Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Calculos Basicos de La Caña de Azucar0015

Cargado por

Carlos Tomey0 calificaciones0% encontró este documento útil (0 votos)

22 vistas1 páginaCalculos Basicos de La Caña de Azucar 0015

Derechos de autor

© © All Rights Reserved

Formatos disponibles

PDF o lea en línea desde Scribd

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCalculos Basicos de La Caña de Azucar 0015

Copyright:

© All Rights Reserved

Formatos disponibles

Descargue como PDF o lea en línea desde Scribd

0 calificaciones0% encontró este documento útil (0 votos)

22 vistas1 páginaCalculos Basicos de La Caña de Azucar0015

Cargado por

Carlos TomeyCalculos Basicos de La Caña de Azucar 0015

Copyright:

© All Rights Reserved

Formatos disponibles

Descargue como PDF o lea en línea desde Scribd

Está en la página 1de 1

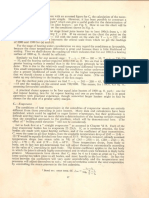

All this shows that we need in fact not concern ourselves with heat transmission

coefficients, but only with the capability of evaporation of the last body when this is scaled

to an extent still allowing reasonable operation. We need consider the last body only

(or the worst scaled body), because, as we have seen in Chapter VI B, no body of a straight

evaporator can evaporate more than the one that evaporates least.

The capability of evaporation may be simply expressed in pounds per sq. ft. per hour

(Ib/sq. ft. h) and experience has shown that for a straight quadruple, operated with exhaust

steam of 10 — 12 psig and a vacuum of 26 — 27 in. Hg, about 7 Ibjsq. ft. h. may be safely

assumed.

9p 22°25 X 2240 _ 7159 sq, ft, and,

as we choose to make all four bodies alike, the total heating surface of our straight

quadruple effect evaporator will be nearly 29,000 sq. ft

Tt can easily be shown that such an evaporator can be made to evaporate considerably

more, if some bleeding from the Ist and 2nd bodies is practised. We will, however, not

analyse further the evaporator with equal bodies and proceed to consider an evaporator

to serve the conditions as shown in Fig. 4.

Let us start with the last body. This has to evaporate only 13-3t/h, and if we assume as

before 7 Ib/sq. ft. h, the required heating surface is '?3* 274 _ 4909 sq. ft. As the

3rd body has to evaporate the same amount as the 4th, we will give it also 4200 sq. ft.,

although it could safely be made somewhat smaller. For the second and first bodies we

will, however, assume higher rates of evaporation, and we will take—based on experience

with well-designed evaporators—9 and 10 1b/sq. ft. h respectively. With these figures we

find the heating surfaces of the 2nd and Ist bodies to be >"> a 2240 _ 6100 sq, ft. and

39 x 7

Thus our last body will have a heating surface of

= 8700 sq. ft. respectively. ‘Thus the total heating surface of the evaporator

works out at 8700 + 6100 + 4200 + 4200 = 23,200 sq, ft. This is 209 less heating surface

than we found to be required for the straight evaporator. Thus we see that systematic

vapour bleeding does not only greatly improve the steam economy, but that it also makes

it possible to economise on the size of plant.

In order to make the system of Fig. 4 do its work satisfactorily it is necessary to control

the pressure of the first vapour at, say, 6 psig—so that the users of Ist vapour can rely

on getting their normal pressure at all times. This can easily be done by an automatic

reducing valve, which makes up the Ist vapour from exhaust steam, when the pressure

drops, and a relief valve, which releases surplus Ist vapour to atmosphere, when the

pressure rises. Such an arrangement also makes the whole plant very flexible and adapt-

able to greatly varying working conditions, Even if the Ist body were to prove too small

to satisfy the requirements of all the users of Ist vapour all the time, these users will never

be starved of steam.

‘A well conceived and operated evaporator plant is a very flexible instrument, which

adapts itself largely automatically, and can be adapted further by simple external control

measures, to a very wide range of variations in working conditions ; nevertheless there

is a limit to the total evaporation that can be achieved with a given plant. The main

limiting factors are scaling and the maximum back pressure the prime movers will tolerate.

