Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Viga Monoriel 25 Ton - Sizer

Cargado por

PROYECTOMS0 calificaciones0% encontró este documento útil (0 votos)

58 vistas98 páginasTítulo original

Viga Monoriel 25 ton_Sizer.xls

Derechos de autor

© © All Rights Reserved

Formatos disponibles

XLS, PDF, TXT o lea en línea desde Scribd

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

© All Rights Reserved

Formatos disponibles

Descargue como XLS, PDF, TXT o lea en línea desde Scribd

0 calificaciones0% encontró este documento útil (0 votos)

58 vistas98 páginasViga Monoriel 25 Ton - Sizer

Cargado por

PROYECTOMSCopyright:

© All Rights Reserved

Formatos disponibles

Descargue como XLS, PDF, TXT o lea en línea desde Scribd

Está en la página 1de 98

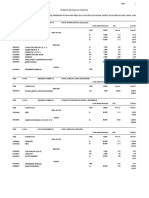

Viga Monoriel - Galeria Sizer

Restricciones Viga Monoriel d

15 < b2

e2

Esquema

Parmetros de Diseo

L = 4.00 m Longitud Tramo

Lb = 4.00 m Longitud No Arriostrada en el Tramo

Cb = 1.00 Coeficiente de Flexin en el tramo

Lo = 0.00 m Longitud Voladizo

Lbo = 4.00 m Longitud No Arriostrada en el Voladizo

0.670 Cbo = 1.00 Coeficiente de Flexin en el voladizo

P = 25 ton Carga Mxima de Levante

Wt = 1.1 ton Peso Equipo de Levante (Trolley)

Wh = 0.4 ton Peso Sistema de Izaje (Hoist)

Vi = 25 % Impacto Vertical %

HLF = 20 % Factor de Carga Horizontal %

a = 0 m Distancia entre atiesadores transversales

Nw = 4 N Total de Ruedas del Carro

S = 64 m Espaciamiento entre Ruedas

RL(min) RR(max)

L Lo

Pv

Viga Monoriel

x

a = 2 cm Distancia de rueda al borde ala

Propiedades Material

Fy = 2531 kg/cm

2

Tensin de Fluencia Acero Viga Monoriel

E = 2100000 kg/cm

2

Mdulo de Elasticidad del Acero

G = 807692 kg/cm

2

Mdulo de Corte =G/2/(1+n)

Cargas

Pv = 26.50 ton Pv = P+Wh+Wt (without vertical impact)

Pv = 32.75 ton Pv = P*(1+Vi/100)+Wt+Wh (carga vertical)

Pw = 8.19 ton/rueda Pw = Pv/Nw (carga por rueda de carro)

Ph = 5.00 ton Ph = HLF*P/100 (carga horizontal)

Reacciones en Apoyos

RR(max) = 30.41 ton = Pv*(L-S/2)/L+w*L/2

RL(min) = 2.90 ton = Pv*(S/2)/L+w*L/2

Momentos de flexin para el Tramo

x = 1.8 ton-m x = 1/2*(L-S/2) (ubicacin del momento mximo desde el extremo izquierdo en el tramo)

Mx = 28.00 ton-m Mx = (Pv/2)/(2*L)*(L-S/2)^2+w*x/2*(L-x)

My = 4.23 ton-m My = (Ph/2)/(2*L)*(L-S/2)^2

Momentos segn Eje X en el Tramo

Mx = 28.00 ton-m Mx = (Pv/2)/(2*L)*(L-S/2)^2+w*x/2*(L-x)

Mnx = 54 ton-m CFY

Momento de Flexin Lateral del Ala por Torsin en el Tramo

e = 18 cm Ver expresiones del Roark Section 10.7 Table 10.2, page 415

at = 172 cm at = SQRT(E*Cw/(J*G))

Mt = 1.180 ton-m Mt = Ph*e*at/(2*(d-tf))*TANH(L/(2*at))

Momentos segn Eje Y en el Tramo

My = 4.23 ton-m My = (Ph/2)/(2*L)*(L-S/2)^2

Mt = 1.180 ton-m Mt = Ph*e*at/(2*(d-tf))*TANH(L/(2*at))

My(total) = 5.412 ton-m My(total) = My+Mt

Mny = 11.641 ton-m Yielding

Razn de Momentos Combinados en el Tramo

R.M. = 0.9789 R.M. = Mx/Mnx+My(total)/Mny

Flecha en el Tramo

Pv = 26.50 ton Pv = P+Wh+Wt (sin Impacto Vertical)

D(max) = 0.183 cm D(max) = Pv/2*(L-S)/2/(24*E*I)*(3*L^2-4*((L-S)/2)^2)+5*w*L^4/(384*E*I)

D(ratio) = L/2187 D(razn) = L*100/D(max)

D(allow) = 0.89 cm D(admisible) = L*100/300 o L*100/450

Momentos de flexin en el Voladizo

Mx = 0.00 ton-m Mx = (Pv/2)*(Lo+(Lo-S))+w*Lo^2/2

My = 0.00 ton-m My = (Ph/2)*(Lo+(Lo-S))

Momento segn Eje X en el Voladizo

Mx = 0.00 ton-m

Mnx = 0.00 ton-m CFY

Momento de Flexin Lateral del Ala por Torsin en el Voladizo

e = N.A. cm Ver expresiones del Roark Section 10.7 Table 10.2, page 415

at = 172 cm at = SQRT(E*Cw/(J*G))

Mt = 0.0000 ton-m Mt = Ph*e*at/(d-tf)*TANH(Lo/at)

Momento segn Eje Y en el Voladizo

My = 0.000 ton-m

Mt = 0.000 ton-m Mt = Ph*e*at/(d-tf)*TANH(Lo/at)

My(total) = 0.000 ton-m My(total) = My+Mt

Mny = 0.000 ton-m Yielding

Razn de Momentos Combinadas en el Voladizo

R.M. = 0.00 R.M. = Mx/Mnx+My(total)/Mny

Flecha en el Voladizo (asumiendo toda la carga de diseo Pv, sin impacto, en el extremo del voladizo)

Pv = N.A. ton Pv = P+Wh+Wt (sin Impacto Vertical)

