Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Datos Pernos Rdty Ty

Datos Pernos Rdty Ty

Cargado por

Anonymous vjQmaeA0 calificaciones0% encontró este documento útil (0 votos)

6 vistas37 páginasrdydrt tyh tyty

Título original

datos pernos rdty ty

Derechos de autor

© © All Rights Reserved

Formatos disponibles

PDF o lea en línea desde Scribd

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentordydrt tyh tyty

Copyright:

© All Rights Reserved

Formatos disponibles

Descargue como PDF o lea en línea desde Scribd

0 calificaciones0% encontró este documento útil (0 votos)

6 vistas37 páginasDatos Pernos Rdty Ty

Datos Pernos Rdty Ty

Cargado por

Anonymous vjQmaeArdydrt tyh tyty

Copyright:

© All Rights Reserved

Formatos disponibles

Descargue como PDF o lea en línea desde Scribd

Está en la página 1de 37

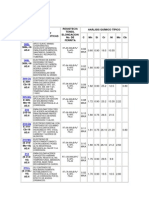

UNIDADES DE CONVERSIO!

‘MULTIPLYING COEFFICIENTS

Length units

var

connate

tobe determined

wot 1 284 30.48 ouae 1

39.31.1092 3997102 1 2 36 set

3.281.102 ‘sze102 8,393.10 1 a 3281

1,0096.102 1,0936.10 2.178102 0.3333 , 1.0036

10> 10 2stio= 03088 ots 1

‘Surface units

Valeur connues

Krown alice

vvaleare

Values

tobe determined!

1 1 15,6 10% szesi0° | e961.27.108 1

wo , 64516 1 929.03 8361.27 to

1,85.102 188.101 1 68 Ma 1296. 1.88.10

tos wo? 6451610 1 929 23613 ot

noreios | 076.109 | esseai02 | ono7es 1 ° vores

1, 196.108 nass.i0¢ | 7716102 1.196.102 oan 1 1.196

toe os 6.4816.10+ oz 920.102 0936 1

Volume units

Valours cones

1 ro 1637 1 2916.10 7545108 ro

os , 1397 10 zssieio | 1645109 10

sr2i0¢ | 6102.102 1 6102 rze10 | 463510 | 61.02.10

oe 102 1.387.103 1 2sa16 764,985 ro

353.109 asa.i0¢ | os7eri02 | 3509 1 a 358

1,908.10" ra0a.io¢ | 21,43106 108107 | 7:04.02 1 1,300

0 lo 16,387.10 102 zsaie.0> | 1648102 1

Valers connie

Weight units

1 28,38 ssa6 w 80,900.10 | 907,2.108 oe 1016.10

35,27.10° 1 6 38a 192 e000 | 5.27310 | 5004

2208102 | 628.102 1 2,208 ua 2000 2,205 2240

103 zeas.ic2 | 459,6.102 1 soo 901.2 we wie

isesio¢ | osse.i0> | agez10> | 960.102 , masz 1968 20

aaozio¢ | siasioe | osio> | raozo> | seo 1 1.0 Le

oe 2e6.10¢ | 4536.10 wos | soso2.io9 | 907,2.102 1 1016

oseaios | aze.10¢ | os4csio> | oesio> | soos ogsat 0.966 1

Pressure units

valeur Known values

Aonnatre

Yates

obo determined

, ust M51 1 145110 1422.94 2240

0.889.101 1 10 639 oe 99,1 14a

0680.10 0 1 699 10 oat 144

0 241109 4st , 14st Lae. 224

0.689.102 oe 101 0.889 1 0981 18a

703.102 | 102102 1.02.10 0.703 102 1 1878

oss.i03 | osseio: | 640.10 0.446 ose 0.35.10 1

‘Temperature units

(CF) = 1.810) + 32

Tightening torque units

001 (0.001 (0.0001 oie | ooo | ose | oo0ee | aooorse

100 on, 01 1,02 ope 1418 0.886 00738)

1000 10 aa 102 02 wie 3.863 (0738

10000 100 10 108, 102 118 28,63 138)

98 098 0.088 0.0098 001 Ex) 0.868 opr24

9810 on oat 0.98) 109) 1380) 86,80 7

708; ‘ores | ooor0s | 0.0007 007 ‘000072 00068 (0.0082,

128 18 ones | oor 1182 0115 16 0,088

1350 138 138 0,135 138 018 102, 1

Bott dsign lad in dat Boaring surfs radia iam

‘ightoning torque i m dat 1/2 angle Cos at top of tend (0.866 or 80)

= Mhrosd pitch in m Section at minor alameter in mn?

‘rrosd fiction colicint = Bot sre in bar

Bearing suraco tein cation = a with across at nm

BODY ELONGATION

CALCULATION

L= Length at 1/2 nut thicl

Resistance R Hardness:

Viekers Brinett Rockwell

Nim? Kgt/mm* si x 1000 wv HB HRB HRC

330 93.6 479 95 90 520

340 34,7 49.8 99 94 55.4

350 387 50.8 103 98 88.1

360 367 52.2 106 101 603

370 377 83,7 110 105 622

380 387 56.1 113 108 639

390 998 56.6 417 m1 655

400, 408 58,0 120 4 670

410 a8 59.5 124 118 68.5

420 428 60.9 127 121 699

430 438 62.4 131 128 713

440 449 63.8 134 128 726

450 489 65.3 138 131 739

460 469 66,7 141 134 75.1

470 479 68,2 145 138, 763

480 489 68.6 148 141 178

490 50.0 Tt 152 144 786

500 51.0 72.5 158 147 797

810 520 74.0 159 151 808

820 53.0 75.4 162 154 818

830 540 769 166 158 828

840 554 78.3 169 161 838

850 561 73.8 173 164 847

560 STA B12 176 167 858

870 58.1 82.7 180 71 86.7

580 59.4 84,1 183 174 e758

590 60.2 85.6 187 17 883

600 e12 87.0 190 180 29.0

610 62.2 28,5 193 183 897

620 632 89,9 196 186 90.4

630 64.2 91.4 199 188 910

640 653 92,8 202 192, 918

650 663 94,3 208 195, 922

660 673 98,7 208 198 928

670 683 97.2 au 201 93.4

680 69.8 98,6 214 204 940

690 704 100,1 217 207 945

Resistance R

Hardness

Brinell Rockwell

N/mm? Kgt/mm? pst x 1000 a HB HRB HRC

700 714 1015 220 210 950

740 724 103.0 228 212 955

720 734 104.4 226 215 960

730 744 1059 229 218 965

740 758 107.3 232 221 97.0

750 765 108.8 235 224 974

760 78 110.2 238 227 978

770 785 47 241 229 98.2 208

780 79.5 113.4 244 232 986 aaa

790 80,6 114.6 247 298 99.0 2u7

800 B16 1160 250 238 294 222

810 82.6 175 283 Bat 22,7

820 93.6 118.9 256 244 2338

830 846 1204 260 247 238

240 85,7 1218 263 250 248

850 867 1233 266 253 248

860 er7 1247 269 256 253

870 88,7 1262 272 258 258

880 897 1276 278 261 263

90 208 129.1 278 264 268

900 918 1305 281 267 278

910 928 1320 284 270 277

920 938 193.4 287 273 28.

930 948. 1349 290 276 285

240, 969 1363 294 279 289

950 969 1378 297 282 293

960 97.9 139.2 300 285 297

970 989 140.7 903 288 30.1

980 999 142.4 306 291 90.5

990 101 143.6 309 294 30.9

1000 102 1450 312 296 31.2

1010 103 146.5 315 299 31.6

1020 104 147.9 318 302 319

1030) 105 149.4 321 305 92.2

1040 106.1 1508, 324 308 32.6

1050 107.1 152.3, 327 3 329

1060 108,1 183.7 330 314 33,2

Resistance R Hardness

Brinelt Rockwell

N/mm? Kgt/mm? psi x 1000 av HB HRB HRC

1070 109,1 185.2 333 3i7 336

1080 110.4 156.6 336 320 339

1090 1112 158,1 339 323 34.2

1100 112.2 159,5 342 325 34.6

1110) 11,2 1610 345 328 34,9

1120 1142 162.4 348 331 352

1130 115.2 163.9 351 334 356

1140 116.3 1653 954 337 359

1150 117.3 1668 987 340 96.2

1160 1183 168.2 360 342 96.6

1170 119.3 1697 363 345 369

1180 1208 1741 366 348 372

1190 1214 172.6 369 351 375

1200) 122.4 1740 972 354 379

1210 123.4 1758 378 387 382

1220) 124.4 176.9 378 360 388

1280 125.4 178.4 981 3683 38.9

1240 1265 179.8 384 366 39.2

1250 127.8 181.3 387 369 995

1260 128.5 1827 380 371 99.8

1270 129.5 184.2 383 374 40,1

1280) 130.5 1856 386 377 40.4

1290 1318 187.1 399 380 40,7

1900 132.6 1885, 402 382 410

1310 133.6 190.0 405 388 413

1320 184.6 1914 408 388 416

1330 1358 1929 aut 391 419,

1340 1987 194.3, aia 304 424

1350 197,7 1958 47 397 424

1360 1387 197.2 420 399 427

1370 199,7 198,7 429 402 430

1380) 140.7 200,1 426 405 43.8

1390) 1418 2016 429 408 438

1400) 1428 203.0 432 an 438

1410 143.8 204.5, 435 41g 444

1420 1448 2089 438 416 444

1430) 1458 207.4 441 419 448

ag

{thread d ma Ms wz Me 10 m2,

pitch P oF 1 7 125) is. 175

26 30

32 26

= 45. 9

is O15 015 015)

os 1 r 06 06

i, max. 47, SI 68. 78 92 112 137

Fa max 4 io 7 = 10 12,

ss rin 382 582 678 978 1173

a, ‘min 59 69 89 28, 18, 156. 174

je min. 7.66 879 11,05 1212 1438 18:90 2110

F max, 14 2 2 3

iz “min. 3.35) 385 622 732

max. 3.65, 415 658, 7.63.

