Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Compresion Tablas

Cargado por

Javier ChoqueDerechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Compresion Tablas

Cargado por

Javier ChoqueCopyright:

Formatos disponibles

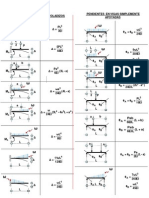

STEEL COMPRESSION—MEMBER SELECTION TABLES 4–17

Table 4-1 (continued)

Available Strength in

Fy = 50 ksi

Axial Compression, kips

W-Shapes W12

Shape W12×

h h h

lb/ft 336 305 279 252h 230h 210

Pn /Ωc φc Pn Pn /Ωc φc Pn Pn /Ωc φc Pn Pn /Ωc φc Pn Pn /Ωc φc Pn Pn /Ωc φc Pn

Design

ASD LRFD ASD LRFD ASD LRFD ASD LRFD ASD LRFD ASD LRFD

0 2960 4450 2680 4030 2450 3690 2220 3330 2030 3050 1850 2780

6 2870 4310 2590 3900 2370 3570 2140 3220 1960 2940 1790 2680

Effective length, KL (ft), with respect to least radius of gyration, ry

7 2840 4260 2560 3850 2340 3520 2120 3180 1930 2910 1760 2650

8 2800 4210 2530 3800 2310 3470 2090 3140 1910 2860 1740 2610

9 2760 4150 2490 3740 2280 3420 2060 3090 1880 2820 1710 2570

10 2710 4080 2450 3680 2240 3360 2020 3030 1840 2770 1680 2520

11 2660 4000 2400 3610 2190 3300 1980 2970 1800 2710 1640 2470

12 2610 3920 2350 3540 2150 3230 1940 2910 1760 2650 1610 2420

13 2550 3840 2300 3460 2100 3150 1890 2840 1720 2590 1570 2360

14 2490 3750 2250 3380 2050 3080 1840 2770 1680 2520 1530 2300

15 2430 3660 2190 3290 1990 3000 1790 2700 1630 2450 1480 2230

16 2370 3560 2130 3200 1940 2910 1740 2620 1580 2380 1440 2160

17 2300 3460 2070 3100 1880 2820 1690 2540 1540 2310 1390 2100

18 2230 3350 2000 3010 1820 2730 1630 2460 1480 2230 1350 2030

19 2160 3250 1940 2910 1760 2640 1580 2370 1430 2150 1300 1950

20 2090 3140 1870 2810 1700 2550 1520 2290 1380 2070 1250 1880

22 1940 2910 1730 2610 1570 2360 1410 2110 1270 1910 1150 1730

24 1790 2690 1600 2400 1440 2170 1290 1940 1170 1750 1050 1580

26 1640 2460 1460 2190 1320 1980 1170 1760 1060 1590 955 1440

28 1490 2240 1320 1990 1190 1790 1060 1590 954 1430 859 1290

30 1350 2030 1190 1790 1070 1610 949 1430 854 1280 767 1150

32 1210 1820 1070 1600 954 1430 843 1270 756 1140 678 1020

34 1080 1620 945 1420 845 1270 746 1120 670 1010 600 902

36 959 1440 843 1270 754 1130 666 1000 597 898 535 805

38 861 1290 757 1140 676 1020 598 898 536 806 481 722

40 777 1170 683 1030 610 917 539 811 484 727 434 652

Properties

Pwo , kips 1050 1580 897 1340 783 1170 665 998 574 861 492 738

Pwi , kips/in. 59.3 89.0 54.3 81.5 51.0 76.5 46.7 70.0 43.0 64.5 39.3 59.0

Pwb , kips 10000 15100 7690 11600 6380 9590 4870 7320 3810 5730 2930 4400

Pfb , kips 1640 2460 1370 2070 1140 1720 947 1420 802 1210 676 1020

Lp , ft 12.3 12.1 11.9 11.8 11.7 11.6

Lr , ft 150 137 126 114 105 95.8

Ag , in.2 98.9 89.5 81.9 74.1 67.7 61.8

Ix , in.4 4060 3550 3110 2720 2420 2140

Iy , in.4 1190 1050 937 828 742 664

ry , in. 3.47 3.42 3.38 3.34 3.31 3.28

rx /ry 1.85 1.84 1.82 1.81 1.80 1.80

Pex (KL) 2/104, k-in.2 116000 102000 89000 77900 69300 61300

Pey (KL) 2/104, k-in.2 34100 30100 26800 23700 21200 19000

ASD LRFD h

Flange thickness is greater than 2 in. Special requirements may apply per AISC

Specification Section A3.1c.

