Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Resumen de Resultados Torre Sl2

Cargado por

Joaquin Diaz CandeloDerechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Resumen de Resultados Torre Sl2

Cargado por

Joaquin Diaz CandeloCopyright:

Formatos disponibles

h a n g e Pro h a n g e Pro

XC d XC d

F- F-

uc

uc

PD

PD

!

!

W

W

t

t

O

O

N

N

y

y

bu

bu

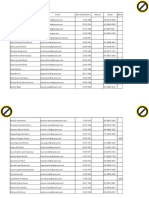

Project Name : TORRE SL2-1

to

to

ww

ww

om

om

k

k

lic

lic

Project Notes: PROYECTO ECUADOR

C

C

.c

.c

w

w

tr e tr re

ar

.

.

ac ac

k e r -Project

s o ft w File : C:\Users\sarit\Desktop\JOAQUIN\ECUADOR\14-06-20_MODELOS FINALES\DOBLE CIRCUITO\SL2-1\sl2_def.tow k e r- s o ft w a

Date run : 1:06:46 p. m. jueves, 29 de octubre de 2020

by : Tower Version 9.20

Licensed to : JOAQUIN DIAZ CANDELO

Successfully performed nonlinear analysis

Member check option: ASCE 10

Connection rupture check: Not Checked

Crossing diagonal check: Fixed

Loads from file: c:\users\sarit\desktop\joaquin\ecuador\14-06-20_modelos finales\doble circuito\sl2-1\cargas.lca

*** Analysis Results:

Maximum element usage is 148.06% for Angle "72P" in load case "ROT. 2COND" NG

Maximum insulator usage is 0.18% for Clamp "L11" in load case "SOBCAR V (2CON)"

Summary of Joint Support Reactions For All Load Cases:

Load Case Joint

Long. Tran. Vert. Shear Tran. Long. Vert. Bending Found.

Label

Force Force Force Force Moment Moment Moment Moment Usage

(kN) (kN) (kN) (kN) (kN-m) (kN-m) (kN-m) (kN-m) %

------------------------------------------------------------------------------------------

