Documentos de Académico

Documentos de Profesional

Documentos de Cultura

DOSSIER Calidad Inspecci+ N Bombas Ideal 2

DOSSIER Calidad Inspecci+ N Bombas Ideal 2

Cargado por

jpalauguillem0 calificaciones0% encontró este documento útil (0 votos)

52 vistas59 páginasTítulo original

DOSSIER Calidad inspecci+¦n bombas ideal 2

Derechos de autor

© © All Rights Reserved

Formatos disponibles

PDF o lea en línea desde Scribd

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

© All Rights Reserved

Formatos disponibles

Descargue como PDF o lea en línea desde Scribd

0 calificaciones0% encontró este documento útil (0 votos)

52 vistas59 páginasDOSSIER Calidad Inspecci+ N Bombas Ideal 2

DOSSIER Calidad Inspecci+ N Bombas Ideal 2

Cargado por

jpalauguillemCopyright:

© All Rights Reserved

Formatos disponibles

Descargue como PDF o lea en línea desde Scribd

Está en la página 1de 59

€: cas

EIDEAL

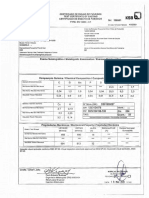

Dossier calidad

N° pedido vanta

Pvts/004948

CONSORCIO AB ESMERALDAS UTE LEY 18/82

4

(CPH 300-700 CIBAN 1500CV SM 1750 TIPO ESPECIAL

0072003

303869-16, 303871-16, 303873-16, 303875-16 (")

INP sete / Serial NPV N° de 3

1__|CERTIFICADO MAT 2.2 EN-10204 PAG A

2__|PRUEBAS PRESENCIADAS Q-H Y NSPH PAG_ A

3__|CERTIFICADO PRUEBAS RUTINA MOTOR PAG A

4 |CERT EQUILIBRADO RODETE PAG

5 __|CERT ALINEACION PAG

6 __|CERT CONTROL DIMENSIONAL. PAG A

7__ [CERT REVISION PLACAS PAG A

8 _|CERT PRUEBA HIDROSTRATICA PAG

9 [CERT PINTURA Y ADHERENCIA, PAG

40_|PRUEBAS INTERNAS Q H PAG A

"1 CERT CTRL DIMENSIONAL Y ALINEAMIENTO BOMBA PAG A

TESTEADA EN BANCO _

12 CERT DEFINITIVO PRUEBA HIDROSTATICA RESISTENCIA | PAG.

Y ESTANQUEIDAD.

43 EVIDENCIA DE PRUEBA HIDROSTATICA RESISTENCIA Y |PAG A

ESTANQUEIDAD

(*) BOMBA 303875-16

INSPECCION 12/01/2017

Situada en BANCO DE PRUEBAS durante la inspeccién 12/01/2017

Se incluye dicha bomba en los certificados relativos a la bomba: Certificados 1, 2, 4, 8,

9 segtin cuadro de més arriba

Se obvia dicha bomba en los certificados relativos al conjunto bombay motoren ~~

bancada: Certificado 6 segin cuadro de més arriba

INSPECCION 23/01/2017

Se afiaden ITEMS 11, 1213 de la tabla de mas arriba

la eee

bombas - | m7

Eibe A L CERTIFICADO DE MATERIALES

CERTIFICATE OF MATERIALS |i

Seite coum | CERTIFICAT DES MATERIAUX mo fom

BIEN 10 204-34. ¥22,

| Pvt6/o04s4s -

cien| CONSORCIO AB ESMERALDAS UTE LEY 18/82

ren @

(=| Nessie d= por» | CPH 300-700 BOMBA TIPO ESP. (GGG40/SS304/SS/MS)

cous! Poo72002

303869-16, 303871-16, 303873-16, 303875-16

Bombas Ideal S.A. certifica que los materiales de las bombas amparadas por este certificado

‘cumplen con los requisitos de nuestro pedido de venta:

Bombas Ideal S.A. certifies that the pump materials covered by this certificate meet the

requirements of our sales order:

Bombas Ideal S.A. certifi que les matériaux employés pour la fabrication des pompes

répondent aux exigences de notre ordre de vente:

Narre par ‘Materals

Ele bomba / Pump shat / Arbre poms: ‘AISI 420 S/EN 10 20422

Rosete/ impels! Rove: ‘AISI 304 S/EN 10.204 3.1

Cuerpo bomba /Pump casing! Cop pomps: (GGG- 40 S/EN 10 204-3.

