0 calificaciones0% encontró este documento útil (0 votos)

1K vistas10 páginasSurTec 650

Surtec 650 TDS

Cargado por

vijay yadavDerechos de autor

© © All Rights Reserved

Nos tomamos en serio los derechos de los contenidos. Si sospechas que se trata de tu contenido, reclámalo aquí.

Formatos disponibles

Descarga como PDF o lee en línea desde Scribd

0 calificaciones0% encontró este documento útil (0 votos)

1K vistas10 páginasSurTec 650

Surtec 650 TDS

Cargado por

vijay yadavDerechos de autor

© © All Rights Reserved

Nos tomamos en serio los derechos de los contenidos. Si sospechas que se trata de tu contenido, reclámalo aquí.

Formatos disponibles

Descarga como PDF o lee en línea desde Scribd

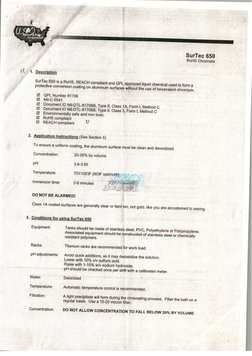

6.

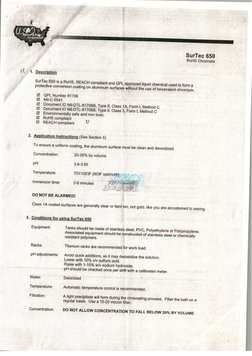

SurTec 650

RoHS Chromate

Description

SurTee 660 is @ RoHS, REACH compliant and QPL approved liquid chemical used to form @

Protective conversion coating on aluminum surfaces without the use of hexavalent chromur.

QPL Number 81706

MiLC-5541

Document ID MiLDTL-81706B, Type Il, Class 1A, Form J, Method C

Document ID MiLDTL-817068, Type I, Class 3, Form i, Method C

Environmentally safe and non tox.

RoHS compliant

REACH compliant

Application instructions (See Section 5)

To ensure a uniform coating, the aluminum surface must be clean and deoxidized.

S89s5900

Concentration: 20-30% by volume

pit: 3.8-3.95

Temperature: TOE 100¥F (90. trum >

Immersion time: 2-6 minutes :

DO NOT BE ALARMED!

lass 1A coated Surfaces are generally clear or faint tan, not gold, ke you are accustomed to seeing,

Conditions for using SurTec 650

Equipment: 7anks should be made of stainless steel, PVC, Polyethylene or Polypropylene.

Associated equipment should be constructed of stainiess steel or chemically

resistant polymers. ,

Racks Titanium racks are recommended for work load,

PH adjustments: Avoid quick additions, as it may destabilize the solution.

Lower with 10% viv sulfuric acid,

Raise with 1-10% wiv sodium hydroxide,

PH should be checked once per shift with a calibrated meter.

Water, Deionized

‘Temperature: Automatic temperature control is recommended.

Filtration: A light precipitate will form during the chromating process. Fiter the bath on a

regular basis. Use a 15-20 micron fiter.

Concentration: DO NOT ALLOW CONCENTRATION TO FALL BELOW 20% BY VOLUME.

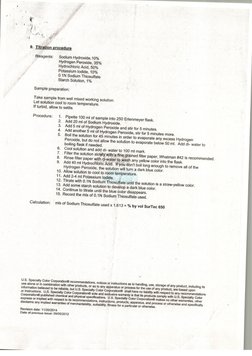

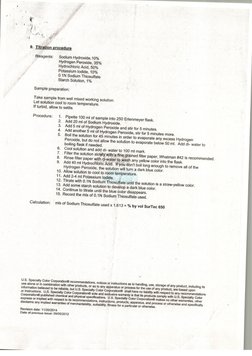

9. Titration procedure

Reagents: Sodium Hydroxide, 10%

Hydrogen Peroxide, 35%

Hydrochloric Acid, 50%

Potassium lodide, 10%

O.4N Sodium Thiosuifate

‘Starch Solution, 1%

‘Sample preparation:

Take sample trom well mixed working solution.

Let solution cool to room temperature.