D(max) = N.A. cm D(max) = Pv*Lo^2*(L+Lo)/(3*E*I)+w*Lo*(4*Lo^2*L-L^3+3*Lo^3)/(24*E*I)

D(ratio) = N.A. D(razn) = Lo*100/D(max)

D(allow) = N.A. cm D(admisible) = Lo*100/150 o Lo*100/450

Flexin en Ala Inferior (simplificado)

be = 38.40 cm Min. de: be = 12*tf or S (largo efectivo de flexin del ala inferior)

am = 11.02 cm am = (b2/2-t/2)-(k-e2) (donde: k-e2 = radio de filete)

Mf = 0.90 m*t Mf = Pw*am

Sf = 66 cm

3

Sf = be*e2^2/6

fb = 1377 kg/cm

2

fb = Mf/Sf

Fb = 1898 kg/cm

2

Fb = 0.75*Fy

Flexin en Ala Inferior segn CMAA Specification No. 74 (2004):

Tensin por Flexin Local en el Ala Inferior @ Punto 0

sxo = -1403 kg/cm

2

sxo = Cxo*Pw/ta^2

szo = 158 kg/cm

2

szo = Czo*Pw/ta^2

Tensin por Flexin Local en el Ala Inferior @ Punto 1

sx1 = 660 kg/cm

2

sx1 = Cx1*Pw/ta^2

sz1 = 1634 kg/cm

2

sz1 = Cz1*Pw/ta^2

Tensin por Flexin Local en el Ala Inferior @ Punto 2

sx2 = 1403 kg/cm

2

sx2 = -sxo

sz2 = -158 kg/cm

2

sz2 = -szo

Tensin Biaxial Resultante @ Punto 0

sz = 1986 kg/cm

2

sz = fbx+fby+0.75*szo

sx = -1052 kg/cm

2

sx = 0.75*sxo

txz = 0 kg/cm

2

txz = 0 (se asume despreciable)

sto = 2673 kg/cm

2

sto = SQRT(sx^2+sz^2-sx*sz+3*txz^2)

Tensin Biaxial Resultante @ Punto 1

sz = 3093 kg/cm

2

sy = fbx+fby+0.75*sz1

sx = 495 kg/cm

2

sx = 0.75*sx1

txz = 0 kg/cm

2

txz = 0 (se asume despreciable)

st1 = 2877 kg/cm

2

st1 = SQRT(sx^2+sz^2-sx*sz+3*txz^2)

Tensin Biaxial Resultante @ Punto 2

sz = 1749 kg/cm

2

sz = fbx+fby+0.75*sz2

sx = 1052 kg/cm

2

sx = 0.75*sx2

txz = 0 kg/cm

2

txz = 0 (se asume despreciable)

st2 = 1525 kg/cm

2

st2 = SQRT(sx^2+sz^2-sx*sz+3*txz^2)

RESUMEN DE CHEQUEOS

Resultados

Momentos y Deformaciones en el Tramo

Mx <= Mnx, O.K.

My <= Mny, O.K.

R.M.(combinado) <= 1.0, O.K.

Def.(max) <= Defl.(adm), O.K.

Momentos y Deformaciones en el Voladizo

N.A.

N.A.

N.A.

N.A.

Flexin en el Ala Inferior (simplificado)

fb <= Fb = 0.75*Fy, O.K.

Flexin en el Ala Inferior (por CMAA No. 74)

fto > Fb = 0.66*Fy

ft1 > Fb = 0.66*Fy

ft2 <= Fb = 0.66*Fy, O.K.

SIMETRIA SIMPLE

ALA COMPACTA

ALMA COMPACTA

> 40 cm

< 25 cm

< 3.5 cm

Dimensiones Seccin Viga Monoriel

d = 55 cm O.K.

b1 = 25 cm

b2 = 25 cm O.K.

t = 1.20 cm

e1 = 1.60 cm

e2 = 3.20 cm O.K.

f = 7.8 w = 41.8

pf = 10.95 pw = 68.57

rf = 25.72 rw = 164.19

1.31 4 Ruedas y S > a Valor de Cb Calculado

Lo

Pv = P*(1+Vi/100)+Wt+Wh (carga vertical)

x = 1/2*(L-S/2) (ubicacin del momento mximo desde el extremo izquierdo en el tramo)

16375

Mx <= Mnx, O.K.

Ver expresiones del Roark Section 10.7 Table 10.2, page 415

385.2302

My <= Mny, O.K.

R.M. <= 1.0, O.K.

Pv/2*(L-S)/2/(24*E*I)*(3*L^2-4*((L-S)/2)^2)+5*w*L^4/(384*E*I)

Defl.(max) <= Defl.(admisible), O.K.

Ver expresiones del Roark Section 10.7 Table 10.2, page 415

(asumiendo toda la carga de diseo Pv, sin impacto, en el extremo del voladizo)

Pv*Lo^2*(L+Lo)/(3*E*I)+w*Lo*(4*Lo^2*L-L^3+3*Lo^3)/(24*E*I)

Defl.(max) <= Defl.(admisible), O.K.

Min. de: be = 12*tf or S (largo efectivo de flexin del ala inferior)

am = (b2/2-t/2)-(k-e2) (donde: k-e2 = radio de filete)

fb <= Fb, O.K.

(Nota: Se desprecia Torsin)

(Convencin de Signos: + = traccin, - = compresin)

t

Punto 2

> Fb = 0.66*Fy = 1670.46 kg/cm^2

> Fb = 0.66*Fy = 1670.46 kg/cm^2

<= Fb = 0.66*Fy = 1670.46 kg/cm^2, O.K.