“Tapa cuerpo / Casing cover / Couverce de corps (GGG. 40 S/EN 10 204-31

‘Aros cere / Wear Ring / Bague d'sure AISI 316 S/ EN 10 2043.4

Tomilera Bots and Nuts Visser ‘AISI 316 S/EN 10 204-22

Massalfassar, 12/01/17 aubén March

EIDEAL CERTIFICADO DE MATERIALES “fs

CERTIFICATE OF MATERIALS ess me

Seeger. | _ CERTIFICAT DES MATERIAUX =f

EJE BOMBA

Valbruna /bérica, s.1.

strates ‘Ceriieado de Coines

“oo Ew (once 3.1 2004

Andis quenico) Chemical Anais.

am] * [s,s s,s, =] =] = el

Losses [ow [oa | om [ox ocx [om

conme | os [ls [elsl[el = f= |= |

EAT TREATNRCT MRCOG @ DC DOMENG FORT We ©4. CUEING,

TEENS BEE Gannctns HORE

Gosmbas — ae,

EIDEAL CERTIFICADO DE MATERIALES z

nical CERTIFICATE OF MATERIALS reo | scars

Se seer cere CERTIFICAT DES MATERIAUX ma |

RODETE

___ Chemistry Analyse Test Report -

Lsupotier | - Wuxi YiDe casting _ -

Hien | “Bombas geal SA

rem | CPHIO0-TO0.IMPELLER

Description) _ For ower NOPC16/004059_ Number] ___aisiaoa

a. | 0 Size

Bathno, | __1610375 . _ - |

Tensile Swongivoa) | S23 pa [vield strnging) | 210tpa

sem) —_—s ongstiond [ain

_______Ghemscal eompasiton %

si wn] ep | os) | Ni | | Sn Joters|

osr | oe2 | oo | oom | are | 120 |

| t a /

a = =

Centficate according the Ewopean non “EN 10:

44

[pretesmarager ti. 7, ~ [oem 1252006

CUERPO BOMBA Y TAPA BOMBA.

Chemistry Analyse Test Re|

“Shanghal NO_1 Machine Tool Foundry (Suzhou) G08

‘Supp!

wmf

sew - son 790. caeng, tang cre :

|Deser a OPC 1004059 umber | —_GOG40

ay | Drawing, [8656070 resrno] zrevaan |

eno | Brienio "008208

~ TensieSvenath | ‘ines Tene

[= ati

vieto STRENGTH | ata 808

Chemical compesiton

others

(Cerificate according the European norm ‘EN 102042004 3 ¥

broncineye 05:3,

T Delvery 19 OA Centre Quality Inspection Deparment, Outsource group Py

0) 20] 01

Sv0r:0: >=

EIDEAL CERTIFICADO DE MATERIALES

Renae CERTIFICATE OF MATERIALS

Rares cr, 8 CERTIFICAT DES MATERIAUX a hid

ARO CIERRE

Chemistry Analyse Test Report

| supptio Shanghai Lianglt metal articles limited company

Chant Bomoas ideal SA

_ (GPH300.700, Wear rings _

Number $5318

size_|

—anneating

ce | wi | mo |

| azas | tose | 205 |

T

(Gertticate according to European norm “EN 10204/2004 3.1 |

[Product manager ag | _ Date, 10.18.2016

1 Balkan OO Cante, Guan Wapean Gapaiiait Oulseuce eup, Pathase depart

Gb omd0s

EIDZAL CERTIFICADO DE MATERIALES =

CERTIFICATE OF MATERIALS a

Feats c/cee CERTIFICAT DES MATERIAUX “|

TORNILLERIA,

EHS Cerieate NodSO1NB

Inspection ceiiate DIN EN 10204(1995-08) 3.18 PO NozMO8

EAE Customer + ‘HE LotNo: HH Dimensions N24]

GE Nene: GARR EO 425) Heat No:_¥XC1408-695 Heit

‘HR Mater «Stainless Steels 316 QTY 1000LTS.