K min, 23 27 44 54

r min 02 0.25) 04 06.

max. 7 8 10 7 19

120.

4130)

160

170

180.

_190

200,

210.

220

[2

240

| 160 159.2 1608

250.

11931207 |

1292

140 139.2 1408 |

2 1508

189

4792

1

198.1

200.1

219;

229.1

299,1 2409

(2509

245

(sn eccordance with the standard ISO 401

4th te oxcop

ified hereunder for whieh ISO prescribes:

= The screws can be constructed in steel for property classes: 45

(17.88 0°08 (27), 818 (GF), 109 4F), 12.9 GF, orinstalniess steel

for property class A2-70.

S510 ZT TZ aaa

ie aos OS STA sions mechaciel charectonstes,sirlace protesion, approval

e s177 20032368 97,72 okaging, consult part 2 of the catalog,

16 18 21 34 = For property classes and dimensions normally carried In stock,

s ea) anault te Fontana price lt

~ The masses (weighs) or hexagonal head screws a

The tolerance for tineed ls 5 Ieee eR

'

Dimensions in mm.

mts mio me M20 22 M24 Mar M30

2 2 25 25 25 3 3 35.

3 38 22 rn 50 34 2 38

40 “4 40 52 58 00 68 72

9 57 et 65 o 73 72 85

035: 02 02 02 02 02 02 02

06 08 08 08 08 08 08 08

357 i77 202 22.4 Baa 26.4 30.6 334

14 16 18 20 22 24 27 20

1973 1573 1773 1967 2187 2367 2648 2948

205 225 253 282 30 33.6 38. 427

24.49 2675 30,14 3359 3572) 39,98 4520 50.85

2 2 3 4 4 ‘ 6 6

3a 2m 7128 1228 7378 478 1655 1828

298 0,18 47 12,72 14.22 1522 178 19,12

6 62 79 36 28 103 irra 128

08 06) 08 08 08 + +

22 24 2 eS eS E a aes

2167 2367 2067 2067 3161 “0 45

te hy i Ih i rn he te be I he h i I

iin. mak min max min max min mami ma iia. max, min. ma

Fortes

Cees

a 2 ae:

1626 228518 en

ainsi jos 2359

2836; 7 Sian 2 A ZS

31a 20583168295 zl

3646 2553821534175

5 4790543265 —99—~—«228

as 56 2855 48S 27S

1 6t a a

866 245558 54 a5

676: 7265568 e475

7386 265578 74875

2090 “869582 Te 615

90100 970502755874

1001101 05895102558

110120) 116995112955 108-915

120130 126 10951224055 1181015114 95110

130140. 1301195 1921155 1281115 124105120

1461295 1421255 1981215 134115190

1561995 1921958 1481915 144—128~—~140

1501965 1491925 1481285 T4122 197

1631465159 ~—*1425~«165~~«1085~«151—«192——«*147

173.1585 16941525 ~—«*165—«1485 tei 142187

4891665 179 1625~4175~~«1585_—4171_—«152—*167

1931765 169 41725~—«185~~«1685 181162177

thread d Ms Me ma to m2

itch P OB, i 125 15 175

b 15125 16 18 22 26 30)

$0 795 <1 200 = = 28 2 36

5 max 2a 3 375 45 525)

in 08: 1 1.25 15 175

e max 05, 05 08 06 08

a, max 6 72 102 122 147

F max 58 648) 358 1058 27,

min, 452 552 742 942 13

a, min, oF, a7 Ta 154 172

e min 863 7089 142 1672 20,88

h rin 312 362 492 595 705;

max 388 438 568) 685 795:

Ke mi 22 25 35 42 5

r in 02 025; 08 04 06

5 max 2 13 7, 19

‘in, 1257 1657 18.48

7 7h te i ‘e a h ie B fe ‘y

nom. _min max | min max min max min max min max min max

16161169

2019 2

252426 = ®

202031 | 10 4 7 ra

nurs 7a] ots 19 2 7

40987413 | 20 2 7 22) ORAS

45437463 | 25 2 22 a 1675_—_—-2 ne 9

so 487 513 | 90 4 a 22 ai76lZs 185 24

55535 565 32 37287588 215) 7 162525

co 585 615 a7 (Sa 265) EE)

os 635 085 se7s 43 315 0262596

70685715 7548 365. “4912540

a0 785615 317558 455 4125 «80

90882 918 565 Ca)

100 98.2 1018 665 7 61.25 70

1101082 _111,8 | _UNI6727 screws with partially threaded shank 712560

7201162 421,8 312590

1901268 192

140198142,

150148152 7

160156 166

100176 184

200196 208

NoTES:

~ The setews inthis table conform to those of standard ISO 4018

(UNI'5725) and ISO 4016 (UNI 5727) with the ex<

dimensions listed Below for which the ISO presen

lon of the:

= Tho screws can be constructed in stool for property classes 48

(iP), 58 rea (2),

= Tho nuts aro according to UNI'5592 (thats equal in dimension to

So Sas eevee] eg ea anita ee fo

A le he to i B i Te le fe

CUADRO DE VALORES STANDARD DE TORQUE

ie

% (ox

ssonce | mum | “ane

sue, | "a | apex foslarlasr|ze| w]e |x| re |e] a |} ass] ufso] 2} as] oo] | os

nor ‘co

a,

rasonen0 ie aor SE 2 Se Wats tn ones re sn a

erostorrent e conpnds cen gues can ane pone gan i

eo esee cate ese seo ngo eros ln peste ene ue eer a

ECHLCON

yee acoso ten i res despre pn panes sda Gen sane

Cortesia de Petersen Publishing Company

CONVERSIONES DE VALORES DE TORQUE

De pulg - Ib a pulg oz

De pulg - 02 a pulg - Ib

OS Se eo C8 BT

(10 Tt ox [pls ot | plo | pl et pag ce pul ox [pt ox [puipea rig cz [pager "9° | papin| pap] pata | page | pla | pag [pts | pug | pa | pals

Oo] of te] 92] <8] 6] co] s6| ui2] 126] 14s oO} of 063] 125[-106] 250] 313] 375] 436] soo] 569]

40 10-176 | 102 | 200] 22 | 240] 256] 272] 208 [ a0 10 | 62s] esa] 750] 613] 075] 096] 1.000] 1.069][1.125 7.100)

20 | a20| 298 | ose| sea] aee| «oo| ere] «a2| «48 | «ca 20 |1.250| 4.910] 1.075] 1.400] 1.500] 1.560] 1.625] 1.680 1.750[ 1.019.

20| 400 | 406] 512526 ssa] 260 576 502] cos | eae _30|1.875] 1.038] 2.000|2.080]2.125| 2.108] 2.250|2.919|2.075|2.450)

40| oso | 656] 672 | -es0 | ros | 720 736| 752] 70 | ree 40 |2500|2.563|2.625|2.608|2.780| 2.015 | 2.075 | 2.038] .000 [3.085

50 | 200 exe] s02] eo] ecs| 000] coe] or2| 026] oc 50 [9.125] 9.160].250|3.13] 3.575|s.436]s.500|s.563 [9.625 | 3.680,

60] 060 076] 002 | 1008 | 1024 [1040 | 1056 | vo72| 1088 [1104 60 | 9.780.813 |2.075| 5.008] «.000] 4085] 4.125] 4.108 | 42504319)

70_[ 1120 [v2a6 [1152 [1160] r16¢[-1200] v2i6 | s202[ 1248 [1264 70 | 4.275] 4438] 4500] 4563 | «625 ]«.606]4750|4.619| «075 | 4.000]

20 | 1200[ 1296] 19:2 [1320 | r3<4) 1960] 1376 | 1992] 1408 | 1424. 00 [5.000] 6.065]5.125] 5.168) 5.250] 5:15] 5.075| 5.408] 5.500 | 5.563]

90 | 1440 [1456 | 1472 | 1400 | 150% | 1520 | 1596 | 1552 | 1568 90 [5.625 5.000|5.750]5.013]5.675|5.036 [6.000 |6.063 [6.125] 6.108

100 | 1600, 00 [6.250] 1

pulg Ib x 16 = pulg oF pulg oz + 16 = pulg ib |

De pie - tb a pulg - Ib De pulg - Ib a pie «tb |

Ff oe ese oa forasal ac faces oes ede © [ave 2_ lose) «fase e [rele asa

Guat [pio [raat [eae [oss [pag w [ooge [ostp [oa [page Toe [pew pet | ree | pe | pet | pie | se | pew

of of 2] 2[ ssf «| col 72] ea] 6] 108 of of 089] 2s0| 335] 17] 00] 563 _667| 750

30] 120 [asa] tsa] 156] 68 [veo] v02 | 20a] are | 228 10 | 003917 [085] 7.167 [7.260 1.359 [7.417 | 7.500] 7.9)

20 240 | asa] 264] 276] 200| 900] a2] szs]as6| 348, _ 20 |.667 [1.750 3.917 [2.000 2250] 2.593 ]2.417)

30. sso |-a72| s84|o96| 0s [azo] soe | aaa] «56| a6 20 |2.s00|asea 2.750] 2.999) 3.003] 9.167 9.250)

20-00 | a02| sos] sie] 520] 540] 552] sea] s76| sos «0 [3.303] 3.617 3.505 |9.667 3.917 «000 4.083.