CARGA V + T ANCLAJEP -14.29 -16.35 133.13 21.71 -4.66 5.28 0.06 7.05 0.00

CARGA V + T ANCLAJEX 6.32 -8.32 -58.11 10.45 -1.46 -2.05 0.04 2.52 0.00

CARGA V + T ANCLAJEXY -6.32 -8.32 -58.11 10.45 -1.46 2.05 -0.04 2.52 0.00

CARGA V + T ANCLAJEY 14.29 -16.35 133.13 21.71 -4.66 -5.28 -0.06 7.05 0.00

SOBCAR V (2CON) ANCLAJEP -9.23 -9.63 85.88 13.33 -3.34 3.49 0.01 4.83 0.00

SOBCAR V (2CON) ANCLAJEX 0.43 -0.77 -3.39 0.88 0.04 -0.10 0.01 0.11 0.00

SOBCAR V (2CON) ANCLAJEXY -0.43 -0.77 -3.39 0.88 0.04 0.10 -0.01 0.11 0.00

SOBCAR V (2CON) ANCLAJEY 9.23 -9.63 85.88 13.33 -3.34 -3.49 -0.01 4.83 0.00

ROT. G + C ANCLAJEP -10.24 -11.21 96.01 15.18 -3.60 3.85 0.03 5.27 0.00

ROT. G + C ANCLAJEX -1.84 1.05 17.73 2.11 1.08 0.82 0.02 1.36 0.00

ROT. G + C ANCLAJEXY -2.40 -3.30 -22.11 4.08 -0.53 0.77 -0.02 0.94 0.00

ROT. G + C ANCLAJEY 6.14 -6.99 56.94 9.30 -1.93 -2.20 -0.02 2.93 0.00

ROT. 2COND ANCLAJEP -17.85 -9.55 119.65 20.24 -5.52 3.46 -0.21 6.52 0.00

ROT. 2COND ANCLAJEX -4.22 10.79 69.30 11.59 2.05 3.52 -0.14 4.07 0.00

ROT. 2COND ANCLAJEXY -4.02 -12.77 -66.95 13.38 -1.02 3.06 -0.13 3.22 0.00

ROT. 2COND ANCLAJEY -3.04 -7.51 19.13 8.10 0.67 -1.97 -0.20 2.08 0.00

DESB. LONG ANCLAJEP -17.41 -17.41 151.23 24.62 -5.67 5.67 -0.00 8.02 0.00

DESB. LONG ANCLAJEX -5.03 2.67 35.49 5.70 1.76 1.05 0.06 2.05 0.00

DESB. LONG ANCLAJEXY -9.68 -9.62 -77.58 13.64 -2.40 2.39 0.00 3.38 0.00

DESB. LONG ANCLAJEY 3.19 -5.61 40.91 6.45 -1.29 -2.00 -0.06 2.38 0.00

Note: Summary of Joint Support Reactions For All Load Cases in Direction of Leg not printed

because none of the angle members attached to foundation joints have a group type of 'Leg'.

Overturning Moment Summary For All Load Cases:

Load Case Transverse Longitudinal Resultant

Moment Moment Moment

(kN-m) (kN-m) (kN-m)

--------------------------------------------------

CARGA V + T 1474.967 -0.000 1474.967

SOBCAR V (2CON) 688.495 -0.000 688.495

ROT. G + C 606.708 304.284 678.737

ROT. 2COND 526.084 913.022 1053.743

DESB. LONG 903.214 861.418 1248.133

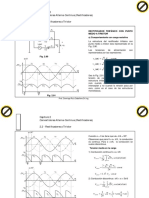

*** Overall summary for all load cases - Usage = Maximum Stress / Allowable Stress

Printed capacities do not include the strength factor entered for each loadcase.

Group Summary (Compression Portion):

Group Group Angle Angle MaxSteel

Max Comp. Comp. Comp. L/R Comp. Conn. Comp. Conn. RLX RLY RLZ L/R Length Curve No. Of

Label Desc. Type Size Strength

Usage Use In Control Force Control Capacity Shear Bearing Comp. No. Bolts

Comp. Member Load Case Capacity Capacity Member Comp.

(MPa) % % (kN) (kN) (kN) (kN) (m)

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------

EP EXT-PAT SAE 4X4X0.25 345.0 43.44 43.44 118P -124.735DESB. LONG 287.155 1120.000 544.354 1.000 1.000 1.000 78.60 1.587 1 8

TP TRANS-PAT SAE 2X2X0.25 345.0 17.91 17.91 82X -2.794CARGA V + 15.602 1120.000 544.354 1.000 1.000 1.000 276.96 2.751 4 8

DP DIAGO-PAT SAE 2X2X0.25 345.0 27.55 27.55 112P -12.755DESB. LONG 46.299 1120.000 544.354 1.000 1.000 1.000 160.78 1.597 4 8

DP1 DIAPA1 SAE 3X3X0.25 345.0 0.00 0.00 0.000 0.000 0.000 0.000 0.000 0.000 0.000 0.00 0.000 0 0

CCP COLUM-CUER-PI SAE 4X4X0.5 345.0 29.67 29.67 58P -134.477DESB. LONG 453.256 1120.000 1088.708 1.000 1.000 1.000 102.25 2.031 1 8

DCP DIAG-CUER-PIR SAE 2.5X2.5X0.1875 345.0 0.00 0.00 0.000 0.000 0.000 0.000 0.000 0.000 0.000 0.00 0.000 0 0

DCP1 DIAG-C-P SAE 2.5X2.5X0.1875 345.0 148.06 148.06 72P -12.149ROT. 2COND 8.205 1120.000 408.265 1.000 1.000 1.000 374.11 4.704 4 8 NG

