Documentos de Académico

Documentos de Profesional

Documentos de Cultura

MC Poste de 20m

Cargado por

Arita_joaquinDerechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

MC Poste de 20m

Cargado por

Arita_joaquinCopyright:

Formatos disponibles

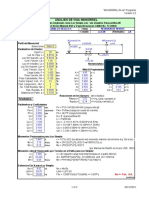

Nombre del proyecto: SOPORTADO 20m Clase E

Notas: FS = 1.5

Archivo del proyecto: c:\users\joaquin arita\documents\cpsi\pls pole\instrumental\costa rica\2020\11 noviembre\1 coopelesca\2 autosoportados\2 poste 20m e\v01 fs 1.5\auto_fs_1.5_

20m_clase_e_v01.pol

Fecha de coorida: 14:23:30 jueves, 10 de diciembre de 2020

by : PLS-POLE Version 12.10

Licensed to : Industrial Instrumentation - Ecuador

Successfully performed nonlinear analysis

The model has 0 warnings.

Cargar de un archivo: c:\users\joaquin arita\documents\cpsi\pls pole\instrumental\costa rica\2020\11 noviembre\1 coopelesca\2 autosoportados\2 poste 20m e\v01 fs 1.5\auto_fs_1.5_

20m_clase_e_v01.lca

*** Análisis de resultados

El uso máximo del elemento es: 96.84% for Steel Pole "PL" in load case "Ruptura"

El uso máximo de los aisladores es: 17.80% for Clamp "F1" in load case "Ruptura"

Maximum pole deflection usage is 67.05% for "PL" in load case "Trabajo"

Summary of Joint Support Reactions For All Load Cases:

Load Case Joint Long. Tran. Vert. Shear Tran. Long. Vert. Bending Found.

Label Force Force Force Force Moment Moment Moment Moment Usage

(kN) (kN) (kN) (kN) (kN-m) (kN-m) (kN-m) (kN-m) %

----------------------------------------------------------------------------------

Trabajo PL:g -0.00 -118.69 41.19 118.69 2021.82 0.00 0.00 2021.82 0.00

Ruptura PL:g -0.00 -178.04 41.19 178.04 3029.27 0.00 0.00 3029.27 0.00

Summary of Tip Deflections For All Load Cases:

Note: postive tip load results in positive deflection

Load Case Joint Long. Tran. Vert. Resultant Long. Tran. Twist

Label Defl. Defl. Defl. Defl. Rot. Rot.

(cm) (cm) (cm) (cm) (deg) (deg) (deg)

---------------------------------------------------------------

Trabajo PL:t -0.00 67.03 -1.74 67.05 -0.00 -4.08 -0.00

Ruptura PL:t -0.00 100.30 -3.90 100.38 -0.00 -6.10 -0.00

Pole Deflection Usages For All Load Cases:

Pole Load Case Deflection Deflection Height Length Tip Allowable Actual Deflection From Usage

Label Check Limit Diameter Deflection Deflection Vertical Axis

% (m) (m) (cm) (m) (m) (m) %

------------------------------------------------------------------------------------------------------------

PL Trabajo % Pole Length 5.00 17.50 20.00 42.00 1.00 0.67 0.67 67.05

Tubes Summary:

Pole Tube Weight Load CaseMaximum Resultant

Label Num. Usage Moment

(N) % (kN-m)

--------------------------------------------------

PL 1 5700 Ruptura 81.54 791.48

PL 2 8570 Ruptura 96.84 1642.10

PL 3 11985 Ruptura 93.24 2476.44

PL 4 15174 Ruptura 86.41 2678.13

*** Resumen completo para todos los casos de carga - uso= esfuerzo máximo/Esfuerzo permisimble

Summary of Steel Pole Usages:

Industrial Instrumentation - Ecuador - auto_fs_1.5_20m_clase_e_v01 Page 1/2

Steel Pole Maximum Load Case Segment Weight

Label Usage % Number (N)

---------------------------------------------

PL 96.84 Ruptura 9 41428.2

*** Resumen de esfuerzos máximos por cada caso de carga

Summary of Maximum Usages by Load Case:

Load Case Maximum Element Element

Usage % Label Type

------------------------------------------

Trabajo 67.05 PL Pole Deflection

Ruptura 96.84 PL Steel Pole

Summary of Steel Pole Usages by Load Case:

Load Case Maximum Steel Pole Segment

Usage % Label Number

-------------------------------------

Trabajo 64.76 PL 9

Ruptura 96.84 PL 9

Summary of Insulator Usages:

Insulator Insulator Maximum Load case Weight

Label Type Usage % (N)

---------------------------------------------

F1 Clamp 17.80 Ruptura 0.0

*** Peso de la estructura (N):

Weight of Steel Poles: 41428.2

Total: 41428.2

*** End of Report

Industrial Instrumentation - Ecuador - auto_fs_1.5_20m_clase_e_v01 Page 2/2

***************************************************************************

* *

* PLS-POLE *

* POLE AND FRAME ANALYSIS AND DESIGN *

* Copyright Power Line Systems, Inc. 1999-2011 *

* *

***************************************************************************

Nombre del proyecto: SOPORTADO 20m Clase E

Notas: FS = 1.5

Archivo del proyecto: c:\users\joaquin arita\documents\cpsi\pls pole\instrumental\costa rica\2020\11 noviembre\1 coopelesca\2 autosoportados\2 poste 20m e\v01 fs 1.5\auto_fs_1.5_

20m_clase_e_v01.pol

Fecha de coorida: 14:23:30 jueves, 10 de diciembre de 2020

by : PLS-POLE Version 12.10

Licensed to : Industrial Instrumentation - Ecuador

Successfully performed nonlinear analysis

The model has 0 warnings.

