Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Cambio de Capuchas Mack

Cargado por

luis lopez0 calificaciones0% encontró este documento útil (0 votos)

10 vistas6 páginasCambio de vasos de inyectores motor MP8

Título original

cambio de capuchas mack

Derechos de autor

© © All Rights Reserved

Formatos disponibles

PDF o lea en línea desde Scribd

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCambio de vasos de inyectores motor MP8

Copyright:

© All Rights Reserved

Formatos disponibles

Descargue como PDF o lea en línea desde Scribd

0 calificaciones0% encontró este documento útil (0 votos)

10 vistas6 páginasCambio de Capuchas Mack

Cargado por

luis lopezCambio de vasos de inyectores motor MP8

Copyright:

© All Rights Reserved

Formatos disponibles

Descargue como PDF o lea en línea desde Scribd

Está en la página 1de 6

Service Bulletin

Mack Trucks, Inc. Trucks

Date Grup (Na, Release © Page

4215 237 46 «02 «9

mack.

‘This service bulletin replaces bulletin 237-59 dated 9.2013.

Sleeve, Engine injector Replacement

(Copper)

MP7, MP8, MP10

Sleeve, Engine Injector, Replacement (Copper)

Q\ CAUTION

This bulletin describes important tools and procedure for injector sleeve replacement.

‘These tools and procedure replace all existing tools and procedures for copper sleeve

replacement. Ifthe procedure in this bulletin not followed exactly, damage to the engine

may result,

Note: Failure to follow the procedure inthis bulletin exactly may result in warranty claim

deni

Contents

“Special Tools’, page 2

* “Sleeve, Engine injector, Replacement (Copper)" page 4

\Note: Information s subject to change without notice.

IMustrations are used for reference only, and may difer slightly from the actual engine

version. However, Key components addressed in this information are represented as

accurately as possible,

Pv7i

7689198181 saro2so

Mack Trucks, Inc.

fn Gee Fe to Peas

Service Bulletin 4205-237 46 206

Tools

Special Tools

For special tools ordering instructions eer to Tools Informa-

tion, Function Group 08,

s90ce65 s098249 9990250

Frye Turing Took, Protection Sleeve Fuel Bore Sealing Ring

9990261 oso82s2 990259

Seating Plug “Topping Tol Ecractor

200014 8000196 ssss0054

Flywhe! Turing Tot ‘Sleeve instalation Too wedging

| onto

88800281

Forming Tap, M8.5

/

‘88800282

Btractor Bit, Ma.5

2815-2700 or 85112740,

Coolant Extractor

3B

Mack Trucks, Inc.

Service Bulletin

Date «Group, No, Rosse Page

425-237 46 02 58)

5

Remove the valve cover. Refer to Function Group 211 for

procedure.

Note: Rotate the valve cover as needed, to clear the cam-

shaft gear and damper.

Note: Dependent upon chassis, engine cover may need to

bbe removed for clearance to remove valve cover.

6

Remove the rocker shaft Refer to Function Group 214 for

procedure,

7

Remove the engine brake control valve, if equipped. Refer to

Function Group 253 for procedure.

8

‘Thoroughly clean around the engine injectors that are to be

removed. Remove the engine injectors). Referto Function

Group 237 for procedure.

°

Install the protective sleeve over the engine injector to pre-

vent damage,

098249,

Mack Trucks, Inc. pate «Group No. Release Page

Service Bulletin 4205-237 AG 02 st)

18

install ap holderin the engine injector bore. Apply moderate

downward force to get the tap started while turning the tap

handle clockwise, Continue turning in the same direction,

‘without reversing, unil the copper sleeve is tapped all the

‘way through. The shoulder ofthe tap handle bottoms on the

copper sleeve. Ensure that the tap is completely through the

copper sleeve

QA CAUTION

threads are not cul completely through the tip of the cop~

per sleeve, the tip can break off and fall into the cylinder.

This can result in damage to the cylinder, piston, valves or

turbocharger. These types of failures are not covered by

warranty.

19998252, 88800261

17

Install the extractor bot into the end of the extractor tool. Ad-~

just the bolt untilit extends approximately 22 mm (0.9 inch)

16

Remove the tap and tapping tool

beyond the end of the tool (dimension A).

‘38800282, 9998253

\)

18

Tighten the set screw ofthe extracortooto secure the bot

fake sure thatthe set screw is seated against the flat part of

the extractor bot

Mack Trucks, Inc.