(The assumed rate of evaporation of 10 Ib/sq, ft. h. for the Ist body, definitely pre-supposes

that the juice entering the Ist body should have been heated in’a pre-heater to a tem-

perature a few degrees above the boiling point of the jnice in the Ist body. The fact that

pre-heaters were not common practice with straight evaporators explains why it was

usual to make all bodies alike, as with unheated juice entering the Ist body, this could

not achieve greater evaporation than even a badly scaled last body),

For the sake of a better understanding let us now return to the consideration of

coefficients of heat transmission. We have assumed, for the system represented in Fig. 4,

8

También podría gustarte

- ACHS Descripcion CalderasDocumento26 páginasACHS Descripcion Calderaspam_8067% (3)

- Calderas Acuat InpsaselDocumento14 páginasCalderas Acuat InpsaselCarlos TomeyAún no hay calificaciones

- Curva Diseño PeabodyDocumento1 páginaCurva Diseño PeabodyCarlos TomeyAún no hay calificaciones

- Calorespec PDFDocumento1 páginaCalorespec PDFjjgaldosAún no hay calificaciones

- Control de Nivel de 3 ElementosDocumento127 páginasControl de Nivel de 3 ElementosCarlos TomeyAún no hay calificaciones

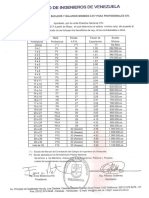

- Tabulador Del Colegio de Ingenieros 2017 PDFDocumento1 páginaTabulador Del Colegio de Ingenieros 2017 PDFCarlos TomeyAún no hay calificaciones

- Tabulador Del Colegio de Ingenieros 2017 PDFDocumento1 páginaTabulador Del Colegio de Ingenieros 2017 PDFCarlos TomeyAún no hay calificaciones

- Etica en Los Negocios PDFDocumento7 páginasEtica en Los Negocios PDFCarlos TomeyAún no hay calificaciones

- Visualizar Conceptualizar Definir ApendicesDocumento128 páginasVisualizar Conceptualizar Definir ApendicesJorge Enrique Silva Roso100% (1)

- 5 Eficiencia PDFDocumento41 páginas5 Eficiencia PDFVictor PobleteAún no hay calificaciones

- Ética y Deontologia PDFDocumento54 páginasÉtica y Deontologia PDFCarlos TomeyAún no hay calificaciones

- Rendimiento Termico de Calderas Bagaceras en Tucuman, Argentina PDFDocumento9 páginasRendimiento Termico de Calderas Bagaceras en Tucuman, Argentina PDFCarlos TomeyAún no hay calificaciones

- Control Inter NoDocumento16 páginasControl Inter NoTibisay RojasAún no hay calificaciones

- Centrales Termicas de Lecho FluidoDocumento47 páginasCentrales Termicas de Lecho FluidorisegraAún no hay calificaciones

- 1 Catalogo Sermateczanini Etanol2012 EspDocumento12 páginas1 Catalogo Sermateczanini Etanol2012 EspCarlos TomeyAún no hay calificaciones

- Calculos Basicos de La Caña de Azucar0017 PDFDocumento1 páginaCalculos Basicos de La Caña de Azucar0017 PDFCarlos TomeyAún no hay calificaciones

- Calculos Basicos de La Caña de Azucar0021Documento1 páginaCalculos Basicos de La Caña de Azucar0021Carlos TomeyAún no hay calificaciones

- Calculos Basicos de La Caña de Azucar0018Documento1 páginaCalculos Basicos de La Caña de Azucar0018Carlos TomeyAún no hay calificaciones

- 1 Catalogo Sermateczanini Etanol2012 EspDocumento12 páginas1 Catalogo Sermateczanini Etanol2012 EspCarlos TomeyAún no hay calificaciones

- Calculos Basicos de La Caña de Azucar0019Documento1 páginaCalculos Basicos de La Caña de Azucar0019Carlos TomeyAún no hay calificaciones

- Calculos Basicos de La Caña de Azucar0020Documento1 páginaCalculos Basicos de La Caña de Azucar0020Carlos TomeyAún no hay calificaciones

- Calculos Basicos de La Caña de Azucar0017 PDFDocumento1 páginaCalculos Basicos de La Caña de Azucar0017 PDFCarlos TomeyAún no hay calificaciones

- Calculos Basicos de La Caña de Azucar0013Documento1 páginaCalculos Basicos de La Caña de Azucar0013Carlos TomeyAún no hay calificaciones

- Calculos Basicos de La Caña de Azucar0016Documento1 páginaCalculos Basicos de La Caña de Azucar0016Carlos TomeyAún no hay calificaciones

- Calculos Basicos de La Caña de Azucar0015 PDFDocumento1 páginaCalculos Basicos de La Caña de Azucar0015 PDFCarlos TomeyAún no hay calificaciones

- Calculos Basicos de La Caña de Azucar0014Documento1 páginaCalculos Basicos de La Caña de Azucar0014Carlos TomeyAún no hay calificaciones

- Calculos Basicos de La Caña de Azucar 0011Documento1 páginaCalculos Basicos de La Caña de Azucar 0011Carlos TomeyAún no hay calificaciones

- Calculos Basicos de La Caña de Azucar 0012Documento1 páginaCalculos Basicos de La Caña de Azucar 0012Carlos TomeyAún no hay calificaciones

- Calculos Basicos de La Caña de Azucar0010Documento1 páginaCalculos Basicos de La Caña de Azucar0010Carlos TomeyAún no hay calificaciones