Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Calculos Basicos de La Caña de Azucar0016

Cargado por

Carlos Tomey0 calificaciones0% encontró este documento útil (0 votos)

12 vistas1 páginaCalculos Basicos de La Caña de Azucar 0016

Derechos de autor

© © All Rights Reserved

Formatos disponibles

PDF o lea en línea desde Scribd

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCalculos Basicos de La Caña de Azucar 0016

Copyright:

© All Rights Reserved

Formatos disponibles

Descargue como PDF o lea en línea desde Scribd

0 calificaciones0% encontró este documento útil (0 votos)

12 vistas1 páginaCalculos Basicos de La Caña de Azucar0016

Cargado por

Carlos TomeyCalculos Basicos de La Caña de Azucar 0016

Copyright:

© All Rights Reserved

Formatos disponibles

Descargue como PDF o lea en línea desde Scribd

Está en la página 1de 1

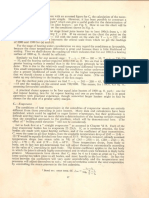

ates of evaporation of 10, 9, 7 and 7 Ib.sq.ft.h and temperature drops of 15, 18, 33 and

65°F for the four bodies respectively. Taking now, from our steam table in Chapter VI,

the latent heat of the vapours, we find (disregarding boiling point elevation) the following

coefficients of heat transmission :

Ist body, 7,958 40 B.Th.U,/sq. fh. °F.

2nd body, °° _ 485 .Th.U,/sq. ft he °F.

3rd body, i = 210 B.Th.U,/sq. ft. h. °F.

4th body, payee = 110 B.Th.U,/sq, ft. h. °F.

These figures are in good agreement with coefficients measured in operation, and show

that our assumptions made with regard to vapour pressures and evaporation rates were

reasonable. If the steam pressure in the calandria of the Ist body is increased above that

of 12 psig assumed, the rate of evaporation in the Ist body will increase considerably.

At 15 psig the temperature is 250°F, i.e., 5°F higher than at 12 psig, and the temperature

difference in the Ist body becomes 20°F instead of 15°F, with a correspondingly greater

rate of evaporation. Thus our Ist body of 8700 sq. ft., and with it the whole plant, has a

considerable reserve of evaporating capacity.*

6 *See Chapter XI, 4,

‘Chapter X

ConDENsERS.

‘The condensers normally used in sugar factories are “ barometric mixing condensers,”

which means that the cooling water and the vapour to be condensed are nixed snd frat

the resulting hot water is removed through a “barometric leg’”; this is in contrast to

surface condensers, in which the cooling water is kept separate from the vapour and

condensate, and from which the condensate is usually removed by a pump.

Taking our example of Fig. 4 the condenser of the evaporator has to deal with 13-3 t/h

and the condensers of the vacuum pans with 10-6 t/h (see Chapter VI. C) of vapour, ‘This

We have to condense a total of 23-9 t/h of vapour at 27 in. Hg of vacuum, having & latent

heat of 1026 B.Th.U./lb and a temperature of 114°F.

Ideally it should be possible to operate the condensers so that the hot water would

leave the condenser with a temperature of 114°F, but this is not possible zn praction ond

we will assume that the hot water will reach a temperature of 104-F (10°F below that of

the vapour). Tn this case each Ib. of vapour will add 1026 + (L14— 104) ~- 1036 BL,

to the heat content of the cooling water.

If the available cooling water has a temperature of 80°F., each Ib of water will take up

10480 = 24 B.TH.U. Thus “036 — 43 Ib of cooling water has to be introduced into

the condenser for each Ib of vapour.

Therefore, for our 23-9 /h of vapour we have to use 43 x 23-9

gal/min) of * injection water ” of 80°F.

If the cooling water available had a temperature of 90°F and we would still wish to

‘maintain a vacuum of 27 in. Hg, then each Ib of water could take up only 14 B-Th.U: ana

the amount of injection water required would be 74 —= 1-7 times, or 70%, greater than

before. Ifso much water could not be made available, the vacuum would inevitably drop.

