Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Bombas Estacionarias SP 4800

Cargado por

SchwingLatinoamericaTítulo original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Bombas Estacionarias SP 4800

Cargado por

SchwingLatinoamericaCopyright:

Formatos disponibles

PISTON SIDE (bar)

ROD SIDE (bar)

(21 stroke per minute P.S.) (31 strokes per minute R.S)

SP 8800

PISTON SIDE (bar)

ROD SIDE (bar)

SPECIFICATIONS

PUMP SPECIFICATIONS

CONCRETE PRESSURE PSI Bar 3045 210 2900 2920 200 201

(21 stroke per minute P.S.) (31 strokes per minute R.S)

SP 8800

CONCRETE PRESSURE PSI Bar 3045 210 200 190 180 170 2364 160 150 140 130 120 1508 110 100 90 80 70 60 50 40 30 20 10 104 163

290

PISTON SIDE

2755 2610

Break point

190 180 170 160 150 140

PISTON SIDE

PERFORMANCE CHARACTERISTICS OF THE HYDRAULIC PUMP PUMP SPEED 2100 RPM HYDRAULIC PRESSURE LIMITED TO 290 BAR MAX. (4205 PSI).

2900 2755 2610 2465 2320 2175

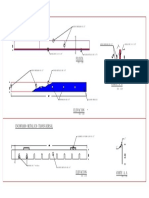

SP 4800 SP 4800 SP 8800 SP 8800 2018-5 150/90 2020-5 150/90 2018-7 150/90 2020-7 150/90 U.S. Metric U.S. Metric U.S. Metric U.S. Metric

Rod/Piston Rod/Piston Rod/Piston Rod/Piston Rod/Piston Rod/Piston Rod/Piston Rod/Piston

OIL PRESSURE

250

2465 2320

300

SP 4800 / SP 8800

Stationary concrete pumps

350

ROD SIDE

2175 2030

200

250

2030

300 250

1885 1869 130 129 1740

Break point

350

200

Break point

1885 1740 1595

Break point

ROD SIDE

120 110

Concrete Output (cu. yds./hr. - cu. m./hr.) 86/56 66/43 106/69 81/53 123/82 94/63 152/101 116/77 Max. Pressure on Concrete (psi - bar) 1869/2920 129/201 1508/2364 104/163 1869/2920 129/201 1508/2364 104/163 Max. Strokes Per Minute 21 14 21 14 31 21 31 21 Pump Cylinder Diameter (in. - mm) 7 180 8 200 7 180 8 200 Pump Cylinder Stroke (in. - mm) 79 2000 79 2000 79 2000 79 2000 Differential Cylinder Size (in. - mm) 5.9 150 5.9 150 5.9 150 5.9 150 Maximum Aggregate Size (in. - mm) 2.5 64 2.5 64 2.5 64 2.5 64 Concrete Valve Type High Pressure Rock with Double Shift Cylinders Hopper Capacity (cu. ft. - cu. m.) 21.5 .6 21.5 .6 21.2 .6 21.2 .6 Engine Power with CAT (hp. - kw.) 440 328 440 328 630 470 630 470 Axle Single Axle Job Site Only Outrigger Legs Manual Manual Hydraulic Hydraulic Length (ft - mm) 23 7010 23 7010 27 8230 27 8230 Width (ft-in. - mm) 6-3 1905 6-3 1905 8 2438 8 2438 Height (ft-in. - mm) 8-1 2476 8-1 2476 8-8 2640 8-8 2640 Trailer Units Weight (lbs. - kg.) 17,637 8000 17,637 8000 22,000 9980 22,000 9980 Remote Control Cable (ft. - m.)

Specifications are subject to change without prior notice.

