Ejemplos de Circulos de Calidad

Cargado por

JoyArteagaRiveraEjemplos de Circulos de Calidad

Cargado por

JoyArteagaRiveraCommon questions

Con tecnología de IAIn the case study, the quality circle contributed to cost savings by efficiently managing resources, such as eliminating unnecessary documents and recovering office materials for reuse. The meticulous implementation of improvements, like reducing time and resource wastage, led to substantial savings, evidenced by recovered office supplies valued at $8000.65, demonstrating the financial benefits of structured team efforts in optimizing processes .

Continuity between meetings is crucial for the success of quality circles as it ensures ongoing engagement and progress tracking. Regular meetings help maintain focus on objectives, allow for timely addressing of issues, and facilitate the follow-up on previous actions. This continuity helps uphold momentum and fosters a culture of consistency in tackling work-related problems .

The 'archivo muerto funcional' project exemplifies practical application of quality circle principles by demonstrating how a small group identified specific problems within their work environment and systematically addressed them using the eight-step problem-solving process. They effectively reduced document retrieval time, eliminated misplaced documents, and minimized access to unnecessary personnel, showcasing practical improvements and resource efficiency. Such structured efforts highlight the circle's positive impacts on process efficiencies, cost savings, and team dynamics .

Quality circles have limitations in addressing organizational restructuring because they are primarily focused on solving immediate, localized issues rather than broader organizational change. They do not serve as a strategy for overhauling administrative frameworks or addressing macro-level financial issues. Furthermore, their impact is often confined to improving existing processes rather than implementing entirely new systems .

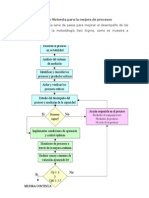

The eight-step problem-solving process enhances the effectiveness of quality circles by providing a structured approach for identifying and resolving issues systematically. Steps such as finding a problem, investigating causes, and implementing solutions ensure thorough analysis and decision-making. This methodology helps employees focus efforts, encourages consensus-building, and allows for clear evaluation of outcomes, leading to effective and lasting improvements .

Successful teamwork requires elements such as dialogue, learning to listen to others, reflection, and collective thinking. These elements foster participant engagement and the achievement of objectives through creativity, innovation, and a commitment to continuous quality improvement .

The employees gained several benefits from participating in the quality circle project, including improved communication skills, enhanced teamwork abilities, and personal growth. The project also elevated the quality of their work environment and provided opportunities for material recovery and cost savings, reflecting increased resourcefulness and effectiveness in their roles .

Involving all members in decision-making within quality circles is important because it enlivens diverse perspectives and fosters collective ownership of solutions. It enhances team cohesion, ensures that decisions are well-rounded and considerate of different viewpoints, and bolsters employee buy-in and motivation by making them stakeholders in the process. This inclusivity is fundamental to cultivating a cooperative work environment .

Quality circles play a crucial role in product quality improvement and employee motivation by involving employees in identifying and solving work-related problems. They encourage continuous learning and skill development, which enhances employee motivation. By empowering employees to implement solutions and verify their impact, quality circles also contribute to better product quality and a sense of ownership among workers .

Organizations may face several challenges when implementing quality circles, such as the difficulties in restructuring administration, solving financial problems, or replacing long-term planning. Quality circles are not designed to innovate the product or process radically or to improve human relations sustainably. Additionally, achieving significant results typically takes time, emphasizing the need for patience and persistent effort .