Factor de Utilizacin

0.514

0.465

0.979

0.206

0.725

1.600

1.722

0.913

t

b2

e2

a

Pw Pw

Punto 0

Punto 1

FACTOR DE FORMA

ASD Mnx/b = 54.5 ton-m CFY 0.51

ASD Mny/b = 11.64 ton-m Yielding 0.364

Mx = 28.00 ton-m OK

My = 4.23 ton-m OK

FACTOR DE FORMA

ASD Mnx/b = 0.0 ton-m CFY 0.000

ASD Mny/b = 0.00 ton-m Yielding 0.00

Mx = 0.00 ton-m OK

My = 0.00 ton-m OK

Propiedades Viga Monoriel

k = 4.08 cm y = 32.8 cm

A = 180.2 cm

2

e = 17.5 cm

w = 0.141 t/m rt = 6.5 cm

Ix = 89873

cm

4

Sxc = 2740 cm

3

Iy = 6257 cm

4

Sxt = 4049 cm

3

J = 336 cm

4

d/Af1 = 3.49

Cw = 3842722 cm

6

Syc = 501 cm

3

h = 50.20 cm Syt = 501 cm

3

hef = 25.00 cm Aef = 150.00 cm

2

Qa= 0.83 Qs = 1.00 Q = 0.83

Iyc = 2,088 cm^4 Iyt = 4,169 cm^4

Zx = 3594.68 cm

3

Zy = 768.07 cm

3

Coeficientes anlisis ala Inferior

l = 0.168 l = 2*a/(b2-t)

Cxo = -1.755 Cxo = -2.110+1.977*l+0.0076*e^(6.53*l)

Cx1 = 0.826 Cx1 = 10.108-7.408*l-10.108*e^(-1.364*l)

Czo = 0.198 Czo = 0.050-0.580*l+0.148*e^(3.015*l)

Cz1 = 2.043 Cz1 = 2.230-1.490*l+1.390*e^(-18.33*l)

Analisis de Torsion para el Tramo por AISC Design Guide Series No. 9, Case 3:

T = 0.88 m*t T = Ph*e

Wns = 329 cm

2

Wns = (d-tf)*bf/4 (se considera conservadoramente el ancho de ala mayor)

a = 0.50 a = 0.500 (el torque se asume en el punto medio del Tramo)

z = 200 cm z = L/2 (calculado en el punto medio del Tramo)

c1 = 0.000323 1/cm c1 = T/(J*G)

c2 = -0.29 c2 = SINH(a*L/at)/TANH(L/at)-COSH(a*L/at)

q'' = 0.0000 q'' = c1*c2/at*SINH(z/at)

sn = 531.0 kg/cm

2

sn = ABS(E*Wns*q'') (tensin normal de alabeo)

FLEXION USAR F4 - TRAMO

FLEXION USAR F4 - VOLADO

Analisis de Torsion para el Voladizo por AISC Design Guide Series No. 9, Case 9:

T = 0.00 m*t T = Ph*e

Wns = 329 cm

2

Wns = (d-tf)*bf/4 (se considera conservadoramente el ancho de ala mayor)

a = 1.00 a = 1 (el torque se asume en el extremo libre del Voladizo)

z = 0 cm z = Lo (calculado en el extremo fijo del Voladizo)

c1 = 0.0000 1/cm c1 = T/(J*G)

c2 = 0.00 c2 = SINH(a*Lo/at)-TANH(Lo/at)*COSH(a*Lo/at)+TANH(Lo/at)

q'' = 0.0000 q'' = c1/at*(c2*COSH(z/at)-SINH(z/at))

sn = 0.0 kg/cm

2

sn = ABS(E*Wns*q'') (tensin normal de alabeo)

Calculo de Momento Plastico en trono al eje fuerta (x-x)

x = 41.8 cm

M1 = 4,309,449.33 ton-cm

M2 = 2,031,549.33 ton-cm

M3 = 2,649,128.5 ton-cm

M4 = 108,004.52 ton-cm

Mp = 9,098,131.71 ton-cm

Zx = 3,594.68 cm^3

Calculo de Momento Plastico en torno al eje debil (y-y)

M1 = 632750 kg-cm

M2 = 1265500 kg-cm

M3 = 45740.232 kg-cm

Mp = 1943990.232 kg-cm

Zy = 768 cm3

Support Reactions:

For Lo = 0 (no overhang):

RR(max) = 30.41 t RR(max) =

RL(min) = 2.90 t RL(min) =

For Lo > 0 (with overhang):

RR(max) = N.A. t RR(max) =

RL(min) = N.A. t RL(min) =

Section Ratios and Parameters:

bf/(2*tf) = 7.8

h/tw = 41.8

kc = 0.6184 OK kc = 4,0/sqrt(h/t); 0,35 < kc < 0,76

Qs = 1.00

f = 2531.00

hef 25.0

A = 180.2

Aef = 150.00

Qa = 0.83

From: "Allowable Bending Stresses for Overhanging Monorails"

by N. Stephen Tanner - AISC Engineering Journal (3rd Quarter, 1985)

Use: Lbo = Lo+L = 4.00 m

K = Lo/(Lo+L) = 0.000

Use: Cbo = 0.670

l = 2*a/(b2-t)

Cxo = -2.110+1.977*l+0.0076*e^(6.53*l)

Cx1 = 10.108-7.408*l-10.108*e^(-1.364*l)

Czo = 0.050-0.580*l+0.148*e^(3.015*l)

Cz1 = 2.230-1.490*l+1.390*e^(-18.33*l)

Analisis de Torsion para el Tramo por AISC Design Guide Series No. 9, Case 3:

Wns = (d-tf)*bf/4 (se considera conservadoramente el ancho de ala mayor)

a = 0.500 (el torque se asume en el punto medio del Tramo)

z = L/2 (calculado en el punto medio del Tramo)

c1 = T/(J*G)

c2 = SINH(a*L/at)/TANH(L/at)-COSH(a*L/at)

q'' = c1*c2/at*SINH(z/at)

sn = ABS(E*Wns*q'') (tensin normal de alabeo)

Analisis de Torsion para el Voladizo por AISC Design Guide Series No. 9, Case 9:

Wns = (d-tf)*bf/4 (se considera conservadoramente el ancho de ala mayor)

a = 1 (el torque se asume en el extremo libre del Voladizo)

z = Lo (calculado en el extremo fijo del Voladizo)

c1 = T/(J*G)

c2 = SINH(a*Lo/at)-TANH(Lo/at)*COSH(a*Lo/at)+TANH(Lo/at)

q'' = c1/at*(c2*COSH(z/at)-SINH(z/at))

sn = ABS(E*Wns*q'') (tensin normal de alabeo)

145

Pv*(L-S/2)/L+w*L/2

Pv*(S/2)/L+w*L/2

N.A.

