Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Keramik PDF

Cargado por

belladiinaTítulo original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Keramik PDF

Cargado por

belladiinaCopyright:

Formatos disponibles

BOLSOC.ESP.CERAM.VIDR.

30 (1991) I, 5-9

Preparation of a ceramic floor tile body containing pure bentonite

as strengthening agent

T. MANFREDINI, G. C. PELLACANI, P. POZZI

Dipartimento di Chimica, Universit di Modena, Via Campi 183, 41100 Modena, Italy

G. MARZOLA, C. PASQUALI

FLOOR GRES Ceramiche S.p.A., Via Canaletto 24, 41042 Fiorano Modenese, Modena, Italy

ABSTRACT.Preparation of a ceramic floor tile body

containing pure bentonite as strengthening agent.

This paper demonstrates that the use of a low amount

(2 wt%) of alkali activated bentonite as strengthening

agent of low plastic ceramic body is greatly recommended since it appreciably reduces ruptures of unfred

ceramic tiles in their dry state during handling and

transporting, and enables the pre-firing steps of a ceramic

factory to be rationalised and productivity to be increased. Semi-industrial tests demonstrate that the addition

of 1-4 wt% of natural or alkali activated bentonites, containing a high smectite content (> 90 wt%), in a ceramic

body notably improves the mechanical strength and

favours greiflcation, while not affecting the other important bulk physico-chemical properties. Industrial tests

demonstrate that an amount of about 2 wt% of activated

bentonite is sufficient to fully substitute in a body the 7.5

wt% of bentonitic clay previously used, further improving mechanical, rheological and sintering properties.

KEY WORDS: ceramic floor tiles, ceramic bodies, unfred bodies, bentonites, strengthening agent.

RESUMEN.Preparacin de una pasta para pavimentos cermicos conteniendo bentonita pura como agente de reforzamiento.

Este artculo demuestra la conveniencia del uso de una

baja cantidad (2% peso) de bentonita activada alcalina

como agente de reforzamiento de pastas cermicas de baja

plasticidad, puesto que reduce apreciablemente las roturas de los pavimentos en crudo, en seco, durante su manipulacin y transporte y permite que las etapas de precocido se racionalicen aumentndose la produccin.

Ensayos a escala piloto han demostrado que la adicin

del 1 al 4% peso de bentonitas naturales o activadas con

lcalis, conteniendo una elevada proporcin de esmectitas (>90% peso) en una pasta cermica mejora notablemente la resistencia mecnica y favorece la gresificacin

sin afectar a otras importantes propiedades fisicoqumicas. Ensayos en la industria han demostrado que una cantidad de cerca del 2% en peso de bentonita activada es

suficiente para sustituir completamente en una pasta el

7,5% peso de arcilla bentontica previamente usada, mejorando las propiedades mecnicas, reolgicas y de sinterizacin.

PALABRAS CLAVE: pavimentos cermicos, pastas cermicas, bentonitas, agente de reforzamiento.

1.

INTRODUCTION

The problem of reinforcement of the mechanical strength

of green tiles, in order to avoid faults or breaking during

pre-firing steps, has hitherto concerned all the manufacturing of single fired ceramic tiles, as a result of the introduction of high-speed firing roller kilns. This has been generally obtained by tailored addition to the bodies, containing

a great amount of filler minerals, of various types of organic or inorganic binders, that lubricate the non-plastic particles during pressing and introduce cohesive forces between

particles, even though this may lead to new types of defect (1).

Among inorganic compounds the addition of large amounts

of bentonitic clays (4-7.4 wt%) has been demonstrated to

favour the increase of the modulus of rupture of the green

ceramic tiles (2,3), but at the same time it modifies the bulk

physico-chemical properties of the original bodies, in particular strongly deteriorating the rheological behaviour of the

concentrated slips (3). On the contrary, the same mechaniRecibido el 10-10-90 y aceptado el 22-2-90.