1595 1450

300 250

OIL PRESSURE

150

100 90 80 70 60 50 40 30 20 10

1450 1305 1160

200

100

1305 1160

150

200

100

150 100

1015 870 725 PERFORMANCE CHARACTERISTICS OF THE HYDRAULIC PUMP PUMP SPEED 2100 RPM HYDRAULIC PRESSURE LIMITED TO 290 BAR MAX. (4205 PSI). 84 80 90 61 69 64 580 435 290 145 123 100 110 120 130 140 150 160 cu yd / h 76.5 84 92 99 94.6 107 114

1015 870 725 580

150 100

50

8'150

50

9'10 SP 4800

10 7.5 20 15 30 40 50 38 60 46 70 53.5 80 61 90

435 290 145

50

breakpoint =249 bar @ 290 bar =670 l/m

10 7.5

20 15

30

40

50 38

60 46

70 53.5

23 30.5

122 cu meters/ h

breakpoint =249 bar @ 290 bar =670 l/m

101 151 66 100 110 120 130 140 150 160 cu yd / h 84 92 99 107 114 122 cu meters/ h 116

23 30.5

69 76.5 77

CONCRETE OUTPUT ROD SIDE 5 10 15 20 25

CONCRETE OUTPUT NUMBER OF STROKES (stroke / min.) OIL VOLUME (liter / min.) 35 NUMBER OF STROKES (stroke / min.) OIL VOLUME (liter / min.) ROD SIDE 5'5" 5

50

31 30

10

15

20

25

31 NUMBER OF STROKES 30 (stroke / min.) OIL VOLUME (liter / min.)

50 100 150 200 250 300 350 400 450 500 550 600 650 700 750 800

7'3"

PISTON SIDE

100 150 200 250 300 350 400 450 500 550 600 650 700 750 800

PISTON SIDE

100

5

200 300

10

400 500

15

600

21 20

700 800

25

30

5

100 200

22'10" 10

300 400 500

15

600 700

21 20

800

25

900 1000

30

1100

NUMBER OF STROKES (stroke / min.) OIL VOLUME (liter / min.)

900 1000 1100 1200 1300

6'10"

8'8

SP 8800

10'4 8'

4'2" 27'1"

8'2"

Cable-Pump Forward/Stop/Reverse/E-Stop

Piston Side

Rod Side

(14 stroke per minute P.S.) (21 strokes per minute R.S)

SP 4800

CONCRETE PRESSURE PSI Bar

(14 stroke per minute P.S.) (21 strokes per minute R.S)

SP 4800

CONCRETE PRESSURE PSI 3045 2900 Bar 210 200 190 180 170 2365 160 150 140 130 120 1514 110 100 90 80 70 60 50 40 30 20 10 104.4 163

SCHWING-STETTER MOVES CONCRETE. WORLDWIDE.

Wherever concrete is produced and moved is where you will find Schwing-Stetter machinery. With plants in Germany, Austria, USA, Brazil, Russia, China and India as well as with more than 100 sales and service facilities, the group of companies is always close to the customer. Our wide range of products with something for every application is what makes Schwing-Stetter the No. 1 system supplier for concrete machinery worldwide.

Piston Side

2900

200 190 180 170 160 150 140

Rod Side

300 290

PISTON SIDE PERFORMANCE CHARACTERISTICS OF THE HYDRAULIC PUMP PUMP SPEED 2100 RPM HYDRAULIC PRESSURE LIMITED TO 290 BAR MAX. (4205 PSI).

3045

2920

210

201

2755 2610 2465 2320 2175 2030

250

300 290

PERFORMANCE CHARACTERISTICS OF THE HYDRAULIC PUMP PUMP SPEED 2100 RPM HYDRAULIC PRESSURE LIMITED TO 290 BAR MAX. (4205 PSI). PISTON SIDE

2755 2610 2465 2320 2175 2030

350

200

ROD SIDE

break point

250 350

300 290 250

1885 1869 130 129 1740 120 200

ROD SIDE

300 290 250 150 200 100

break point

1885 1740 1595 1450 1305

break point

OIL PRESSURE (Bar)

break point

1450 1305 1160

100 90 80 70 60 50 40 30 20 10

200

100

OIL PRESSURE (Bar)

150

1595

110

1160 1015 870

150

1015 870

150

100

50

725 580 435

725 580 435

100 50 50

50

290 145

290 145

breakpoint =227 bar Min Q @ 290 bar =410 l/m

56 10 7.5 20 15 30 23 40 30.5 50 38 43 60 46 70 53.5 80 61

86 90 69 66 100 76.5 110 84 120 92 130 99 140 150 cu yd / h 107 114 cu meters/ h

breakpoint =227 bar Min Q @ 290 bar =410 l/m

10 7.5

20 15

30 23

40 30.5

50 38

60 46

69 70 53.5 53

80 61

90 69

106 100 110 76.5 84 81

120 92

130 99

140 150 cu yd / h 107 114 cu meters/ h

ROD SIDE

10

CONCRETE OUTPUT 21 15 20

CONCRETE OUTPUT 25 NUMBER OF STROKES (stroke / min.) OIL VOLUME (liter / min.) 35 NUMBER OF STROKES (stroke / min.) OIL VOLUME (liter / min.) PISTON SIDE