Opciones de modelado:

Offset de crucetas desde el poste/mastil: Yes

Offset de brazos desde el poste/mastil Yes

Offset de retenidas desde el poste/mastil Yes

Offset de ?????? desde el poste/mastil Yes

Offset Strains from Pole/Mast: Yes

Use Alternate Convergence Process: No

Steel poles checked with ASCE/SEI 48-11

Default Modulus of Elasticity for Steel = 199947.60 (MPa)

Default Weight Density for Steel = 76972.84 (N/m^3)

Steel Pole Properties:

Steel Pole Stock Length Default Base Shape Tip Base Taper Default Tubes Modulus of Weight Shape Strength Distance Ultimate Ultimate

Property Number Embedded Plate Diameter Diameter Drag Elasticity Density At Check From Trans. Long.

Label Length Coef. Override Override Base Type Tip Load Load

(m) (m) (mm) (mm) (mm/m) (MPa) (N/m^3) (m) (kN) (kN)

---------------------------------------------------------------------------------------------------------------------------------------------------------------------

A_20m_E 20.00 2.5 No 8F 420 0 24 1 4 tubes 0 0 Calculated 0.000 0.0000 0.0000

Steel Tubes Properties:

Pole Tube Length Thickness Lap Lap Yield Moment Cap. Tube Center of Calculated Tube Top Tube Bot. 1.5x Diam.

Property No. Length Gap Stress Override Weight Gravity Taper Diameter Diameter Lap Length

Industrial Instrumentation - Ecuador - auto_fs_1.5_20m_clase_e_v01 Page 1/10

(m) (cm) (m) (mm) (MPa) (kN-m) (N) (m) (mm/m) (cm) (cm) (m)

---------------------------------------------------------------------------------------------------------------------------

A_20m_E 1 5.8 0.8 0.840 0.000 500.000 0.000 5700 3.04 24.00000 42.00 55.92 0.81

A_20m_E 2 5.77 1 1.000 0.000 500.000 0.000 8570 3.00 24.00000 52.30 66.15 0.96

A_20m_E 3 5.8 1.2 1.130 0.000 500.000 0.000 11985 3.00 24.00000 61.75 75.67 1.10

A_20m_E 4 5.6 1.4 0.000 0.000 500.000 0.000 15174 2.88 24.00000 70.56 84.00 0.00

Steel Pole Connectivity:

Pole Tip Base X of Y of Z of Inclin. Inclin. Property Attach. Base Embed % Embed C.

Label Joint Joint Base Base Base About X About Y Set Labels Connect Override Override

(m) (m) (m) (deg) (deg) (m)

-------------------------------------------------------------------------------------------------

PL 0 0 0 0 0 A_20m_E 1 labels Fixed 0.00 0

Relative Attachment Labels for Steel Pole "PL":

Joint Distance From Global Z

Label Origin/Top Joint of Attach

(m) (m)

------------------------------------------

PL:1 0.50 0.00

Pole Steel Properties:

Element Joint Joint Rel. Outer Area T-Moment L-Moment D/t W/t Fy Fa ASCE Cap ASCE Cap

Label Label Position Dist. Diam. Inertia Inertia Max. Min. Trans. Long.

(m) (cm) (cm^2) (cm^4) (cm^4) (MPa) (MPa) (kN-m) (kN-m)

-------------------------------------------------------------------------------------------------------------

PL PL:t PL:t Ori 0.00 42.00 109.22 24508.72 24508.72 0.00 17.6 500.00 500.00 583.54 583.54

PL PL:1 PL:1 End 0.50 43.20 112.40 26712.68 26712.68 0.00 18.2 500.00 500.00 618.35 618.35

PL PL:1 PL:1 Ori 0.50 43.20 112.40 26712.68 26712.68 0.00 18.2 500.00 500.00 618.35 618.35

PL #PL:0 Tube 1 End 2.02 46.86 122.10 34237.36 34237.36 0.00 20.1 500.00 500.00 730.67 730.67

PL #PL:0 Tube 1 Ori 2.02 46.86 122.10 34237.38 34237.38 0.00 20.1 500.00 500.00 730.67 730.67

PL #PL:1 Tube 1 End 3.49 50.38 131.44 42708.98 42708.98 0.00 21.9 500.00 500.00 847.72 847.72

Industrial Instrumentation - Ecuador - auto_fs_1.5_20m_clase_e_v01 Page 2/10

PL #PL:1 Tube 1 Ori 3.49 50.38 131.44 42708.99 42708.99 0.00 21.9 500.00 500.00 847.72 847.72

PL #PL:2 SpliceT End 4.96 53.90 140.78 52474.21 52474.21 0.00 23.8 500.00 500.00 973.48 973.48

PL #PL:2 SpliceT Ori 4.96 53.90 140.78 52474.22 52474.22 0.00 23.8 500.00 500.00 973.48 973.48

PL #PL:3 SpliceB End 5.80 54.32 176.69 66404.64 66404.64 0.00 18.4 500.00 500.00 1222.47 1222.47

PL #PL:3 SpliceB Ori 5.80 54.32 176.69 66404.66 66404.66 0.00 18.4 500.00 500.00 1222.47 1222.47