Bie Mark: AA A2-70, 100 NUTS Gi) Ae?

Ta Sample plan 1 1503268-2000

HEAD Techaical Sundards: DIN GBUTSB/ANSI REM Dae of extings 20761210

‘BUBATERE Mechanical propeniea

wR wae Eca WRaR

Test ites Teatstandards | Requisement | Testsesults

TW Teasle SuengQvmma) | _1503506.1:1957 | 700Min 720

TEER, Conical componinon

CTR

cfs fu felts] mu fc falm] w

Percent v6 [0058] 14 | 24 [000 | 0001 [07 [1830 33

WRN TEST RESULT PASSED

a DATE

ChunVan Pan 2016.12.10

TESTED CONFORMTO ALL OF SHECIRCADON AS ABOVE. THIS REGORTMUST Nor

AND TO THE ITEMG) TESTED ONLY. WHENEVER TESTING DISCRERANCIES ARE

DOCUMENTED POLES AND PROCEDURE OCCUR, THEY WL BE SHOWN 1

AZQDOR G2 RIA

@ bombas

as PROTOCOLO ISO 9906 GR2B BOMBA N° 303875-16

EIDEAL PROC. PR-09 PRUEBA N° 6842c!

- FECHA: 12/01/2017

BOMBA: CPH 300-700 ORDEN: PV16/004949

RODETE: 602

DATOS DEL MOTOR

Vel: 990 RPM P34 GV TIPO: CEMER PRUEBAS

f 50 hz P. 250 KW 437 A N° MOTOR: 9188-0270

Rend: 94 % Cosy: 0,87 400 V 1P.55

DATOS DE SERVICIO

CAUD. 24000 min CAUD: 1440 man P: 1500 CV

HMT | 485,5 m Vel 1750 RPM P 1118.55 KW

CONDICIONES DEL ENSAYO

@TUBOASP: 400 mm CAUDALIMETRO: DN400 CAUDAL MAXIMO: m3

@TUBOIMP: 260 mm PRESION IMPULSION: 0/16 P m ALTURAMAXIMA: sm

DIFEJES: = 2.1m PRESION ASPIRACION: -1/3P m VEL. ENSAYO: rpm Fija

PROTOCOLO DE ENSAYOS BOMBA N° 303875-16

Vel Hasp Himp| Hvel Hman| i | U12 | Pred | Pab + Caudal Vib Temp

Remoom | om | mom AV | RW) CV % _ timin | myn mms °C

199858 -4 |64.16| 0 66.86 174.47 396.83) 77.52, 99.01 0 ooo | 2

| 2|904.72) -86| 6261, .03 656 190.8 397.06| 92.45|118.07) 31.88 |2582.65 154.96 2.61 | 42

3 [995.4 | -83 | 62.03 .08 | 65.04 205.67,396.13|104.14/133 48.37 4450.9] 26705 243 | 43

| 4997.23 -51 | 60.92] .23 | 63.76 230.2 394.93|123.64|157.91| 66.41 7401.56444.09 2.86 | 44

| 500570 -6 | 59.08 38 62.16 253.19 396.1 |140.18 179.03] 7361 9541 572.48 271 | 44

6 (994.75 -71 | 57.45) 54 |60.8 272.76 396.20/185.33 198.38 | 78.02 11455.78687.35 28 | 44

| 7 990.86, -1.27 58.76 69 59.82 287.84/305.14 165.55 211.44 81.31 129325277595 301 | 44

| 8 992,78 -1.24 54.92] 7 | 59.13 294.79|304.81 170,39)217.62) 82.32 136347 818.08 2.98 | 45

99938 | -142 532 | 89 7.61 30467 395.21 177.62 226.85) 83.02 /4710.068826 3 | 45

10/995.43, -1.51 51.71, 1.03 56.35 316.97/393.69 185.18|236.51/ 83.47 1576562946 | 2.96 | 45

11,994.13) -1.65 | 49.43 | 1.22 54.4 331,15|394.11 194.88 248.89 83.61 17214.23032.85 2.95 | 45

RPM GARANTIZADAS BOMBA N° 303875-16!