If turbid, allow to settle,

Procedure: Pipette 100 mi of sample into 250 Erlenmeyer flask.

‘Add 20 ml of Sodium Hydroxide,

ohene

zg

3

g

2

i

Q

:

a

z

3

.

a

boling ask if needed.

8. Cool solution and add ot- water to 100 ml mark

oes na cltion siya fine grained iter paper, Whatman #42 s recommended.

§; Rinse iter paper with chwvaterto wash any yellow color inte tha Nc

‘9. Add 40 mi Hydrochforic Aéid. If you don't boll long enough to remove all of the

10. Allow solution to cool to room temperature.

11, Add 2-4 mi Potassium lode. 5

12: Tat wit 01 Sodium Thicsulfate unl te solutions a straw-ylow cle.

18, Add some starch soliton fo deveiog ada ee

14. Continue to trate untl tebe Coke tees

15. Record the mis of 0.1N ‘Sodium Thiosulfate used.

Calculation: "mis of Sodium Thiosulfate used x 1.613 = % by vol SurTee 650

te alone a tt Comeralon® recommendations, notca or insucions a handig, we storage of any produ! nung its

iemeon aloe be ce Oana oun pen esa ee oo el

information baioved to be refabe, bt U.S. Specialy Coor Goren, Shall Nave no laity with respect to any recommendations

orinstrucions ied cna oreo sale and exave waranty a ate pose aeehnee Specialty Color

Corporaton® published chemical and piysea specncanrs US. Specially Color Coporaion® makes no other waraniey sone

Sedna mpl ware neste rao Poth, mpegs oer eee

“eiaireany implied warns of mercarabity, sual, ress a parieesen

Revision date: 117202014

Date of previous isu: 03/05/2012

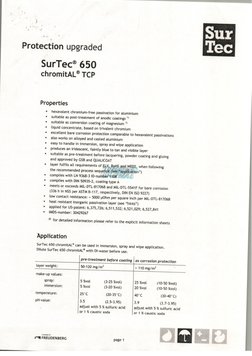

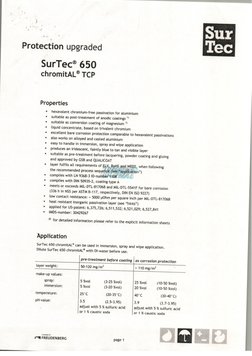

Protection upgraded

SurTec® 650

chromitAL® TCP

Properties

‘hexavalent chromium-free passivation for aluminium

* suftable as post-treatment of anodic coatings "

‘suitable as conversion coating of magnesium '!

* liquid concentrate, based on trivalent chromium

‘excellent bare corrosion protection comparable to hexavalent passivations

‘also works on alloyed and casted aluminium

‘easy to handle in immersion, spray and wipe application

* produces an iridescent, faintly blue to tan and visible layer

"suitable as pre-treatment before lacquering, powder coating and gluing

and approved by GSB and QUALICOAT

+ layer fulfils all requirements of when following

the recommended process sequi a”)

‘complies with LN 9368-3 1D: =

"complies with DIN 50935-2, coating type A

‘Meets oF exceeds MIL-DTL-81706B and MIL-DTL-5541F for bare corrosion

(G36 h in NSS per ASTM B-117, respectively, DIN EN ISO $227)

+ low contact resistance: < 5000 Ohm per square inch per MIL-DTL-817068

‘heat resistant inorganic passivation layer (see “hints”

* applied for US:patent: 6,375,726; 6,511,532; 6,521,029; 6,527,841

+ MDS-number: 30429267

“ for detailed information please refer to the explicit information sheets

Application

SurTec 650 chromitAL® can be used in immersion, spray and wipe application,

Dilute SurTee 650 chromitaL® with DI-water before use.

Pre-treatment before coating | as corrosion protection

layer weight: 50-120 mg/m? > 110 mg/m?