PL #PL:4 Tube 2 End 7.32 57.98 188.81 81025.48 81025.48 0.00 19.9 500.00 500.00 1397.53 1397.53

PL #PL:4 Tube 2 Ori 7.32 57.98 188.81 81025.50 81025.50 0.00 19.9 500.00 500.00 1397.53 1397.53

PL #PL:5 Tube 2 End 8.53 60.86 198.37 93974.77 93974.77 0.00 21.1 500.00 500.00 1543.99 1543.99

PL #PL:5 Tube 2 Ori 8.53 60.86 198.37 93974.79 93974.79 0.00 21.1 500.00 500.00 1543.99 1543.99

PL #PL:6 SpliceT End 9.73 63.75 207.94 108235.21 108235.21 0.00 22.3 500.00 500.00 1697.75 1697.75

PL #PL:6 SpliceT Ori 9.73 63.75 207.94 108235.24 108235.24 0.00 22.3 500.00 500.00 1697.75 1697.75

PL #PL:7 SpliceB End 10.73 64.15 250.33 131142.32 131142.32 0.00 18.0 500.00 500.00 2044.24 2044.24

PL #PL:7 SpliceB Ori 10.73 64.15 250.33 131142.35 131142.35 0.00 18.0 500.00 500.00 2044.24 2044.24

PL #PL:8 Tube 3 End 12.25 67.81 264.87 155348.84 155348.84 0.00 19.3 500.00 500.00 2290.96 2290.96

PL #PL:8 Tube 3 Ori 12.25 67.81 264.87 155348.88 155348.88 0.00 19.3 500.00 500.00 2290.96 2290.96

PL #PL:9 Tube 3 End 13.33 70.38 275.11 174068.18 174068.18 0.00 20.2 500.00 500.00 2473.09 2473.09

PL #PL:9 Tube 3 Ori 13.33 70.38 275.11 174068.22 174068.22 0.00 20.2 500.00 500.00 2473.09 2473.09

PL #PL:10 SpliceT End 14.40 72.96 285.35 194234.10 194234.10 0.00 21.0 500.00 500.00 2662.20 2662.20

PL #PL:10 SpliceT Ori 14.40 72.96 285.35 194234.14 194234.14 0.00 21.0 500.00 500.00 2662.20 2662.20

PL #PL:11 SpliceB End 15.53 73.27 333.43 227691.69 227691.69 0.00 17.5 500.00 500.00 3107.49 3107.49

PL #PL:11 SpliceB Ori 15.53 73.27 333.43 227691.74 227691.74 0.00 17.5 500.00 500.00 3107.49 3107.49

PL #PL:12 Tube 4 End 16.52 75.64 344.39 250900.45 250900.45 0.00 18.2 500.00 500.00 3317.21 3317.21

PL #PL:12 Tube 4 Ori 16.52 75.64 344.39 250900.50 250900.50 0.00 18.2 500.00 500.00 3317.21 3317.21

PL PL:g PL:g End 17.50 78.00 355.36 275635.24 275635.24 0.00 18.9 500.00 500.00 3533.79 3533.79

*** Datos del aislador

Aisladores Tipo Ahuja:

EtiquetNúmeroCapacidad

de de

Stock Torque

(N)

----------------------

CL1 1e+006

Clamp Insulator Connectivity:

Clamp Structure Property Min. Required

Label And Tip Set Vertical Load

Attach (uplift)

(N)

---------------------------------------

F1 PL:1 CL1 No Limit

Industrial Instrumentation - Ecuador - auto_fs_1.5_20m_clase_e_v01 Page 3/10

*** Datos de las cargas

Cargar de un archivo: c:\users\joaquin arita\documents\cpsi\pls pole\instrumental\costa rica\2020\11 noviembre\1 coopelesca\2 autosoportados\2 poste 20m e\v01 fs 1.5\auto_fs_1.5_

20m_clase_e_v01.lca

Insulator dead and wind loads are already included in the point loads printed below.

Loading Method Parameters:

Structure Height Summary (used for calculating wind/ice adjust with height):

Z of ground for wind height adjust 0.00 (m) and structure Z coordinate that will be put on the centerline ground profile in PLS-CADD.

Ground elevation shift 0.00 (m)

Z of ground with shift 0.00 (m)

Z of structure top (highest joint) 17.50 (m)

Structure height 17.50 (m)

Structure height above ground 17.50 (m)

Vector Load Cases:

Load Case Dead Wind SF for SF for SF for SF for SF for SF for SF for SF for SF for SF For Point Wind/Ice Trans. Longit. Ice Ice Temperature Pole

Pole

Description Load Area Steel Poles Wood Conc. Conc. Conc. Guys Non Braces Insuls. Found. Loads Model Wind Wind Thick. Density Deflection

Deflection

Factor Factor Tubular Arms Poles Ult. First Zero and Tubular Pressure Pressure Check

Limit

and Towers Crack Tens. Cables Arms (Pa) (Pa) (cm) (N/m^3) (deg C)

% or (m)

------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

----------

Trabajo 1.2000 1.0000 1.00000 0.0000 0.0000 0.0000 0.0000 1.0000 1.0000 1.0000 1.0000 1.0000 1 load Wind on All 0 0 0.000 0.000 15.0 % Pole Length