50] 00 |-e12| cea] e260] 40 | 660] c72 | 604] co6| 708, so |«167] 4.250 ‘aat7 | 4.500) 74.750] 4003 [4.917

co] 720 [732] 744] 756] 760] 700] 702 | soa] er6| a2 60 | 5.000] 5.083 '5.250|5.399) 5.585 | 5.667 | 5.750)

70-| s40| es2| 064] 076] 80] 000] 012 | o24] s06| 048 70 [5.603] 5.017 e003 [6.167 [6-417 [6500/6565

'20-|_a60.| 972] 284] 096] 1008 | 7020] 1092 | ao4a] 1056] 1068. eo | 6.667] 6.750 (617 |7.000) 7.250] 7.599] 7.417)

‘90 | 1000.[ 1092 | 110s [r116 | 128 [1140] 1152 ase4] v176] 1108, 90 [7.500] 7.509 7.750 |7.635) o.093 [6.167 [8.250

00 | 1200 700 [6.333 |

io bx 12 = pulg lg b+ ¥2 = pio

De pulg - Ib acm - kg De cm - kg a pulg - Ib

nfs ee fuse afore 0 ee

p04 Fg [emg | cmeg | emig | emg | cmap | emg ts enag_[-emug | emg [emp [ omip | emg | cmap | emt i

7.152] 2.304]3.456] 4.608 5.760] 6.012 [of _.s6al_+.7as] 2.600) 9.471] «099] 5.206] 6.074) 6.002] 7.000

42.07| 19.05] 1497 | 16.13] 17.28 16.49 30 | wa77] o.545}10.<12}11200)i2. 140|13.01e10.803|14.761]15.019]16.406)

24.19] 25.95 | 26.49] 27.65 26.00] 70.96 20_|ir.asaf10.272]10.005]10.057]20.628|21.603]22.560|23- ]

De pie - Ib am-kg De m-kg a pie - Ib

TE NT fore fatal a [ec] or ren ols

may [oe | mag | tg [mtg | mtg | mtg [tg [mtg [io pie | pe | pe | pe | pee | ple | oem | pee

9.106 [0.277 [oais|o.ss3[o.cor|oss0]o.css|it06[i25 ol 0 44.47 [21.70 20.95 [96.17] «3.40 50.69] 57.06 [65.10]

521] 1.660.700] 1.006|2.07«[2.212[2.351|2009|2028 10 | 724 6.8] 940] 101.3] 108. 250 190.2[ 197.4]

200s[aoea[a.1e1]3.s19|9457|3.506]3.706]3.07214011 20 [rer 750.1 [166.4] 173.6] 1003) 1953 [202.5] 200.8)

4.207 ]4.426 [asee[«.702|4ed0|ao7o[s.n17]5255|5c98 30 [217.0 231.5 [220.7 [246.0] 250.2[260.4| 267.6 274.0206

5.670 |[5 200 [5.047 [6.005 [6223 [6.262|6.500]6020|6777 «0 | 2603 202.0 [s11.0]316.3|325.5|s02.7 [340.0 [947.2544

7.053 [7.181 | 7.990| 7.468 [7.608 | 7.745, coe fe.tse so [oer 276.1 [309.3] 990.6] 307.8] «05.0 [4123] s10.5 420.7,

3.496]8574[ 8713] 0.051[ 8.089] 9.126 fei. 60 [aae0 a0. [455.7 | 462.0] 470.1] 477.4] 404.6] 01.8 [490.1

9.819] 0.057 10.00] v0.29 10.97] 10.51 10.70 [10.02 70 [5063 320.5] 520.0] 505.2| 542.5 | 519.7 | 566.0] 568.2) 571.4)

a120[ 1134 [s40[r.62[s175[ 80] a203[i217 [1231 _ 80 [s7e8 399.1 [000.3] 607.6 [614.5 [622.0 [620.3] 636.5

12.50 1206] 13.00[19.14[ 19.20] 19.42] 19.55]13.69, 90 [651.0 65.4] 6727| 670.0 607.1 [004.5] 701.6] 708.8 [716.1

oo [7203 }

plo 1 x.41989 = m kg mkgx 7.233 = pie ib

NOTA: Un metro kilogramo es igual a un metro kilolibra (expresado como: 1 mkg = 1 mkp)

De pie - Ib Nm

De Nm a pie - Ib

! CONVERSIONES DE VALORES DE TORQUE NEWTON METRO

ay ae ete ca feof Poses 6 Perel a fone wr eae gfe aa geo [ear po

es a pet [pee | pet [eb | veh | peb | vem | pee | oem | pom

oI] of 1.96] 2.73] 4.07] 5.42] 6.70] 0.13] 0.40) 10.84 of of «| iat 22s] 20s] ses] cas] 516] 500] aoe

30 | sa:56] 14.91] 16.27] 17.62] 18.08] 20.23) 21.60] 25.08] 24.20] so | 728 [ex | eas] 959 10.99 [11.06 | 71.00 | 1254] 1326 [1401

20 | 27.13] 28.47] 29.69] 91.10] 92.54] 03.09] 95.25] 96.61] 7.97 20 [47s [5.40 | 16.23 | 1696 | 17.70 | 16.44 | 19.16 | 18. | 2065 | 2120)

‘30 | 40.67] 42.02] 49.38] 44.73] 6.00] 47.45] 48.60] 50.16] 51.53 30 | 2213 | 22.6 | 29.60 | 24.34 | 25.00 | 25.81 | 26.55 | 27.20 | 26.03 | 2076)

40_| 54.22] 55.50] 56.04] 68.20] 50.65] 61.00] 62.26] 63.71] 65.07 40 | 2950 | 90:24 | 90.96 [31.72 | 92.45 | 29.19 | 03.95 | 9467 | 35.40 | 96.14)

50_| 67.76] 69.14] 70.49] 71.85] 73.20] 74.56] 75.91] 77.27] 78.62 50_| 260s | o7.62 | 98.25 | 0.09 | 99.63 | 40.57 | 41.30 | 4200] «278 | 40501

60] 81.99] 62.69] 64.05] 05.40] 66.76) 68.11] 09.7] 90.00] 02. eo 45.73 | 4647 | 47.20 | 47.96 | 28.68 | 4042 | 50.15 | 50.80

70_| 94.89] 96.28] 97.60] 98.06|100.31]101.67]103.03]104.36]108.74 70_| 51.63 | 62.37 | 59.10 | .04 | 54.56 | 85.32 | 96.05 | 68.79 | 57.59 | 5827)

(80, |108.45|109.80}111.r6}i12.51|1¥9.67]116.23)116.56]117.04{119.29] 120_| 59.00 [59.74 | 60.48 | 61.22 | 61.96 | 62.60 | 63.49 | 64.17 | 64.01 [ese

90 |122.00}129.36|124.72]126.07|127.<9]128.78]130.14]131.49]132.65 ‘s0 [658 [67.12] 67.86 | 68:59 | 69.29 | 70.07 | 7081 | 72.54 | 72.26 | 73.02

700" ]135.66) 100] 73:76

| ple bx 1.9556 = Nm 11m = 0.78756 pie to

De puig - Ib 2 Nm De Nm a pulg -

EE ee 2 ee o [ested 3 feagea] 4 fase] 6 [aero [eas

(p00 imme |e [nm | nm [eff [ae [ae [ee | ee | oe | op | oe | oe | oe | me

[of of sal 226] ‘s90] 452] 565] cra] 701] 004) 1.02 o| of 9.85] 17.70] 26.55] 35.<0] 4425] 69.10] 61.95| 7083] 7006

so [v.19 [4.24 [a.96 [47 [3.50 [4.70 [1.81 [a.92 [203 [2s 10 [68:51] 97.26] 106.21 115.06] 128.91 [122.76] 141.61] 150.46] 50.31] 168.16

(Foo [2.26 [2.97 [24s [aco [em | 209 | 20e | 905 | 3.16 | 3.20 ‘20 |177.0: [165.06] 194.72] 203 57|2v2.<2| 22127] 200.12|236.08| 247-62] 256.67

(20 [3.39 [73.50 [362 [3.79 [9.06 [a6 | 4.07 | aie | 420 | aan '30_[265.s2[274.08] 280.22] 292.07| 900.92] 900.77] 31862]227.48]336.33]345.18,

40 | 4.52 | 4.69 | 4.75 | 406 | 297 | 509 | 520] 831 | 5.42 | 6.54 '40_| 954.03] 962.08]371.73] 990.58|989.<3] 0828] 207.13] 415.08] «24.69] 439.68

so | 5.65 [5.76 | 5.08 | 5.99 | 6.10 | 22 | 633 | 64s | 055 | 6.67 '50_| 442.53] 451.26] 60.24| 469.09] 477.94] 06.70] 105.63) 504.49|513:34|522.19|

