Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Calculos Basicos de La Caña de Azucar0017 PDF

Cargado por

Carlos Tomey0 calificaciones0% encontró este documento útil (0 votos)

28 vistas1 páginaTítulo original

Calculos basicos de la caña de azucar0017.pdf

Derechos de autor

© © All Rights Reserved

Formatos disponibles

PDF o lea en línea desde Scribd

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

© All Rights Reserved

Formatos disponibles

Descargue como PDF o lea en línea desde Scribd

0 calificaciones0% encontró este documento útil (0 votos)

28 vistas1 páginaCalculos Basicos de La Caña de Azucar0017 PDF

Cargado por

Carlos TomeyCopyright:

© All Rights Reserved

Formatos disponibles

Descargue como PDF o lea en línea desde Scribd

Está en la página 1de 1

(With careful control it should be possible to operate condensers with a temperature

difference between vapour and hot water of less than 10°F with a consequent saving of

water or a higher vacuum).

BACAZ = &)

Chapter XT

Comments

() Steam and Bagasse

We have seen that with 12-5% fibre in cane we get 25t of bagasse, which is sufficient for

generating over 60t of steam. ‘This assures an adequate steam supply if vapour bleeding is

practised, but it would not be so with a straight evaporator. If the fibre content of the

cane were to drop below 11%, the steam situation would, however, become precarious

even with a scheme such as that of our Fig. 4.

Many who have been troubled with an inadequate steam supply have been induced to

improve the situation by increasing the boiler efficiency through the installation of

economisers and/or air pre-heaters. The improvement obtainable in this way is, however,

not great (with hot water available for boiler feed and with bagasse as fuel), and the cost

of such installations—and of their maintenance—is high. It also seems wrong to produce

more steam than necessary, though efficiently, only to waste some of it through inefficient

utilization of the steam. A factory which has steam troubles, and which is not making good use

of the possibilities of vapour bleeding, ought to improve the efficiency of steam utilization

before spending money on additions to its boilers. In fact better boiler efficiency will in

many cases be obtained when less steam is used and the boilers are not forced.

There are special cases when in a cane sugar factory economisers or air heaters may be

justified ; namely, when additional steam is needed for sugar refining and/or distilling.

However, even in such cases it should be possible—as long as the fibre content of the cane

is not abnormally low—to generate sufficient steam for all requirements without having

recourse to economisers and/or air heaters, provided all reasonable steps are taken towards

a good steam economy.

(2) Steam and Power

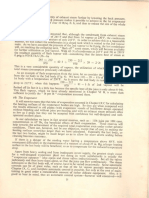

We have shown that with our steam conditions, prime movers of 50% overall efficiency

require 31:5 Ib of steam per hph. It is often not realised what the effect of various steam

pressures on the one hand, and of superheat on the other, have on this figure. A few

examples are given below

Steam Steam Back Available Utilise Steam

pressure temp. pressure heat heat at required

psig °F psig B.Th.U,/Ib, 50% eff. Ib/hph.

B.TB.U,/lb.

180 380 (sat) 15 140 70 36-5

180 500 1S 160 80 31-5

180 500 10 172 86 29-5

250 407 (sat) 15 166 83 30-5

250 500 15 180 90 28-0

250 500 10 196 98 26-0

In the previous chapters we have chosen an admission pressure to the prime movers of

180 psig. The reason for this is that boilers operating at 180-200 psig are still in the low

pressure range and are therefore less exacting in operation and- maintenance than high

Pressure boilers. We have chosen superheat, because without it the quantity of exhaust

steam would have been 16% greater, and also because steam turbines would operate less

well with saturated steam.

20

También podría gustarte

- ACHS Descripcion CalderasDocumento26 páginasACHS Descripcion Calderaspam_8067% (3)

- Calderas Acuat InpsaselDocumento14 páginasCalderas Acuat InpsaselCarlos TomeyAún no hay calificaciones

- Curva Diseño PeabodyDocumento1 páginaCurva Diseño PeabodyCarlos TomeyAún no hay calificaciones

- Calorespec PDFDocumento1 páginaCalorespec PDFjjgaldosAún no hay calificaciones

- Control de Nivel de 3 ElementosDocumento127 páginasControl de Nivel de 3 ElementosCarlos TomeyAún no hay calificaciones