CCC COLUM-CUER-CEN SAE 4X4X0.5 345.0 20.47 20.47 40P -81.944DESB. LONG 742.210 400.340 816.531 1.000 1.000 1.000 50.35 1.000 1 6

CCC1 COLUMCUCE1 SAE 3X3X0.3125 345.0 21.06 21.06 34P -46.774DESB. LONG 222.118 400.340 510.332 1.000 1.000 1.000 100.26 1.500 1 6

TCC TRANS-CUER-CEN SAE 2X2X0.25 345.0 68.33 68.33 5P -20.165SOBCAR V ( 29.510 400.340 408.265 1.000 1.000 1.000 201.38 2.000 4 6

DCC DIA-CUER-CEN SAE 2X2X0.25 345.0 83.22 83.22 16Y -15.717ROT. 2COND 18.887 400.340 408.265 1.000 1.000 1.000 251.73 2.500 4 6

DCC1 DICUCE1 SAE 2.5X2.5X0.25 345.0 83.76 83.76 36Y -31.581ROT. 2COND 37.703 400.340 408.265 1.000 1.000 1.000 200.46 2.500 4 6

BB BASE-BRAZ SAE 2.5X2.5X0.375 345.0 29.54 29.54 29P -30.058SOBCAR V ( 101.742 400.340 612.398 1.000 1.000 1.000 147.13 1.820 4 6

DB DIAG-BRAZ SAE 2X2X0.25 345.0 38.21 38.21 9P -3.166ROT. 2COND 8.284 400.340 408.265 1.000 1.000 1.000 380.10 3.775 4 6

DB1 DIBRA1 SAE 2.5X2.5X0.375 345.0 15.11 15.11 14P -9.584SOBCAR V ( 63.439 400.340 612.398 1.000 1.000 1.000 186.33 2.305 4 6

G GUARDA SAE 3X3X0.375 345.0 14.01 14.01 1P -13.945ROT. 2COND 99.531 400.340 612.398 1.000 1.000 1.000 164.29 2.449 4 6

Group Summary (Tension Portion):

Group Group Angle Angle MaxSteel

Max Tension Tension Tension Net Tens. Conn. Tens. Conn. Tens. Conn. Length No. Of No. Of Hole

Label Desc. Type Size Strength

Usage Use In Control Force Control Section Shear Bearing Rupture Tens. Bolts Holes Diameter

Tens. Member Load Case Capacity Capacity Capacity Capacity Member Tens.

(MPa) % % (kN) (kN) (kN) (kN) (kN) (m) (cm)

----------------------------------------------------------------------------------------------------------------------------------------------------------------------

Dulhunty Industries - sl2_def Page 1/2

h a n g e Pro h a n g e Pro

XC d XC d

F- F-

uc

uc

PD

PD

!

!

W

W

t

t

O

O

N

N

y

y

bu

bu

EP EXT-PAT SAE 4X4X0.25 345.0 43.44 18.94 91XY 67.289DESB. LONG 355.294 1120.000 544.354 0.000 1.587 8 2.000 1.746

to

to

ww

ww

om

om

k

k

lic

lic

TP TRANS-PAT SAE 2X2X0.25 345.0 17.91 3.52 81P 4.671CARGA V + 132.713 1120.000 544.354 0.000 2.751 8 2.000 1.746

C

C

.c

.c

w

w

tr re tr re

.