N.A.

Se considera para el ala superior

kc = 4,0/sqrt(h/t); 0,35 < kc < 0,76

G2

G 2-2

G 2-2

by N. Stephen Tanner - AISC Engineering Journal (3rd Quarter, 1985) N.A.

Table 1: Computed Values N.A.

Index

k = Lo/(Lo+L)

Cbo ASD

1 0 0.67

2 0.1 0.7

3 0.2 0.73 ASD

4 0.3 0.76 LRFD

5 0.4 0.8

6 0.5 0.84

7 0.6 0.9

8 0.7 0.96

9 0.8 1.05

10 0.9 1.15

11 1 1.28

1 0 0.67

2 0.1 0.7

G 2-3

G 2-4

G 2-5

#DIV/0!

G 2-6

G 2-3 con kv =5

G 2-4 con kv =5

G 2-5 con kv =5

G 2-3 con kv =5

Fsold = 1470 kg/cm

2

Electrodos E70XX

g = 0.6*Fy*t/(Fsold*2)

g = 0.62

k = e2 + g/cos(p/2)

k = 4.08 cm

NSS #DIV/0! ton #DIV/0!

Vn = #DIV/0! ton #DIV/0!

TS SIN ATIESADORES

Vn i = N.A. ton w <= 2,46sqrt(E/Fy)

Vn ii = N.A. ton V <= Vn/v or V <=Vn*v

Vn/v = #DIV/0! ton #DIV/0!

v = 1.67

v = 0.90

Fy = 2531 kg/cm^2

Aw = 60.2 cm^2

E = 2100000 kg/cm^2

kv i = #DIV/0! a/h <= 3 o a/h <= (260/ w)^2

kv ii = 5 a/h > 3 o a/h > (260/ w)^2

kv = #DIV/0! a/h <= 3 o a/h <= (260/ w)^2

w = 41.8

h = 50.20 cm

a = 0 cm

Cv i = 1 w <= 1,1sqrt(kv*E/Fy)

Cv ii = #DIV/0! 1,1sqrt(kv*E/Fy) < w <= 1,37sqrt(kv*E/Fy)

Cv iii = #DIV/0! w > 1,37sqrt(kv*E/Fy)

Cv = #DIV/0! #DIV/0!

j = #DIV/0! 2,5/(a/h)^2

Is = #DIV/0! cm^4

ts = #DIV/0! cm

Cv i = 1 w <= 1,1sqrt(kv*E/Fy)

Cv ii = 1.69 1,1sqrt(kv*E/Fy) < w <= 1,37sqrt(kv*E/Fy)

Cv iii = 3.58 w > 1,37sqrt(kv*E/Fy)

Cv = 1.00 w <= 1,1sqrt(kv*E/Fy)