ENERO-FEBRERO, 1991

cal strength benefits can be obtained with the addition to the

bodies of treated bentonites, with high smectite content, in

such small amounts (1.5-2.5%) as to leave the rheological

behavior of the slips unaffected (3).

In order to complete our previous study, in this paper we

investigate the effects of the addition of treated bentonites

with high smectite content (>90 wt%) on the thermal and

mechanical properties of a ceramic body commonly used to

produce white floor gres tiles in the Sassuolo factories. The

results of this study have enabled design of a ceramic floor

tile body for fast single firing.

2.

2.1.

EXPERIMENTAL PROCEDURE

Raw materials and sample preparations

The white spray-dried body (hereafter indicated as body

or base body) with a typical composition used in the factories of Sassuolo (Italy) was obtained by mixing 35% illitic

and kaolinitic clays and 65% of non-plastic raw materials

(feldspar and quartz).

T. MANFREDINI, G. C. PELLACANI, P. POZZI, G. MARZOLA, C. PASQUALI

The examined bentonites were a natural Na/Ca bentonite

(Bl) and the same bentonite, purified and alkali-activated with

Na2C03 (B2). Their analyses are reported in Table I. As

previously reported (3) the natural bentonite (Bl) presents

a smectite content of about 90%, the treated bentonite (B2)

of about 95%.

The bentonites were added to the body in amounts of 1,

2, 3 and 4 wt%. Higher percentages were not considered

since at these levels they can be considered true body components, which strongly modify the bulk physico-chemical

properties of the ceramic body.

of 10C/min from 25C to 1,200C. Modulus of rupture

of green and fired tiles were determined using a Gabbrielli

apparatus. Linear shrinkages and water absorptions in the

900-1,200C temperature range of the bodies were determined with the procedure indicated in refs. (4) and (5) on

specimens 4 0 x 4 0 x 5 mm, obtained in a small pilot press.

3.

RESULT AND DISCUSSION

3.1.

TABLE I

3.1.1.

CHEMICAL ANALYSIS OF THE DRIED BENTONITES

Bentonite

SO2

AI2O3

TO2

FesOg

MgO

CaO

K2O

Na20

Ignition loss

Green tiles

Bl

B2

60.2

21.4

0.3

3.3

4.5

1.5

0.1

1.1

7.5

59.4

21.0

0.3

3.1

4.5

1.4

0.1

2.8

7.5

The mechanical and thermal measurements were performed on semi-industrial samples prepared as follows: 8 kg

of aqueous slips (body+bentonite+deflocculant (about 0.3

wt% of tripolyphosphate sodium salt or 1:1 mixture of tripolyphosphate and metasilicate) + industrial water) (70 wt%

of solid content) were ground for 8 hours in a bal mill (15

1). The slips wereftiUydried at 115 C and the powders further dry-ground and humidified up to 5.2-6 wt% of water

in order to fully reproduce the characteristics of the powders obtained from the industrial spray-drying process. The

powders were pressed with a hydraulic press (250-270

kg/cm2) ijjto 213x213x8 mm tiles. On these dried green

tiles the modulus of rupture and the dilatometric and thermal (water absorption and linear shrinkage) measurements

were performed.

Industrial tests were measured on powders pressed at 300

kg/cm2 jj^to 337x337x8 mm tiles and on these tiles fired

in a high-speed roller kiln with thermal cycle of 45 minutes.

MECHANICAL STRENGTH

As shown in Table II the modulus of rupture of green tiles sharply increases on increasing the amount of bentonite,

significantly larger for B2 than Bl, in agreement with the

smaller particle size dimensions and higher smectite content

of B2, which enables an otimum lubricating effect to be exerted on the non-plastic particles (feldspar and quartz). It is

known that the strengthening effect of bentonites on green

tiles of low plastic bodies is afforded by the electrostatic attractive forces among bentonite colloidal particles (3).

