blow-up ratio at 12 lb/hr/in. die. Actual film properties

may vary depending on operating conditions and additive packages. Film properties are not intended to be used as specifications.

Base density is estimated using the assumption that every 1000 ppm of antiblock in the finished product raises the density of the polymer by 0.0006

g/cm3. Base density is the estimated density of the polymer if it did not contain any antiblock.

Published 11/1/2019

6/19

También podría gustarte

- Ficha de Costo ImprentaDocumento3 páginasFicha de Costo ImprentaYuleysi Nicold Trocones ColladoAún no hay calificaciones

- Organizacion Documental 2 Actividad Evaluativa 3Documento8 páginasOrganizacion Documental 2 Actividad Evaluativa 3dannielaAún no hay calificaciones

- Trabajo para NegociarrrrrrrrrrrrrrrrrrrrrDocumento22 páginasTrabajo para NegociarrrrrrrrrrrrrrrrrrrrrluvijuAún no hay calificaciones

- Presentacion N 2Documento34 páginasPresentacion N 2Lorena SalazarAún no hay calificaciones

- Matriz de InnovaciónDocumento1 páginaMatriz de InnovaciónDAMARISAún no hay calificaciones

- Cómo hacer una excavadora JCB de cartón en casaDocumento2 páginasCómo hacer una excavadora JCB de cartón en casaTeresa Gutierrez FernandezAún no hay calificaciones

- Terminologia ContableDocumento58 páginasTerminologia ContableEdinson Marquez100% (1)

- Primer Parcial ToledoDocumento73 páginasPrimer Parcial ToledoGerson Adrian Sandoval MezaAún no hay calificaciones

- Guía Taller Identificación ProductoresDocumento3 páginasGuía Taller Identificación ProductoresYERLIS FUENTES TARAZONAAún no hay calificaciones

- Proyecto Empresarial de Vinos ArtesanalesDocumento23 páginasProyecto Empresarial de Vinos ArtesanalesMontse BarronAún no hay calificaciones

- Guia de Aprendizaje 1 - Clasificar DocumentosDocumento12 páginasGuia de Aprendizaje 1 - Clasificar DocumentosLorena VelandiaAún no hay calificaciones

- GUIA - 2 Organizacion de DocumentosDocumento11 páginasGUIA - 2 Organizacion de Documentosedier julian angarita machadoAún no hay calificaciones

- Fondo EmprenderDocumento17 páginasFondo EmprenderSilvia FlorezAún no hay calificaciones

- Diseño y confección de ropa para bebésDocumento12 páginasDiseño y confección de ropa para bebésGeneziz MƌrquezAún no hay calificaciones

- Acta #1 Papas MargaritaDocumento2 páginasActa #1 Papas MargaritaYuleimis Silgado MedinaAún no hay calificaciones

- Guia Semana 29 CODIFICACIÓN DE INVENTARIOSDocumento9 páginasGuia Semana 29 CODIFICACIÓN DE INVENTARIOSgestiondenegocios100% (1)

- Protocolo KiotoDocumento1 páginaProtocolo KiotoRonaldo GuerreroAún no hay calificaciones

- Solicitud de Alta de Proveedor (CENCOSUD)Documento1 páginaSolicitud de Alta de Proveedor (CENCOSUD)Kimisu YonAún no hay calificaciones

- Unidad I Sistema ContableDocumento6 páginasUnidad I Sistema ContableMartaAún no hay calificaciones

- Manual de Políticas ComercialesDocumento10 páginasManual de Políticas ComercialesDarly Gomez MontesAún no hay calificaciones

- Instituto Técnico Financiero Boliviano Holandés: Carrera de Comercio Internacional Y Administracion AduaneraDocumento184 páginasInstituto Técnico Financiero Boliviano Holandés: Carrera de Comercio Internacional Y Administracion AduaneraJuan Pablo Cusi CachagaAún no hay calificaciones

- Formalidad para La Presentacion Del Legajo ContableDocumento1 páginaFormalidad para La Presentacion Del Legajo ContableAnonymous 8ftrZJCVAún no hay calificaciones

- GD-F-017 Formato Identificación Rótulo CarpetaDocumento15 páginasGD-F-017 Formato Identificación Rótulo CarpetaAdriana Marcela Nuñez CalderonAún no hay calificaciones

- Indice de ProyectoDocumento2 páginasIndice de Proyectotomgrn415100% (1)

- Exportación de Café Verde en Grano Esperanza BlancoDocumento10 páginasExportación de Café Verde en Grano Esperanza BlancoMaSter TopsAún no hay calificaciones

- Tarea Virtual 2 COMERCIO EXTERIOR. ASS 97 RONALDocumento6 páginasTarea Virtual 2 COMERCIO EXTERIOR. ASS 97 RONALJohnny Romero100% (1)

- Induccion Al Mercado LaboralDocumento16 páginasInduccion Al Mercado LaboralSol Fernanda BaylonAún no hay calificaciones