60_| 6.78 | 6.69 | 7.01 | 7.12 | 7.23 | 7.35 | 7.46 | 7.57 | 7.68 | 7.00 '60_ [591.04] 530.00] 548.74 |557.50]566.<4] 575.20] 504.15] 502.10] 601.85[610.70|

70_[ 7.91 [8.02 | 614 | 625 | 636 | 648 | 659 | 670 | oor | 0.99 70_|610.55|626.40| 607.25] 646.10] 654.95] 669.00] 67265] 681.50] 690.35] 690.20

(20 [0.06 [9.15 | 9.27 [9209.49 [9.61] 9.72 | 983 | 9.04 [10.08 708.06] 716.91 726.76|794.61] 749.46) 752.31 j770.01|776.86|767.21

‘90 f10.17 |10.28 [10.40 ]10.51 ]10.62 {10.74 |10.65 [10.96 [11.07 [11.10 '90_|79656|005.41]014.26]629.12[ 691.07] 840.82] 820.67) 058.52| 067 37]976.22

100 11.90 700 [885.07

ug tox 1190 ‘Nm x 8.0507 = pulg

De pulls De Nm g pulg - oz

praee| le aal 2 fee peo a pce os Nace) aia pean 6 era (a

t Wa_[ em _| Wm We Ha_| tee tao | sox | pig ox | pup 0 | ox | ply or | pulp ox | pla or [pinot | pager

| _0 [007 [014 [028 3049. [ 056 | 064 oof 1.42] 203] 425| 566] 708] 050] 9.01] 11.39 1274

10 | 071 [070 | 085 | .092 | 098 | 106 [113] -120 | 127 | 194 1 | axe] 15.56] 1699] 10.1| 19.69] 2124] 22.66] 2407] 2549] 2501

20 [141 ass { 162 [169 | 177 | 184 | 191 [ 198 | 205 2 | 2952{ 29.74] 91.15] 9257| 2899] 9540] 9602] 08.25] 00.65] 41.07

(30 [212 [are | 226 | 202 | 240 | 2a7 | 254 | 261 | 268 | 275 3 | 428] 49.00) «5:92| 46.79] 48.15] 4056] 50.98] 52.40] 53.01] 5523

40 | 202 [200 | 207 | 204 212 | 918 | 924 | 392 | 399 | 346 4 | s6.6s{ 58.06] s0.48[ 60.9] 6231] 372] 65.14] 66.56] 67.97| 6930

's0_[ sa | 360 | 967 | 974 | 961 | 900 | 305 | -«02 | 009 | 017 S| 7ost| 72.22] 7364] 7505] 7647] 7789] 7920] 00.72] 62.19] 63.65

(so [ze [aa [90 | aas | 52 | 450 | 466 | 473 | 400 | 487 s | e49r{ 06.43] 7.20] 99.21] 9063] 9205] 90.46] 94.00] 96.0] 07.71

(“7 | ase [501 [500 [515 | 522 | 500 | 07 | sea | 551 | .ss0 7 | 99.13] 100.54] 101.96] 103.38] 104.79] 106-21] 107-62] 109.08) 110.46) 711.87,

0 | 565 | 572 | 570 | see | 599 | 600 | 607 | 614 | 621 | 628 8 [113.20)114,70]116.12| 117.54] 118.95] 1207] 121.70] 123.20] 128.62]12609

‘00 [635 | 642 | -650 | 657 | .664 | 671 | 676 | 605 | 602 | 099 9 |127.45| 128.67] 190-28 191.70] 193.11] 194.53] 195.05| 197.96] 198.70] 140.10

100] 706 a Lrsx.64

lg 0 x.00706 = Nm 01 Nm x 141.6182 = 0% pulg oz

De N-Kg a Nm De Nm a M-Kg

faggot ad efor a Pees |e feeras | afer pea [efits 2 fees) a as 6 fora) a

A ta [tg | mig [mtg [tg [mtg [mtg [mag | ot [mtg

‘o {of 281] 19.61] 29.<2] 9.23] 40.03) 56.62) 9.65] 70.45 00.26 O[ of 102] 208] 306] 406] 10] 6ri|_.714] 016] 018

40 { 98.07]107.87|117.68]127.49]137.30)147.10]186.90]166.711176.s2l1e6.09 10 | 1020] 1.122] 1.206| 1326] 1.426] 1.590] 1632[ 1.709] 1.605] 1.907

20 |196.13]208.94)e15.75]225.55|235.96|248.17|254,90|264.70]274.S9]2e4.40 20 | 2039] 2ra1| 2249] 2345] 2407) 2.540] 2651] 2.750] 205s] 2067

20 |294.20]304.09)913.61329.62{939.49|349.23]959.04)962.05]972.65|062.46 0 | 3.059] 3.61] 0.269] 3.365] 2.467) 560] 2.671] 9.770] 2675] 3977

40 fo92.27]4032.07]411,00)421.60]é31.49|¢41,90]451.11]460.91]470.72|480.58 40 | 4070] aren] 4.209] «305| «497| 4500] 4.601] 4.709] «095| «097

50 |+90.53]500,14]509,95]519.75]529.56]599.97)549.17/550.90|569.79]576.60 _ 50 | 5.099] 5.200] 5.302] soa] 5506] 608) s.710] 6.812] so] Gore!

60 |588.40]508.21]608.01)617.62)627.63]697.43|647. 24657. 05666 6676.06 ‘ex1s| 6220] 6.072] 24] 6.526] 6.620] 6.790) 6.292] 6934) 7.036)

70 {sas.47]696.27]706.08)718.e0)725.70]735.50|745.s0)755.13|764.92]774.78 70 | 7.198] 7.240] 7.302] 7.424] 7.546] 7.648] 7.750] 7.052| 7.054] 056]

20 |784.59]704.34)604.15)19,05[623.76|609.57]043.37859.10]062.90)e72.79 8.158] @260| 6.962] 8.464] 0.565] 8.667] 6.760) 0.671] 0073] 0075)

80 [s82.60]002.43]002.25)9¥2.02)o2%.69]991,63]941.44]o51.25]061.05]070.06 3.17| 9279| 9.381 9.488] 0.585] 0.687] 0.780] 0.091] 0099] 10.005]

100” [900.67]

0

700 [10:07

‘akg (0" mip) = 0.80665 Nm

NOTA: El sistema métrico internacional mide la torsién en newton metros

kilogramo a un metro por segundo.

‘nx 10107 — ekg" nkp)

(Nm), Un newton se define como la fuerza necesaria para mover un

Exécution solon NFE 25112

‘According to NFE 25112

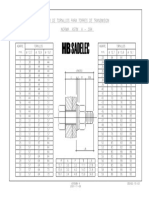

PERNOS HEXAGONALES

(Serie Métrica)

Exécution selon NFE 25113

‘et DIN 831 Forme B

According to NFE 25113

‘and DIN 831 Forme B

TNoavelle nore frangalze

Ruling fronch standard

Nouvelle norme DIN

Raling DIN standard

DIN ean + Sw DIN 031 - Forme B

TNoavelle norme ISO

Raling ISO standard

ou

Diamaire

nominal | Pas gros Longuour fete X

Nominal | "Pitch ‘Threaded length X

diameter

@ creo |120"

‘Max Basic [Max | Min | Max | Min | Basic | Max | Min | Max | Min Basic

Tajosoy) oss 778 [oars oso} 1010 [oss] 11732 |ose«|osoa| 003 | oor 500

5/8 06250 | osi2 ais | os2|r0s1|1z27|1175] area [oa4a|o.s70| 0.08 | 0.02 1750

3/4 07800 | 0768 we | 120 1212 | 1443 | 1.385 172 —_|osas|oass| 006 | o02 2.000

178 08750 | 0895 rans [14381994 [1660] 1589| 31761 __|o608 |0.831 | 006 | a2 2.250

110000 | 1022 162s [srs | iste |i7es| «3/6 [0-700 [0591 | coor] aos 72.500

1ave i250 | 1149 nisnis | 1siz |1756 | 2093 | 2002 3/4 [0.780 0.688] 0.09, | 03 2750

17s 12500 | 1277 2 2000] 193823092209] 27/3 [ozs [0.249| 09 | 03 3.000

aa 13760 | 1406 zane _|aiss|2ie|2525|2416| 29/32 [0940/0810 | 009 | oo 3.280

Tava 18000 | 1531 29/8 |asrs|200/2742| 2622/1 1036 [0.802 [0.09 | 0.08, ‘3.800

19/4 17500 | 1785 zara |a7s0|2682/3175|s035| 1-ssz_—_| 1198 | 1054 | a2 | oo “4.000

2 20000 | 2039 31s |szs|3028|3508|sea9| 1-11/32 | 1388 | 1178 | o12 | oo 4500

2.1/4 22800 | 2.308 a1v2___|3s00|3.88/ 408 |sas2| 11/2 | 1848 | 1327 | 019 | 08 5.000

27a 25000 | 2559 33/8 |3a7s|azs0|sa7s|«z7| _1-21/32 | 20a} L470] 019 | 008 ‘3.500

23/4 21800 | 2827 aia [4250/4112 | 4907 | 4608 | isis | 16a | 1622 | 018 | aos 6.000

330000 | 3081 4s/e___|4625|4a75|5340|si02| 2 2060 | 1818 | 019 | 0 6.500

NOTE: Filetage UNC, UNF ou 8.UNS, selon tableaux NOTE: UNC, UNF or 8.UNS thread according to previous

S les.