7 Vel Hman | __-Pab I Caudal _

RPM. m cv Umin mah

1 1750 204,73 532,88 | 0 0

2) 1750 203,03 642,93 | 4543.63 272,62

| 3 1750 201,04 722,78 7825,07 469.5

4| 1750 196,34 853,37 12988,71 779,32

5 1750 191,96 971,73 16767,34 106,04

6 1750 | «(188,18 4080,13 20183,42 1209.21

7 1750 | 186,97 1168.34 22863,75 1371.83

8 1750 183,72 191,92 2403425 142,06

9 1750 1765 | 1238.68 25903,21 1854.19

10| 1750 17415 | 1285.08 2718.26 1663,1

1" 1750 168.58 | 1387.69 30302,76 1818,17

OBSERVACIONES: ENSAYO REALIZADO POR:

& fey DE

t [37 Ns

\é . 2 Unt )

Xe KCAL 7) Pagina 1

\ On| Z8/

NSS

PUNTO TRABAJO:

Q= 1440 m%/h

H = 183,15 mca

Eff. = 82,3 %

NPSHr corregido (1800rpm) = 4,56m

Pagina 2

&

@ vombas PROTOCOLO ISO 9906 GR2B CPH 300-700 BOMBA N° 303875-16

EIDEAL _ PROC. PR-09 1750 RPM PRUEBA N° 6842cl

220

Hman (m)

2007

sol

160|

105 140 _|

r(%) |

75, 10}

60 80

45, ot

| |Pab (cv)

600 ‘800 4000 1200 1400 1600 1800 2000

Caudal (main)

Hobos PROTOCOLO ISO 9906 GR2B CPH 300-700 BOMBA N° 303875-16

8

EIDEAIL PROC. PR-09 1000 RPM PRUEBAN? 68421

70.

Han (rif

60,

40. 20;

150

| | |Pab (CV)

|

| | |

- _ _. lo

500 600 700 800 900 4000 1700

Caudal (m3/h)

100 200

@ Dombes

EIDEAL

BOMBA: CPH 300-700

PROTOCOLO ISO 9906 GR2B

PROC. PR-09

BOMBA N° 303875-16

PRUEBA N° 6842cI2

FECHA: 12/01/2017

ORDEN: PV16/004949

RODETE: 602

DATOS DEL MOTOR

Vel: 990 RPM P 340 CV TIPO: CEMER PRUEBAS

f 80 hz P: 250 KW 1 437 A N° MOTOR: 9158-0270

Rend: 94 % Cos 9: 0.87 U 400 V IP-55

DATOS DE SERVICIO

CAUD.: 24000 min CAUD: 1440 ma/n P 1500 cv

HMT. 1855 m Vel: 1750 RPM Po 1118.55 kW

CONDICIONES DEL ENSAYO

@TUBOASP: 400 mm CAUDALIMETRO: DN400 CAUDAL MAXIMO: = m3/h

@TUBO IMP: 260 mm PRESION IMPULSION: 0/16 Pm — ALTURAMAXIMA: sm

DIF. EVES: 21m PRESION ASPIRACION: -1/3P m VEL. ENSAYO: rpm Fija

|PROTOCOLO DE ENSAYOS BOMBA N° 303875-16|

nr el [Hasp |Himp | Hvel Hman 1 12 | Pred | Pab |r [Caudal Vib | Temp

RPM) om | om om om AV | RW) | % | tmin | my mms °C

| 1 /99858/ -4 |6416/ 0 | 6668 174.47/396.83 7.52, 99.01] 0 0) 0 | 188) 42

| 2 [90472 96 6261) 039 656 |1908 (997.06) 92.45 11807] 31.68 2582.65 15496 261 | 42

3 1995.4 83 6203) 08 65.04 |205.67/396.13|104.14 133 | 48.37 4450.9) 267.05 243 43

4 997.23) -51 | 60.92| 23 63.76 230.2 304.93/123.64 157.91, 66.41 7401.56444.09 2.86 | 44