‘make-up values:

spray: 5 tvol G25 vol) | 258v0l (10-50 vol)

immersion: 5 fol G-20%v0l) | 20%v01 (10-50 vol)

temperature: 2c o35'¢) aoc (0-40°¢)

pH-value: 35 253.95) [39 G.7:3.95)

adjust with 5 X sulfuric acid | adjust with 5 X sulfuric acid

or 4 % caustic soda oF 1 ® caustic soda

(PA FREUOENBERG page 1 Py

application time:

spray:

immersion:

spraying pressure:

agitation:

make-up:

tank material:

(for temperature dependency | (for temperature dependency

see “hints") see “hints”)

1 min (0.5-3 min) | 2 min (1-6 min

4 min (0.5-3 min) | 2 min (1-6 min

tbar tar (0.5-1.5 bar)

ot necessary ot necessary

Steps for make-up:

1. Dilute SurTec 650 chromitAL® with deionised water under vigorous

stirring.

2. Control the p-value and adjust it cautiously with sulfuric acid

(5) resp. sodium hydroxide solution (1 %), if necessary.

stainless steel or steel with acid- and fluoride-resistant coating

titanium, stainless steel (V4A), aluminium, plastic

‘necessary (0.1-0.5 times the total bath volume per hour

before coating: pore size < 25 ym

heating: ‘necessary; out of acid- and fluoride-resistant material

exhaust: required for worker

?

recommended process sequence:

Standard procedures for immersion:

For aluminium alloys with <1 % siicium:

1. mild alkaline degreasing e.g. surTec 133

2. alkaline etching e.g, Surtec 181

3. deoxidising €.. SurTec 495 or SurTec 495 L

‘4. passivation with SurTec 650 chromitaL®

For aluminium alloys with > 1 silicium:

41, mild alkaline degreasing e.g. SurTec 133

2. deoxidising €.8. SurTec 495 or SurTee 495 L

3. passivation with SurTec 650 chromitaL®

‘Standard procedure for spray:

1. acid degreasing e.g. SurTec 478

2. passivation with SurTec 650 chromitAL®

Between each step the surface has to be rinsed. The rinsing methods

have to be adapted to the plating line,

‘The process sequences above are general recommendations.

‘To qualify the process, modifications may be necessary.

general hints: Metallic tank material and goods to be passivated must be electrically

isolated from each other.

‘Storage: During storage a slight precipitation may occur inside SurTec 650

Concentrate, which will not impair quality or function of the product.

7O5 FREUDENBERG age 2 P) a) BE)

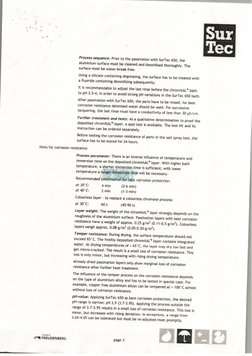

Process sequence: Prior to the passivation with SurTec 650, the

aluminium surface must be cleaned and deoxidised thoroughly. The

surface must be water-break free.

Using a silicate containing degreasing, the surface has to be treated with

® fluoride containing deoxidising subsequently.

It's recommendable to adjust the last rinse before the chromitAL® bath

{0 PH 3.54, in order to avold strong pH variations in the SurTec 650 bath,

After passivation with SurTec 650, the parts have to be rinsed, for best

Corrosion resistance deionised water should be used. For successive

\acquering, the last rinse must have a conductivity of less than 30 uS/cm.

Further treatment and tests: As a qualitative determination to proof the

deposited chromitAL*-layer, a spot testis available. The test kit and its

Instruction can be ordered separately.

Before testing the corrosion resistance of parts in the salt spray test, the

surface has to be stored for 24 hours.

hints for corrosion resistance:

(778 FREUDENBERG

Process parameter: There ts an inverse influence of temperature and

‘immersion time on the deposited chromitAL® layer. With higher bath

temperature, a shorter immersion time is sufficient; with lower

‘temperature a will be necessary,

Recommended corresion protection:

at 30°C: Amin (2-6 min)

at 40°C: 2min——(1-3min)

Colouriess layer - to replace a colourless chromate process:

at 30°¢: 60s (45-90)

Layer weight: The weight of the chromitAL® layer strongly depends on the

‘oughness of the aluminium surface. Passivation layers with best corrosion

resistance have a weight of approx. 0.25 g/m? (0.11-0.5 g/m?). Colourless

layers weigh approx. 0.08 g/m (0.05-0.20 g/m?).