Ωc = 1.67 φc = 0.90

AMERICAN INSTITUTE OF STEEL CONSTRUCTION

También podría gustarte

- Ejercicios Tema 7 MetalicasDocumento4 páginasEjercicios Tema 7 MetalicasSol Mamani RodriguezAún no hay calificaciones

- Problema 1 Capitulo 4Documento36 páginasProblema 1 Capitulo 4Anonymous pk3dJaAún no hay calificaciones

- Día 7Documento2 páginasDía 7JPablo Cortés MataAún no hay calificaciones

- Diseño de Viga para Puente Peatonal PostensadoDocumento56 páginasDiseño de Viga para Puente Peatonal PostensadoJesus Alberto Martelo MarteloAún no hay calificaciones

- Tabla de Distribucion de Barras de AceroDocumento1 páginaTabla de Distribucion de Barras de AceroAugusto Tuto MarcanoAún no hay calificaciones

- Sesion 7 - Balance Hidrologico Mensual.1Documento8 páginasSesion 7 - Balance Hidrologico Mensual.1merlyn riverosAún no hay calificaciones

- Problemas de ACERO Cap 7Documento16 páginasProblemas de ACERO Cap 7Diego CordovaAún no hay calificaciones

- TAREA No.3 ECUACION DE MOVIMIENTODocumento3 páginasTAREA No.3 ECUACION DE MOVIMIENTORosa JiménezAún no hay calificaciones

- Tabla RigidezDocumento1 páginaTabla RigidezValentin Morales100% (1)

- Columna Fija en La Base y Libre en La Parte SuperiorDocumento28 páginasColumna Fija en La Base y Libre en La Parte SuperiorAnonymous o1MKQMEh100% (1)

- Tabla Perfiles - Icha AISCDocumento41 páginasTabla Perfiles - Icha AISCTimoteo MoralesAún no hay calificaciones

- Ejercicio Diseño A Flexión Viga Doblemente Reforzada PDFDocumento5 páginasEjercicio Diseño A Flexión Viga Doblemente Reforzada PDFMATIAS ABARZUA SANDOVALAún no hay calificaciones

- Deber 2 1Documento3 páginasDeber 2 1Mary Palacios100% (1)

- Quiz 13042020 Diego QuirogaDocumento5 páginasQuiz 13042020 Diego QuirogaDiego Alejandro QuirogaAún no hay calificaciones

- Ejercicio Resuelto PlateaDocumento5 páginasEjercicio Resuelto Plateajulio arismendiAún no hay calificaciones

- Chequeo de Punzonamiento Columna InteriorDocumento2 páginasChequeo de Punzonamiento Columna InteriorPavlova GómezAún no hay calificaciones

- 09 Tabla 2 SchaumDocumento1 página09 Tabla 2 Schaumwilliam arguetaAún no hay calificaciones

- Traccion Indirecta AdoquinesDocumento10 páginasTraccion Indirecta AdoquinesMauricio RemacheAún no hay calificaciones

- Cartera de RasanteDocumento176 páginasCartera de Rasanteandresfc37Aún no hay calificaciones

- Acero-Tabla Fy Miembro A Compresion PDFDocumento5 páginasAcero-Tabla Fy Miembro A Compresion PDFBrian Añaguari100% (1)

- Formulario Resistencia de MaterialesDocumento6 páginasFormulario Resistencia de MaterialesCarlos Alfredo Huaman MaqueraAún no hay calificaciones

- Trabajo de ColumnasDocumento2 páginasTrabajo de ColumnasJulieta Caceres LlampiAún no hay calificaciones

- Espectros Elásticos de DiseñoDocumento45 páginasEspectros Elásticos de DiseñoElmer Diaz TelloAún no hay calificaciones

- Semana 7 Extensión de La Fórmula de Euler y SecanteDocumento17 páginasSemana 7 Extensión de La Fórmula de Euler y SecanteWilder WilderbrAún no hay calificaciones

- Imprimir Zapata BiaxialDocumento10 páginasImprimir Zapata BiaxialGary Ramirez ToledoAún no hay calificaciones

- Pendiente Deflexion KassimaliDocumento61 páginasPendiente Deflexion KassimaliCristian Alejandro Briones VinetAún no hay calificaciones

- Taller 3Documento4 páginasTaller 3Boris Moncayo100% (1)

- Ejemplo Leyes FundamentalesDocumento3 páginasEjemplo Leyes FundamentalesGeraldin Montañez HuamánAún no hay calificaciones

- Practica #1, #2, #3 - Civ 2209 A VeranoDocumento5 páginasPractica #1, #2, #3 - Civ 2209 A VeranoDiegoAún no hay calificaciones