It is work remarking that the addition of only a mere 2

wt% of activated bentonite to the low plastic base body enables an increase of the modulus of rupture of the green ceramic tiles greater than 100% as compared to that of unfired

tiles from base body.

3.1.2.

THERMAL RESULTS

The differential thermal (DTA) and thermogravimetric

(TGA) analyses of the low plastic base body are shown in

Figure 1. The weight loss at about 500-600C may be due

0

""^Nfc^

0

LU

X

" ^

\

C/)

(/>

0

- 2.

"-^1 \/V"

LU

' \

Chemical analyses of the raw materials and of the prepared mixtures were performed with a Philips PU 9000 Atomic Absorption Instrument. X-ray powder spectra on orientated samples were recorded with a Philips PW 1050 diffractometer, using a Ni filtered Cu-Ka radiation (X= 1.5418 )

in the 26 angle range from 4 to 40. Differential thermal

analyses were carried out with a Netzsch Sta 409 thermobalance on about 50 mg of finely powdered clay samples heated at 10C/min from 25C to 1,250C in a Pt crucible, using

fired kaolin as reference. Dilatometric measurements were

performed with a Netzsch dilatometer on samples of

40 X 8 X 8 mm obtained from dried green tiles at heating rate

LU

ce

LU

Li.

LL

-J

2.2. Measurements and apparatus

^,^^

UJ

0

LU

){

ce

V

!J

5 -4_

ce

LU

Q.

UJ

-6.

400

800

1200

TEMFERATURE ("C)

Fig. \. TG (

) and DTA (

} curves of hase body.

BOL.SOC.ESP.CERAM.VIDR. VOL. 30 - NUM. 1

T. MANFREDINI, G. C. PELLACANI, P. POZZI, G. MARZOLA, C. PASQUALI

to dehydroxylation of the clay minerals, whereas at higher

temperatures some endothermic transformations affect firing

reactions.

The thermal behavior of dehumidified bentonites are discussed in ref. (3). Although they present some relevant and

interesting characteristics, due to the loss of uncoordinated

water molecules and structural hydroxyl groups and to firing phenomena (6, 7), when present in 0-4 wt% amounts

in the body they do not significantly affect its thermal trend

in the 20-l,200C temperature range.

3.1.3.

DILATOMETRIC ANALYSES

In Table II the linear thermal expansion coefficients of the

bodies with 0-4 wt% amount of natural and treated bentonites are reported in the temperatures below 800C. The presence of bentonites (Bl and B2) up to 4 wt% does not affect

the dilatometric behaviour of the low-plastic base body in

the 20-800C temperature range, agreeing with DTA and

DTG results.

800

900

1000

1100

1200

TEMPERATURE (C)

Fig. 2.Dilatometric behaviour of green tiles with 0 {

-), 2 (-- -) and

4 ^_._._._j ^t% of natural bentonite (Bl).

TABLE II

MODULUS OF RUPTURE (AV. OF 5 MEASUREMENTS)

(N/mm2) AND DILATOMETRIC RESULTS [a ' 10^ CC'^)]

OF THE UNFIRED TILES IN PRESENCE

OF BENTONITE (wt%)

Bentonite

2.66

2.99

2.90

3.28

MODULUS OF RUPTURE

1.27

1.27

Bl

B2

1.94

2.24

2.24

2.69

DILATOMETRIC RESULTS

Bl (25-400C)

B2 (25-400C)

9.90

9.90

9.37

9.56

9.36

9.84

Bl (25-800C)

B2 (25-800C)

12.50

12.50

12.30

12.10

12.20

12.30

9.46

9.65

12.30

12.20

800

900

1000

1100

1200

TEMPERATURE CQ

At higher temperatures (850-1,200 C) relevant shrinkages are observed (Figure 2 and Figure 3). In fact the dilatometric behavior of base body shows a slight contraction due

to a first sinterization step in the 850-1,000C temperature

range, followed by a more marked shrinkage in the

1,000-1,200 C temperature range for the firing reactions

which form a glassy that enhances the bulk densification.