Temper resistance: During drying, the surface temperature should not

‘exceed 65°C. The freshly deposited chromitaL® layer contains integrated

Water. At drying temperatures of » 65°C, the layer may dry too fast and

‘get micro-cracked. The result is a small loss of corrosion resistance. This

‘oss is only minor, but increasing with rising drying temperature.

Already dried passivation layers only show marginal loss of corrosion

resistance after further heat treatment.

‘The influence ofthe temper process on the corrosion resistance depends

(on the type of aluminium alloy and has to be tested in special case. For

‘example, copper free aluminium alloys can be tempered at > 100°C almost

Without loss of corrosion resistance.

p-value: Applying SurTec 650 as bare corrosion protection, the desired

H-range is narrow: pH 3,9 (3.7-3.95). Applying the process outside the

range of 3.7-3.95 results in a small loss of corrosion resistance. This loss is

‘minor, but increases with rising deviation. n exceptions, a range from

3:65-4.05 can be tolerated but must be re-adjusted mast promptly.

os Pl il BE)

hints for coating: Storage: Treated surfaces canbe coated immediately ater drying, or

stored as long as they are protected from contamination and temperature

extremes. For optimum results, the parts should be coated within 7 days.

To be compliant with QUALICOAT, the coating should be applied within

16h, for GSB within 24h, respectively as Premium Coater within 12h.

Layer weight: For pre-treatment of extruded profiles before powder

coating, a layer weight of 0.05-0.12 g/m must be observed. The

formation of the passivation layer should be tested directly after the

Pre-treatment with a spot test.

5 Drying temperature: The drying temperature should be 65°C (room

temperature up to 100°C),

Maintenance and Analysis

Check the pH-value regularly. Analyse and adjust the concentration of SurTec 650 regularly.

{Analysing methods of SurTec 650 by photometry are less exact; an analysing method for

Zirconium (HACH Cuvette Test) can be requested separately).

Sample Preparation

‘Take the sample at a homogeneously mixed position and let it coot down to room temperature.

Hf the sample is turbid Ut the rity sete do With a biue band filter paper.

Z

SurTec 650 - Analysis by Titration

reagents: sulfuric acid (cone.)

ammonium peroxodisufate p. a

silver nitrate solution (0.1 mol/t)

potassium fluoride pa.

Potassium iodide solution (10 %)

0.1 N sodium thiosulfate solution

starch solution (2 %)

Procedure: 1. Pipette 100 ml bath sample into a 250 mi Erlenmeyer flask.

2. Acidify with 3 ml suifuric ac.

3. Add 3 g ammonium peroxodisufate.

4. Add 10 ml silver nitrate solution.

5. Cover the Erlenmeyer flask with a watch glass. Then heat up the

solution and boit it slightly for 20 min (the solution must not

evaporate completely!).

. Let it cool down to room temperature.

= Add a spatula tip of potassium fluoride.

‘Add 15 ml potassium jodide solution.

. Leave 5 min for reaction,

.Titrate with 0.1 N sodium thiosulfate solution unt.

the solution becomes weakly yellow.

11. ‘Add 5 mt starch solution (solution colour turns to blue-black).

12. Continue to titrate to the colour change to milky light green.

‘calculation: ‘consumption in ml 1.613 = vol SurTec 650

ii. -~ Pie

SurTec 650 - Analysis by AAS

‘equipment: atomic absorption spectrometer (AAS):

wave length: 357.9 nm; sit: 0.7 nm

reagents: nitric acid (Y4 conc.) p. a.

Chromium standard solutions

procedure: Make an exact dilution of 1

4. Pour 5 mi nitric acid p. a. into a 100 ml volumetric flask,

2, Pipette 5 ml bath sample into the flask and mix well,

3. Wait 5 min, then fill up with deionised water and mix well,

4. Calibrate the AAS with comparable chromium standards and

‘measure the prepared dilution of the sample (in ppm).