»

1030 t/h (3850

También podría gustarte

- ACHS Descripcion CalderasDocumento26 páginasACHS Descripcion Calderaspam_8067% (3)

- Calderas Acuat InpsaselDocumento14 páginasCalderas Acuat InpsaselCarlos TomeyAún no hay calificaciones

- Curva Diseño PeabodyDocumento1 páginaCurva Diseño PeabodyCarlos TomeyAún no hay calificaciones

- Calorespec PDFDocumento1 páginaCalorespec PDFjjgaldosAún no hay calificaciones

- Control de Nivel de 3 ElementosDocumento127 páginasControl de Nivel de 3 ElementosCarlos TomeyAún no hay calificaciones

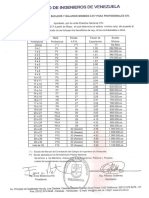

- Tabulador Del Colegio de Ingenieros 2017 PDFDocumento1 páginaTabulador Del Colegio de Ingenieros 2017 PDFCarlos TomeyAún no hay calificaciones

- Tabulador Del Colegio de Ingenieros 2017 PDFDocumento1 páginaTabulador Del Colegio de Ingenieros 2017 PDFCarlos TomeyAún no hay calificaciones

- Etica en Los Negocios PDFDocumento7 páginasEtica en Los Negocios PDFCarlos TomeyAún no hay calificaciones

- Visualizar Conceptualizar Definir ApendicesDocumento128 páginasVisualizar Conceptualizar Definir ApendicesJorge Enrique Silva Roso100% (1)

- 5 Eficiencia PDFDocumento41 páginas5 Eficiencia PDFVictor PobleteAún no hay calificaciones

- Ética y Deontologia PDFDocumento54 páginasÉtica y Deontologia PDFCarlos TomeyAún no hay calificaciones

- Rendimiento Termico de Calderas Bagaceras en Tucuman, Argentina PDFDocumento9 páginasRendimiento Termico de Calderas Bagaceras en Tucuman, Argentina PDFCarlos TomeyAún no hay calificaciones

- Control Inter NoDocumento16 páginasControl Inter NoTibisay RojasAún no hay calificaciones

- Centrales Termicas de Lecho FluidoDocumento47 páginasCentrales Termicas de Lecho FluidorisegraAún no hay calificaciones

- 1 Catalogo Sermateczanini Etanol2012 EspDocumento12 páginas1 Catalogo Sermateczanini Etanol2012 EspCarlos TomeyAún no hay calificaciones

- Calculos Basicos de La Caña de Azucar0017 PDFDocumento1 páginaCalculos Basicos de La Caña de Azucar0017 PDFCarlos TomeyAún no hay calificaciones

- Calculos Basicos de La Caña de Azucar0021Documento1 páginaCalculos Basicos de La Caña de Azucar0021Carlos TomeyAún no hay calificaciones

- Calculos Basicos de La Caña de Azucar0018Documento1 páginaCalculos Basicos de La Caña de Azucar0018Carlos TomeyAún no hay calificaciones

- 1 Catalogo Sermateczanini Etanol2012 EspDocumento12 páginas1 Catalogo Sermateczanini Etanol2012 EspCarlos TomeyAún no hay calificaciones

- Calculos Basicos de La Caña de Azucar0019Documento1 páginaCalculos Basicos de La Caña de Azucar0019Carlos TomeyAún no hay calificaciones

- Calculos Basicos de La Caña de Azucar0020Documento1 páginaCalculos Basicos de La Caña de Azucar0020Carlos TomeyAún no hay calificaciones

- Calculos Basicos de La Caña de Azucar0017 PDFDocumento1 páginaCalculos Basicos de La Caña de Azucar0017 PDFCarlos TomeyAún no hay calificaciones

- Calculos Basicos de La Caña de Azucar0013Documento1 páginaCalculos Basicos de La Caña de Azucar0013Carlos TomeyAún no hay calificaciones

- Calculos Basicos de La Caña de Azucar0015 PDFDocumento1 páginaCalculos Basicos de La Caña de Azucar0015 PDFCarlos TomeyAún no hay calificaciones

- Calculos Basicos de La Caña de Azucar0015Documento1 páginaCalculos Basicos de La Caña de Azucar0015Carlos TomeyAún no hay calificaciones

- Calculos Basicos de La Caña de Azucar0014Documento1 páginaCalculos Basicos de La Caña de Azucar0014Carlos TomeyAún no hay calificaciones

- Calculos Basicos de La Caña de Azucar 0011Documento1 páginaCalculos Basicos de La Caña de Azucar 0011Carlos TomeyAún no hay calificaciones

- Calculos Basicos de La Caña de Azucar 0012Documento1 páginaCalculos Basicos de La Caña de Azucar 0012Carlos TomeyAún no hay calificaciones

- Calculos Basicos de La Caña de Azucar0010Documento1 páginaCalculos Basicos de La Caña de Azucar0010Carlos TomeyAún no hay calificaciones