After 1,200C pyroplastic deformation occurs.

In the same temperature range, the presence in the body

of increasing amounts of bentonites enhances the linear shrinkage of the samples, in agreement with their alkaline and

alkaline-earth cation content, which favours the melting and

thermal reactivity of the samples. Furthermore, the very fine particle size dimensions (high specific surface area) of

the bentonites strongly favours the vitrification of the samples (8). This can be also supported by the fact that the acvated bentonite (B2), with higher alkali ion content, has more

pronounced shrinkage effects on the samples than does Bl.

ENERO-FEBRERO, 1991

Fig. 3.Dilatometric behaviour of green tiles which 0 (

), 2 (

4 (

) wt% of activated bentonite (B2).

) and

3.2. Fired tiles

3.2.1.

SINTERING DIAGRAMS

The considerations above reported, based on the thermal

and thermomechanical measurements, were fully confirmed

by firing trials (tests). Figures 4 and 5 report the changes

of the linear shrinkage as a function of the firing temperature for the green tiles added with different amounts of natural and treated bentonites. In particular, for all the samples

the sinterization phenomena are observed to start at about

Preparation of a ceramic floor tile body containing pure bentonite as strengthening agent

900-1,000C with an increase in Unear shrinkage and a consequent decrease in open porosity.

Increasing amounts of bentonites in the body, which leave the water absorption unaffected, slightly increase the linear shrinkage of tiles during firing, since, by providing more

areas of contact between the particles (8), as suggested above, they favour the vitrification processes. All samples present a maximum linear shrinkage value at about 1,1801,200C. This value is strictly dependent on the bentonite

content, varying from 5.40% for the base body to 6.50%

for samples containing 4% of untreated bentonite (Bl) or

to 7.00% for samples containing 4% of treated bentonite

(B2). In further agreement with the above reported results,

the samples containing activated bentonite (B2) present higher maximum shrinkage values than those containing the natural bentonite (Bl), in accordance with a stronger flux effect of B2, which promotes earlier liquid formation and hence

vitrification.

Furthermore, it is important to note that the presence of

pure bentonites, having a strong flux action, in a non-plastic

base body significantly reduces the optimum greification range and therefore amounts higher than 4/5 % can produce undesirable effects.

900

1000

1100

1200

TEMPERATURE (C)

Fig. 4.Linear shrinkage (%) against firing temperature {C) for green

tiles with 0 (O), 2 {) and 4 (Dj wt% of natural bentonite (Bl).

4. INDUSTMAL TESTS

On the basis of the above results obtained on a laboratory

scale and of economic considerations, the addition of about

2 wt% of treated bentonite to low plastic base bodies seems

to be the most appropriate from the industrial point of view.

For these reasons, at the floor gres factory of Sassuolo (Italy)

we performed some tests in order to verify the industrial compatibility of the base body, added with 2 wt% of activated

bentonite (B2), and to compare the results with those obtained with the same base body added with 7.5% of a natural

bentonitic clay, containing about 40 wt% of smectitic minerals, hitherto used for floor tile production.

In Table III the modulus of rupture, water absorption and

linear shrinkage of green floor tiles obtained from body containing 7.5 wt% of bentonitic clay or 2 wt% of treated bentonite are compared. The most striking result is a strengthening action of 2 wt% of activated bentonite 30% greater than

TABLE III

COMPARISON BETWEEN THE MODULUS OF RUPTURE

(N/mm2) WATER ABSORPTION (%) AND LINEAR

SHRINKAGE (%) OF INDUSTRIALLY PREPARED

TILES FROM BODY CONTAINING 7.5 wt%

OF BENTONITIC CLAY (A) AND 2 wt%

OF TREATED BENTONITE (B2) (B)^^)

Modulus of

Rupture*

900

1000

1100

1200

TEMPERATURE (C)

Fig. 5.Linear shrinkage (%) against firing temperature CQ for green

tiles with 0 (O), 2 () and 4 (Oj wt% of activated bentonite (B2).