.

ac ac

k e r - s o f t w a DP DIAGO-PAT SAE 2X2X0.25 345.0 27.55 5.47 112XY 7.257ROT. 2COND 132.713 1120.000 544.354 0.000 1.597 8 2.000 1.746 k e r- s o ft w a

DP1 DIAPA1 SAE 3X3X0.25 345.0 0.00 0.00 0.000 0.000 0.000 0.000 0.000 0.000 0 0.000 0

CCP COLUM-CUER-PI SAE 4X4X0.5 345.0 29.67 10.63 58XY 72.444DESB. LONG 681.652 1120.000 1088.708 0.000 2.031 8 2.000 1.746

DCP DIAG-CUER-PIR SAE 2.5X2.5X0.1875 345.0 0.00 0.00 0.000 0.000 0.000 0.000 0.000 0.000 0 0.000 0

DCP1 DIAG-C-P SAE 2.5X2.5X0.1875 345.0 148.06 16.42 63XY 23.549ROT. 2COND 143.383 1120.000 408.265 0.000 3.021 8 2.000 1.746 NG

CCC COLUM-CUER-CEN SAE 4X4X0.5 345.0 20.47 9.64 40XY 38.608DESB. LONG 681.652 400.340 816.531 0.000 1.000 6 2.000 1.746

CCC1 COLUMCUCE1 SAE 3X3X0.3125 345.0 21.06 6.98 34XY 20.984DESB. LONG 300.551 400.340 510.332 0.000 1.500 6 2.000 1.746

TCC TRANS-CUER-CEN SAE 2X2X0.25 345.0 68.33 18.63 3P 24.720SOBCAR V ( 132.713 400.340 408.265 0.000 2.000 6 2.000 1.746

DCC DIA-CUER-CEN SAE 2X2X0.25 345.0 83.22 12.57 17Y 16.684ROT. 2COND 132.713 400.340 408.265 0.000 2.500 6 2.000 1.746

DCC1 DICUCE1 SAE 2.5X2.5X0.25 345.0 83.76 16.70 38XY 31.451ROT. 2COND 188.358 400.340 408.265 0.000 2.500 6 2.000 1.746

BB BASE-BRAZ SAE 2.5X2.5X0.375 345.0 29.54 4.39 28Y 11.877ROT. 2COND 270.297 400.340 612.398 0.000 1.820 6 2.000 1.746

DB DIAG-BRAZ SAE 2X2X0.25 345.0 38.21 24.83 32P 32.953SOBCAR V ( 132.713 400.340 408.265 0.000 3.775 6 2.000 1.746

DB1 DIBRA1 SAE 2.5X2.5X0.375 345.0 15.11 3.07 11P 8.303SOBCAR V ( 270.297 400.340 612.398 0.000 1.000 6 2.000 1.746

G GUARDA SAE 3X3X0.375 345.0 14.01 3.15 1X 11.183ROT. 2COND 354.877 400.340 612.398 0.000 2.449 6 2.000 1.746

*** Maximum Stress Summary for Each Load Case

Summary of Maximum Usages by Load Case:

Load Case Maximum Element Element

Usage % Label Type

----------------------------------------

CARGA V + T 65.97 72Y Angle

SOBCAR V (2CON) 68.33 5P Angle

ROT. G + C 56.60 44P Angle

ROT. 2COND 148.06 72P Angle NG

DESB. LONG 70.11 67P Angle

Summary of Insulator Usages:

Insulator Insulator Maximum Load Case Weight

Label Type Usage % (N)

---------------------------------------------------

G Clamp 0.09 ROT. G + C 0.0

L11 Clamp 0.18 SOBCAR V (2CON) 0.0

L21 Clamp 0.13 CARGA V + T 0.0

L12 Clamp 0.18 SOBCAR V (2CON) 0.0

L22 Clamp 0.13 CARGA V + T 0.0

L13 Clamp 0.13 CARGA V + T 0.0

L23 Clamp 0.13 CARGA V + T 0.0

*** Weight of structure (N):

Weight of Angles*Section DLF: 87265.3

Total: 87265.3

*** End of Report

Dulhunty Industries - sl2_def Page 2/2

También podría gustarte

- Diseño y Cálculo de Tanques de AlmacenamientoDocumento130 páginasDiseño y Cálculo de Tanques de AlmacenamientoA. C. V.98% (89)

