Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Recristalización PDF

Cargado por

david torres0 calificaciones0% encontró este documento útil (0 votos)

12 vistas4 páginasTítulo original

recristalización.pdf

Derechos de autor

© © All Rights Reserved

Formatos disponibles

PDF o lea en línea desde Scribd

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

© All Rights Reserved

Formatos disponibles

Descargue como PDF o lea en línea desde Scribd

0 calificaciones0% encontró este documento útil (0 votos)

12 vistas4 páginasRecristalización PDF

Cargado por

david torresCopyright:

© All Rights Reserved

Formatos disponibles

Descargue como PDF o lea en línea desde Scribd

Está en la página 1de 4

4.7 ISOLATION AND PURIFICATION OF SOLIDS 105

Contifuge id

Centrifuge

Centrifuge tube 5

Fppendort

Figure 4.16: Centrifuge,

Centrifugation generates much higher gravity forces in certain periods of

time, allowing the separation of precipitates, suspended cells in biological fluids,

etc., more efficiently than with conventional filtration. Although not a filtration

technique, it can be used to separate impurities that are suspended within a

liquid.

4.7.3. Recrystallization

In a typical laboratory experiment, a solid that is separated from a reaction

crude is usually accompanied by impurities, so that purification is necessary.

By the technique called recrystallization, many solids can be purified using pure

solvents or solvent mixtures. Recrystallization is based on the different solubility

that a solid substance presents in a solvent at r-t. or when the solvent is hot. The

recrystallization process is carried out with product loss, so the overall reaction

yield is affected,

The crucial point of the crystal

that must mect the following properti

tion process is the choice of the solvent

* Total solubility of the substance to be purified at high temperatures.

* Low capacity of dissolving the impuriti

any temperature range.

‘that contaminate the product in

‘* Absence of chemical reaction with the product to be purified.

* Generation of good crystals of the product to be purified,

Easy removal.

For practical purposes, two types of recrystallization can be distinguished:

in water and in organic solvents.

1, Recrystallization from water: Many organic compounds are insoluble in

water at r-t., but they are hot. For this purpose a suspension of the solid is

106

4.7 ISOLATION AND PURIFICATION OF SOLIDS

prepared in the minimum amount of water in a beaker or Exlenmeyer flask,

and the mixture is brought to a boil. If the solid does not dissolve under

‘these conditions, small amounts are added and the water is boiled again

until the compound dissolves. Note that suspended particles corresponding

to part of the insoluble impurities often remain. If the solid is dark in color,

the addition of small amounts of activated carbon will retain most of these

colored impurities.

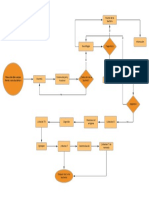

‘The procedure for recrystallization from water is as follows (see Fig-

ure 4.17):

* Transfer the solid for recrystallization to an Erlenmeyer or beaker.

* Dissolve the substance in the minimum amount of hot solvent.

‘* If the starting crystals exhibit intense color due to the presence of

impurities, add some activated carbon to remove them, since the

colored impurities are retained in the activated carbon.

‘* Heat the mixture to boiling on a hot plate, checking that the prod-

uct to recrystallize has been completely dissolved. Magnetic stirring

should be performed (or add a boiling chip) to avoid sudden boiling

and the formation of solid splashes.

* Disconnect the hot plate.

* Filter the hot solution by gravity using a conical funnel and fluted

filter to remove insoluble impurities as well as activated carbon (dis-

carding the solid residue, composed of activated carbon and insoluble

impurities, on the fluted filter). Tweezers, tongs, or a piece of filter pa-

per should be used when manipulating an Erlenmeyer flask or beaker

to avoid burns when handling hot glass containers.

* When the product solidifies in the funnel, add hot water.

* As the solution cools, the corresponding product crystals will form

(external cooling helps this process).

* Finally, after the filtrate completely cools, these crystals are filtered

under vacuum and washed (with the cold solvent used for recrystal-

ization) in a Biichner to remove adhering filtrate and then dried to

remove traces of solvent.

In the case of incomplete crystallization, concentrate the filtrate (by heat-

ing and by evaporating half of the solvent), and repeat the process

Recrystallization in organic solvents: When a volatile organic solvent is

used instead of water, the heating part of the solution is performed with a

refiux assembly to prevent flammable volatile organic solvent vapors from

causing fires.

‘The procedure for recrystallization is as follows:

107

4.7 ISOLATION AND PURIFICATION OF SOLIDS

‘Ad activated carbon

‘organic solvent (rfl)

the solid in a volatile

1A) Dissolve the solid in water

4) Crystallization

{external cool)

Figure 4.17: Stops in recrystallization.

108 4.7 ISOLATION AND PURIFICATION OF SOLIDS

# Set a round-bottom flask with a clamp and a connector on a hot

plate

« Transfer the solid to be recrystallized using a solid funnel or a pi

of coated paper.

* Add the solvent or solvent mixture and a boiling chip or a stir bar

(if a magnetic stirring plate is available)

* Attach a reflux condenser to the flask, connect the tubing, and open

the water or cooling circuit.

‘* Heat the mixture to reflux to dissolve the solid.

‘¢ Tum off the heating plate and allow to cool in order to stop the

reflux.

* While the flask is still warm, gravity filter the contents of the flask,

helping with tongs.

© Cool the filtrate to r.t. and let stand until the end of the erystallizae

tion of the solid.

Sometimes crystallization is facilitated by seeding a few crystals of the

product or scratching the bottom of the container with a glass rod. In

both cases crystallization nuclei are generated, accelerating the process

‘The main reasons for failure with this technique are:

* ‘The wrong solvent is chosen for the recrystallization,

* The wrong amount of solvent is used to dissolve the recrystallization

solid.