PERNO PARKER

(Serie Métrica)

150 NFE 09014 ot DIN;

Above table records the following data:

ia, up to M 48: according to AFNOR 26126 and

Dia. between M 52 and M 80: according to DIN 912

PERNO PARKER

(Serie ANSI)

ANSI B 18.3 1969

AT AAT

LULU

D aA 4 s i 7 [oo F K

Dia Nominal

Nominal size

or Basic

Screw Dia,

Max [min [max | min [ max [ min | tin | Nom | min | Min | Max | min | ax

oas00 [oases | oars | oaes | ons | azae | ozas | avisaiea| ois | 00s | oo | 0008 | 00s

oaizs | oa0ss | o4sa | o4s7 | osi2 | 0306 | oe | irs o2s0| oust | ori | ool | oo | cos

oarso | o3s7e | ossz | osso | 037s | osse | oss _| srisasiz| o1se | ous | 0020 | oo1s | 0.008

‘o4a7s | oa2es | osse | ose | 0.498 | 0490 | 0.504 | 76 09758| 0219 | 0188 | oc2 | ome | 0010

08000 | o4e19 | 0.750 | 0.735 | o800 | o4s2 | 0450 | 378 0375| 0245 | o190 | ozs | 0020 | o010

‘6260 | osies | o9se | 0921 | o62s | ogi | ose | 1/2 0800] 0307 | oaaa | ooze | ooze | o010

01800 | 0.7406 | 1128 | iior_| o780 | 0740 | 07s | sve 0625 | 0370 | 020s | oo39 | 0030 | 0010

‘oas0 | oaee | 1912 | 1293 | asrs | 096s | 0.787 | a7 0750] oas2 | 0293 | oo | 0008 | 001s

10000 | oseas | 1800 | 1479 | 1.000 | 098s | 0-200 | 374 0760] o4ss | oso | 0080 | coi | oots

zizso | iioss | 1668 | ue6s | xizs | iin | oz | 1a oars] ossr | o4zs | ooss | cos | oo1s

zso0 | 12008 | 1875 | asz | 1250 | 1236 | iis | 1a oa7s| 0620 | 047s | 0080 | 0080 | oo1s

13760 | 1as68 [2.062 | 2098 | 1975 | 1360 | 1237 [1 1.000} oes2 | osza | o0es | 008s | 001s

15000 | 1ae1e | 2.260 | 2224 | 1800 | 1485 | 130 |1 1000 o74s | os70 | ooz0 | 0060 | o01s

11800 | 1.7295 | 2628 | 2897 | 1750 | 179¢ | srs |1-17¢ 1250| oso | oss | ooo | 0070 | ois

2.0000 | 1s7e0 | 3.000 | 2970 | 2000 | 196s | 1600 |11/2 1800] 0.965 | az60 | 0060 | oor | 0018

‘aaso0 | aaze0 | sa7s | asea | 2250 | 2282 | 2.025 [1-3/4 1760] 1120 | o8ss | 100 | 0085 | coat

2.8000 | 2a7ez | 3750 | 3717 | 2500 | 24a | 2260 | 1-2/4 1750] 1248 | 0880 0095 | oat

2.7800 | 27262 | ais | «090 | 2750 | 2290 | 247s |2 2000] 370 | Lows 0108 | aoa

3.0000 | 2s7ez | 2500 | sass | x00 | 2070 | 2700 [ars 2260) 1498 | ido ous | aoa

2500 [32262 | asi | «so | s250 | szze | 2025 [aise 2250] 1620 | 1205 os | 00st

‘3.000 | a47e2 | 8.280 | sani | soo | sa7e | 3.150 |29/4 2750) 1748 | 1300 oss | cost

‘3.7500 | a7ze2 | 8.928 | see | 3.180 | 3727 | ars |2a/4 2750) 1870 | 1405 ous | ost

4.0000 | 39762 | 6.000 | sess | 4.000 | sore | 3600 |3 3000] 190s | 1520 oss | cost

Note : UNC, UNF or 8.UNS thread according to pre-

vious tables,

HEX NUTS

(Metric Serie)

i

aM

"Nouvelles normes frangalses

‘Ruling french standards

NFE 25401,

NFE 25405,

‘Ancienne norme

Former standard

NFE 27411

Nouvelles normes DIN

Ruling DIN standards

DIN 499

Treminal | Peace Cotes mr plats Haan

Nomina | wie th cron ate ‘eight

diameter

ig Pp iH maxi ‘ maxi mini Mt maxi mini i maxi

a Tz 7% M 24 ou > 104 ou 150 mm

Tolérances Tolerances

Nome Standard NFE 27-02

aes Type Type 1-2

Nome Standard INFE 25.008

USUAL STUDS

-la longueur d’implantation nominale, en millimé-

tres, précédée de la mention by

~éventuellement le symbole d'extrémité brite de

roulage RL,

=la classe de qualité,

sfvontuellomentle type (sans précision il s'agit du

type 2),

la référence & la présente nonme,

-le revétement éventuel,

~éventuellement la mention «tige réduite» (sans

précision, les goujons sont livrés avec une tige

normale).

Exemple de désignation d’un goujon asymétrique,

de grade A, a tige réduite, de diamétre d = 10, de

longueur 1 = 80, de longueur d'implantation 1,54

(bm = 15), avec extrémité brute de roulage, de

classe de qualité 8.8, de type 1, avecrevétement de

zine épalsseur Sum suivie d'une chromatation type

Goujon M 10-80, bm 15, RL,8.8, type 1, NF E25-

195, 2n5/B/Fe, tige réduite.

Longueur dimplantation Tap length, = 1,84

Fictage d Tivead aia

Ex

en max | 176 _| 200 230 | 335 s10_| 850 | 600

. nommin| 160 | 180 280 | 300 380 460 | 500 | S40

Tae i || ||| #80 370 | 610 _| 650

eS SS SS 440 520 | 860 | 600

nom] 78 | 9 [2 [is | 24 so [33/36

oanE max | 7.98 | 945 | 28s | 1658 | 1958 | 2165 | 2468 | 2765 | 208s | 2060 | 3650

N min | 7.08 | 858 [1145 | 1445 | 17.48 | 2005 | aaas | 2605 | 200s | a0 | 520

ae mx! — | — | — | — | — | — | 2s0s | 20s | 3.08 | oaa5 | onas

min | — [| = = | = |= Jess [ess | 200s | anzs | 247s

& rommax| 5 | 6 | 6 | | |w |i |w |20 |e [2

tige nomale Grade min | 462 [ sae | 776 | ore | 193 | 1978 | 1570 | izes | 1967 | exer | ese7

fu body Grade B mint — [| — | — | — | — | — |aser | azsz | teas | ance | 2500

a tige rédute_undersizo body ew.[ 44 [53 [71 | a0 | 07 | zs [1s | 162 | 192 | coz | ae

x mex | 20 [| 26 | 32 | 38 | «a | 50 | 50 | 63 | 63 | 03 | a5

“DESIGNATION DESIGNATION

Les goujons, objet de la présente norme, sont =Studs are to be designated in the following

désignés dans ordre par : sequence:

-le terme goujon, =product name stud,

-le symbole du filetage M, -metric thread M,

-le diamétre nominal d, en millimétres, -nominal size, in mm,

-la longueur nominal |, en millimetres, =nominal length, in mam,

-nominal tap end in mrn with b,, mention,

-as rolled end RL symbol, if required,

-strength grade,

- type (without mention, type 2 applies),

angered relerence,

- coating if require

-“undersize body”, mention when required.

Example of designation of a grade A stud, with

undersize body, diameter d= 10mm, lengthI =80,

‘ap length 1,8 dia (by — 18), as rolled end, strength

grade 8.8, type 1, zinc coated thickness Sum and.

type B chromated :

Stad M 10-80, ba 15, RL,8.8, type 1, NF E25-

135, 2n5/B/Fe, undersize body.