- Especificaciones Tecnicas de Obra GruesaDocumento48 páginasEspecificaciones Tecnicas de Obra Gruesaarqmcelis1614100% (5)

- Pinout Peugeot 306 Boch MP 7.2Documento6 páginasPinout Peugeot 306 Boch MP 7.2ramon hidalgoAún no hay calificaciones

- NTP 613Documento41 páginasNTP 613angelAún no hay calificaciones

- Sistema de Combustible Peugeot 306Documento4 páginasSistema de Combustible Peugeot 306ramon hidalgoAún no hay calificaciones

- 83211516Documento18 páginas83211516Juan Carlos Cahuasquí IntriagoAún no hay calificaciones

- Códigos de Erro 200D (2) - SolenóidesDocumento4 páginasCódigos de Erro 200D (2) - SolenóidesMANUTENÇÃO CAVA ENGENHARIA100% (1)

- Torres PetronasDocumento16 páginasTorres PetronasOmarVilca100% (1)

- 1.a Pancreas Exocrino. Sabiston. Tratado de Cirugia 20a EdicionDocumento12 páginas1.a Pancreas Exocrino. Sabiston. Tratado de Cirugia 20a Edicionmarcela belen100% (1)

- Abdón Ubidia y El Eterno Retorno Del Tiempo - Leonardo Parrini - Ciencia Ficción en EcuadorDocumento6 páginasAbdón Ubidia y El Eterno Retorno Del Tiempo - Leonardo Parrini - Ciencia Ficción en EcuadorAngélica EspinelAún no hay calificaciones

- Mapa 2Documento1 páginaMapa 2AXEL GABRIEL MORON MOZOAún no hay calificaciones

- Mapa 3Documento1 páginaMapa 3AXEL GABRIEL MORON MOZOAún no hay calificaciones

- Infografía ProgramacionDocumento2 páginasInfografía ProgramacionjoseAún no hay calificaciones

- Relatorio de Usuarios 23 May 2018Documento6 páginasRelatorio de Usuarios 23 May 2018Augusto CedaroAún no hay calificaciones

- Octavio Ianni El Estado Oligarquico PDFDocumento1 páginaOctavio Ianni El Estado Oligarquico PDFHugo AndradeAún no hay calificaciones

- ClaseDocumento16 páginasClaseCielitol Mariam CollantzAún no hay calificaciones

- Laboratorio IV - VDocumento6 páginasLaboratorio IV - VJuan Pablo TiqueAún no hay calificaciones

- Estilograficas PDFDocumento1 páginaEstilograficas PDFpapaquinAún no hay calificaciones

- 7 PDFDocumento4 páginas7 PDFJavi ColoAún no hay calificaciones

- Para Una Lectura de Facundo, de D. F Sarmiento JitrikDocumento10 páginasPara Una Lectura de Facundo, de D. F Sarmiento JitrikAngélica EspinelAún no hay calificaciones

- Tomas, L El Nadador Trans Que Ganó Demasiado 2Documento9 páginasTomas, L El Nadador Trans Que Ganó Demasiado 2Juan Pablo DuarteAún no hay calificaciones

- DFDFDDocumento15 páginasDFDFDAndrés JimaAún no hay calificaciones

- CFGTES MMP Tarea02Documento2 páginasCFGTES MMP Tarea02eltpm19Aún no hay calificaciones

- Tiringuis Tinguis 2Documento3 páginasTiringuis Tinguis 2john.angelAún no hay calificaciones

- Estudio de TiemposDocumento1 páginaEstudio de Tiemposjoseangelrojassoledad31Aún no hay calificaciones

- Cicatrizacion Sabiston 20edDocumento33 páginasCicatrizacion Sabiston 20edJosue LayedraAún no hay calificaciones

- BanescOnline Lunes, 29 de Junio de 2020 07 - 26 - 09 652 AmDocumento1 páginaBanescOnline Lunes, 29 de Junio de 2020 07 - 26 - 09 652 AmAbraham GonzalezAún no hay calificaciones