Vn ASD = 54.78 ton

Vn LFRD = 82.33 ton

Vn = 54.78 ton

k

E 3-3 CSFB

E 3-2 Pn y =

E 3-3 Pn x =

E 3-2 Fcry =

E 3-3 Fcrx =

k =

ry =

rx =

L =

y =

x =

E 3-4 Fey =

E 3-4 Fex =

E 3-2 Fcry a =

E 3-3 Fcry b =

E 3-2 Fcrx a =

35 ton Pn x

360 ton Fey >= 0,44Fy

35 ton Fex < 0,44Fy

1999.80551 kg/cm^2 Fey >= 0,44Fy

196.655375 kg/cm^2 Fex < 0,44Fy

1

5.89 cm

22.33 cm

4.00 m

67.9

304.0

4497 kg/cm^2

224 kg/cm^2

2000 kg/cm^2 Fey >= 0,44Fy

3944 kg/cm^2 Fey < 0,44Fy

22 kg/cm^2 Fex >= 0,44Fy

E 3-3 Fcrx b =

197 kg/cm^2 Fex < 0,44Fy

F 2-1 Mp = 90.98 ton-m

N.A Mna = N.A. ton-m Lb<=Lp

F 2-2 Mnb = 86.66 ton-m Lp<Lb<=Lr

F 2-3 Mnc = 90.98 ton-m Lb>Lr

ASD b = 1.67

LRFD b = 0.90

F 2-4 Fcr = 9,020.40 kg/cm^2

F 2-5 Lp = 298.70 cm

F 2-6 Lr = 1,293.08 m

F 2-7 rts = 7.52 cm

F 2-8a c = 1.00

Mr = 48.54 ton-m

ho = 52.60 cm

ry = 5.89 cm

N.A Mna = N.A. ton-m Lb<=Lp

F 2-2 Mnb = 86.66 ton-m Lp<Lb<=Lr

F 2-3 Mnc = 90.98 ton-m Lb>Lr

N.A Mna = N.A ton-m ALA COMPACTA

F 3-1 Mnb = 99.98 ton-m ALA NO COMPACTA

F 3-2 Mnc = 524.68 ton-m ALA ESBELTA

ASD b = 1.67

LRFD b = 0.90

F 2-4 Fcr = 9,020.40 ton/cm^2

F 2-5 Lp = 298.70 m

F 2-6 Lr = 1,293.08 m

F 2-7 rts = 7.52 cm

F 2-8a c = 1.00

ho = 52.60 cm

ry = 5.89 cm

Mp = 90.98 ton-m

Mr = 48.54 ton-m 0,7*Fy*Sx

pf = 10.95

rf = 25.72

kc = 0.62 OK kc = 4,0/sqrt(h/t); 0,35 < kc < 0,76

F 4-1 Mn 90.98 ton-m

N.A. Mn a = N.A ton-m Lb<=Lp

F 4-2 Mn b = 90.98 ton-m Lp<Lb<=Lr

F 4-3 Mn c = 90.98 ton-m Lb>Lr

N.A. Mn a = N.A ton-m ALA COMPACTA

F 4-12 Mn b = 99.98 ton-m ALA NO COMPACTA

F 4-13 Mn c = 524.68 ton-m ALA ESBELTA

N.A. Mn a = N.A. ton-m Sxt >=Sxc

F 4-14 Mn b = 90.98 ton-m Sxt < Sxc

ASD b = 1.67

LRFD b = 0.90

F 4-4 Myc = 69.34 ton-m Fy*Sxc

F 4-5 Fcr = 7,132.29 kg/cm^2

F 4-6a FL i = 1,771.70 kg/cm^2 Sxt/Sxc >= 0,7

F3 - TRAMO

F2 - TRAMO

F4 - TRAMO

F4-6b FL ii = 2,531.00 kg/cm^2 Sxt/Sxc < 0,7

F 4-7 Lp = 206.34 cm

F 4-8 Lr = 1,119.31 cm

F 4-9a Rpc i = 1.31 hc/tw <= pw

F 4-9b RPc ii = 1.31 hc/tw > pw

F 4-10 rt = 6.51 cm

F 4-11 aw = 1.87

F 4-15a Rpt i = 1.31 hc/tw <= pw

F 4-15b Rpt ii = 1.31 hc/tw > pw

Sx = 2,739.77 cm^3 min( Sxc , Sxt)