PRESS 1

PRESS 2

Water

Absorption**

Shrinkage**

1.35

1.33

1.72

1.70

3.0

2.9

3.0

2.7

6.9

6.9

6.8

6.7

^^^ The measurements were performed on unfired (*) and fired

(**) tiles and the values average the results performed on nine

samples (three dies for each press).

BOL.SOC.ESP.CERAM.VIDR. VOL. 30 - NUM. 1

T. MANFREDINI, G. C. PELLACANI, P. POZZI, G. MARZOLA, C. PASQUALI

that of 7.5 wt% of natural bentonitic clay. The values of the

modulus of rupture of about 1.71 N/rtim^ in the industrial

tests as against about 2.69 N/mm^ obtained in the laboratory tests depend on the different technological sample preparation. On fired tiles no relevant changes in modulus of

rupture (about 48.5-49.5 N/mm^) are observed among base body or in presence of 2 wt.% of treated bentonite or 7.5

wt% of natural bentonitic clay.

sintering processes and (c) they do not cause the defects

(black core, reduction of oxides, which alters color, etc.)

characteristic of the organic strengthening agents.

The lesser amount of activated bentonites necessary to enhance mechanical strength of green ceramic tiles from low

plastic bodies and their clearness make them inorganic additives rather than true components of the body, and therefore they do not appreciably affect the bulk physicochemical properties of the bodies. At the same time, their chemical

composition promotes the sinterization processes.

TABLE IV

PHYSICO-CHEMICAL PROPERTIES OF SLIPS

OF BASE BODY (A) AND CONTAINING

BENTONITIC CLAY (7.5 wt%) (B) OR TREATED

BENTONITE (B2) (2 wt%) (C)

Density (gr/cm^)

Apparent viscosity (mPa s)

Solid content (wt%)

Residue (wt%) at 60 im

Residue (wt%) at 45 fim

1.68

120

70

3.9

9.5

1.68

205

70

4.4

9.8

1.69

140

70

3.8

9.4

ACKNOWLEDGEMENTS

The authors are grateful to C.N.R. for financial support,

to Ceramco S.r.l. of Sassuolo (Italy), who supplies us the

bentonites and to Floor Gres Ceramiche S.p.a. Sassuolo

(Italy) whose cooperation is greatly acknowledged.

6.

1. PiNCUS, A. and SHIPLEY, L . : The role of organic binders in ceramic processing, Cer. Ind., 92. (1969) (4),

106.

2.

Another very important advantage in substituting natural

bentonitic clay (7.5 wt%) with activated bentonite (2 wt%)

is the fact that the rheological behavior of the industrial slip

remains unmodified, as observed in Table IV which compares some significant physical properties of slips of base body,

base body added with 2 wt% of activated bentonite or with

7.50 wt% of bentonitic clay. The high amount of bentonitic

clay necessary to improve a low plastic body drastically increases the apparent viscosity of the slip, since it acts as a

true body component and not an additive.

5.

REFERENCES

EL-KHOLI, M . B., MOSTAFA, M . Z . , EL-DEFRAWY, S.

A. and ABDEL-FATTAH, W . I.: Strengthening of parian

porcelain casting bodies, Interceram, 37 (1988) (1),

21-24.

3.

MARZOLA, G . , PASQUALI, C , BOSCARDIN, L . , MAN-

FREDINI, T., PELLACANI, G. C. and Pozzi, P.: Bentonites as strengthening agents of low-plastic bodies for

the production of floor gres ceramic tiles. Mat. Eng.,

in press.

4.

AMORS ALBARO, J. L., BLASCO FUENTES, A., ENRIQUE NAVARRO, J. E . , ESCARDINO BENLLOCH, A. and

BELTRN PORGAR, V . : Variables en la compactacion de

soportes cermicos de pavimento y revestimiento. Tcnica Cermica, 105 (1982), 792-812.