- Elman - Todos Despiden A La Globalización Menos VosDocumento14 páginasElman - Todos Despiden A La Globalización Menos VosAngélica EspinelAún no hay calificaciones

- Rebote Del Centralizado (Tutorial)Documento7 páginasRebote Del Centralizado (Tutorial)Baterias BrownAún no hay calificaciones

- Elman - No Voy A Pagar Por Esta MierdaDocumento15 páginasElman - No Voy A Pagar Por Esta MierdaAngélica EspinelAún no hay calificaciones

- Tiringuis TinguisDocumento2 páginasTiringuis Tinguisjohn.angelAún no hay calificaciones

- CAP2conv CacccDocumento31 páginasCAP2conv CacccincógnitoAún no hay calificaciones

- Como Llora Una Estrella PDFDocumento1 páginaComo Llora Una Estrella PDFEzequiel HERNANDEZ FAún no hay calificaciones

- 16.3.2 Packet Tracer - Troubleshoot Ipv4 and Ipv6 Static and Default Routes - Physical Mode - Es XLDocumento3 páginas16.3.2 Packet Tracer - Troubleshoot Ipv4 and Ipv6 Static and Default Routes - Physical Mode - Es XLcristian zuletaAún no hay calificaciones

- Consideraciones Acerca Del Concepto de Muerte Bajo Criterios Neurologicos Muerte Encefalica 1Documento5 páginasConsideraciones Acerca Del Concepto de Muerte Bajo Criterios Neurologicos Muerte Encefalica 1rociosuarez0614Aún no hay calificaciones

- Monosacaridos Derivados MathewsDocumento4 páginasMonosacaridos Derivados MathewsMary Alejandra MontielAún no hay calificaciones

- 1.2 Art Sistema de FrenosDocumento1 página1.2 Art Sistema de FrenosOrlandoAún no hay calificaciones

- Res. 717-2011 (SEC) - Aprueba y Reemplaza Protocolos de Análisis y Ensayos para Productos de Combustibles Que Se IndicanDocumento2 páginasRes. 717-2011 (SEC) - Aprueba y Reemplaza Protocolos de Análisis y Ensayos para Productos de Combustibles Que Se IndicanpmAún no hay calificaciones

- 1.4 Art SoldaduraDocumento1 página1.4 Art SoldaduraOrlandoAún no hay calificaciones

- CAP2conv CaccdDocumento29 páginasCAP2conv CaccdincógnitoAún no hay calificaciones

- Document 4 El Horario de PatriciaDocumento2 páginasDocument 4 El Horario de PatriciaTyphaine SerieysAún no hay calificaciones

- Constituciones Del 79 y 93Documento1 páginaConstituciones Del 79 y 93Christian R. BuenoAún no hay calificaciones

- Escuelas y Dogmatica PenalDocumento2 páginasEscuelas y Dogmatica Penalcelina.charafAún no hay calificaciones

- Porque Insurgimos MBR200 0792Documento7 páginasPorque Insurgimos MBR200 0792servitelAún no hay calificaciones

- Yván Figueroa - Imputación Objetiva en El Homicidio ConcausalDocumento4 páginasYván Figueroa - Imputación Objetiva en El Homicidio ConcausalCésarAugustoGuevaraColmenaresAún no hay calificaciones

- Caixa de Fusível 2Documento1 páginaCaixa de Fusível 2Moises fernandesAún no hay calificaciones

- Gestion de Proyectos MS Project - Oficina TributariaDocumento5 páginasGestion de Proyectos MS Project - Oficina TributariaJORGE LUIS VEGA OÑAAún no hay calificaciones

- Sistemas de Barras Colectoras - 5Documento1 páginaSistemas de Barras Colectoras - 5daniel ruiz fraustoAún no hay calificaciones