5. In respect to the dilution calculate the concentration of chrome

fin the bath (in ppm),

calculation ‘concentration of chrome in ppm + 0.0974 = vol SurTec 650

hint: Choose the dilution in order that the measured values are in the linear

‘measurement range of the AAS,

SurTee 650 - Determination ofthe ses

equipment: anata bate (70.4 a)

50 Svol nitric acid (65 &)

1 Passvate a test part with a known surface area in m? (preferably

> 2 dm) in SurTec 650.

2. Rinse with defonised water and dry with compressed air at room

‘temperature.

3. Weigh the dry part within 3 h after passivation with the analytical

balance (= M,).

4+ Remove the passivation layer in nitric acid (4 min at 20-25°C).

5. Rinse with detonised water and dry with compressed air at room

temperature.

&. Weigh the dry part again with the analytical balance (= My).

7. Repeat the analysis with a cleaned and deoxidised but

‘NOt-passivated test part (= My and M,)

(My Ma) / surface area = A

(My--Ma) / surface area = B

A-B = layer weight in g/m?

hint: ‘To determine the layer weight always a fresh solution should be used.

At the latest after 1 m?/ the solution has to be renewed.

‘The determination is suitable for extruded and sheet material. In case of

‘aluminium cast, containing high amounts of silicon and sometimes being

porous, the method is not applicable.

7A FREUDENBERG page 5

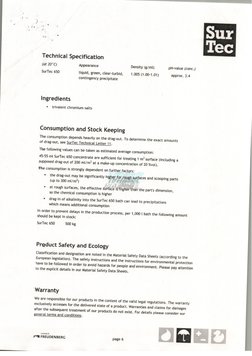

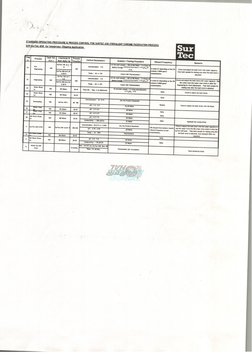

Technical Specification

(at 20°¢) ‘Appearance Density g/ml) p-value cone.)

SurTec 650 Liquid, green, clear-turbid, 1.005 (1,00-1.01) approx. 3.4

Contingency precipitate

Ingredients

+ trivalent chromium salts

Consumption and Stock Keeping

‘The consumption depends heavily onthe drag-out. To determine the exact amounts

of drag-out, see SurTec Technical Letter 11.

The following values can be taken as estimated average consumption:

35°55 mi SurTec 650 concentrate are suficient for treating 1 m? surface (including a

Supposed drag-out of 200 mi/m? at a make-up concentration of 20 vol).

‘The consumption is strongly dependent on further factors:

"the drag-out maybe significantly higher for rough surfaces and scoping parts

eam sy baat

at rough surfaces, the effective surface higher than the part's dimension,

50 the chemical consumption is higher

* drag-in of alkalinity into the SurTec 650 bath can lead to precipitations

which means additional consumption

In order to prevent delays in the production process, er 1,000 bath the following amount

should be kept instock:

SurTec 650 500kg

Praduct Safety and Ecology

Gassfcation and designation are noted inthe Material Safety Data Sheets (according tothe

Rurpeanletslaton). The safety instructions andthe instructions for environmental protection

have to be fllowed in order to avoid hazards for people and environment. Please pay attention

to the explicit details in our Material Safety Data Sheets.

Warranty

We are responsible for our products in the context ofthe vali legal regulations. The warranty

Srauslvely acesies forthe delivered state ofa product. Warranties and claims for damages

after the subsequent treatment of our products do not exist. For detalls please consider ee

7A FREUDENBERG page 6

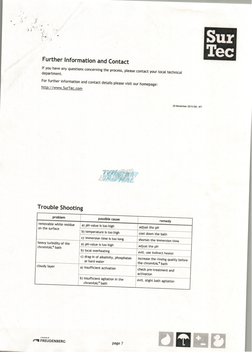

Further Information and Contact

{f you have any questions concerning the process, please contact your local technical

department,

For further information and contact details please visit our homepage:

http://www. SurTec.com

removable white residue

on the surtace Etawaieicas

le Es

También podría gustarte

- Análisis de Cromo en Aguas: Cr(VI) y Cr(III)Aún no hay calificacionesAnálisis de Cromo en Aguas: Cr(VI) y Cr(III)13 páginas