5 905.70 -6 |5908/ .38 62.16 253.19 396.1 140.18/179.03 73.61 9641 | 972.48 271 | 44

| 6 904,75! .71 57.45 | 54 | 60.8 272.76 305,29) 185.33 198.38) 78.02 11455.78687.35 28 | 44

| 7 992,78) -1.34 | 54.9277 | 59.13 294.79 394.81 170.99 217.62| 82.32 136347 818.08 296 | 45 |

| 8 [9038 -142 532 89 | 67.61 304.67/305.21|177.62 22685 89.02 {4710088026 3 45 |

9 |995.43 -1.51 51,71 1.03 | 56.35 |316.97 393.69 185.18 236.51 83.47 15765.62946 | 296 | 45 |

10 994.13, -1.65 | 49.43 1.22 54.4 331.15/904.11 194.88 248.89 83.61 47214.22032.85 295 45

11,995.03) -1.82 | 55.38 | 73 59.53 291.07 395.7 168 214.56 82.03 13304.29798.26 3.28 0

12/9974 | 1.31 | 55.34.73 | 59.48 291.07 396,86/168.72)215.48, 81.46 13281.26796.88 4.08 0

| 13/096.95| -4.96 | 61.31 72 | 69.09 |290.72|397.47)168,.58/215.31 80.7213235.2| 794.11 403 0

| 14/996.38| 8.89 5067 73 | 89.99 |292.19 306.94/169.6 '21661, 81.02 13297.24797.83 4.19 0

15/996.16 -84 41,96, 72 53.18 |280.91|207.67 16753 213.06| 729 131994870197 411) 0

16 996.44 -1.23 | 55.35) 72 59.4 290.09.3955 167.96 214.51) 81.1 13179.74790.78 382 0

17 996.53) -1.03 | 66,79 54 60.46 273.1 [392.79 154.07 196.77! 78.05 11491.3468589 439 | 0 |

18 997.28| -7.68 50.13 55 | 60.46 277.19 394.36 187.2 \200.77 77.15 ]1528.63691.72 458 0

19|996.78| -7.72 49.74 | 55 | 60.11 |274.6 396.491156.73|200.17 77.29 11581.74694.9| 463 0 |

| 20)900.51! -7.96 | 48.15) 85 | 58.76 |273.92 398.02) 157.11 200.68 74.85 508256802 | 418 | 0 |

| 21,996.02 -7.95 48.45/55 | 69.05 273.04 /397.05 156.66/200.08| 75.55 11519.7/ 691.18 4.14 0

22'995.65|-828 46.83) 55 57.76 2757 |394.8 156.95 200.45| 74.26 11596.78695.81 4.15 0

23 995.32) -117 50.45| 114 54.86 323.31/395.54 190.99 243.93| 83.05 16617.79997.07 452 0

24 994.56, -426 | 47.38 1.14 54.88 325.12 306.63 192.52 245.88| 82.47 16626.729076 | 46 | 0

25 995.63, 467 | 46.78 1.14 54.69 323.89 396.78 192.11 245.36, 82.49 16653.04.999.18 465 0

26 996.22) -5.48 | 458 | 1.14 54.52 326.08 395.99|192.87 246.33) 81 1 jo6507 28603 46 | 0

27 90487 59 45.72 1.16 | $4.88 92452 39662 19269 248.1 83.00 16766 74006 01 455 | 0

| 28|991.88| -7.51 4352 113 $4.26 (3232 397.56|191.75 244.9 81 52 jossoopo0s. | 497 Oo}

29 994.08 -7.35 | 43.25| 113 53.83 /326.78|396.84 193.9 247.64 80.01 16563279938 476 | 0

30 990.53) -7.35 | 43.1 | 1.14 53.69 (324.99 398.09 193.34|246.93 80.28 16615.44996.93 488 0

31 992.42) -7.56 | 39.28 324.63 397.57 192.72 24G yy 74.98 166: 2 4880

SPR WRN cd Pagina 1

Sy TtNESSED gue MORENO | -

RSPEI, OF SN Tg

GA) \ \owel We ea

BOMBAS IDEAL,S.A.