- Amas de Casa Infieles 3 - La Regla de La Hermanita - Poringa!Documento30 páginasAmas de Casa Infieles 3 - La Regla de La Hermanita - Poringa!Dante Ramos MuñozAún no hay calificaciones

- Amas de Casa Infieles 3 - La Regla de La Hermanita - Poringa!Documento30 páginasAmas de Casa Infieles 3 - La Regla de La Hermanita - Poringa!Dante Ramos MuñozAún no hay calificaciones

- Renault Scenic 2.ol 2003Documento1 páginaRenault Scenic 2.ol 2003noeAún no hay calificaciones

- Sistema de Admision Peugeot 306Documento5 páginasSistema de Admision Peugeot 306ramon hidalgoAún no hay calificaciones

- Complemento Directo e IndirectoDocumento2 páginasComplemento Directo e Indirectomiscosas100% (1)

- Mantas Aislantes de Hule: Manta LisaDocumento1 páginaMantas Aislantes de Hule: Manta LisaRENATOAún no hay calificaciones

- Gmail - Pasó McCarthy y Dijo Che, No DaDocumento16 páginasGmail - Pasó McCarthy y Dijo Che, No DaAngélica EspinelAún no hay calificaciones

- Elman - TikTok y El Fin de La Globalización VER PREGUNTASDocumento16 páginasElman - TikTok y El Fin de La Globalización VER PREGUNTASAngélica EspinelAún no hay calificaciones

- Manual de Seguridad y Salud en El Trabajo PeruDocumento20 páginasManual de Seguridad y Salud en El Trabajo PeruNehemer QuispeAún no hay calificaciones

- El Cuento Popular y El LiterarioDocumento2 páginasEl Cuento Popular y El LiterarioYolanda MartinAún no hay calificaciones

- Sinónimos PDFDocumento2 páginasSinónimos PDFYolanda MartinAún no hay calificaciones

- 05e) Teoría de CircuitosDocumento5 páginas05e) Teoría de CircuitosCristian Eduardo Garay CarrenoAún no hay calificaciones

- Página 58 Desde 455651539-El-Croquis-203-HArquitectes-2010-2020 PDFDocumento1 páginaPágina 58 Desde 455651539-El-Croquis-203-HArquitectes-2010-2020 PDFAndrés ZeaAún no hay calificaciones

- Evaluacià N Audiolà Gica CortaDocumento1 páginaEvaluacià N Audiolà Gica Cortapolett muñozAún no hay calificaciones

- Preliminar Torres de SuspensionDocumento1 páginaPreliminar Torres de SuspensionJoaquin Diaz CandeloAún no hay calificaciones

- Estudio de Vigas Metalicas Con Losas deDocumento181 páginasEstudio de Vigas Metalicas Con Losas deJoaquin Diaz CandeloAún no hay calificaciones

- Informe de Análisis de La Estructura - 1Documento44 páginasInforme de Análisis de La Estructura - 1Joaquin Diaz CandeloAún no hay calificaciones

- Construccion de Recipientes Contenedores de Fondos Cilindricos y OvalesDocumento25 páginasConstruccion de Recipientes Contenedores de Fondos Cilindricos y OvalespetreAún no hay calificaciones

- Informe de Análisis de TensiónDocumento32 páginasInforme de Análisis de TensiónJoaquin Diaz CandeloAún no hay calificaciones

- La Vida EternaDocumento32 páginasLa Vida EternaJoaquin Diaz CandeloAún no hay calificaciones

- 3.vigas Doblem ReforzadasDocumento4 páginas3.vigas Doblem ReforzadasElias Vital BAún no hay calificaciones

- Ficha Técnica Placa RF KnaufDocumento2 páginasFicha Técnica Placa RF KnaufMati SanchezAún no hay calificaciones

- PROBLEMAS CM GQ Propiedades Mecanicas T5Documento2 páginasPROBLEMAS CM GQ Propiedades Mecanicas T5Ana Priscila MurroAún no hay calificaciones