pf = 10.95

rf = 25.72

kc = 0.62

pw = 68.57

rw = 164.19

Rpc = 1.31 hc/tw <= pw

Rpt = 1.31 hc/tw <= pw

J = 335.78 cm Si Iyc/Iy <=0,23, J=0 cm

h0 = 52.60 cm

FL = 1,771.70 kg/cm^2 Sxt/Sxc >= 0,7

Myt = 69.34 ton-m

Mp = 90.98 ton-m

hc = 62.41 cm

hp = 68.53 cm

F 5-1 Mn = 69.34 ton-m

F 5-2 Mn a = N.A. ton-m Lb<=Lp

F 5-2 Mn b = 61.25 ton-m Lp<Lb<=Lr

F 5-2 Mn c = 69.34 ton-m Lb>Lr

F 5-7 Mn a = N.A. ton-m COMPACTA

F 5-7 Mn b = 75.51 ton-m NO COMPACTA

F 5-7 Mn c = 524.68 ton-m ESBELTA

F 5-10 Mn a = N.A. ton-m Sxt >= Sxc

F 5-10 Mn b = 69.34 ton-m Sxt < Sxc

ASD b = 1.67

LRFD b = 0.90

F 4-7 Lp = 206.34 cm

F 4-10 rt = 6.51 cm

F 4-11 aw = 1.87 OK

F 5-3 Fcr b = 2,235.73 kg/cm^2 Lp<Lb<=Lr

F 5-4 Fcr c= 2,531.00 kg/cm^2 Lb>Lr

F 5-5 Lr = 704.34 cm

F 5-6 Rpg = 1.00

F 5-8 Fcr b = 2,756.00 kg/cm^2 NO COMPACTA

F 5-9 Fcr c = 19,150.5 kg/cm^2 ESBELTA

pf = 10.95

rf = 21.52

kc = 0.62

hc = 62.41 cm

Fcr a = N.A. kg/cm^2 Lb<=Lp

Fcr = 2,235.73 kg/cm^2 Lp<Lb<=Lr

Fcr a = N.A. kg/cm^2 COMPACTA

F5 - TRAMO

Fcr= N.A. kg/cm^2

F 2-1 Yielding 90.98 ton-m

F 2-2 LTB 86.66 ton-m Lp<Lb<=Lr

ASD Mnx/b = 51.89 ton-m LTB

F 2-2 LTB 86.66 ton-m Lp<Lb<=Lr

N.A CFLB N.A ton-m ALA COMPACTA

ASD Mnx/b = 51.89 ton-m LTB

F 4-1 CFY 90.98 ton-m

F 4-3 LTB 90.98 ton-m Lp<Lb<=Lr

N.A. CFLB N.A ton-m ALA COMPACTA

N.A. TFY N.A. ton-m Sxt >=Sxc

ASD Mnx/b = 54.48 ton-m CFY

F 5-1 CFY 69.34 ton-m

F 5-2 LTB 61.25 ton-m Lp<Lb<=Lr

F 5-7 CFLB N.A. ton-m COMPACTA

F 5-10 TFY N.A. ton-m Sxt >= Sxc

ASD Mnx/b = 36.68 ton-m LTB

FLEXION F4 - TRAMO

ASD Mnx/b = 54.5 ton-m CFY

d = 55.0 cm

b1 = 25.0 cm

b2 = 25.0 cm

t = 1.2 cm

e1 = 1.6 cm

e2 = 3.2 cm

Fy = 2,531.0 kg / cm^2

Zx = 3,594.7 cm^3

Sxc = 2,739.8 cm^3

Sxt = 2,739.8 cm^3

Lb = 400.0 cm

E = 2,100,000.0 kg / cm^2

Iy = 6,257.2 cm^4

Iyc = 2,087.8 cm^4

A = 180.2 cm^2

J = 335.8 cm^4

Cw = 3,842,722.2 cm^6

Cb = 1.0

f = 7.8

w = 41.8

h = 50.2 cm

y = 32.8 cm

e = 17.5 cm

F2 - TRAMO

F3 - TRAMO

F4 - TRAMO

F5 - TRAMO

TRAMO

f = 7.81

ALA pf = 10.95 COMPACTA

rf = 25.72

w = 41.83

ALMA pw = 108.31 COMPACTA

rw = 164.19

f = 7.81

ALA pf = 10.95 COMPACTA

rf = 25.72

w = 41.83

ALMA pw = 108.31 COMPACTA

rw = 164.19

f = 7.81

ALA pf = 10.95 COMPACTA

rf = 25.72

w = 41.83

ALMA pw = 68.57 COMPACTA

rw = 164.19

f = 7.81

ALA pf = 10.95 COMPACTA

rf = 25.72

w = 41.83

ALMA pw = 108.31 COMPACTA

rw = 164.19

F5 - TRAMO Y VOLADO

F4 - TRAMO Y VOLADO

F3 - TRAMO Y VOLADO

F2 - TRAMO Y VOLADO

F 2-1 Mp = 90.98 ton-m

N.A Mna = N.A. ton-m

F 2-2 Mnb = 90.98 ton-m

F 2-3 Mnc = #DIV/0! ton-m

ASD b = 1.67

LRFD b = 0.90

F 2-4 Fcr = #DIV/0! kg/cm^2

F 2-5 Lp = 298.70 cm

F 2-6 Lr = 1,293.08 m

F 2-7 rts = 7.52 cm

F 2-8a c = 1.00

Mr = 48.54 ton-m

ho = 52.60 cm

ry = 5.89 cm

N.A Mna = N.A. ton-m

F 2-2 Mnb = 90.98 ton-m

F 2-3 Mnc = #DIV/0! ton-m

N.A Mna = N.A ton-m

F 3-1 Mnb = 99.98 ton-m

F 3-2 Mnc = 524.68 ton-m

ASD b = 1.67

LRFD b = 0.90

F 2-4 Fcr = #DIV/0! ton/cm^2

F 2-5 Lp = 298.70 m

F 2-6 Lr = 1,293.08 m

F 2-7 rts = 7.52 cm

F 2-8a c = 1.00

ho = 52.60 cm

ry = 5.89 cm

Mp = 90.98 ton-m

Mr = 48.54 ton-m

pf = 10.95

rf = 25.72

kc = 0.62 OK

F 4-1 Mn 90.98 ton-m

N.A. Mn a = N.A ton-m

F 4-2 Mn b = ######### ton-m

F 4-3 Mn c = #DIV/0! ton-m

N.A. Mn a = N.A ton-m

F 4-12 Mn b = 99.98 ton-m

F 4-13 Mn c = 524.68 ton-m

N.A. Mn a = N.A. ton-m

F 4-14 Mn b = 90.98 ton-m

ASD b = 1.67

LRFD b = 0.90

F 4-4 Myc = 69.34 ton-m

F 4-5 Fcr = #DIV/0! kg/cm^2

F 4-6a FL i = 1,771.70 kg/cm^2

F3 - VOLADO

F4 - VOLADO

F2 - VOLADO

F4-6b FL ii = 2,531.00 kg/cm^2

F 4-7 Lp = 206.34 cm

F 4-8 Lr = 1,119.31 cm

F 4-9a Rpc i = 1.31

F 4-9b RPc ii = 1.31

F 4-10 rt = 6.51 cm

F 4-11 aw = 1.87

F 4-15a Rpt i = 1.31

F 4-15b Rpt ii = 1.31

Sx = 2,739.77 cm^3

pf = 10.95

rf = 25.72

kc = 0.62

pw = 68.57

rw = 164.19

Rpc = 1.31

Rpt = 1.31

J = 335.78 cm

h0 = 52.60 cm

FL = 1,771.70 kg/cm^2

Myt = 69.34 ton-m

Mp = 90.98 ton-m

hc = 62.41 cm

hp = 68.53 cm

F 5-1 Mn = 69.34 ton-m

F 5-2 Mn a = N.A. ton-m

F 5-2 Mn b = 69.34 ton-m

F 5-2 Mn c = #DIV/0! ton-m

F 5-7 Mn a = N.A. ton-m

F 5-7 Mn b = 75.51 ton-m

F 5-7 Mn c = 524.68 ton-m

F 5-10 Mn a = N.A. ton-m

F 5-10 Mn b = 69.34 ton-m

ASD b = 1.67

LRFD b = 0.90

F 4-7 Lp = 206.34 cm

F 4-10 rt = 6.51 cm

F 4-11 aw = 1.87 OK

F 5-3 Fcr b = 2,531.00 kg/cm^2

F 5-4 Fcr c= #DIV/0! kg/cm^2

F 5-5 Lr = 704.34 cm

F 5-6 Rpg = 1.00

F 5-8 Fcr b = 2,756.00 kg/cm^2

F 5-9 Fcr c = 19,150.5 kg/cm^2

pf = 10.95

rf = 21.52

kc = 0.62

hc = 62.41 cm

Fcr a = N.A. kg/cm^2

Fcr = N.A. kg/cm^2

Fcr a = N.A. kg/cm^2

F5 -VOLADO

Fcr= N.A. kg/cm^2

F 2-1 Yielding 90.98 ton-m

Lbo<=Lp N.A LTB N.A. ton-m

Lp<Lbo<=Lr ASD Mnx/b = 54.48 ton-m

Lbo >Lr

N.A LTB N.A. ton-m

N.A CFLB N.A ton-m

ASD Mnx/b = - ton-m

F 4-1 CFY 90.98 ton-m

N.A. LTB N.A ton-m

N.A. CFLB N.A ton-m

N.A. TFY N.A. ton-m

ASD Mnx/b = 54.48 ton-m

F 5-1 CFY 69.34 ton-m

Lbo <=Lp F 5-2 LTB N.A. ton-m

Lp<Lbo <=Lr F 5-7 CFLB N.A. ton-m

Lbo >Lr F 5-10 TFY N.A. ton-m

ALA COMPACTA ASD Mnx/b = 41.52 ton-m

ALA NO COMPACTA FLEXION F4 - VOLADO

ALA ESBELTA ASD Mnx/b = 54.5 ton-m

d = 55.0 cm

b1 = 25.0 cm

b2 = 25.0 cm

t = 1.2 cm

e1 = 1.6 cm

e2 = 3.2 cm

Fy = 2,531.0 kg / cm^2

Zx = 3,594.7 cm^3

0,7*Fy*Sx Sxc = 2,739.8 cm^3

Sxt = 2,739.8 cm^3

Lbo = - cm

kc = 4,0/sqrt(h/t); 0,35 < kc < 0,76 E = 2,100,000.0 kg / cm^2

Iy = 6,257.2 cm^4

Iyc = 2,087.8 cm^4

Lbo <=Lp A = 180.2 cm^2

Lp<Lbo <=Lr J = 335.8 cm^4

Lbo >Lr Cw = 3,842,722.2 cm^6

ALA COMPACTA Cbo = 1.0

ALA NO COMPACTA f = 7.8

ALA ESBELTA w = 41.8

Sxt >=Sxc h = 50.2 cm

Sxt < Sxc y = 32.8 cm

e = 17.5 cm

Fy*Sxc

Sxt/Sxc >= 0,7

F5 - VOLADO

F3 - VOLADO

F4 - VOLADO

VOLADO

F2 - VOLADO

F3 - VOLADO

F4 - VOLADO

F2 - VOLADO

Sxt/Sxc < 0,7

hc/tw <= pw

hc/tw > pw

hc/tw <= pw

hc/tw > pw

min( Sxc , Sxt)