5

Ruptura 1.2000 1.0000 1.00000 0.0000 0.0000 0.0000 0.0000 1.0000 1.0000 1.0000 1.0000 1.0000 1 load Wind on All 0 0 0.000 0.000 15.0 No Limit

0

Point Loads for Load Case "Trabajo":

Joint Vertical Transverse Longitudinal Load

Label Load Load Load Comment

(N) (N) (N)

-----------------------------------------------

PL:1 0 118689 0

Point Loads for Load Case "Ruptura":

Joint Vertical Transverse Longitudinal Load

Label Load Load Load Comment

(N) (N) (N)

-----------------------------------------------

PL:1 0 178040 0

Industrial Instrumentation - Ecuador - auto_fs_1.5_20m_clase_e_v01 Page 4/10

*** Análisis de resultados

El uso máximo del elemento es: 96.84% for Steel Pole "PL" in load case "Ruptura"

El uso máximo de los aisladores es: 17.80% for Clamp "F1" in load case "Ruptura"

Maximum pole deflection usage is 67.05% for "PL" in load case "Trabajo"

*** Análisis de resultados por caso de carga No. 1 "Trabajo" - Number of iterations in SAPS 10

Equilibrium Joint Positions and Rotations for Load Case "Trabajo":

Joint X-Displ Y-Displ Z-Displ X-Rot Y-Rot Z-Rot X-Pos Y-Pos Z-Pos

Label (m) (m) (m) (deg) (deg) (deg) (m) (m) (m)

------------------------------------------------------------------------------------

PL:g 0 0 0 0.0000 0.0000 0.0000 0 0 0

PL:t -2.062e-020 0.6703 -0.01742 -4.0763 -0.0000 -0.0000 -2.062e-020 0.6703 17.48

PL:1 -1.878e-020 0.6347 -0.01615 -4.0763 -0.0000 -0.0000 -1.878e-020 0.6347 16.98

Joint Support Reactions for Load Case "Trabajo":

Joint X X Y Y Horz. Shear Z Comp. Uplift Result. Result. X X-M. Y Y-M. Z Z-M. Max.

Label Force Usage Force Usage Usage Force Usage Usage Force Usage Moment Usage Moment Usage Moment Usage Usage

(kN) % (kN) % % (kN) % % (kN) % (kN-m) % (kN-m) % (kN-m) % %

-----------------------------------------------------------------------------------------------------------------------------

PL:g -0.00 0.0 -118.69 0.0 0.0 41.19 0.0 0.0 125.63 0.0 2021.82 0.0 0.0 0.0 0.00 0.0 0.0

Detailed Steel Pole Usages for Load Case "Trabajo":

Industrial Instrumentation - Ecuador - auto_fs_1.5_20m_clase_e_v01 Page 5/10

Element Joint Joint Rel. Trans. Long. Vert. Trans. Mom. Long. Mom. Tors. Axial Tran. Long. P/A M/S. V/Q. T/R. Res. Max. At

Label Label Position Dist. Defl. Defl. Defl. (Local Mx) (Local My) Mom. Force Shear Shear Usage Pt.

(m) (cm) (cm) (cm) (kN-m) (kN-m)(kN-m) (kN) (kN) (kN) (MPa) (MPa) (MPa) (MPa) (MPa) %

--------------------------------------------------------------------------------------------------------------------------------------------------

PL PL:t Origin 0.00 67.03 -0.00 -1.74 -0.00 0.00 0.0 -0.26 0.02 0.00 -0.02 0.00 0.00 0.00 0.02 0.0 4

PL PL:1 End 0.50 63.47 -0.00 -1.62 0.01 0.00 0.0 -0.26 0.02 0.00 -0.02 0.01 0.00 0.00 0.03 0.0 2

PL PL:1 Origin 0.50 63.47 -0.00 -1.62 0.01 0.00 0.0 7.03 118.49 0.00 0.63 0.00 21.84 0.00 37.83 7.6 4

PL Tube 1 End 2.02 52.74 -0.00 -1.24 180.59 0.00 0.0 7.03 118.49 0.00 0.58 123.58 7.73 0.00 124.87 25.0 2

PL Tube 1 Origin 2.02 52.74 -0.00 -1.24 180.59 0.00 -0.0 4.90 118.63 0.00 0.40 123.58 7.74 0.00 124.70 24.9 2

PL Tube 1 End 3.49 42.95 -0.00 -0.91 354.73 0.00 -0.0 4.90 118.63 0.00 0.37 209.22 7.18 0.00 209.97 42.0 2

PL Tube 1 Origin 3.49 42.95 -0.00 -0.91 354.73 0.00 -0.0 2.41 118.76 0.00 0.18 209.22 7.19 0.00 209.78 42.0 2

PL SpliceT End 4.96 34.04 -0.00 -0.64 529.07 0.00 -0.0 2.41 118.76 0.00 0.17 271.74 6.71 0.00 272.16 54.4 2

PL SpliceT Origin 4.96 34.04 -0.00 -0.64 529.07 0.00 -0.0 -0.41 118.89 0.00 -0.03 271.74 6.72 0.00 272.02 54.4 2

PL SpliceB End 5.80 29.42 -0.00 -0.51 628.94 0.00 -0.0 -0.41 118.89 0.00 -0.02 257.24 5.37 0.00 257.43 51.5 2

PL SpliceB Origin 5.80 29.42 -0.00 -0.51 628.94 0.00 -0.0 -3.60 119.01 0.00 -0.20 257.24 5.38 0.00 257.61 51.5 2

