Guía Completa sobre Hangares

Cargado por

Dudu GómezGuía Completa sobre Hangares

Cargado por

Dudu GómezCommon questions

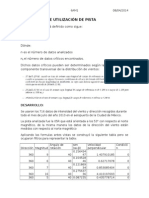

Con tecnología de IAMRO (Maintenance, Repair, and Overhaul) operations classified from Classes A to D dictate their scope, specialization, and technical requirements. Class A includes complete aircraft, engines, and components, necessitating extensive facilities, diversified expertise, and more rigorous quality controls. Class B focuses on engines only, demanding specialized machinery and skilled technicians to handle complex powerplant systems. Class C addresses components, which involves detailed precision work and diagnostic capabilities. Class D pertains to self-contained, involving non-destructive testing and often needing specialized equipment for testing integrity without disassembly. The classification affects equipment, staff qualifications, and regulatory compliance necessary for each type's unique demands .

Integrated office spaces within hangars enhance operational efficiency by centralizing administrative and technical functions in proximity to maintenance activities. This setup allows for quick information exchange and decision-making, fostering better coordination between maintenance crews and management. It also provides maintenance personnel with immediate access to data, tools, and workspace necessary to complete records and studies, thus streamlining workflow and reducing delay. Efficient layout design of segregated but accessible areas enhances safety by preventing cross-contamination while facilitating concurrent tasks through spatial organization .

'Glove type' hangar designs are tailored to fit specific aircraft, optimizing space by adapting the hangar's dimensions and entrance to the aircraft's unique shape. This specialization results in reduced construction and operational costs, as less space needs to be covered and conditioned, thus lowering heating or cooling expenses. Structurally, these hangars economize material use, focusing durability where it's most needed, and minimize unnecessary space, which also enhances logistical efficiency by reducing maintenance and maneuvering space requirements. Such targeted design ensures that hangars align precisely with the operational requirements of particular aircraft types .

Different types of hangar doors are designed to optimize space and operation through their specific movement mechanics. Canopy doors, counterbalanced with cables and weights, open vertically to maximize interior space effectively. Vertical sliding doors consist of horizontal panels moving at varying speeds, allowing simultaneous destination arrival, thus optimizing space time efficiently. Sliding doors, which are less expensive, involve panels moving on designated tracks at different speeds, ensuring seamless opening and closing cycles. These door designs contribute to efficient spatial utilization, particularly in facilities that handle large aircraft, facilitating maintenance operations without spatial constraints .

Proximity between hangars and runways is emphasized to minimize taxiing time and potential damage during aircraft movement. This arrangement reduces the risk of operational delays and accidents, enhancing overall efficiency and safety in aircraft operations. Immediate proximity ensures aircraft can be easily moved for take-off or post-landing maintenance, aligning with best practices for time-critical aerospace operations. Additionally, it enables quick access to runways, facilitating faster response in logistics and any emergency scenarios that may arise .

Aircraft hangars are primarily designed to house aircraft and provide protection from environmental phenomena and potential collisions due to wind displacement. Key characteristics include structures to prevent entry of rain, wind, hail, and dust, as well as a sealed floor to minimize dust accumulation. Hangars must be large enough to accommodate aircraft undergoing maintenance, with a location near runways to facilitate easy taxiing. They also need proximity to utilities like gas, water, and electricity, and provide a secure work environment, including separate work areas to prevent contamination. The structure typically involves elements such as pórtico transversal, lateral and frontal frameworks, along with foundation and doors, which might include options like canopy doors for efficient space utilization .

Hangars like Archspan and voladizo address diverse airport needs through distinctive structural designs. Archspan hangars, characterized by radial tension, support expansive widths over 200 meters, ideal for large aircraft like jumbo jets, fulfilling capacity demands for major airline hubs. The tensioned structure allows vast clear-span areas without internal supports, maximizing interior space efficiency. Conversely, voladizo hangars, with cantilever designs, facilitate future expansion and are suitable for long configurations—up to 1 kilometer—when ample storage and maintenance space behind the hangar is required. They balance spatial demands against economic efficiency, adapting to airports requiring customizable expansion options .

Hangar design elements, such as door alignment and floor sealing, significantly impact maintenance operations by enhancing efficiency, safety, and environmental protection. Doors aligned in a continuous row with service platforms facilitate swift aircraft movement, optimizing time and labor during entry and exit. Floor sealing is crucial to minimize dust, which could damage sensitive equipment or contaminate work areas, thereby reducing equipment wear and ensuring better environmental conditions for maintenance tasks. Such considerations ensure logistical fluidity and help maintain high operational standards within maintenance facilities .

Industry certifications are pivotal for Fixed Base Operators (FBOs) to ensure service standards and operational safety. Certifications such as those issued by the DGAC (Dirección General de Aviación Civil) validate that an FBO has met prescribed criteria, including qualified, trained personnel and adequate equipment. These certifications imply a commitment to industry standards, impacting service quality by ensuring consistent, reliable, and safe operations. Without such certifications, an FBO would struggle to offer assured service levels, potentially risking customer trust and safety of operations .

A Fixed Base Operator (FBO) offers specialized aeronautical services ranging from fuel supply to aircraft parking, distinguishing itself from typical airport services by focusing on personal touch and premium experiences. Clients might prefer FBO services as they offer enhanced luxury, convenience, and privacy, such as access to conference rooms, personalized attention, and exclusive amenities like cafes, bathrooms, internet, and hangars. These operators often operate as a private terminal adjunct to main airports, catering specifically to high-end, executive clientele who value differentiated service in their travel experiences .