WASHERS

Programme de fabrication : Manufacturing range :

NFE 25134 Rondelles plates NFE 25134 Plain washers

NEE 25138 Rondelles plates NFE 25185 Plain washers

NFE 27614 Freins d’écrous normalisés DIN 125 - 126 Plain washers

NFE 27624 Rondelles éventail ANSI B 27-2 Plain washers

NFE 25515-25516-25517 Rondelles Grower FE 27614 Tab washers

DIN 125 - 126 Rondelles plates \NFE 27624 Internal and external teeth lock washers

ANSI B 27-2 Rondelles plates NFE 25515-25516-25517 Single coil spring lock

Rondelles selon plan client washers

Washers according to customers'drawings

Matiére:

‘Tous aciers et matiéres Materials

Ail steels and materials

Extrait NFE 25-513 grade C

4 5 a 4 @

vein [max | nom pmax | min | max “fin ax min | max] min

32 088 6 | sz w first | | 87

43 oss a | 784 uw fassr | is | i557

53 110 wo | 966 i | 1ss7 | 20 | i948

84 12 w | usr ws firs | 24 | 2248

Ta 15. uw | agsr 20 | 1948 | 27 | 2548

a4 U5, 1 | 1587 zz | aias | 30 | 2040

tos 220 20 | 1948 | 22 | arse] a7 | assa| a6 | asae

1B 218 2 | 2345] 27 | 2640] 32 | aise | 40 | aoa8

8 22s | 22s | 27 | 2643] 30 | anas| 36 | asae| 4s | «cae

1 33 | 27 | 30 | 2048] 32 | arse] 4 | 2998] so | sose

19 33 | a7 | 32 | siss| 35 | ase] 4s ss | saz6

2 33 | 27 | 35 | asss| 40 | s0s¢| so | «ose | 60 | saze

23 aa | 27 | 40 | s9s3 | 45 | case | 55 | sezs

3 a | a8 | 4s | sean | so | dose | 0 | saze

28 aa | as | ae | s7aa| ss | seze| es | ence

a a | a8 [se | su26 | 60 | sozs | 70

a ss | 4s os | eae

31 ss | 4s 0 | 638

0 66 | 54 | Dimensionsnon | 75 | 738 Dimensions non

a 65 | sa | normalies | a0 | 708 ormalisées

«6 m2 | 63 as | ass

so 11 | 63 | Dimensions | 90 | 096 Dimensions to

5 88 | 72 | bedelined | 100 | 886 Be defined

BOLTING FOR THE OIL

AND PETROCHEMICAL

INDUSTRY

- STUD BOLTS FOR ANSI FLANGES

REDUCED SHANK STUDS FOR DIN FLANGES.

STUD BOLTS FOR

ANSI FLANGES

Manufacturing process:

—Pre-heated steels are used. Thread rolling

guarantees quality of profiles, smooth surface finish

and resistance to seizing.

‘Stud flat ends are chamfered at 45°.

Parts are marked with grade identification symbol,

and our trade mark "BC".

— Nits are hot-forged and treated before tapping.

Dimensions :

M8 to M 200-ISO thread

Dia 3/8" to 8” - UNC andi UNS thread

Materials:

© ASTM A 193 BS, B6, B7, B7 M, B 16, B 8class 1 and

2,B8T class 1 and 2, B8 Mclass 1 and 2, BB Class 1

@ ASTM & 320 class L7, £43, B8 class 1 and 2, 8 T

class ] and 2, BB M class J and 2, BB C class 1

© ASTM A 194 Grade 2H, 2M, 3, 4, 6, 6F, 7, 8, 87, 8M,

8F 8C

ASTM A 453 Grade 660

ASTM A 540 Grade B21, B22, B23, B24

ASTM A 522

ASTM A 564 Grade 630

Testing :

— Visual and dimensional examination

= Metallurgical tests :

Chemical analysis on heat and on final product

Tensile strength tests

Hardness tests

‘Low and room temperature impact tests

Stress rupture tests

— Supplementary tests, when required:

High temperature tests (A 193-S1)

Impact tests (A 193-S2 - A 320-SI ~ A 522-82)

Ultrasonic examination (A 822 S1-1)

Die penetrant test (A 822 S1-2)

Official inspection: by customers and/or

recognised organisation.

Coatings : Cadmium, zinc, hot-dipped galvanised,

"BECK-COTE” (PTFE), etc.

RECOMMENDABLE MATERIALS

ACCORDING SERVICE CONDITIONS

‘CONDITIONS De SERVICE TMATIERE RECOMMANDEE

‘SERVICE CONDITIONS RECOMMENDABLE MATERIAL

service ‘Température ‘Tigo flotéo Berou

FC) ‘Stud belt ‘Nat

ma pou 32148 (_ 0-620) Voir pages ASTMAIOO BS ‘ASTM A 104 Gr

hante température ‘32~ 896 (0-480) wulvanies AISBS ‘A194 61.6

=S8~ 842 (—50~ 450) ‘A193 87, A194 Gx.2it

58 1022 (=50~ 850) A193 B16 A194 Gr. 4or7

High prossuro and Ga) See next 483 660

‘igh temperature shoots

‘isa correetf ot 1104 1472 ($40~ 800) Aes _Be ‘A104 G8

haute temperature

dom

ato

aga corccie ant 1041472 (_ 840 800) A103 BaM A104 Gr aM

high temperatizo T104— 1472 (640— 800) od A194 Gr SF

aaenaeuaa bec —148=— 88 (—100~—80) 20LT Ris4Gr sor?

temper

ito

high pressure and

Tow temperature ae — 90 (= 100-50) re RioGet

—tB—— 148 (—280~—100) 532088 RING.

Basse température idem

Low tomporature S28 — 148 (— 200 —100), ito ‘Azo BaM, A194 Gr on

= 328 —148 (—200~ —100) ‘X20 BOT 194 Gr 67

HIGH TEMPERATURE SERVICE

BOLTING ALLOY STEELS

ASTM Designation A 193

CARBONE carBGN | 3010 | 018 [os7040|097-040] 096047

MANGANESE MANGANESE] <1 | <1 [oss1i0]oep110foaso70| ce_| D> Wo 20 20

wwo>D wo | Te oo asa a

Wao > D> 7 7

5D oe

WO5d>%, to 0

we sD 5284 720 es

25 0>00 720 20

230 eo 70

>> 1 oo me

wwo>D wo | a 8 08208 8

Wo>D> ws os

5D a E

CSTR a a

wie sD>a84 0 0

28 5D> 00 zo 0

230 zal mo 5

WO>> Wo = w

so | eo t % a= %

Wo>D> 8 @ a

5D [ee

WO50>3 2 e

wesD>a84 20 2

285 0> 20 8 20.

230 i

>> Wo = =

W050 == = we _[ =

o>D> 08 % @

5D a

wosD>a = =

we sp>a84 3 ©

28 5D>20, 8 ©

25D = =

A o_| | ae | ae | — [om | a | a | oe] oe [oe

Anion |zacos|ziacis | z2co4 | cos [acove| wana [worn nem wnlaeo mle mn] ——

av BEM leiocrwhacrmodpacrmed — | EN | HGM | xec [xsqxae] x80 feioce

as vsonsas | woes | #08821 [ 180641 [aoe | 90880" | Woe 801 [208021 | 5 45 | onan | ORSAY

LOW TEMPERATURE SERVICE

BOLTING ALLOY STEELS

ASTM Designation A 320

CARBONE CARBON <008

wauIGANESE MANGANESE | 075-100 | osoass | <2 D @

w>0>a | s 3

m>D>25 38 6

25>D>20 20 6

20>D 38 s

Temptrature fone = s

cmptrre doses! | sore | i010 | voirna2 | voirnoto2 | vornotot | veirnowe2 | voirnto | voirnte2

nae 4 1 1 note note

= a 21 | Seonote2 | seencte2 | Sovnote! | Soo note | seenote 1 | See note2

AS aa |e 304 me = a6 aie 2

“APHOR waco _|onco723|z6en 100 |zecuisi0 zor skecnp waikecw ina) —

oom | xScINMe | xBcRMo | xI0CRND

Din secon] = —fxscarareoafrs caw noo] "GoM | xBciNDMo | scrMo | xI0cRND

s 808621 Gral__— | isoneo1 Gro fs06.01 Gra] oneal Grm| t20e-e4s | 1906-048 [1806-821 No

Note 1: Valeur de résilience non exigée pour les Note 1: Impact value not required for use at

températures de service mures & — 200°C, temperatures above — 200°C,

Note 2: supérieures a — 258°C. Note 2: above — 255°C.

VARIOUS ASTM

a a

Aclre a catbone | POBSEIMCED cir 0% 8 pour sore} Sueltemon seta | TS sacl

Conditions de service | demploigénéral | temper ‘basse poms paz le cuvee

Sores cenditons' | Carbonstooisfor | ,umbameetmorenne || 3 ictal aly ste! or| yaa 'SPAHES | igh ren sainss

general application ee en ey siaels| low temperature service ue ‘ste! for use at limited

temperature temperature mpenire,

Appellation ASTM

rae

Sas el oes eee = ao

foes 080 < 200 < 100

ee ee ee ae a

Smt Sma | 018 | 008 | 0000 [000 2040 2080 080

Seo ae aH ae a a

Yom ete | 9 in 850950 7400-2700, 00800

=e h lh a

woe, | GH Hl oie

Tiane Thankan i Hh 1902.38

I ] j 00s

cars| Bee i ce

Es FE i 2 ao010 0000

Samal 3 ae

Colombia + Tale 3 018048

ae SE

aa

a ial nae

al

reamed an | wo = 5 a

Sa malls

as

Ee ae

al ;

All dior ele * 7

Sa ame

aa

oe |e

radimied —y z ' a

=

os =a

al

Au diameters S 1 *

= aaa

wet Pinan | wae | ae | ae ae ae

mae ANE

‘Rockwell C 36 38 cael

eae oa =

ee ee EO

meer Se] “ameee [fe — ee =

= mae

ASTM STEELS

METALLURGICAL CURVES

CONTRAINTES ADMISSIBLES ALLOWABLE STRESS

HAUTE TEMPERATURE AT HIGH TEMPERATURE,

Contrainte admissible

‘Allowable Stress

960 750-840 630 10201110 120012901980 1470 oF.