CONCLUSIONS

5.

The addition of low amounts (1.5-2.5%) of pure bentonites with a high smectite content to low-plastic ceramic body

seems particularly indicated from an industrial point of view,

since it notably improves the mechanical strengti of the green

tiles, which permits handling and transporting of unfired ceramic tiles in their dry state with a noticeable reduction in

ruptures. This enables the pre-firing steps of a ceramic factory to be rationalised, and the productivity to be increased.

Other advantages which strongly recommend the use of

1.5-2.5 wt% treated bentonites in low plastic bodies are: pure

bentonites (a) do not significantly modify the rheological behavior of the slips nor the thermal behavior of the base body,

(b) they speed up the vitrification, favouring the firing and

ESCARDINO BENLLOCH, A., AMORS ALBARO, J. L .

and ENRIQUE NAVARRO, J. E . : Estudio de gres para pavimentos. Bol. Soc. Esp. Cerm. Vidr., 20 (1981) (1),

17-24.

6.

DEL PENNING, U . , MAZZEGA, E . , VALERI, S., ALIET-

Ti, A., BRIGATTI, M . F . and POPPI, L . : Interlayer water and swelling properties of monoionic montmorillonites. J. Coll. Int. Se, 84, 301 (1981).

7. ALIETTI, A . and PALUMBO, G . : Mineral with an intermediate behaviour ween saponite an corrensite. Miner.

Petrogr. Acta, XXX, 247 (1986-87).

8. GRIMM, R. E . and GUVEN, N . : Bentonites Geology,

Mineralogy, Properties and Uses. Elsevier Publ. Co.

Ed., 1978.

CEVISAMA'91 (Valencia)

As every year, The Spanish Glass and Ceramic Society

will be present with information and books desk at the

SECY STAND in CEVISAMA'91 (8-12 mars)

ENERO-FEBRERO, 1991

<

27 FERIA INTERNACIONAL DE CERMICA,

VIDRIO Y ELEMENTOS DECORATIVOS

^ \

LA FERIA DE LA CERMICA Y EL VIDRIO EN ESPAA

V A L E N C I A ( E S P A A ) , DEL 18 A L 2 2 DE ABRIL DE

1991

:^2

27 FERIA INTERNACIONAL DE CERMICA,

VIDRIO Y ELEMENTOS DECORATIVOS

26 FERIA INTERNACIONAL DE ILUMINACIN

MUEBLES C O M P L E M E N T A R I O S ,

INTERIORISMO Y DECORACIN

APARTADO 476 46080 VALENCIA-ESPAA TELS. (96) 386 11 54/55 FAX (96) 363 61 11 TELEX 62435

si

También podría gustarte

- Dios Usa Lápiz Labial (Karen Berg)Documento223 páginasDios Usa Lápiz Labial (Karen Berg)Analia Nawrath100% (3)

- Tornillos de PotenciaDocumento4 páginasTornillos de Potenciamardoz100% (2)

- Cinética de FlotacionDocumento30 páginasCinética de Flotacionbriasade1100% (2)

- 920.85 (32.1.13) AOAC Grasa (Cruda) o Extracto Etereo en Harinas FreeDocumento7 páginas920.85 (32.1.13) AOAC Grasa (Cruda) o Extracto Etereo en Harinas FreeSilvia OleasAún no hay calificaciones

- 2 Diseño de Un Sistema de Monitoreo, Registro y Control de Temperatura y Humedad para Un Cultivo de InvernaderoDocumento79 páginas2 Diseño de Un Sistema de Monitoreo, Registro y Control de Temperatura y Humedad para Un Cultivo de InvernaderoHans CastroAún no hay calificaciones

- Método PepsDocumento5 páginasMétodo Pepswillie almanzarAún no hay calificaciones