Ensayo: 684tel = 12/00/2017

Orden: Pvt6io04s49

BOMBA: 303875-16 (CPH 300-700)

oymas)= 022

2 NOMINAL: [ENEEB|TUBO ASP (mis): 6p. ATMOS 1038 seccionimp= 0.13

(nam) wervs}= wir

HNOMINAL: [SEICTUGO IMP (mis): «OAPVAPOR (IS o.t74

RPM 10000F EuES: "arate: pose

‘V2i2g (imp):

CCOMPROBACION PUNTO DE SERVICIO:

Qs 800 HNOMINAL X0.97 |//////57/6956,

Himan = Himp sHasp +H el DIF JES BBOAB A noun xose NSE SITZ

NPSHd Hasp - P vapor + V2/2g (asp)

PROTOCOLO DE ENSAYO

PTO (mm) — Hasp—-Himp vareg it EVES

‘800 13 ; 07a 24

8004.86 O72 24

300-589 073 2a

a0 8.59 om a

800 24 o72 2 |CAVITAGION (Hman <0,94 H nominal)

SE REPITE PROCESO

18

O7 4,58NPSHe

83

[NPStir final de 4,58m, inferior al NPSHr ofertado. Resultado ceptable

456 = 109x815

slendo:

1.8 factor correccion velocidad corregidavelocidac prueba (1800Kpm/1000rpm)

“15 factor correccion NPSH a velocidad reducida para este modelo de bomba

4b

BOMBAS IDEAL,S.A.

NOMINAL: IR}OTUBO ASP (mts):

(en3/h)

H NOMINAL: [BINS TBO IM (mts:

RPM 11000 DIF EJES:

(COMPROBACION PUNTO DE SERVICIO:

a= 200

Hman = H imp +H asp + H vel + DIF EJES

NPSHd= Hsp -P vapor + V2/2g (asp)

PROTOCOLO DE ENSAYO

PTO (mm) Hass Himp vareg

700-103 S679 ose

700-788 503 oss

70 8-772 48,74 05

7000-796 48.45, 055

Too 828 46.69 055

INPSHr Final de 4,59m

459= 1,9K1,81,5

slendo:

Ensayo:

‘Orden: PV 8004949

‘BOMBA: 303876-16 (CPH 200-700)

sestel 1201/2017

aqnais}=

a6P. ATMOS 1039 secon mp.

vrisy=

O4PVAPOR(I5) 0,174

“Vaasteo: zoned

‘V2r2q (imp):

notin xoer S462

MEBOABY nouns xooe WBE

aHEJES Han NPSH

24

24

24

24 = 15

24 459NPSHr

18 factor coreccién velocidad comreidalvelocidad prueba (1800rpmn/1000rpm)

1 factor coreccién NPSH a velocided reducida para este modelo de bombs

0,194

0.126

1.547

‘B

BOMBAS IDEAL,S.A.

Ensayo S84tcl 1270112017

Oren: PVTE/004049

BOMBA: 203875-16 (CPH 300-700)

yma 0278

NOMINAL: IDBCSTUBO ASP (mis): 06P. ATMOS 1029 seccon imp= 0.128,

(rain) wes 2210

HINOMINAL:(NISHBOSTUGO IMP (ns: 0.4P VAPOR (15) oara

RPM 1000DIF EES: 1 var69 asp}

vara im:

CCOMPROBACION PUNTO DE SERVICIO.

as 00 coma. xo. issi2442

Himan= imp +H asp +H vel DIF EsES (GERREH ncnnsn xose |NSHSERA

NPSHa= — Hasp-P vapor + v279 (asp)

PROTOCOLO DE ENSAYO

PTO(mm Has Hime vere EVES HHman

“000 20.45 14

1000 47.38

1000 4878

1000 458

1000 x 45,72 CAVITACION (Hman < 0,94 H nominal)

+000 4952

wr 18

‘000 39,28 113 275 664

PSH fnal de 4,56, infrio

6,64 = 2,651,915,

slendo:

| NPSHrofetado, Resutado aceptable

1,8 factor coneccién velocidad comegida/velocdad prueba (1800qpm/1000"pm)

1 factor coreccién NPSH a velocidad reducida para este modelo de bomba

wh

BOMBAS IDEAL,S.A.