(50) (400) (480) (500) (S80) (600) (680) (700) (750) (800) *C

SSS

‘VALEURS DE RESILIENCE LOW TEMPERATURE IMPACT TEST VALUES

A BASSE TEMPERATURE

(kgm) feb

ay

(98)

(a)

(10)

(86)

(42)

Valeur de résilionce KCU-Entalle 8am

‘mm U-notch Charpy Impact Value

(28)

(1410

400 —300 209 10 0 100 200 200

F200) 185) EU) G7) GB) G18)

$$ Temporatire. —__—————

Noto: Les essais ont 6t6 réalisé, solon lo Noto: The tests were pertormed according

(Code ASME section 3, pour les contraintes fo ASME Sec. 3'Boller Vassels" for allo-

Admissibles ot, selon ASTM A 370, pourles Wablo Stress, and of ASTM ASTO "Mechani-

‘valeurs de résilience. ting of Stoel Products” for impact

CARBON AND ALLOY STEELS

FOR NUTS

ASTM Designation A194

tM Mf At Ni ni}

me)

en

pean

RADE ee

Gxhone 3040 | p00 | >0u0 forooso| | ,Pi rongweur| >| ,P2M |rongunr| | DR. [ongueur|

ov} 4° song Jor] S| sensi for] St | renain oy] S82 | sansa | ow

a a | | 4] | At fe | Se

«|e | me [+] | eet le] | ae |

| fe | Sot || te ‘| @ | im [+] 2

«| “|e +| @ | im [+| @

| | stom | we le | a

| fe | Se [2 | Se | | Mm lel ae

| | we [2] % elim | “et lel a

| fo | “ust |e | a | @ | Met |e] So | its

soo | Sat ee Sle=o elo =

8| | “ao |e] a 8] io 8 | is

lio sl a e| ts" 8 | a

»| el a | | 3° | aot

nl 2 2 72s n| ty? 2 | ae

w|ia w | Yat | ase [oe | t3e° |B" | ast

eae me | es mw | ee Pea

ela | Met [| "3° | is [ao] 8° | let | a0 | Oy? we | Pat | ts

wel ae | See [2 "os" | To |20| 3? | as [2] 8? | POP | Mas?

ef eT gy foe] hye | ae [oo | Pee | meat Lao Pe | | we] Be ae

me |e ee | aa aaa

tse |i [20 Maat | ao | |e [Pe |= | SS [=| Se

ao | Nas" | ito [| "aa? | Sane [2 | Be | to | | 28? 8 | So"

a] Nas’ | io [| “ae | Snot [| B® | See (-| = | = [=| = [ =

we | Yat | To [| et [on [=| Pet [=-[ = [| = [-[ = [=

oa | Moor | “aot |e] “? | Mt [| Fat [Moe [-| = | = [-| = | =

2 Par eo en ae SF Sale=

ola sees 2 ES Sees See Le

Attention: Les longueurs ci-dessus s‘entendent

hauteur des chanfreins non comprise pour les

longueurs exprimées en

pouces.

‘Dans la conversion en millimétres des longueurs

exprimées en pouces, la hauteur des chanfreins a

ence, les longueurs en

millimétres du tableau sont des longueurs totales.

été ajoutée ; en co

Attention: When expressed in inches, above

Jengths do not include height of points.

When converting the lengths expressed

into millimeters, height of points has been

included ; therefore lengths in millimeters are over-

all lengths.

Jin inches

_ DIMENSIONS OF STUD

BOLTS

FOR RING JOINT (RJ) ANSI B 16.5

FLANGES

lam iam iam lam

Longueur | Nb de la tige: eur | ND | so a tige | Longweur| Nb | a ig tige | Longweur| NB | a0 1a tige | Lonoweur

tong |r} St | renga |r} S| sensi | ov] St | enn | or] St | Lenn

We =e ee | ore]

= “| 0 “| & wo | “iis zo_| “te

= |,| @ |mal],| se |oal,] on | mal, | sm | oie

= | as 16 | 99 20_| “wo 20 | “20

7) esa 1a 8s | een] a |e Tee

8 | “io0 6 _| “too ‘a ‘| to

+] |el,) oe] « |.) we 1) | &

ve | ico ie | be Bs ta_|_ 0

aa | aa aa r | eae

s 20, us. 2 20 is it 27 ss ar 145

we] Ve we] ue 178 178) 607

2 16 us i 16 120 2 22 a 22. 180

aL) een aap rT ro pew

2 20 128 ie 20, 130, o ar 2 27 165

a4 an] ee 778 a

z 20 u 20 140 : 22 a 30 188

wa wa | Ba =aie= ales

ef 20. 2 22, 150. ior = = a = =

wa 77 | 6 re | 7 ria | Pea

s 20 Q 22 185 = 30 185 a 33 208

ape [melee pee |e) aa | tea], | Pa) osm

wo | “us z_| “1 ae | “ane ao | “ae

a | 89/4 ro rie | Pere ree plows

um 20 150 2 aT 185 a 30 208 us; 36 218

7 rie | tea ree | vse |

a 22, 3 30. 200 Zs 36 240 oa 42, 378

r ria | 69/4 ree | oe vrs | wor

- a7 ui 33 230 us) 36 250 a) 48 360

Tie maa | s Tee [oa ewe

B 30. oo ES 240 cy 36 270 go 52 408

rie ree | ove vie | iri] yg] mie | ar

i 30, = 38 280 zs 39 298 bs 86 440

rie Tia [wi |g | Pee area) Bae | eae

a 33 2 ED 210 2 aa 310 z 480

TWA vse | un" ve | v2 wie

= 33 a 42 280 = 48 388 au 830

Tia ree [area a [ie me

ES 33 es 42, 310 oo 82 370 Bg 880

rae rea | = es

= 39 eS 48 340 oy = - m - -

Tae | Wa) gg | PE | BWA) ge BLA aA

af 39, azo_| 74 48 348 bo 64 19) 665

= vere parie rae | wie PRS ==

=- i 42 300 | 28 48 370 ca = = cs _ -

= re | as @] ar =ais= =a

= a 45 330 | 28 82, 380 = - = = = =

= vie | ware ma | evs Aras =e

- = 48 ‘300 | 28 86 420 Se - - i - -

= | wae foe Be | ae =a =e

= a 52 20 | 28 64 440 i = = = =- =

Attention: Les longueurs ci-dessus s'entendent Attention: ressed in inches, above

auteur des chanfreins non comprise pour les letter en cela fea

longueurs exprimées en pouces.

Dans la conversion en millimétres des longueurs

exprimées en pouces, la hauteur des chantreins a

été ajoutée; en conséquence, les longueurs en

millimétres du tableau sont des longueurs totales.

When converting the lengths expressed in inches

info millimeters, height of points has been inclu-

le ore eng ia niet ere elo vecaly

len

55

ara

483.

509

53,4

559

585.

535

an

654

7

735

78

7386

aia

[e327

63

208

ana

93.9

65)

nox.

Baa)

58.2 80

(60 |ear7

(63,2 [65.6

(652 |e2.4

(69,2 [06.3

i722 fio0a|

75.2 104

778.1 [108

ana [ 2,

[8

88,4 120,

(eal |iaa

944] 127

(szafis03)

109,4]134.]

[rosie

108,4]162,5]

roar a6

112,4)150,1

fs) 188

haiahie1.7

iazali60|

133,3]177.1

hea]

92.9)

WEIGHTS OF STUD BOLTS

(Metric Dimensions)

In kilos per 100 pieces,

with 2 assembled nuts

98)

1008]

1025|

n047|

1089

1099]

14

mi36|

fr)

225|

1269

1a

1258

1H03|

M447

sea]

1896

1580]

1624

1689]

113

1802

1226]

191

1835]

1980

2024]

iia

1206}

1231

1287]

1232|

1307

1339]

1389]

1634]

1404

1535]

1885]

1636]

1686]

1737]

1787]

1639]

1689]

1839]

1889]

2090

aaa]

2191)

jazaa|

22s

saa}

1343

ism]

1409]

rs29|

M487

1385

1842

1609]

1656|

ima

1710]

829]

1885

ie]

1998

085

2113|

iso

1823]

1655]

1687

ims

1783]

1ea7|

1911

1975]

2038]

aio

ause|

[2220]

2204

[2369]

eae

wy

1812

149

1883]

1055

2028)

2097

aie

239

an

2302]

2483)

224

596)

267

fax7o 2406) 2736]

[2227 2890| 2008]

178] 2040 | 2284) 2614 | 2680)

[2361] 2679|2982|

28082742) 3028]

2455] 2608] 3004]

asia|2860| 3165]

2869) 2993] 5236]

[2626 20073308]

WEIGHTS OF STUD BOLTS

(Nei Dimensions)

in kilos per 100 pieces,

with 2 assembled nuts

ANCHOR BOLTS

Programme de fabrication :

selon plans et spécifications

Dimensions :

MB a ~ Filetage ISO

3/8 a Filetage UNC-8UN-WW

Matiéres:

ACIERS CLASSE 4-6, 5-6, 8-8, 10-9

ACIERS pour service & basse température

ACIERS résistants a la corrosion

Toutes nuances selon spécifications.

‘ype. crosse

Round bend type

‘Type droit manchon

Right with sloove type

‘ype coudé

Right angie bend ype

Manufacturing range =

According to customers’drawings and specifi-

cations

Dimensions :

M8 to =, ISO thread

3/8" to, UNC-8UN-WW threads

Materials

Class 4-6, 5-6, 8-8, 10-9 Steels

Bolting materials for low temperature use.