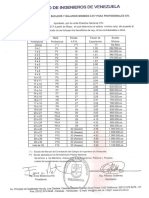

- Tabulador Del Colegio de Ingenieros 2017 PDFDocumento1 páginaTabulador Del Colegio de Ingenieros 2017 PDFCarlos TomeyAún no hay calificaciones

- Tabulador Del Colegio de Ingenieros 2017 PDFDocumento1 páginaTabulador Del Colegio de Ingenieros 2017 PDFCarlos TomeyAún no hay calificaciones

- Etica en Los Negocios PDFDocumento7 páginasEtica en Los Negocios PDFCarlos TomeyAún no hay calificaciones

- Visualizar Conceptualizar Definir ApendicesDocumento128 páginasVisualizar Conceptualizar Definir ApendicesJorge Enrique Silva Roso100% (1)

- 5 Eficiencia PDFDocumento41 páginas5 Eficiencia PDFVictor PobleteAún no hay calificaciones

- Ética y Deontologia PDFDocumento54 páginasÉtica y Deontologia PDFCarlos TomeyAún no hay calificaciones

- Rendimiento Termico de Calderas Bagaceras en Tucuman, Argentina PDFDocumento9 páginasRendimiento Termico de Calderas Bagaceras en Tucuman, Argentina PDFCarlos TomeyAún no hay calificaciones

- Control Inter NoDocumento16 páginasControl Inter NoTibisay RojasAún no hay calificaciones

- Centrales Termicas de Lecho FluidoDocumento47 páginasCentrales Termicas de Lecho FluidorisegraAún no hay calificaciones

- 1 Catalogo Sermateczanini Etanol2012 EspDocumento12 páginas1 Catalogo Sermateczanini Etanol2012 EspCarlos TomeyAún no hay calificaciones

- Calculos Basicos de La Caña de Azucar0016Documento1 páginaCalculos Basicos de La Caña de Azucar0016Carlos TomeyAún no hay calificaciones

- Calculos Basicos de La Caña de Azucar0021Documento1 páginaCalculos Basicos de La Caña de Azucar0021Carlos TomeyAún no hay calificaciones

- Calculos Basicos de La Caña de Azucar0018Documento1 páginaCalculos Basicos de La Caña de Azucar0018Carlos TomeyAún no hay calificaciones

- 1 Catalogo Sermateczanini Etanol2012 EspDocumento12 páginas1 Catalogo Sermateczanini Etanol2012 EspCarlos TomeyAún no hay calificaciones

- Calculos Basicos de La Caña de Azucar0019Documento1 páginaCalculos Basicos de La Caña de Azucar0019Carlos TomeyAún no hay calificaciones

- Calculos Basicos de La Caña de Azucar0020Documento1 páginaCalculos Basicos de La Caña de Azucar0020Carlos TomeyAún no hay calificaciones

- Calculos Basicos de La Caña de Azucar0017 PDFDocumento1 páginaCalculos Basicos de La Caña de Azucar0017 PDFCarlos TomeyAún no hay calificaciones

- Calculos Basicos de La Caña de Azucar0013Documento1 páginaCalculos Basicos de La Caña de Azucar0013Carlos TomeyAún no hay calificaciones

- Calculos Basicos de La Caña de Azucar0015 PDFDocumento1 páginaCalculos Basicos de La Caña de Azucar0015 PDFCarlos TomeyAún no hay calificaciones

- Calculos Basicos de La Caña de Azucar0015Documento1 páginaCalculos Basicos de La Caña de Azucar0015Carlos TomeyAún no hay calificaciones

- Calculos Basicos de La Caña de Azucar0014Documento1 páginaCalculos Basicos de La Caña de Azucar0014Carlos TomeyAún no hay calificaciones

- Calculos Basicos de La Caña de Azucar 0011Documento1 páginaCalculos Basicos de La Caña de Azucar 0011Carlos TomeyAún no hay calificaciones

- Calculos Basicos de La Caña de Azucar 0012Documento1 páginaCalculos Basicos de La Caña de Azucar 0012Carlos TomeyAún no hay calificaciones

- Calculos Basicos de La Caña de Azucar0010Documento1 páginaCalculos Basicos de La Caña de Azucar0010Carlos TomeyAún no hay calificaciones