PL Tube 2 End 7.32 21.89 -0.00 -0.33 810.31 0.00 -0.0 -3.60 119.01 0.00 -0.19 289.91 5.02 0.00 290.23 58.0 2

PL Tube 2 Origin 7.32 21.89 -0.00 -0.33 810.31 0.00 -0.0 -6.77 119.08 0.00 -0.36 289.91 5.03 0.00 290.40 58.1 2

PL Tube 2 End 8.53 16.77 -0.00 -0.22 953.57 0.00 -0.0 -6.77 119.08 0.00 -0.34 308.80 4.78 0.00 309.25 61.9 2

PL Tube 2 Origin 8.53 16.77 -0.00 -0.22 953.57 0.00 -0.0 -9.70 119.12 0.00 -0.49 308.80 4.78 0.00 309.40 61.9 2

PL SpliceT End 9.73 12.39 -0.00 -0.14 1096.88 0.00 -0.0 -9.70 119.12 0.00 -0.47 323.04 4.56 0.00 323.60 64.7 2

PL SpliceT Origin 9.73 12.39 -0.00 -0.14 1096.88 0.00 -0.0 -13.60 119.17 0.00 -0.65 323.04 4.56 0.00 323.79 64.8 2

PL SpliceB End 10.73 9.29 -0.00 -0.09 1216.04 0.00 -0.0 -13.60 119.17 0.00 -0.54 297.43 3.80 0.00 298.05 59.6 2

PL SpliceB Origin 10.73 9.29 -0.00 -0.09 1216.04 0.00 -0.0 -18.22 119.18 0.00 -0.73 297.43 3.80 0.00 298.23 59.6 2

PL Tube 3 End 12.25 5.47 -0.00 -0.04 1397.68 0.00 -0.0 -18.22 119.18 0.00 -0.69 305.04 3.59 0.00 305.79 61.2 2

PL Tube 3 Origin 12.25 5.47 -0.00 -0.04 1397.68 0.00 -0.0 -22.07 119.13 0.00 -0.83 305.04 3.59 0.00 305.94 61.2 2

PL Tube 3 End 13.33 3.41 -0.00 -0.02 1525.51 0.00 -0.0 -22.07 119.13 0.00 -0.80 308.42 3.45 0.00 309.28 61.9 2

PL Tube 3 Origin 13.33 3.41 -0.00 -0.02 1525.51 0.00 -0.0 -25.36 119.07 0.00 -0.92 308.42 3.45 0.00 309.40 61.9 2

PL SpliceT End 14.40 1.86 -0.00 -0.01 1653.27 0.00 -0.0 -25.36 119.07 0.00 -0.89 310.51 3.32 0.00 311.45 62.3 2

PL SpliceT Origin 14.40 1.86 -0.00 -0.01 1653.27 0.00 -0.0 -30.52 119.00 0.00 -1.07 310.51 3.32 0.00 311.63 62.3 2

PL SpliceB End 15.53 0.74 -0.00 -0.00 1787.73 0.00 -0.0 -30.52 119.00 0.00 -0.92 287.65 2.85 0.00 288.61 57.7 2

PL SpliceB Origin 15.53 0.74 -0.00 -0.00 1787.73 0.00 -0.0 -35.79 118.89 0.00 -1.07 287.65 2.85 0.00 288.77 57.8 2

PL Tube 4 End 16.52 0.19 -0.00 -0.00 1904.84 0.00 -0.0 -35.79 118.89 0.00 -1.04 287.12 2.76 0.00 288.19 57.6 2

PL Tube 4 Origin 16.52 0.19 -0.00 -0.00 1904.84 0.00 -0.0 -39.37 118.76 0.00 -1.14 287.12 2.75 0.00 288.30 57.7 2

PL PL:g End 17.50 0.00 0.00 0.00 2021.82 0.00 -0.0 -39.37 118.76 0.00 -1.11 286.07 2.67 0.00 287.22 57.4 2

Summary of Clamp Capacities and Usages for Load Case "Trabajo":

Clamp Force Input Factored Usage

Label Holding Holding

Capacity Capacity

(kN) (kN) (kN) %

------------------------------------------

F1 118.689 1000.00 1000.00 11.87

Industrial Instrumentation - Ecuador - auto_fs_1.5_20m_clase_e_v01 Page 6/10

*** Análisis de resultados por caso de carga No. 2 "Ruptura" - Number of iterations in SAPS 11

Equilibrium Joint Positions and Rotations for Load Case "Ruptura":

Joint X-Displ Y-Displ Z-Displ X-Rot Y-Rot Z-Rot X-Pos Y-Pos Z-Pos

Label (m) (m) (m) (deg) (deg) (deg) (m) (m) (m)

------------------------------------------------------------------------------------

PL:g 0 0 0 0.0000 0.0000 0.0000 0 0 0

PL:t -6.905e-020 1.003 -0.03896 -6.1020 -0.0000 -0.0000 -6.905e-020 1.003 17.46

PL:1 -6.289e-020 0.9499 -0.03613 -6.1020 -0.0000 -0.0000 -6.289e-020 0.9499 16.96

Joint Support Reactions for Load Case "Ruptura":

Joint X X Y Y Horz. Shear Z Comp. Uplift Result. Result. X X-M. Y Y-M. Z Z-M. Max.