hc/tw <= pw

hc/tw <= pw

Si Iyc/Iy <=0,23, J=0 cm

Sxt/Sxc >= 0,7

Lbo <=Lp

Lp<Lbo <=Lr

Lbo >Lr

COMPACTA

NO COMPACTA

ESBELTA

Sxt >= Sxc

Sxt < Sxc

Lp<Lb<=Lr

Lb>Lr

NO COMPACTA

ESBELTA

Lb<=Lp

Lb<=Lp

COMPACTA

F5 -VOLADO

Lbo<=Lp

Yielding

Lbo <=Lp

ALA COMPACTA

CFLB

Lbo <=Lp

ALA COMPACTA

Sxt >=Sxc

CFY

Lbo <=Lp

COMPACTA

Sxt >= Sxc

CFY

CFY

F5 - VOLADO

F2 - VOLADO

F3 - VOLADO

F4 - VOLADO

Fy = 2,531.00 kg / cm^2

Zy = 768.07 cm^3

Sy = 500.58 cm^3

E = 2,100,000.00 kg / cm^2

= 15.63

f = 7.81

ALA pf = 10.95 COMPACTA

rf = 25.72

w = 41.83

ALMA pw = 108.31 COMPACTA

rw = 164.19

f = 7.81

ALA pf = 10.95 COMPACTA

rf = 25.72

w = 41.83

ALMA pw = 68.57 COMPACTA

rw = 164.19

f = 7.81

ALA pf = 10.95 COMPACTA

rf = 25.72

w = 41.83

ALMA pw = 108.31 COMPACTA

rw = 164.19

ASD b = 1.67

LRFD b = 0.90

F5 - TRAMO Y VOLADO

F4 - TRAMO Y VOLADO

F3 - TRAMO Y VOLADO

TRAMO

Yielding Mn = 19.4 ton-m

Mpy = 19.4 ton-m

FLB Mn = 19.4 ton-m COMPACTA

Mna = 19.4 COMPACTA

Mnb = 16.1 ton-m NO COMPACTA

Fcr = 23740.4 kg/cm^2

Mnc = 118.8 ton-m ESBELTA

ASD Mny/b = 11.64 ton-m Yielding

2 ruedas

M(x) = ql/2*x-q*x^2/2 + P/2*x 0<= x <= L/2

ql/2*x-q*x^2/2 + P/2*x-P*(x-L/2) L/2 <= x <= L

M(1/4 L) 16.5872326 ton-m x = L/4 1

M(1/2 L) 33.0329768 ton-m x = L/2 2

M(3/4 L) 16.5872326 ton-m x = 3L/4 3

M(max) 33.0329768 ton-m x = L/2 2

Cb = 1.31

L = 4.00

Nw = 4

S = 64 m

a = 2.344

Cb = 1.31 4 Ruedas y S > a

4 ruedas s = 64

a = 2.344

Caso s <= a

M(x) = ql/2*x-q*x^2/2 + P/2*x - Ps/(4L)*x

ql/2*x-q*x^2/2 + PL/4 - Ps/8 - Ps/(4L)*x

ql/2*x-q*x^2/2 + PL/2 + Ps/4 - P/2*x - Ps/(4L)*x

0<= x <= 2,5 M(1/4 L) -114.412767

2,5 <= x <= 5 M(1/2 L) -490.967023

2,5 <= x <= 5 M(3/4 L) 147.587233

2,5 <= x <= 5 M(max) 1586.92246

Cb = 3.00

Caso s > a

M(x) = ql/2*x-q*x^2/2 + P/4*x

ql/2*x-q*x^2/2 + P/4*x-P/2*(x-L/2)

M(1/4 L) 8.3997326 ton-m

M(1/2 L) 16.6579768 ton-m

M(3/4 L) 8.3997326 ton-m

M(max) 16.6579768 ton-m

Cb = 1.31

0,586*L

ql/2*x-q*x^2/2 + P/2*x - Ps/(4L)*x 0<= x <= 1/2(L-s/2)

ql/2*x-q*x^2/2 + PL/4 - Ps/8 - Ps/(4L)*x 1/2(L-s/2)<= x <= 1/2(L+3s/2)

ql/2*x-q*x^2/2 + PL/2 + Ps/4 - P/2*x - Ps/(4L)*x 1/2(L+3s/2)<= x <= L

x = L/4 1 0<= x <= 2,4625

x = L/2 2 2,4625 <= x <= 2,6125

x = 3L/4 3 2,6125 <= x <= 5

x = L/2 - s/4 -14 2,4625 <= x <= 2,6125

0<= x <= L/2

ql/2*x-q*x^2/2 + P/4*x-P/2*(x-L/2) L/2 <= x <= L

x = L/4 1 0<= x <= 2,5

x = L/2 2 2,5 <= x <= 5

x = 3L/4 3 2,5 <= x <= 5

x = L/2 2 2,5 <= x <= 5

También podría gustarte

- 3.5 Dilataciones Térmicas PDFDocumento28 páginas3.5 Dilataciones Térmicas PDFPROYECTOMS0% (1)

- 3.1 Clasificación de Las Tensiones en Un Sistema de Tuberías PDFDocumento39 páginas3.1 Clasificación de Las Tensiones en Un Sistema de Tuberías PDFPROYECTOMS100% (1)

- Sistemas de Soportes en TuberiasDocumento54 páginasSistemas de Soportes en TuberiasPROYECTOMS67% (3)

- Reglamento Registro Contratistas ParticularesDocumento18 páginasReglamento Registro Contratistas ParticularesPROYECTOMSAún no hay calificaciones