- Tipos de Cimentaciones PDFDocumento29 páginasTipos de Cimentaciones PDFEnrique MouAún no hay calificaciones

- Estabilidad - de - Medicamentos - (PG - 1 203) PDFDocumento203 páginasEstabilidad - de - Medicamentos - (PG - 1 203) PDFIvan Monroy100% (1)

- TesisDocumento167 páginasTesissib3liusAún no hay calificaciones

- RETO. Bungee Jumping.Documento9 páginasRETO. Bungee Jumping.Unicornio bonito100% (1)

- Resumen Primer Parcial Calculo IntegralDocumento4 páginasResumen Primer Parcial Calculo IntegralStiven GaviriaAún no hay calificaciones

- Resumen Sobre El Pensamiento Filosófico ModernoDocumento5 páginasResumen Sobre El Pensamiento Filosófico ModernoINVERSIONES MANAAún no hay calificaciones

- Cuestionario de Estudio.Documento6 páginasCuestionario de Estudio.Marina Loza Flores0% (1)

- ACTUALIZACIÓN DEL POMCA DEL RÍO ALGODONAL - NORTE DE SANTANDER (1605) Versión Final. Actividades Complementarias GeneralDocumento203 páginasACTUALIZACIÓN DEL POMCA DEL RÍO ALGODONAL - NORTE DE SANTANDER (1605) Versión Final. Actividades Complementarias GeneralAlexandra FonsecaAún no hay calificaciones

- 3 Atomos y MoleculasDocumento27 páginas3 Atomos y MoleculasJavier LopezAún no hay calificaciones

- Primera Actividad (10%)Documento2 páginasPrimera Actividad (10%)AriannysmonAún no hay calificaciones

- 2.3. Efectuar Sumas de DatosDocumento7 páginas2.3. Efectuar Sumas de DatosJose CruxAún no hay calificaciones

- Arreglos BidimensionalesDocumento3 páginasArreglos BidimensionalesSofía AmiráAún no hay calificaciones

- La Oracion Gramatical1Documento20 páginasLa Oracion Gramatical1Máximo Cisneros PiantoAún no hay calificaciones

- Materialdeestudiodia1-43Documento22 páginasMaterialdeestudiodia1-43richard gutierrezAún no hay calificaciones

- Poligono CUARTO 2021Documento11 páginasPoligono CUARTO 2021MARIMORRIS 006Aún no hay calificaciones

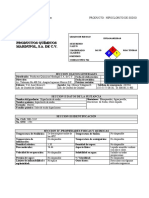

- Hipoclorito de SodioDocumento3 páginasHipoclorito de SodioJuan Vicente Reyes LimaAún no hay calificaciones

- Trabajo Practico Adicional Funcion ExponencialDocumento3 páginasTrabajo Practico Adicional Funcion ExponencialTobias Abraham UreñaAún no hay calificaciones

- 17 El Tema 5. Teoria. Ejercicios y Problemas Resueltos y para Resolver. (P. 319 A 383) PDFDocumento65 páginas17 El Tema 5. Teoria. Ejercicios y Problemas Resueltos y para Resolver. (P. 319 A 383) PDFLucia Bonilla VaraAún no hay calificaciones

- Efoque DescrictivoDocumento2 páginasEfoque Descrictivoalexis montoyaAún no hay calificaciones

- Tipos de Variable JavaDocumento7 páginasTipos de Variable JavaRafael HernandezAún no hay calificaciones

- Joa Tarea 2 Practica Docente 4Documento9 páginasJoa Tarea 2 Practica Docente 4joanna100% (1)

- Guia Estudio IngenieriaDocumento141 páginasGuia Estudio IngenieriaJorge ReyesAún no hay calificaciones

- ESTTOPNOLDocumento22 páginasESTTOPNOLKlinton Lino aquinoAún no hay calificaciones

- Vocabulario GeográficoDocumento10 páginasVocabulario Geográficolucia castel RuzAún no hay calificaciones