Label Force Usage Force Usage Usage Force Usage Usage Force Usage Moment Usage Moment Usage Moment Usage Usage

(kN) % (kN) % % (kN) % % (kN) % (kN-m) % (kN-m) % (kN-m) % %

-----------------------------------------------------------------------------------------------------------------------------

PL:g -0.00 0.0 -178.04 0.0 0.0 41.19 0.0 0.0 182.74 0.0 3029.27 0.0 0.0 0.0 0.00 0.0 0.0

Detailed Steel Pole Usages for Load Case "Ruptura":

Element Joint Joint Rel. Trans. Long. Vert. Trans. Mom. Long. Mom. Tors. Axial Tran. Long. P/A M/S. V/Q. T/R. Res. Max. At

Label Label Position Dist. Defl. Defl. Defl. (Local Mx) (Local My) Mom. Force Shear Shear Usage Pt.

(m) (cm) (cm) (cm) (kN-m) (kN-m)(kN-m) (kN) (kN) (kN) (MPa) (MPa) (MPa) (MPa) (MPa) %

--------------------------------------------------------------------------------------------------------------------------------------------------

PL PL:t Origin 0.00 100.30 -0.00 -3.90 -0.00 0.00 0.0 -0.25 0.03 0.00 -0.02 0.00 0.01 0.00 0.02 0.0 4

PL PL:1 End 0.50 94.99 -0.00 -3.61 0.01 0.00 0.0 -0.25 0.03 0.00 -0.02 0.01 0.00 0.00 0.03 0.0 2

PL PL:1 Origin 0.50 94.99 -0.00 -3.61 0.01 0.00 0.0 17.43 177.19 0.00 1.55 0.00 32.65 0.00 56.58 11.3 4

PL Tube 1 End 2.02 78.93 -0.00 -2.77 270.05 0.00 0.0 17.43 177.19 0.00 1.43 184.80 11.57 0.00 187.30 37.5 2

PL Tube 1 Origin 2.02 78.93 -0.00 -2.77 270.05 0.00 -0.0 14.75 177.45 0.00 1.21 184.80 11.58 0.00 187.09 37.4 2

PL Tube 1 End 3.49 64.29 -0.00 -2.03 530.56 0.00 -0.0 14.75 177.45 0.00 1.12 312.93 10.75 0.00 314.60 62.9 2

PL Tube 1 Origin 3.49 64.29 -0.00 -2.03 530.56 0.00 -0.0 11.38 177.74 0.00 0.87 312.93 10.76 0.00 314.35 62.9 2

PL SpliceT End 4.96 50.96 -0.00 -1.43 791.48 0.00 -0.0 11.38 177.74 0.00 0.81 406.52 10.04 0.00 407.70 81.5 2

PL SpliceT Origin 4.96 50.96 -0.00 -1.43 791.48 0.00 -0.0 7.73 178.01 0.00 0.55 406.52 10.06 0.00 407.45 81.5 2

PL SpliceB End 5.80 44.04 -0.00 -1.14 941.01 0.00 -0.0 7.73 178.01 0.00 0.44 384.88 8.04 0.00 385.57 77.1 2

PL SpliceB Origin 5.80 44.04 -0.00 -1.14 941.01 0.00 -0.0 3.71 178.25 0.00 0.21 384.88 8.05 0.00 385.34 77.1 2

PL Tube 2 End 7.32 32.78 -0.00 -0.73 1212.67 0.00 -0.0 3.71 178.25 0.00 0.20 433.86 7.53 0.00 434.25 86.9 2

PL Tube 2 Origin 7.32 32.78 -0.00 -0.73 1212.67 0.00 -0.0 -0.47 178.43 0.00 -0.02 433.86 7.53 0.00 434.08 86.8 2

PL Tube 2 End 8.53 25.12 -0.00 -0.48 1427.32 0.00 -0.0 -0.47 178.43 0.00 -0.02 462.22 7.16 0.00 462.41 92.5 2

PL Tube 2 Origin 8.53 25.12 -0.00 -0.48 1427.32 0.00 -0.0 -4.30 178.54 0.00 -0.22 462.22 7.17 0.00 462.60 92.5 2

PL SpliceT End 9.73 18.56 -0.00 -0.30 1642.10 0.00 -0.0 -4.30 178.54 0.00 -0.21 483.61 6.83 0.00 483.96 96.8 2

PL SpliceT Origin 9.73 18.56 -0.00 -0.30 1642.10 0.00 -0.0 -9.01 178.65 0.00 -0.43 483.61 6.84 0.00 484.19 96.8 2

PL SpliceB End 10.73 13.92 -0.00 -0.20 1820.75 0.00 -0.0 -9.01 178.65 0.00 -0.36 445.34 5.70 0.00 445.81 89.2 2

PL SpliceB Origin 10.73 13.92 -0.00 -0.20 1820.75 0.00 -0.0 -14.50 178.71 0.00 -0.58 445.34 5.70 0.00 446.03 89.2 2

PL Tube 3 End 12.25 8.19 -0.00 -0.09 2093.11 0.00 -0.0 -14.50 178.71 0.00 -0.55 456.82 5.38 0.00 457.46 91.5 2

PL Tube 3 Origin 12.25 8.19 -0.00 -0.09 2093.11 0.00 -0.0 -19.23 178.67 0.00 -0.73 456.82 5.38 0.00 457.64 91.5 2

PL Tube 3 End 13.33 5.11 -0.00 -0.04 2284.82 0.00 -0.0 -19.23 178.67 0.00 -0.70 461.94 5.18 0.00 462.72 92.5 2