Stainless steels for corrosion and oxydation resis-

tant use.

All materials according to specifications.

yet

J

Neti oy

Be

Pee

Sean ae

Sie eae eee

También podría gustarte

- Tablas de Perfiles ICHADocumento31 páginasTablas de Perfiles ICHAJaime Reyes89% (9)

- Proy NMX B 013 AprobadaDocumento12 páginasProy NMX B 013 AprobadaMARIO SALVATORE SANDOVAL PAIPAYAún no hay calificaciones

- Codigo de Practicas Generales Imca-Cicqro PDFDocumento65 páginasCodigo de Practicas Generales Imca-Cicqro PDFOscar De los Santos0% (1)

- Calculos de Pernos en MathcadDocumento7 páginasCalculos de Pernos en MathcadFernando FloresAún no hay calificaciones

- Calculo y Diseno de Conectores Con PernoDocumento29 páginasCalculo y Diseno de Conectores Con PernoBernardo MorAún no hay calificaciones

- Resumen PernosDocumento6 páginasResumen Pernosdanielmario1985Aún no hay calificaciones

- Cómo Manejar Las Tablas de TorquesDocumento3 páginasCómo Manejar Las Tablas de TorquesOmar RuizAún no hay calificaciones

- Racores DinDocumento130 páginasRacores DinEdwin Javier SierraAún no hay calificaciones

- En 288-4-Especificacion de Procedimiento de Soldeo para Materiales Metalicos-parte4-Cualificacion de Procedimiento de Soldeo Por Arco de Aluminio y Aleaciones ImprimidoDocumento42 páginasEn 288-4-Especificacion de Procedimiento de Soldeo para Materiales Metalicos-parte4-Cualificacion de Procedimiento de Soldeo Por Arco de Aluminio y Aleaciones Imprimidomanuel floresAún no hay calificaciones

- Pernos y TornillosDocumento33 páginasPernos y TornillosNicolás BarreraAún no hay calificaciones

- Oxicorte Con Varilla PDFDocumento61 páginasOxicorte Con Varilla PDFAzucena Gonzalez LopezAún no hay calificaciones

- Examen Radiográfico y Ultrasónico - Asme Viii (Uw-11)Documento2 páginasExamen Radiográfico y Ultrasónico - Asme Viii (Uw-11)Nanu Iula100% (1)

- Astm C-90 - Unidades de Mampostería de Hormigón - Santos - RamirezDocumento19 páginasAstm C-90 - Unidades de Mampostería de Hormigón - Santos - RamirezJAVIER NAPOLEON COLINA POZOAún no hay calificaciones

- Esfuerzos ResidualesDocumento387 páginasEsfuerzos ResidualesHerrera YuridiaAún no hay calificaciones

- Apendice ADocumento14 páginasApendice AMydestiny Istobe WhityouAún no hay calificaciones

- Diseno de Un Silo Cilindrico para ElDocumento181 páginasDiseno de Un Silo Cilindrico para ElGonzaloEdmundoOrtegaSotoAún no hay calificaciones

- Tipos de ElectrodosDocumento4 páginasTipos de ElectrodosJorge SeguraAún no hay calificaciones

- 02-Perfiles EstructuralesDocumento34 páginas02-Perfiles EstructuralesDiego Fernando GaviriaAún no hay calificaciones

- Et Tuberia Forzada CH ZañaDocumento7 páginasEt Tuberia Forzada CH ZañaRubén CallataAún no hay calificaciones

- Structural Welding Code Parte 1Documento21 páginasStructural Welding Code Parte 1Arnela HodzicAún no hay calificaciones

- Tabiqueria ARMCODocumento6 páginasTabiqueria ARMCOgamepass123Aún no hay calificaciones

- 6 3 Vigas H Alas Anchas WF Standard AmericanoDocumento8 páginas6 3 Vigas H Alas Anchas WF Standard AmericanoCarlos OrozcoAún no hay calificaciones

- DrywallDocumento36 páginasDrywall777jhon777Aún no hay calificaciones

- Grapas para Riel - UnistrutDocumento1 páginaGrapas para Riel - UnistrutRafael NarvaezAún no hay calificaciones

- 02 Manometro ETSA Modelo 643Documento2 páginas02 Manometro ETSA Modelo 643Omar BecerrilAún no hay calificaciones

- Manual de Apoyo para TuberosDocumento44 páginasManual de Apoyo para TuberosJUAN CARLOS PACHECO MONTESAún no hay calificaciones

- Torque de PernosDocumento1 páginaTorque de Pernos[Pellin]Aún no hay calificaciones

- Catalogo Pilas Torre Iii CuajimalpaDocumento5 páginasCatalogo Pilas Torre Iii CuajimalpaAlejandro LópezAún no hay calificaciones

- Bombas Centrífugas de Alta PresiónDocumento11 páginasBombas Centrífugas de Alta PresiónRamon Viscalla AlvarezAún no hay calificaciones

- Presion HidrostaticaDocumento5 páginasPresion Hidrostaticamarco100% (1)

- Tabla de Torque PDFDocumento1 páginaTabla de Torque PDFSergio Martínez De JesúsAún no hay calificaciones

- Baranda Metalica PDFDocumento12 páginasBaranda Metalica PDFFabian Alberto Lasso M100% (1)

- LOSACERODocumento113 páginasLOSACEROEduardo100% (1)

- Catalogo FERMAR AndamiosDocumento12 páginasCatalogo FERMAR AndamiosTonyAún no hay calificaciones

- Norma Astm A53 BDocumento74 páginasNorma Astm A53 BmemoAún no hay calificaciones

- Revision de Los Procedimientos de Analisis y Diseño de Una Trabe Carril PDFDocumento235 páginasRevision de Los Procedimientos de Analisis y Diseño de Una Trabe Carril PDFJdedios Jimenez100% (1)

- ASTM A515 Grado 60Documento8 páginasASTM A515 Grado 60guidin89Aún no hay calificaciones

- Tabla de Equivalencia de MaterialesDocumento8 páginasTabla de Equivalencia de MaterialesJorge Luis Chino CelisAún no hay calificaciones

- Válvula Howell Bunger - ESDPDocumento8 páginasVálvula Howell Bunger - ESDPErika Sánchez Del PozoAún no hay calificaciones

- Procedimiento de Ejecución SoldaduraDocumento6 páginasProcedimiento de Ejecución SoldaduraAlex AstuhuamanAún no hay calificaciones

- Especificaciones Acero EstructuralDocumento9 páginasEspecificaciones Acero EstructuralPedro Antonio Porras GodoyAún no hay calificaciones

- Comparativa de MaterialesDocumento2 páginasComparativa de MaterialesSantiago GarciaAún no hay calificaciones

- Fierros Car 4X4-WPS-001-2020Documento2 páginasFierros Car 4X4-WPS-001-2020secomet eirlAún no hay calificaciones

- Modulo 9 - DISCONTINUIDADE DEL METAL BASE Y DE LA SOLDADURADocumento28 páginasModulo 9 - DISCONTINUIDADE DEL METAL BASE Y DE LA SOLDADURAlorena14Aún no hay calificaciones

- PND-PR-14 Api 1104Documento37 páginasPND-PR-14 Api 1104Arnoldo López MéndezAún no hay calificaciones

- NiplesDocumento4 páginasNiplesJC Chamz RAún no hay calificaciones

- IT - Consideraciones Técnicas en Conexiones EmpernadasDocumento28 páginasIT - Consideraciones Técnicas en Conexiones EmpernadasjeffersonAún no hay calificaciones

- NRF 107 PEMEX 2010 - P29Abr101Documento66 páginasNRF 107 PEMEX 2010 - P29Abr101aaguilarm73Aún no hay calificaciones

- Catalogo de Vigas UDocumento7 páginasCatalogo de Vigas UGerald VargasAún no hay calificaciones

- Ficha Planchas AislapolDocumento3 páginasFicha Planchas Aislapolronald gonzalezAún no hay calificaciones

- Tabla de AgarreDocumento1 páginaTabla de AgarreCarlosEduardoMorenoManceraAún no hay calificaciones

- Normas MexicanasDocumento4 páginasNormas MexicanasDanny SantizAún no hay calificaciones

- Tabla de Rendimiento - PolykenDocumento1 páginaTabla de Rendimiento - PolykenOmar VilchezAún no hay calificaciones

- Materiale (1)Documento21 páginasMateriale (1)WitherrosasAún no hay calificaciones

- Especificacionmecanica Mecanicos Piping TuberiasDocumento114 páginasEspecificacionmecanica Mecanicos Piping TuberiasPROYECTOMS100% (1)

- Tablas Completas de Pesos y Medidas de Perfiles de HierroDocumento5 páginasTablas Completas de Pesos y Medidas de Perfiles de Hierrocesarraulledesma100% (8)

- Catalogo Rejilla IrvingDocumento20 páginasCatalogo Rejilla IrvingGeorgeMty100% (1)

- Catalogo Completo DipacDocumento58 páginasCatalogo Completo DipacAnonymous iOu4QDIAún no hay calificaciones

- DIPACDocumento49 páginasDIPACFrancisco Montero MoyaAún no hay calificaciones

- Pesos y Medidas Del AceroDocumento25 páginasPesos y Medidas Del AcerofranciscoalvarezpadiAún no hay calificaciones