- Problema 631Documento4 páginasProblema 631Yuri Htlv100% (1)

- Determinar La Capacidad Resistente Última de La Siguiente Viga de Sección Transversal RectangularDocumento7 páginasDeterminar La Capacidad Resistente Última de La Siguiente Viga de Sección Transversal RectangularNahomi NanireAún no hay calificaciones

- Ejercicio 2 Armaduras Maquinas y ArmazonesDocumento13 páginasEjercicio 2 Armaduras Maquinas y ArmazonesCARLOS ALFREDO FRANCIS CABRERAAún no hay calificaciones

- Ensayo de Flexión Aluminio InformeDocumento4 páginasEnsayo de Flexión Aluminio InformeAlex Garcia RiosAún no hay calificaciones

- Miembro de Tensión de Angulo DobleDocumento4 páginasMiembro de Tensión de Angulo DobleJuan Carlos Amén ZambranoAún no hay calificaciones

- Propiedades Arquitectonicas Perfiles AISC PDFDocumento79 páginasPropiedades Arquitectonicas Perfiles AISC PDFEleazar Mendez100% (1)

- Problemas Vigas IsostaticasDocumento4 páginasProblemas Vigas IsostaticasGuayo Ojeda Mendoza100% (1)

- Diagramas Momento Curvatura 02 PDFDocumento4 páginasDiagramas Momento Curvatura 02 PDFelzer saicoAún no hay calificaciones

- Zapata PiramidalDocumento3 páginasZapata PiramidalMigue Cazorla0% (1)

- Ejercicios de Estructuras MetálicasDocumento4 páginasEjercicios de Estructuras MetálicasMica Ríos Del Castillo100% (1)

- INSTRUCTIVO DE ACCESO UPS - COLABORADORES 2022 v1.0Documento19 páginasINSTRUCTIVO DE ACCESO UPS - COLABORADORES 2022 v1.0ROGELIO LEONAún no hay calificaciones

- Flexocompresion Biaxial (Metodo de Bresler)Documento9 páginasFlexocompresion Biaxial (Metodo de Bresler)Kevin Capuma Cruz100% (1)

- Taller 2 de HormigonDocumento14 páginasTaller 2 de HormigonEmmanuel Chacon VargasAún no hay calificaciones

- Madera TrabajoDocumento14 páginasMadera TrabajoStefano SebastianAún no hay calificaciones

- Ejercicio 4Documento5 páginasEjercicio 4Sergio Delgado EscobedoAún no hay calificaciones

- INFORME 2 Ensayo de Doblado en FríoDocumento9 páginasINFORME 2 Ensayo de Doblado en FríoLogan JD Tdf TdayAún no hay calificaciones

- Estacion Hidrometeorológica EvapotranspiraciónDocumento11 páginasEstacion Hidrometeorológica Evapotranspiraciónbacilia Condori choque100% (1)

- Matriz de Rigidez Por El Principio de Trabajo VirtualDocumento16 páginasMatriz de Rigidez Por El Principio de Trabajo Virtualluis alberto ramirez ayraAún no hay calificaciones

- Vibraciones Libres 1GDL Ejercicios PracticosDocumento27 páginasVibraciones Libres 1GDL Ejercicios PracticosMAX FAún no hay calificaciones

- 384181615-Informe-Dosificacion FINALDocumento11 páginas384181615-Informe-Dosificacion FINALCeal EscobarAún no hay calificaciones

- Diseño de Vigas Te (Modelo en Mathcad)Documento9 páginasDiseño de Vigas Te (Modelo en Mathcad)Espinoza AntonioAún no hay calificaciones

- Resistencia de Materiales - Tarea 4Documento2 páginasResistencia de Materiales - Tarea 4Abel Villa100% (1)

- Costo Horario d8Documento1 páginaCosto Horario d8betaAún no hay calificaciones

- Norma 2554 HDocumento8 páginasNorma 2554 HByron Vladimir ArévaloAún no hay calificaciones

- Practica 1 de MecanicaDocumento6 páginasPractica 1 de MecanicaDiego Armando Zavaleta VasquezAún no hay calificaciones

- Longitud de Desarrollo 2 PDFDocumento4 páginasLongitud de Desarrollo 2 PDFmau199321Aún no hay calificaciones

- Estructuras Practica 2Documento3 páginasEstructuras Practica 2neiver centellasAún no hay calificaciones

- Manual de Uso Grúa Torre COMANSA 5LC5010Documento50 páginasManual de Uso Grúa Torre COMANSA 5LC5010Sara100% (1)

- Bomba de Desplazamiento PositivoDocumento2 páginasBomba de Desplazamiento Positivocelina podettiAún no hay calificaciones