- Marco SituacionalDocumento9 páginasMarco SituacionalPablo Paniagua VillalobosAún no hay calificaciones

- Evento Proyecto FormativoDocumento12 páginasEvento Proyecto FormativoNIKOLLAún no hay calificaciones

- Planilla Arqueo CajaDocumento4 páginasPlanilla Arqueo Cajadiana peñaAún no hay calificaciones

- Presupuesto Proyecto de Animacion 2Documento3 páginasPresupuesto Proyecto de Animacion 2Canciones InéditasAún no hay calificaciones

- Documentacion Arancelaria PDFDocumento45 páginasDocumentacion Arancelaria PDFNATHALY NICOLE AMAU MONTESAún no hay calificaciones

- Trámites quejas CORPOCHIVORDocumento5 páginasTrámites quejas CORPOCHIVORmafe betancourtAún no hay calificaciones

- Trámites Legales para Crear EmpresaDocumento4 páginasTrámites Legales para Crear Empresamarcos SAún no hay calificaciones

- Formato Seguimiento Asignacion de CitasDocumento7 páginasFormato Seguimiento Asignacion de CitasYira Marcela GuerraAún no hay calificaciones

- Calendario de EntregasDocumento2 páginasCalendario de EntregasBerumen MiguelAún no hay calificaciones

- Guia Municipal RifcamDocumento102 páginasGuia Municipal RifcamGonzalo ZambranaAún no hay calificaciones

- Investigación de Las 4 PDocumento8 páginasInvestigación de Las 4 PYarithzaAún no hay calificaciones

- 007 Formulario Registro Ambiental Industrial1Documento11 páginas007 Formulario Registro Ambiental Industrial1Eduardo CorsAún no hay calificaciones

- Ejercicios de Clasificacion Arancelaria Parte IDocumento3 páginasEjercicios de Clasificacion Arancelaria Parte ILuciano GalloAún no hay calificaciones

- Firma Digital en Bolivia: Marco legal y aplicacionesDocumento8 páginasFirma Digital en Bolivia: Marco legal y aplicacionesjhonny ramiro mamani garciaAún no hay calificaciones

- SUNAT Misión VisiónDocumento9 páginasSUNAT Misión VisiónHugo De la CruzAún no hay calificaciones

- Ejercicios de Gastos Head CountDocumento3 páginasEjercicios de Gastos Head CountMelissa IsuizaAún no hay calificaciones

- Proyecto de GradoDocumento63 páginasProyecto de GradoArmando SolizAún no hay calificaciones

- Tablero retención documentalDocumento126 páginasTablero retención documentalLeydy Angelica DAZA ARIAS100% (1)

- Cartilla Informativa Nuevo Padron de Importadores PDFDocumento8 páginasCartilla Informativa Nuevo Padron de Importadores PDFRodinho JimenezAún no hay calificaciones

- Precedencia y Orden de Banderas en ElDocumento4 páginasPrecedencia y Orden de Banderas en ElSTEFANYAún no hay calificaciones

- Curso Complementario de Liquidacion de Nomina y Prestaciones Sociales PDFDocumento36 páginasCurso Complementario de Liquidacion de Nomina y Prestaciones Sociales PDFalexita11Aún no hay calificaciones

- Nuevo SIGAD v1 0Documento23 páginasNuevo SIGAD v1 0MrPrincess100% (2)

- Ficha Empresarial TitosDocumento15 páginasFicha Empresarial TitosDerick HerreraAún no hay calificaciones

- Contrato de Compraventa Internacional deDocumento4 páginasContrato de Compraventa Internacional deDiego RiveraAún no hay calificaciones

- SenapiDocumento13 páginasSenapikevin100% (1)

- Trabajo DirijidoDocumento54 páginasTrabajo DirijidoArmando SolizAún no hay calificaciones

- Ejemplo - Construcción de Instrumentos de Medición en La Matriz OperacionalDocumento1 páginaEjemplo - Construcción de Instrumentos de Medición en La Matriz OperacionalRobertz ManriqueAún no hay calificaciones

- Diplo - Supply - Chain - Management 2023Documento15 páginasDiplo - Supply - Chain - Management 2023Andy Josue RiveraAún no hay calificaciones

- LB1810E2 LL Butene Mfi 1 Con Ads - En.es PDFDocumento1 páginaLB1810E2 LL Butene Mfi 1 Con Ads - En.es PDFOScarAún no hay calificaciones

- HD2000F esMX ASTMDocumento1 páginaHD2000F esMX ASTMLFCV5Aún no hay calificaciones

- HF2208S3 Esp Rev.1Documento2 páginasHF2208S3 Esp Rev.1Issem IngenieríaAún no hay calificaciones

- HDPE HDF8000-Brasken - PEDocumento1 páginaHDPE HDF8000-Brasken - PEkeny arandaAún no hay calificaciones

- GM9450F esMX ASTMDocumento1 páginaGM9450F esMX ASTMLFCV5Aún no hay calificaciones