100

ROD SIDE

50 100

5

150 200

10

250 300

15

350 400 450

20

21

25

600 650 700

NUMBER OF STROKES (stroke / min.) OIL VOLUME (liter / min.) NUMBER OF STROKES (stroke / min.)

50 100 150 200 250 300 350 400 450 500 550 600 650 700 750 800

500

550

PISTON SIDE

100

5

200 300

10

400

14 15

500 600

20

700 800

25

900

30

1000 1100 1200

5

200 300

10

400

14 15

500 600 700

20

800

25

900 1000

1100

OIL VOLUME (liter / min.)

CONCRETE BATCHING PLANTS

TRUCK MIXERS

TRUCK-MOUNTED CONCRETE PUMPS

STATIONARY CONCRETE PUMPS

SEPARATE PLACING BOOMS

CONCRETE RECYCLERS

8'1 SP 4800

9'10

1/09- 3M

66

5'5" 7'3" 22'10"

5900 Centerville Road | St. Paul, MN 55127 | TEL 1-888-SCHWING FAX 651-429-3464 | www.schwing.com

OUTPUT AND DISTANCE TO MEET YOUR GOALS

Output to 152 cu. yds./hr. Pressure to 2920 psi High Pressure Rock Valve

When you are going to the top, choose the pumps that have already been there the SP 4800 and SP 8800. These are the high pressure workhorse pumps that have topped out more high rise buildings than any others. The technology of our twin-cylinder, all-hydraulic open loop system concrete pump has been refined for decades along with the proven Rock Valve that is so important to reliability and cost of operation. The Rock Valves design creates positive pressure within the valve which is ideal for high pressure pumping applications. As pressure from the concrete acts on the pressure spring, a tighter seal is created between the carbide cutting ring and the wear plate. This allows Schwing to pump at higher pressures with less maintenance. Major pumping projects benefit from the Schwing experience that combines pumping expertise learned on record breaking projects along with unmatched factory support. This includes parts inventory at one of our six company branches strategically located throughout the United States and a staff of service technicians that can travel to your site 24/7. So whether you are taking your mid-rise, high-rise or long distance project to completion, you have the experience of hundreds of successful projects behind you with Schwing.

Only one manufacturer can supply the Schwing experience. Thousands of our customers form a backdrop of success that you can join by letting us spec the right piece of equipment for your needs. Six company stores with technicians and parts placed strategically across the country provide service expertise as close as your phone. And a select group of knowledgeable dealers provides another layer of invaluable experience. You and your staff will be welcomed into our facility to learn how to extract the maximum profitability from your concrete pump. Generations of successful owners have chosen the Schwing experience. As a third generation family owned company we understand how important quality equipment is to your business and how important your business is to us.

This open loop Generation 3 all-hydraulic concrete pump sets the standard for fuel-efficiency, reliability and performance. Controlled acceleration of the differential cylinders reduces surge in the pipeline for smooth, quiet operation. Proven high pressure Rock Valve uses double shifting cylinders to pump the harshest mixes at the lowest operating cost.

Convenient control panel includes electric switches for on/off, forward/reverse and agitator on/off. Gauges monitor pumping pressure and rpm.

Remote control (cable or optional radio remote) frees the operator to monitor pumping progress. Critical functions include on/off and forward/reverse.

Fuel efficient Deutz diesel engine is chosen for performance and reliability. (SP 4800 6 cyl. 443 hp, SP 8800 8 cyl. 590 hp).

Fast cleanout with less wasted concrete is a benefit of these SP models over other valve types. Standard hopper agitator keeps concrete flowing to the material cylinders for smooth pumping of the harshest mixes.

More than 400,000 square feet are devoted to producing the highest quality concrete equipment at our White Bear, Minnesota plant. From close inspection of incoming materials to forming our products with the latest robotic welding techniques, Schwing takes craftsmanship to the highest standards. Our state-of-the-art paint facility produces finished products you will be proud to put your name on. In addition, a vast inventory of parts are on hand to keep your Schwing product running at maximum efficiency. Please schedule a visit to this modern facility located minutes north of Minneapolis/St.Paul to see our long-term commitment to the market.