VELOCIDAD ENSAYADA

1000

Q (m"mn)_]_NPSA (mp

700 7,90

800 7,89

71000) 2.75

VELOCIDAD FUNCIONAMIENTO INSTALACION CORREGIDA

1800 rpm.

‘Q (mih)_|_NPSH (mp

71260 4.59)

1440, 4,56

7800 6.64

Curva de NPSHr CPH 300-700

NPSHr (m)

3

600 800 ©1000 12001400 «1600 «= 1800

Caudal (m*/h)

|

+ 1000 pm = 1800 rpm

2000|

1S

Quality documents

C2 Routine test certificate (001)

C2 Routine test certificate (001)

SIEMENS

‘Test Certificate Induction Machine

Gort. ensayo mag.

Rated Data / Datos de diseio

Vollage /Tonson

Frequency Frecuencia

‘ourentCoriente

Power / Peters

‘Speed /Vekcides

Dect. of ration Sent. oko

Power factor Factor po

Type Too

Torq ass

| clate ae par

‘Connection Consxdn

Standars / Norms: IECIEN 60034

Contin No! NY de certicaco

41900. v

126.00 8

11000 aw

$760. mit

Mor

os

Duty type Serv

Temp, esse Clase ernie

vation

Aprovechamieto

Ste attade/ Ara ins

CCosing mes. Retrgerante

‘Quant of Canta

‘Type of one. Forma con

‘Type of pot Preteen

‘Weight Peso

81

188i)

1308)

=1000

Airae

mt Bs

‘We nereby cent thal at etccal tsts on this machine have been performed in aeoordance wih the relevant

Standards This eloctoncaly generale report is alsa vad thet a andwton signature.

Port presente confmamos queen eta mbgquina se han resizado toda as pruebas election de acuerdo con

Ibe noma aplesbee

Remarks Comentarios

Warssses [] Reviowed [] Stomp Salado

Date Fecha Signature Fira

ToS | RETR [Come — Dae] Feaha | Rane None

INSPECTION CERTIFICATE? a

tere neni Joa ab ee ieee

Raia (Asotin gat EN 10206 3.1

SIEMENS AG. type LM ase-4anooz Page Pag

POLDPME-NMAM TEC

Pe 1800780020001 16

[SIMOTICS HV Series H-compact

(Operating instructors Rev.201701 110838 J11500780030001,.004 / 2017

1LAdA544aN0-2

Quality documents

G2 Routine test certificate (001)

SIEMENS

‘Test Certificate Induction Machi

Cort. ensayo maq. asincr.

Routine test / Prueba de rutina Pages Datos Passed

Pag. Fecna Ext

Resistance measurement of windings a2 ptzao8 v

Medicon dla essanca des Bobaados

Resistance measurement of temperature detectors 4 2322016 v

‘asiedn dela reioncl oscontoreslemiene

‘Reastance measurement of heater 4 zua22018 ¥

‘Meaion ea resitnca dela caletaccion

Netoas tot 5 ma22016 v

says de marcha en vaclo

Shertreut tet 5 t22018 v

Ensayo de corocicuto

chock of accessories 5 iaaa016 v

Corral de os accesoros

‘Check of decton of rotston 5 122016 “

omit de! sonido de gro

an voltage test 5 zaa206 ra

Erayo 6 ata tosion

Measurement of insulston resistance 5 aus22016 v

Medio dela resistencia de aiaeon

eration measurement at rotoas 6 mi2206 “

Meciin de vraciones en vaca

INSPECTION CERTIFICATE ae

Name ewes seat ely ha

eae avonecin Fok EN 10206 31

SIEMENS AG Hype sua ase 4ancoz Page Pag

FW ‘800780030001 218

SIMOTICS HV Series H-compact 1LA445444N90-2

Operating Instructions Rev.2017011 10838 J1150078003000'..004 /2017

4

SIEMENS

Test Cert

Cort. ensay

Quality documents

€.2 Routine test certificate (001)

Induction Machin

Resistance measurement of windings / Medicién de la resistencia de los bobinados

ones o.onees

esto 08608

Geet? eer

Remarks / Comentarios:

INSPECTION CERTIFICATE! (nse

ere Nene; Sher end Sun Rieree ha

Reese crac spat EN 1020431

‘SIEMENS AG Type tL ast-aanco.z Pave Pa

POLO PMF-NMAM TEC E

Pi 1500780020001, ef as

'SIMOTIOS HV Series H-compact 1LAS4S44AN90-Z

(Operating Instructons Rev.2017011 10838 J1750078003000",..004 2017

Quality documents

G2 Routine test certificate (001)

SIEMENS

‘Test Certificate Induction Machine

Gort. ensayo még. asincr.

stance measurement of temporature detectors

Medici6n de la resistencia de los sensores térmicos

Tpmaromarcremwm ni | PTD] PTVOO] PTIGO ] PTTOO] PTIOO ] Pro

sora | 1079 | sora | sore | sore | 1079

one a o | Pree

esata ee |

Prvao

poeseeraicameeucs a | PHO?

a can a | 1050

Remarks ! Comentatos

n INSPECTION CERIFICATE cs

swene/torse om Sorte qe ha

ene Auer Jom Fut EN 102063"

“SIENENS AG i sua asacnnso.z Page Pa

POLDPIMF-NIWA MTEC es = re

bear 1800780030001 ah as

oRts©

— ‘SIMOTIOS HY Series H-compact 1LAG4S444NG0-2

‘Operating instuctons Rev.201701 110838 J11500780030001..004/ 2017

1%

Quality documents

C2 Routine test certificate (001)

SIEMENS Test Certificate Induction Machine

Gort ensayo maq, asincr.

Novae test Ensayo de marcha en vaclo. Shon iru tat Ensayo de con

SSS ee |S PE

|

it

Rotor stands voltage Tension rotirca

eaesred values Vaeres nssisoe aE, yates Var

También podría gustarte

- Valvula de Control de Bomba SE-60-11 - SpanishDocumento4 páginasValvula de Control de Bomba SE-60-11 - SpanishjpalauguillemAún no hay calificaciones

- SE-VC-22D E-ControllerDocumento4 páginasSE-VC-22D E-ControllerjpalauguillemAún no hay calificaciones

- Faggiolati Bomba Selecc 1Documento2 páginasFaggiolati Bomba Selecc 1jpalauguillemAún no hay calificaciones

- Catálogo WMAP EVO 2018Documento4 páginasCatálogo WMAP EVO 2018jpalauguillemAún no hay calificaciones

- Catálogo JV600 2018Documento4 páginasCatálogo JV600 2018jpalauguillemAún no hay calificaciones

- LYNX 3F RFP Ventosa para Aguas Limpias 8.2017Documento4 páginasLYNX 3F RFP Ventosa para Aguas Limpias 8.2017jpalauguillemAún no hay calificaciones

- XLC 325-425 Válvula Sostenedora-Alivio Con Electroválvula 8.2017Documento2 páginasXLC 325-425 Válvula Sostenedora-Alivio Con Electroválvula 8.2017jpalauguillemAún no hay calificaciones

- Pruebas Reclamo Cavitación-KSB - OMEGA 300-700Documento9 páginasPruebas Reclamo Cavitación-KSB - OMEGA 300-700jpalauguillemAún no hay calificaciones

- Química Impulsor-KSB OMEGA 300-700-Serial 00087Documento1 páginaQuímica Impulsor-KSB OMEGA 300-700-Serial 00087jpalauguillemAún no hay calificaciones

- HT - V743 - Filtro Tipo - yDocumento3 páginasHT - V743 - Filtro Tipo - yjpalauguillemAún no hay calificaciones

- Prueba Hidrostatica-KSB OMEGA 300-700-Serial 00087Documento1 páginaPrueba Hidrostatica-KSB OMEGA 300-700-Serial 00087jpalauguillemAún no hay calificaciones

- Pag 1 - Dossier de Calidad-Omega 300-700Documento1 páginaPag 1 - Dossier de Calidad-Omega 300-700jpalauguillemAún no hay calificaciones

- Part 1-KSB OMEGA 300-700-Dossier CalidadDocumento101 páginasPart 1-KSB OMEGA 300-700-Dossier CalidadjpalauguillemAún no hay calificaciones