- Capítulo 1 - Factores Que Determinan El Tipo de CimentaciónDocumento55 páginasCapítulo 1 - Factores Que Determinan El Tipo de CimentaciónLigia Cuadros VelásquezAún no hay calificaciones

- Columnas Hormigon Armado H°A°Documento20 páginasColumnas Hormigon Armado H°A°eze_firmatenseAún no hay calificaciones

- Tipos de Ladrilos Que Intervienen en La Construccion de Una ViviendaDocumento3 páginasTipos de Ladrilos Que Intervienen en La Construccion de Una ViviendaWilson Cordova CordovaAún no hay calificaciones

- Presentación Pruebas de DurezaDocumento10 páginasPresentación Pruebas de DurezaHugo Perez CruzAún no hay calificaciones

- MD ArquitecturaDocumento10 páginasMD ArquitecturaKlismann ParedesAún no hay calificaciones

- Leyes Fundamentales de Circuitos MagnéticosDocumento9 páginasLeyes Fundamentales de Circuitos MagnéticosJose ChavezAún no hay calificaciones

- Costos de Materiales en La Construccion 2017Documento54 páginasCostos de Materiales en La Construccion 2017Lupita CarelyAún no hay calificaciones

- Condensadores Vertical y HorizontalDocumento16 páginasCondensadores Vertical y HorizontalLupita LoperenaAún no hay calificaciones

- Teoría Sobre Diseño de MicropilotesDocumento16 páginasTeoría Sobre Diseño de Micropilotesjhilmar alcocerAún no hay calificaciones

- Detalle Ingreso: ProyectoDocumento1 páginaDetalle Ingreso: ProyectoFernando Alonso Cuzziramos GutiérrezAún no hay calificaciones

- CloroprenoDocumento2 páginasCloroprenoCandelario Isaac Brito Rivero100% (1)

- Manto Asfaltico Con Aluminio 3 MMDocumento2 páginasManto Asfaltico Con Aluminio 3 MMAndres Felipe Aranda BalagueraAún no hay calificaciones

- Pandeo CilindrosDocumento26 páginasPandeo CilindrosSantiago EstèfanoAún no hay calificaciones

- 4.3 Procesos Reversibles e IrreversiblesDocumento13 páginas4.3 Procesos Reversibles e IrreversiblesDiana RealAún no hay calificaciones

- Cat. 8 Agosto 2022Documento53 páginasCat. 8 Agosto 2022Yazzmín Ezayd YeemAún no hay calificaciones

- Metrado HonatanDocumento6 páginasMetrado HonatanHonatan Chalco ValenzuelaAún no hay calificaciones

- Estructuras Mercado 2019-Muros de ContenciónDocumento1 páginaEstructuras Mercado 2019-Muros de ContenciónWilson Chinguel CarhualloclloAún no hay calificaciones

- Especificaciones Tecnicas de Arquitectura - JuliacaDocumento140 páginasEspecificaciones Tecnicas de Arquitectura - JuliacayogrungeelAún no hay calificaciones

- Insumos ExcelDocumento22 páginasInsumos ExcelJosué Villanueva QuirozAún no hay calificaciones

- Presupuesto 2013Documento6 páginasPresupuesto 2013Marco Antonio Lima MercadoAún no hay calificaciones

- Tratamiento Termico de Los MetalesDocumento6 páginasTratamiento Termico de Los MetalesValentina Cano LAún no hay calificaciones

- Tipos de Sistemas EstructuralesDocumento13 páginasTipos de Sistemas EstructuralesDiego LozadaAún no hay calificaciones

- Tensión de RoturaDocumento10 páginasTensión de RoturaBram Blas GagoAún no hay calificaciones

- 7 Conductor Preensamblado de Baja TensiónDocumento32 páginas7 Conductor Preensamblado de Baja TensiónEduardo CalfioAún no hay calificaciones