* Lack of precipitation when the solution is cooled.

© An oily substance formed instead of a solid precipitate.

4.7.4. Sublimation

Sublimation or volatilization is a change of state from solid to gas without pass-

ing through the liquid state, A typical example is dry ice, which can sublimate

at rt. and at atmospheric pressure. This technique is used for purification of

solids that exhibit exceptionally high vapor pressures and m.p., making these

solids transform directly to the gas phase. Other substances are subject to sub-

imation, such as iodine, sulfur, naphthalene, ete. This purification technique is

suitable for poorly soluble solids and cannot be isolated in a pure state by suc-

cessive recrystallizations. Normally, it is performed using vacuum distillation

equipment (see Figure 4.18) for very pure yield. Unlike recrystallization, this

technique is not commonly to used purify solids.

For certain substances, sublimation at atmospheric pressure can be per-

formed as follows:

© The solid that is to be converted into steam is heated in a beaker.

También podría gustarte

- Estructura Fisicoquímica y Electrostática de Las Inmunoglobulinas en GeneralDocumento1 páginaEstructura Fisicoquímica y Electrostática de Las Inmunoglobulinas en Generaldavid torresAún no hay calificaciones

- Diagrama en BlancoDocumento1 páginaDiagrama en Blancodavid torresAún no hay calificaciones

- Curso Panaderia y PasteleriaDocumento127 páginasCurso Panaderia y Pasteleriabiribi1978100% (13)

- Práctica 1 BQ 2Documento10 páginasPráctica 1 BQ 2david torresAún no hay calificaciones

- Alcoholes y FenolesDocumento27 páginasAlcoholes y Fenolesdavid torresAún no hay calificaciones

- Aplicacion de Cannabis Sativa Como Analgesico Empleando Un Modelo en VivoDocumento5 páginasAplicacion de Cannabis Sativa Como Analgesico Empleando Un Modelo en Vivodavid torresAún no hay calificaciones

- AminasDocumento26 páginasAminasElsa Cecilia MillanAún no hay calificaciones

- La PermanganometriaDocumento2 páginasLa PermanganometriaValeria Enriquez Ruiseco69% (13)

- Caracterisiticasdelasdivisiones PDFDocumento18 páginasCaracterisiticasdelasdivisiones PDFdavid torresAún no hay calificaciones

- Laboratorio de Quimica Organica IIDocumento72 páginasLaboratorio de Quimica Organica IINany GarciaAún no hay calificaciones

- Seminario Integracion MetabolicaDocumento23 páginasSeminario Integracion MetabolicafawingpeAún no hay calificaciones

- C Química Analítica CuantitativaDocumento42 páginasC Química Analítica CuantitativaAngelManuelOrdayaRiosAún no hay calificaciones

- 5 Regulacion Hepatica Del MetabolismoDocumento27 páginas5 Regulacion Hepatica Del MetabolismoCarlos Alberto HernandezAún no hay calificaciones

- StaphylococcusDocumento5 páginasStaphylococcusSandriuski100% (3)

- Reportaje VergaraDocumento37 páginasReportaje Vergaradavid torresAún no hay calificaciones

- Aplicacion de Cannabis Sativa Como Analgesico Empleando Un Modelo en VivoDocumento5 páginasAplicacion de Cannabis Sativa Como Analgesico Empleando Un Modelo en Vivodavid torresAún no hay calificaciones

- Micro Biolog I ADocumento5 páginasMicro Biolog I Adavid torresAún no hay calificaciones

- Esterilización Por FiltraciónDocumento4 páginasEsterilización Por FiltraciónIngeniero PerezAún no hay calificaciones

- RecristalizaciónDocumento4 páginasRecristalizacióndavid torresAún no hay calificaciones

- TP0341 Dureza Total en Agua Con EDTA Por VolumetríaDocumento12 páginasTP0341 Dureza Total en Agua Con EDTA Por VolumetríasaphkielAún no hay calificaciones

- Eu BacteriaDocumento24 páginasEu BacteriaDavid Ballena GuerreroAún no hay calificaciones

- Efecto de Solutos Sobre El Crecimiento de Hongos Deteriorativos de Alimentos Effect of Solutes On Growth Parameters of Food Spoilage MouldsDocumento6 páginasEfecto de Solutos Sobre El Crecimiento de Hongos Deteriorativos de Alimentos Effect of Solutes On Growth Parameters of Food Spoilage Mouldsdavid torresAún no hay calificaciones

- Métodos de Colecta Identificación y Análisis de Comunidades Biológicas - CompressedDocumento39 páginasMétodos de Colecta Identificación y Análisis de Comunidades Biológicas - CompressedLeydi Manay CadenaAún no hay calificaciones

- Clasificaci N de Los M Todos Volum Tricos Basados en Reacciones RedoxDocumento3 páginasClasificaci N de Los M Todos Volum Tricos Basados en Reacciones Redoxdavid torresAún no hay calificaciones

- Como Eliminar DurezaDocumento20 páginasComo Eliminar Durezaronayme29Aún no hay calificaciones

- 17 Como Elaborar Una Conclusion PDFDocumento8 páginas17 Como Elaborar Una Conclusion PDFdavid torresAún no hay calificaciones

- Sulfonacion Apunte Def 2007Documento20 páginasSulfonacion Apunte Def 2007para_esAún no hay calificaciones

- Analitica ComplejosDocumento7 páginasAnalitica Complejosdavid torresAún no hay calificaciones

- TP0341 Dureza Total en Agua Con EDTA Por VolumetríaDocumento12 páginasTP0341 Dureza Total en Agua Con EDTA Por VolumetríasaphkielAún no hay calificaciones