PL Tube 3 Origin 13.33 5.11 -0.00 -0.04 2284.82 0.00 -0.0 -23.21 178.59 0.00 -0.84 461.93 5.17 0.00 462.87 92.6 2

PL SpliceT End 14.40 2.78 -0.00 -0.02 2476.44 0.00 -0.0 -23.21 178.59 0.00 -0.81 465.11 4.98 0.00 466.00 93.2 2

PL SpliceT Origin 14.40 2.78 -0.00 -0.02 2476.44 0.00 -0.0 -29.06 178.49 0.00 -1.02 465.11 4.98 0.00 466.21 93.2 2

PL SpliceB End 15.53 1.11 -0.00 -0.00 2678.13 0.00 -0.0 -29.06 178.49 0.00 -0.87 430.92 4.27 0.00 431.85 86.4 2

PL SpliceB Origin 15.53 1.11 -0.00 -0.00 2678.13 0.00 -0.0 -34.96 178.34 0.00 -1.05 430.92 4.27 0.00 432.03 86.4 2

PL Tube 4 End 16.52 0.28 -0.00 -0.00 2853.80 0.00 -0.0 -34.96 178.34 0.00 -1.01 430.15 4.13 0.00 431.22 86.2 2

PL Tube 4 Origin 16.52 0.28 -0.00 -0.00 2853.80 0.00 -0.0 -39.09 178.15 0.00 -1.13 430.15 4.13 0.00 431.34 86.3 2

PL PL:g End 17.50 0.00 0.00 0.00 3029.27 0.00 -0.0 -39.09 178.15 0.00 -1.10 428.62 4.00 0.00 429.77 86.0 2

Summary of Clamp Capacities and Usages for Load Case "Ruptura":

Clamp Force Input Factored Usage

Industrial Instrumentation - Ecuador - auto_fs_1.5_20m_clase_e_v01 Page 7/10

Label Holding Holding

Capacity Capacity

(kN) (kN) (kN) %

------------------------------------------

F1 178.040 1000.00 1000.00 17.80

Industrial Instrumentation - Ecuador - auto_fs_1.5_20m_clase_e_v01 Page 8/10

*** Resumen completo para todos los casos de carga - uso= esfuerzo máximo/Esfuerzo permisimble

Summary of Steel Pole Usages:

Steel Pole Maximum Load Case Segment Weight

Label Usage % Number (N)

---------------------------------------------

PL 96.84 Ruptura 9 41428.2

*** Resumen de esfuerzos máximos por cada caso de carga

Summary of Maximum Usages by Load Case:

Load Case Maximum Element Element

Usage % Label Type

------------------------------------------

Trabajo 67.05 PL Pole Deflection

Ruptura 96.84 PL Steel Pole

Summary of Steel Pole Usages by Load Case:

Load Case Maximum Steel Pole Segment

Usage % Label Number

-------------------------------------

Trabajo 64.76 PL 9

Ruptura 96.84 PL 9

Summary of Insulator Usages:

Insulator Insulator Maximum Load case Weight

Label Type Usage % (N)

---------------------------------------------

F1 Clamp 17.80 Ruptura 0.0

Pole Deflection Usages For All Load Cases:

Pole Load Case Deflection Deflection Height Length Tip Allowable Actual Deflection From Usage

Label Check Limit Diameter Deflection Deflection Vertical Axis

% (m) (m) (cm) (m) (m) (m) %

------------------------------------------------------------------------------------------------------------

PL Trabajo % Pole Length 5.00 17.50 20.00 42.00 1.00 0.67 0.67 67.05

Loads At Insulator Attachments For All Load Cases:

Load Insulator Insulator Structure Structure Structure Structure Structure

Case Label Type Attach Attach Attach Attach Attach

Label Load X Load Y Load Z Load Res.

(kN) (kN) (kN) (kN)

------------------------------------------------------------------------------

Trabajo F1 Clamp PL:1 0.000 118.689 0.000 118.689

Ruptura F1 Clamp PL:1 0.000 178.040 0.000 178.040

Overturning Moments For User Input Concentrated Loads:

Moments are static equivalents based on central axis of 0,0 (i.e. a single pole).

Load Case Total Total Total Transverse Longitudinal Torsional

Tran. Long. Vert. Overturning Overturning Moment

Industrial Instrumentation - Ecuador - auto_fs_1.5_20m_clase_e_v01 Page 9/10

Load Load Load Moment Moment

(kN) (kN) (kN) (kN-m) (kN-m) (kN-m)

-------------------------------------------------------------------

Trabajo 118.689 0.000 0.000 2017.713 0.000 0.000

Ruptura 178.040 0.000 0.000 3026.680 0.000 0.000

*** Peso de la estructura (N):

Weight of Steel Poles: 41428.2

Total: 41428.2

*** End of Report

Industrial Instrumentation - Ecuador - auto_fs_1.5_20m_clase_e_v01 Page 10/10

También podría gustarte

- Viga MonorrielDocumento3 páginasViga MonorrielArita_joaquinAún no hay calificaciones

- Diseño de Muro de MamposteriaDocumento5 páginasDiseño de Muro de MamposteriaArita_joaquinAún no hay calificaciones

- Diseño de PortonDocumento18 páginasDiseño de PortonArita_joaquinAún no hay calificaciones