También podría gustarte

- Procedimiento de Interconexion de Paneles de Deteccion Contra IncendioDocumento8 páginasProcedimiento de Interconexion de Paneles de Deteccion Contra IncendioAlvaroNeyraAún no hay calificaciones

- SikaColombia-Rehabilitación-Fisuras en El Concreto ReforzadoDocumento20 páginasSikaColombia-Rehabilitación-Fisuras en El Concreto ReforzadoSebastian TorresAún no hay calificaciones

- Ficha Técnica - SCH 40Documento9 páginasFicha Técnica - SCH 40Henry Bajaña GuevaraAún no hay calificaciones

- Guía del Contratista para Instalación de Tuberías de PVC con Empaque para Agua/ para AlcantarilladoDe EverandGuía del Contratista para Instalación de Tuberías de PVC con Empaque para Agua/ para AlcantarilladoAún no hay calificaciones

- Checklist Del Sistema de Detención de Caídas: Compañía Contratista: Año: Folio: Datos Generales Instrucciones de UsoDocumento7 páginasChecklist Del Sistema de Detención de Caídas: Compañía Contratista: Año: Folio: Datos Generales Instrucciones de UsoManuel Toca GallegosAún no hay calificaciones

- Registro de Seguridad Inducción Hombre NuevoDocumento1 páginaRegistro de Seguridad Inducción Hombre NuevoEric LeguisamonAún no hay calificaciones

- C. Especiales e InnovaciónDocumento12 páginasC. Especiales e InnovaciónHeymi Sifuentes100% (1)

- Tipos de PruebasDocumento5 páginasTipos de PruebasGerardoAún no hay calificaciones

- Canales y Bajantes 2018 1 PDFDocumento4 páginasCanales y Bajantes 2018 1 PDFIvanna ArceAún no hay calificaciones

- GI-001-INGI Rev 00 ElectrocucionDocumento1 páginaGI-001-INGI Rev 00 Electrocucionalexander_cacedaAún no hay calificaciones

- PS-I-25 Construcción Barreras Sedimentadoras FajinasDocumento7 páginasPS-I-25 Construcción Barreras Sedimentadoras FajinasSebastian OjedaAún no hay calificaciones

- Procedimiento de trabajo seguro para desapernado, cegado y apernado de bridasDocumento21 páginasProcedimiento de trabajo seguro para desapernado, cegado y apernado de bridasFlia Parra TriviñoAún no hay calificaciones

- PETSDocumento20 páginasPETSFranchesca CarbajalAún no hay calificaciones

- Fester Grout NM 800Documento4 páginasFester Grout NM 800David Plata OrozcoAún no hay calificaciones

- Plan de Calidad FCR - YesoDocumento7 páginasPlan de Calidad FCR - YesoleoAún no hay calificaciones

- Bandeja de Rejilla SchneiderDocumento20 páginasBandeja de Rejilla Schneiderricardo_74_02Aún no hay calificaciones

- Anexo Programa de Salud Seguridad e Higiene en Trabajo Res. 503-14Documento4 páginasAnexo Programa de Salud Seguridad e Higiene en Trabajo Res. 503-14emi bAún no hay calificaciones

- Especificaciones Tecnicaspavimentacion y Senalizacion 20220214 111912 525Documento25 páginasEspecificaciones Tecnicaspavimentacion y Senalizacion 20220214 111912 525Daniel Ramirez RoncalAún no hay calificaciones

- 01.ESTÁNDAR BÁSICO DE PdRGADocumento3 páginas01.ESTÁNDAR BÁSICO DE PdRGADashiell AriasAún no hay calificaciones

- PUERTA ELECTRICA ENROLLABLEDocumento2 páginasPUERTA ELECTRICA ENROLLABLEJoel Flores Janco100% (1)

- 5.-Cronograma de ObraDocumento1 página5.-Cronograma de ObraElvin Henrry Benites CastilloAún no hay calificaciones

- 4.-Luces de Emergencia 2Documento3 páginas4.-Luces de Emergencia 2FELIPE QUINONES PAUCARAún no hay calificaciones