- Proceso de Estaño Ácido Brillante SurTec 821100% (1)Proceso de Estaño Ácido Brillante SurTec 8216 páginas

- Guía de Galvanizado Inmersión en CalienteAún no hay calificacionesGuía de Galvanizado Inmersión en Caliente19 páginas

- Comportamiento Del Anodizado de Aluminio en Diferentes ElectrolitosAún no hay calificacionesComportamiento Del Anodizado de Aluminio en Diferentes Electrolitos4 páginas

- Guía Técnica: Baño de Plata BrillanteAún no hay calificacionesGuía Técnica: Baño de Plata Brillante5 páginas

- Proceso de Metalizado de PlásticoAún no hay calificacionesProceso de Metalizado de Plástico75 páginas

- Crecimiento Controlado de Óxido en Al 6061Aún no hay calificacionesCrecimiento Controlado de Óxido en Al 606131 páginas

- Anodizado de Aluminio: Práctica de LaboratorioAún no hay calificacionesAnodizado de Aluminio: Práctica de Laboratorio1 página

- Ficha de Seguridad BONDERITE C-NE 320BFAún no hay calificacionesFicha de Seguridad BONDERITE C-NE 320BF5 páginas

- Hoja de Seguridad BONDERITE M-PA 6010Aún no hay calificacionesHoja de Seguridad BONDERITE M-PA 601011 páginas

- Guía para pruebas SAE J2412 y J2527Aún no hay calificacionesGuía para pruebas SAE J2412 y J252752 páginas

- Standard Guide For Cleaning Metals Prior To Electroplating-EspaolAún no hay calificacionesStandard Guide For Cleaning Metals Prior To Electroplating-Espaol9 páginas

- Ficha de Seguridad Loctite 7012 20LAún no hay calificacionesFicha de Seguridad Loctite 7012 20L17 páginas

- Determinación de Acidez y Alcalinidad en JabonesAún no hay calificacionesDeterminación de Acidez y Alcalinidad en Jabones12 páginas

- Preparación de Baño de Decapado ÁcidoAún no hay calificacionesPreparación de Baño de Decapado Ácido2 páginas

- Pasivación Ecológica y de Altas Prestaciones - Brugal Galvapas 320Aún no hay calificacionesPasivación Ecológica y de Altas Prestaciones - Brugal Galvapas 32018 páginas

- Práctica ASTM G155-13: Exposición a Luz Xenón100% (1)Práctica ASTM G155-13: Exposición a Luz Xenón6 páginas

- Solventes Oxigenados Parte II PDFAún no hay calificacionesSolventes Oxigenados Parte II PDF34 páginas

- Producción de Líquidos de Limpieza CaserosAún no hay calificacionesProducción de Líquidos de Limpieza Caseros16 páginas

- Índice de brillo en pinturas y barnicesAún no hay calificacionesÍndice de brillo en pinturas y barnices3 páginas

- Hoja de Seguridad CLEAN 2000 - ES 2021Aún no hay calificacionesHoja de Seguridad CLEAN 2000 - ES 202111 páginas

- Aditec Manual Del Constructor Actualizado100% (1)Aditec Manual Del Constructor Actualizado91 páginas

- Duraplate 301W: Protective & Marine CoatingsAún no hay calificacionesDuraplate 301W: Protective & Marine Coatings4 páginas

- Ficha Técnica Amercoat 240/Sigmacover 240Aún no hay calificacionesFicha Técnica Amercoat 240/Sigmacover 2407 páginas

- Corrotec Wash Primer Base Solvente 509AyBAún no hay calificacionesCorrotec Wash Primer Base Solvente 509AyB3 páginas

- Pintura Primaria DTM PITT-TECH 90-712Aún no hay calificacionesPintura Primaria DTM PITT-TECH 90-7126 páginas