- MEMORIA DE CALCULO t60v125Documento13 páginasMEMORIA DE CALCULO t60v125Arita_joaquinAún no hay calificaciones

- Reglamento para La Seguridad Estructural de Las Construcciones PDFDocumento30 páginasReglamento para La Seguridad Estructural de Las Construcciones PDFArita_joaquinAún no hay calificaciones

- MEMORIA DE CALCULO t60v125Documento13 páginasMEMORIA DE CALCULO t60v125Arita_joaquinAún no hay calificaciones

- Memoria de Calculo de TorreDocumento74 páginasMemoria de Calculo de TorreArita_joaquin100% (1)

- Especificaciones Tecnicas de TorresDocumento105 páginasEspecificaciones Tecnicas de TorresArita_joaquin83% (6)

- Transporte Terrestre InternacionalDocumento9 páginasTransporte Terrestre InternacionalANGELO JOSUE GOMEZ SILVAAún no hay calificaciones

- Sociedades (Parte Teórica)Documento35 páginasSociedades (Parte Teórica)Sergio SalazarAún no hay calificaciones

- Diagnostico Cajamarca PDFDocumento135 páginasDiagnostico Cajamarca PDFFranz Wolf HeartAún no hay calificaciones

- 669 TP 2021-1Documento10 páginas669 TP 2021-1Marian SanojaAún no hay calificaciones

- 3° Medio Gestion Comercial y TributariaDocumento11 páginas3° Medio Gestion Comercial y Tributariamarcos barahonaAún no hay calificaciones

- Marco NormativoDocumento6 páginasMarco NormativoDilson Fernando GRANADOS GRANADOSAún no hay calificaciones

- TAREA9 HistoriadeHondurasDocumento8 páginasTAREA9 HistoriadeHondurasKatherineAún no hay calificaciones

- Laboratorio Cap 23Documento8 páginasLaboratorio Cap 23Mony GRAún no hay calificaciones

- Clase 6Documento14 páginasClase 6moovin tripsAún no hay calificaciones

- Análisis de La Empresa Móvil MovistarDocumento16 páginasAnálisis de La Empresa Móvil MovistarLiliana Bendezu HernandezAún no hay calificaciones

- Tesis Sobre Asociacion de Vecinos 3Documento195 páginasTesis Sobre Asociacion de Vecinos 3Hercha ValAún no hay calificaciones

- 2.caso Practico Control de GestionDocumento3 páginas2.caso Practico Control de GestionJ Ap RoAún no hay calificaciones

- Plan de Inducción y Reinducción Desarrollados en ClaseDocumento6 páginasPlan de Inducción y Reinducción Desarrollados en ClaseKarlla Stefania LUNA GUERRAAún no hay calificaciones

- Baremo para Cálculo de Avalúos InmobiliariosDocumento4 páginasBaremo para Cálculo de Avalúos Inmobiliariosdarwin roman100% (2)

- Upo La Milagresa - PLAZA SATELITE 1 - 8188797Documento2 páginasUpo La Milagresa - PLAZA SATELITE 1 - 8188797iridianmendoza95Aún no hay calificaciones

- Presentación SOFOM Ene23Documento13 páginasPresentación SOFOM Ene23Pedro100% (1)

- Interpretaciones Cientificas de La Realidad SocialDocumento24 páginasInterpretaciones Cientificas de La Realidad SocialVentas HersanAún no hay calificaciones

- PF - Sesión 4 y 5Documento24 páginasPF - Sesión 4 y 5MarioAún no hay calificaciones

- Como Levantar A Una Empresa en QuiebraDocumento2 páginasComo Levantar A Una Empresa en Quiebrahamilton10000100% (2)

- Eot - San Tequendama-2000-Acuerdo No. 029 de 2.000Documento57 páginasEot - San Tequendama-2000-Acuerdo No. 029 de 2.000luisAún no hay calificaciones

- Balota 8Documento6 páginasBalota 8Rodrigo MaronAún no hay calificaciones

- Proyecto Haworth: FarmacéuticaDocumento12 páginasProyecto Haworth: FarmacéuticaKarla CastilloAún no hay calificaciones

- Caso Estudio ManuelitaDocumento12 páginasCaso Estudio ManuelitaANGIE PAOLA SUCUNCHOQUE TORRESAún no hay calificaciones

- Apuntes Seguridad Social Completos CLAUDIADocumento90 páginasApuntes Seguridad Social Completos CLAUDIACarlos SanriAún no hay calificaciones

- Documentos de Sostenibilidad de Un Proyecto de RiegoDocumento14 páginasDocumentos de Sostenibilidad de Un Proyecto de RiegoAngel Moises Huayllani TinocoAún no hay calificaciones

- Modulo 6 Contabilidad GeneralDocumento21 páginasModulo 6 Contabilidad GeneralRiky zavalaAún no hay calificaciones

- TC Inv Operaciones Entrega 1 2 3Documento40 páginasTC Inv Operaciones Entrega 1 2 3SOLDAEXPRESS INGENIERÍA SASAún no hay calificaciones

- RENTAS VITALICIAS - Calculo Financiero IIDocumento10 páginasRENTAS VITALICIAS - Calculo Financiero IIpercyAún no hay calificaciones

- Tarea Semana 6Documento8 páginasTarea Semana 6Esmirna Col SazoAún no hay calificaciones

- Santivañez Diseño de ResilienciaDocumento8 páginasSantivañez Diseño de ResilienciaErlan MedranoAún no hay calificaciones