- 3.4 Elementos Basicos de Soportacion PDFDocumento85 páginas3.4 Elementos Basicos de Soportacion PDFPROYECTOMSAún no hay calificaciones

- Cargas de Viento (Covenin 2003-88) - en GalponesDocumento5 páginasCargas de Viento (Covenin 2003-88) - en GalponesPROYECTOMSAún no hay calificaciones

- Losas PostensadasDocumento31 páginasLosas PostensadasCarlos RoblesAún no hay calificaciones

- 0347 PLN SDI 023 021 005 - DU - 220 33 - KVDocumento1 página0347 PLN SDI 023 021 005 - DU - 220 33 - KVPROYECTOMSAún no hay calificaciones

- Cargas de Viento (Covenin 2003-88) - en GalponesDocumento5 páginasCargas de Viento (Covenin 2003-88) - en GalponesPROYECTOMSAún no hay calificaciones

- 3.2 Teoría de Fallas y Tensiones AdmisiblesDocumento57 páginas3.2 Teoría de Fallas y Tensiones AdmisiblesPROYECTOMSAún no hay calificaciones

- PR120107 - Dossier - 1.4 Inversor - IfX1000-PV Rev 1Documento52 páginasPR120107 - Dossier - 1.4 Inversor - IfX1000-PV Rev 1PROYECTOMS100% (1)

- Mantenimiento Sistema FotovoltaicoDocumento22 páginasMantenimiento Sistema FotovoltaicoPROYECTOMSAún no hay calificaciones

- 3.4 Elementos Basicos de SoportacionDocumento85 páginas3.4 Elementos Basicos de SoportacionPROYECTOMSAún no hay calificaciones

- Clei 6 Guia Taller Quimica OkDocumento5 páginasClei 6 Guia Taller Quimica OkAHIMELEC PANTOJA HERNANDEZAún no hay calificaciones

- Bulones Capítulo11Documento25 páginasBulones Capítulo11marelacamaAún no hay calificaciones

- Amoca-1 Informe FinalDocumento122 páginasAmoca-1 Informe FinalSanti Rod TAún no hay calificaciones

- Carta Sistema 18 - Novaguard Techint 420Documento2 páginasCarta Sistema 18 - Novaguard Techint 420Antonio MejiaAún no hay calificaciones

- 2540m Operacion EspañolDocumento75 páginas2540m Operacion EspañolLeonel Losada CardozoAún no hay calificaciones

- Criterio de Fallas - EjerciciosDocumento4 páginasCriterio de Fallas - EjerciciosAlexander ChoquehuancaAún no hay calificaciones

- 02 Especificaciones SECTOR 7A 9 R3 API-ZLO-13-15Documento65 páginas02 Especificaciones SECTOR 7A 9 R3 API-ZLO-13-15Yazmin MurilloAún no hay calificaciones

- Acabados en Edificios MultifamiliaresDocumento37 páginasAcabados en Edificios MultifamiliaresBania Yahaira Terrones Yzquierdo100% (1)

- Deter Porosidad GredaDocumento9 páginasDeter Porosidad GredaNestor RodasAún no hay calificaciones

- Costos Unitarios Alt 01Documento7 páginasCostos Unitarios Alt 01janeth avalos vegaAún no hay calificaciones

- 039-REPS-EE2-CPL Reposicion de PernosDocumento3 páginas039-REPS-EE2-CPL Reposicion de PernosRuben Mafaldo MoriAún no hay calificaciones

- Bloques de ConcretoDocumento22 páginasBloques de ConcretoLuiguiAún no hay calificaciones

- HPGRDocumento8 páginasHPGRGonzalo Salazar100% (1)

- 540 Pu FullDocumento2 páginas540 Pu FullSheyla Claudia Barriga CuadrosAún no hay calificaciones

- Horno Flash y CT PDFDocumento29 páginasHorno Flash y CT PDFelectrico_concepcionAún no hay calificaciones

- Cobos EjerciciosDocumento3 páginasCobos EjerciciosRaiden. OscuroAún no hay calificaciones

- Aditivos QuimicosDocumento11 páginasAditivos Quimicosluis100% (1)

- DP. Poliurea Fría PS-100.E ModDocumento2 páginasDP. Poliurea Fría PS-100.E ModcesarAún no hay calificaciones

- Cronograma Valorizado de Avance de Obra Mercado PDFDocumento1 páginaCronograma Valorizado de Avance de Obra Mercado PDFwillcivilAún no hay calificaciones

- Practica 07 - Temperatura y CalorDocumento2 páginasPractica 07 - Temperatura y CalorSalomon Rojas HidalgoAún no hay calificaciones

- Pirólisis FlashDocumento4 páginasPirólisis FlashGrace Vera100% (1)

- Csi-F-Sig-007 Lista de Aspectos AmbientalesDocumento5 páginasCsi-F-Sig-007 Lista de Aspectos Ambientalesnrii21Aún no hay calificaciones

- Folleto I326Documento2 páginasFolleto I326Ricardo SanchezAún no hay calificaciones

- Clase Demostrativa Ingeniería Sanitaria I - UNITEC PDFDocumento72 páginasClase Demostrativa Ingeniería Sanitaria I - UNITEC PDFMarco MorenoAún no hay calificaciones

- Acido NitricoDocumento38 páginasAcido NitricoYahir Villanueva0% (1)

- Instrucciones de Uso Del Molino de Palas Tipo SK 100: Retsch GMBH 42781 Haan, Retsch-Allee 1-5, Germany, 14/02/2012 0002Documento24 páginasInstrucciones de Uso Del Molino de Palas Tipo SK 100: Retsch GMBH 42781 Haan, Retsch-Allee 1-5, Germany, 14/02/2012 000220106285Aún no hay calificaciones

- Tabla Periódica y Enlace QuimicoDocumento95 páginasTabla Periódica y Enlace QuimicoAnthony GodoyAún no hay calificaciones

- Ficha HP2 PDA ValdiviaDocumento5 páginasFicha HP2 PDA ValdiviaOde TteAún no hay calificaciones

- Procedimiento de TIE-INDocumento8 páginasProcedimiento de TIE-INrainer2512Aún no hay calificaciones