Service Bulletin

ry

==

9999253

Date Group Release Page

No

42016 237 46 02 og

19

A\ CAUTION

Make sure the extractor boltis threaded completely into

the copper sleeve before attempting to remove itor the tip

of the sleeve may break off as it is removed. This broken

sleeve tip can seriously damage the piston, valves or tur-

bocharger. These types of failures are not covered by

warranty,

Lubricate the threads of the forcing screw on the puller. Lubri-

cate under the face of the nut, Place the extractor tool with

the bolt into the injector bore. Make sure the nut on the spin-

dle is backed off so that the threaded end can be completely

installed through the copper sleeve tip, Hand tighten until the

bolt bottoms out in the sleeve.

Note: Ifitis necessary to replace other copper sleeves, con-

tinue the procedure on pairs of companion cylinders (1 and

6, 2and 5, 3.and 4). Itis necessary to rotate the crankshaft

{and place each pair of companion cylinders at the lowest po-

sition in the cylinder.

20

While holding the top of the tool stationary, turn the large nut

Clockwise to extract the copper sleeve

Note: When the copper sleeve is removed, make sure that

the extractor boltis extended at least one thread beyond the

copper sleeve. If not, make sure that no part of the copper

sleeve has broken off and fallen into the cylinder.

Q\ CAUTION

ee

Do not use air tools to remove copper sleeves, or damage

to the injector bore can result,

|

9998253

2

‘Absorb any remaining coolant with a lint-free cloth.

Note: Check that the piston is free of any fluids.

Mack Trucks, Inc.

Service Bulletin

920.1 mm

bate No. Release Page

Group

42523746 02 1306)

4

Q\ CAUTION

Failure to use the proper bit can resuitin the bit breaking

off into the cylinder head. These types of falures are not

covered by warranty.

Using calipers, measurethe swedging bit to make sure that

the proper swedging toolis used. Measurement should read

7.90.05 mm, Also, vey thatthe swedging bit has four

‘stages and the length is 120 mm,

‘wossrt Note: Any swedging bit wom past the tolerance must be

replaced

Note: Swedging bit 88880054 can be ordered as a spare

parti the bit is worn or broken,

38880054

5

Place the new injector sleeve on the installation tool. Thread

the swedging bit completely into the flaring tool unt it stops

(finger tight) Lubricate the swedging bit and the threads on

the tool with fresh, extreme pressure NLGI#2 grease or

equivalent.

Note: Do not place the injector nozzle gasket (Nat washer) in

the copper sleeve, as this will damage the swedging bit

A CAUTION

Before installing the sleeve on the installation too), inspect

the toolo ensure that tis the correct tool. The correct tool

| identifed by a bottom surface that is perfectly lat with no

‘machined circular recess. Use of a tool with a machined

circular recess on the bottom may result in damage tothe

copper sleeve,

vwoozn 800196,

También podría gustarte

- Modelo Transdiagnóstico de FairburnDocumento1 páginaModelo Transdiagnóstico de Fairburnluis lopez0% (1)

- Preguntas de Forense para ParcialDocumento1 páginaPreguntas de Forense para Parcialluis lopezAún no hay calificaciones

- Resumen de ExposicionDocumento9 páginasResumen de Exposicionluis lopezAún no hay calificaciones

- Lenguaje CorporalDocumento4 páginasLenguaje Corporalluis lopezAún no hay calificaciones

- Resumen Entrevista TEMPLE GRANDINDocumento1 páginaResumen Entrevista TEMPLE GRANDINluis lopez100% (1)

- Enseñanza EfectivaDocumento18 páginasEnseñanza Efectivaluis lopezAún no hay calificaciones

- Sistema de Aire y Filtro SecadorDocumento1 páginaSistema de Aire y Filtro Secadorluis lopezAún no hay calificaciones

- Ford Centroamerica Ranger 2022 Catalogo-Descargable-EspDocumento21 páginasFord Centroamerica Ranger 2022 Catalogo-Descargable-Espluis lopezAún no hay calificaciones

- Charla de Seguridad InduntrialDocumento11 páginasCharla de Seguridad Induntrialluis lopezAún no hay calificaciones

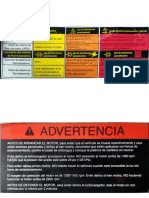

- Etiquetasde ADVERTENCIADocumento3 páginasEtiquetasde ADVERTENCIAluis lopezAún no hay calificaciones

- Desmonte de Grupo de Satélites VolvoDocumento21 páginasDesmonte de Grupo de Satélites Volvoluis lopezAún no hay calificaciones

- Frenodecontraeje MDriveDocumento10 páginasFrenodecontraeje MDriveluis lopezAún no hay calificaciones

- BendixcodigosDocumento4 páginasBendixcodigosluis lopezAún no hay calificaciones