- Datos Completados de MaximasDocumento28 páginasDatos Completados de MaximasRomario Hancco QuispeAún no hay calificaciones

- Tabla de Momentos Positivos y NegativosDocumento1 páginaTabla de Momentos Positivos y NegativosJean Pierre JimenezAún no hay calificaciones

- PilotesDocumento27 páginasPilotesJavier ChoqueAún no hay calificaciones

- Calavera - Calculo de Estructuras de Cimentacion (Sin Sombras) 19.3mbDocumento267 páginasCalavera - Calculo de Estructuras de Cimentacion (Sin Sombras) 19.3mbFernando García SaezAún no hay calificaciones

- Introducción CimentacionesDocumento31 páginasIntroducción Cimentacionesaylin massielAún no hay calificaciones

- AsentamientosDocumento53 páginasAsentamientosJavier ChoqueAún no hay calificaciones

- ZapataDocumento28 páginasZapataJavier ChoqueAún no hay calificaciones

- Coeficiente BalastoDocumento32 páginasCoeficiente BalastoWALTERAún no hay calificaciones

- Ejemplos de Diseño ACI 318-02Documento872 páginasEjemplos de Diseño ACI 318-02Yesenia Ortiz96% (24)

- Reflexion Sobre El Comportamiento de Suelos Parcialmente SaturadosDocumento12 páginasReflexion Sobre El Comportamiento de Suelos Parcialmente SaturadosAlejandro RodríguezAún no hay calificaciones

- Estudio de CasoDocumento20 páginasEstudio de CasoJavier ChoqueAún no hay calificaciones

- CTE DB CimentacionesDocumento164 páginasCTE DB CimentacionesFrancisco Gimenez RothemundAún no hay calificaciones

- Predicción de La Curva CaracterísticaDocumento93 páginasPredicción de La Curva CaracterísticaJavier ChoqueAún no hay calificaciones

- CaracterizacionGeotecnicaDeUnSueloTropicalLateriti 4868989Documento12 páginasCaracterizacionGeotecnicaDeUnSueloTropicalLateriti 4868989Exneyder Andres MontoyaAún no hay calificaciones

- CTE DB CimentacionesDocumento164 páginasCTE DB CimentacionesFrancisco Gimenez RothemundAún no hay calificaciones

- TEMA11-Corte Directo (CU)Documento27 páginasTEMA11-Corte Directo (CU)Javier MendezAún no hay calificaciones

- BULBO PRESION ISOBARA - Distribución de Esfuerzos en El Suelo Debido A CargasDocumento21 páginasBULBO PRESION ISOBARA - Distribución de Esfuerzos en El Suelo Debido A CargasWML1964100% (1)

- BibliografiaDocumento23 páginasBibliografiaJavier ChoqueAún no hay calificaciones

- Proyecto de Pequeñas Presas Bureau of ReclamationDocumento312 páginasProyecto de Pequeñas Presas Bureau of ReclamationRomina LeguizamónAún no hay calificaciones

- Capacidad de Carga en SuelosDocumento13 páginasCapacidad de Carga en SuelosJavier ChoqueAún no hay calificaciones

- 3 - Empujes de TierraDocumento33 páginas3 - Empujes de TierraENRIQUE VERAAún no hay calificaciones

- Puentes - ApuntesDocumento164 páginasPuentes - ApuntesWilvert Reyes NolascoAún no hay calificaciones

- LOUGENOSDocumento4 páginasLOUGENOSJavier ChoqueAún no hay calificaciones

- EsfumadoDocumento75 páginasEsfumadoJavier ChoqueAún no hay calificaciones

- Geome Analit CartesianoDocumento12 páginasGeome Analit CartesianoJavier ChoqueAún no hay calificaciones

- Modulo 6Documento69 páginasModulo 6Jhonatan Rafaele ValenzuelaAún no hay calificaciones

- Esfuerzos y Deformaciones en Pavimentos FlexiblesDocumento86 páginasEsfuerzos y Deformaciones en Pavimentos FlexiblesFabián Ganzhi FajardoAún no hay calificaciones

- Geome Analit CartesianoDocumento12 páginasGeome Analit CartesianoJavier ChoqueAún no hay calificaciones

- 03 Cap 9 ConsolidacionDocumento13 páginas03 Cap 9 ConsolidacionJavier ChoqueAún no hay calificaciones

- Geome Analit CartesianoDocumento12 páginasGeome Analit CartesianoJavier ChoqueAún no hay calificaciones

- 03 Cap 9 ConsolidacionDocumento13 páginas03 Cap 9 ConsolidacionJavier ChoqueAún no hay calificaciones