- Chema Epox Adhesivo 32 1Documento10 páginasChema Epox Adhesivo 32 1Jose Antonio Ortiz SoveroAún no hay calificaciones

- Pets - Pase de Tuberia Por Base de Canal PDFDocumento4 páginasPets - Pase de Tuberia Por Base de Canal PDFWinter CVAún no hay calificaciones

- GGT-PO-OPE-010 (00) Instalación de Muretes en Trabajos de Conexiones en BT Hasta 20kWDocumento7 páginasGGT-PO-OPE-010 (00) Instalación de Muretes en Trabajos de Conexiones en BT Hasta 20kWArmando Saldaña QuispeAún no hay calificaciones

- Cuadro de Programacion Ssoma PDFDocumento3 páginasCuadro de Programacion Ssoma PDFWilly Rojas HuaytaAún no hay calificaciones

- Procedimiento de MATRIZ IPERCDocumento10 páginasProcedimiento de MATRIZ IPERCRicardo AmadoAún no hay calificaciones

- Camaras y Sumideros Tapas MOPDocumento5 páginasCamaras y Sumideros Tapas MOPWilmer Alberto Zambrano CobeñaAún no hay calificaciones

- Plan de seguridad y evacuación local Peke MundoDocumento7 páginasPlan de seguridad y evacuación local Peke MundoCinthya RG100% (1)

- Manual de Instalacion RollerDocumento3 páginasManual de Instalacion RollerAlfredo Ponte100% (1)

- Ficha Tecnica Termoplastica BlancaDocumento3 páginasFicha Tecnica Termoplastica BlancaKikee Torres100% (1)

- Ficha Tecnica - Boquillas Multiproposito (Chorro y Niebla) en Bronce de 1.1-2 - y 2.1-2Documento2 páginasFicha Tecnica - Boquillas Multiproposito (Chorro y Niebla) en Bronce de 1.1-2 - y 2.1-2Alexander Quintero OsorioAún no hay calificaciones

- Procedimiento control encofradosDocumento10 páginasProcedimiento control encofradosFrancisco López Bejarano100% (1)

- Informe - EstructurasDocumento35 páginasInforme - EstructurasAdrian Salcedo AlvarezAún no hay calificaciones

- Check List ExtintoresDocumento1 páginaCheck List ExtintoresMontserrat FortunaAún no hay calificaciones

- Procedimiento de Trabajo para La Instalación Del Sistema de Bombeo de Combustible PDFDocumento8 páginasProcedimiento de Trabajo para La Instalación Del Sistema de Bombeo de Combustible PDFAndreAún no hay calificaciones

- Ficha Tecnica Banda PVCDocumento1 páginaFicha Tecnica Banda PVCvicdiazAún no hay calificaciones

- Guía de Instalación de Acometidas de Enlaces Con Fibra Óptica.Documento3 páginasGuía de Instalación de Acometidas de Enlaces Con Fibra Óptica.JoseAún no hay calificaciones

- PT. ENCOFRADOS DE VIGAS - LOSa BLOQUE ADocumento7 páginasPT. ENCOFRADOS DE VIGAS - LOSa BLOQUE ANimer A. Martinez ADAún no hay calificaciones

- Volumen Iii Línea de Conducción - Quebrada CapiroDocumento41 páginasVolumen Iii Línea de Conducción - Quebrada CapiroJuan Moises Astopillo Vargas100% (1)

- Procedimiento Montaje TrafoDocumento6 páginasProcedimiento Montaje TrafoJorge Alberto Uribe DazaAún no hay calificaciones

- Procedimiento de Trabajo Sistema Contra Incendios. Enero 2022 FebreroDocumento20 páginasProcedimiento de Trabajo Sistema Contra Incendios. Enero 2022 FebreroJulian ClavijoAún no hay calificaciones

- Procedimiento de seguridad para libranzas eléctricasDocumento25 páginasProcedimiento de seguridad para libranzas eléctricasRODAL59Aún no hay calificaciones

- Copia de Procedimientode Prueba de Hermeticidad para Instalaciones Internas en IndustriaDocumento3 páginasCopia de Procedimientode Prueba de Hermeticidad para Instalaciones Internas en IndustriaLuisAún no hay calificaciones

- Detalle de Encofrados MetalicosDocumento1 páginaDetalle de Encofrados MetalicosfranklinAún no hay calificaciones

- Cronograma de Ejecucion de Obra AlcantarDocumento26 páginasCronograma de Ejecucion de Obra AlcantarJesus CondeAún no hay calificaciones

- Certificacion Taladro MagneticoDocumento2 páginasCertificacion Taladro MagneticoPABLO GALAN100% (1)

- Instalaciones sanitarias PVC paso a pasoDocumento7 páginasInstalaciones sanitarias PVC paso a pasoLuis Adolfo Mera DelgadoAún no hay calificaciones

- Manual de Operaciones - Sistema Contraincendios - SotanoDocumento1 páginaManual de Operaciones - Sistema Contraincendios - SotanoSolange RodriguezAún no hay calificaciones

- Control de inventarios de combustibleDocumento7 páginasControl de inventarios de combustibleLuighi2015Aún no hay calificaciones

- FT Cartucho Multigas Abek1 6059Documento2 páginasFT Cartucho Multigas Abek1 6059Julio HerediaAún no hay calificaciones

- HT Polyepox Anclaje 31 v012016Documento2 páginasHT Polyepox Anclaje 31 v012016elopalAún no hay calificaciones

- Fuente, Situación o ActoDocumento4 páginasFuente, Situación o ActoAzael HernándezAún no hay calificaciones

- 0B Certificado de Impermeabilidad y EstanqueidadDocumento2 páginas0B Certificado de Impermeabilidad y EstanqueidadAlex LeónAún no hay calificaciones

- Organigrama VIJICSA Sta MariaDocumento1 páginaOrganigrama VIJICSA Sta Mariajnu6mnju6njAún no hay calificaciones

- Protocolo de Calidad TotalDocumento29 páginasProtocolo de Calidad TotalJorge Luis Lopez MolinaAún no hay calificaciones

- Hidráulica industrial componentesDocumento151 páginasHidráulica industrial componentesg665013Aún no hay calificaciones

- 04 - Reg - 227 - Reguladores de PresiónDocumento4 páginas04 - Reg - 227 - Reguladores de PresiónAnalia PachayAún no hay calificaciones

- GX Brochure Drainagesludge Es 60hz-BOMBAS PDFDocumento12 páginasGX Brochure Drainagesludge Es 60hz-BOMBAS PDFAnonymous iZ9HlTAún no hay calificaciones

- Olla Mezcladora de Concreto ConvencionalDocumento2 páginasOlla Mezcladora de Concreto ConvencionalSchwingLatinoamericaAún no hay calificaciones

- OllasDocumento2 páginasOllasSchwingLatinoamericaAún no hay calificaciones

- Bombas Estacionarias SP 750-15Documento2 páginasBombas Estacionarias SP 750-15SchwingLatinoamerica50% (2)

- Bombas Estacionarias SP 4800Documento2 páginasBombas Estacionarias SP 4800SchwingLatinoamericaAún no hay calificaciones

- Bombas Estacionarias SP 750-15Documento2 páginasBombas Estacionarias SP 750-15SchwingLatinoamerica50% (2)

- Bombas Estacionarias SP 750-15Documento2 páginasBombas Estacionarias SP 750-15SchwingLatinoamerica50% (2)

- Bombas Estacionarias SP 500Documento2 páginasBombas Estacionarias SP 500SchwingLatinoamerica100% (1)

- Autobombas de Concreto Con Pluma S 39 XDocumento2 páginasAutobombas de Concreto Con Pluma S 39 XSchwingLatinoamericaAún no hay calificaciones

- Autobombas de Concreto Con Pluma S 32 XDocumento2 páginasAutobombas de Concreto Con Pluma S 32 XSchwingLatinoamericaAún no hay calificaciones

- Bombas Estacionarias SP 305Documento2 páginasBombas Estacionarias SP 305SchwingLatinoamericaAún no hay calificaciones

- Autobombas de Concreto Con Pluma S 28 XDocumento2 páginasAutobombas de Concreto Con Pluma S 28 XSchwingLatinoamericaAún no hay calificaciones

- Autobombas de Concreto Con Pluma S 32 XDocumento2 páginasAutobombas de Concreto Con Pluma S 32 XSchwingLatinoamericaAún no hay calificaciones