Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Filtro, Valvula y PCV

Cargado por

casandra0 calificaciones0% encontró este documento útil (0 votos)

33 vistas22 páginasCatalogos filtros, valvula pvc

Título original

filtro, valvula y pcv

Derechos de autor

© © All Rights Reserved

Formatos disponibles

PDF o lea en línea desde Scribd

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCatalogos filtros, valvula pvc

Copyright:

© All Rights Reserved

Formatos disponibles

Descargue como PDF o lea en línea desde Scribd

0 calificaciones0% encontró este documento útil (0 votos)

33 vistas22 páginasFiltro, Valvula y PCV

Cargado por

casandraCatalogos filtros, valvula pvc

Copyright:

© All Rights Reserved

Formatos disponibles

Descargue como PDF o lea en línea desde Scribd

Está en la página 1de 22

a

vw

INGENTERIA PARA PROPUESTA

DOCUMENTO GENERAL TECNICO

PROSERTEC

PERO |

1de3

°

Registro

NOMARE DEL PROYECTO:

INGENIERIA, PROCURA, CONSTRUCCION, PRUEBAS FATISAT Y PUESTAEN MARCHA SKID DE

MONITOREO, MEDICION Y DESPACHO DE TURBO At ~ TRANSFERENCIA DE PATIO DE TANQUES A

ZONA DE HPS ~ MALVINAS

pluspetrol [yrrovecro DOCUNENTON®

PSTPE-PR0S5.22, NA

rosy

MALVINAS - PERU.

INDICE DE REVISIONES

REV.

DESCRIPCION

A | PARA APROBACION Y REVISION DEL CLIENTE

Rev.A

Fecha: psnor20z

Preparado por: Mi, Montero

Revieado por M Pinayal

‘Aprobado por PLUSPETROL

PLUSPETROL PERO be

‘CORPORATION

REV

NA Aa

INGENIERIA, PROCURA, CONSTRUCCION, PRUEBAS FATISAT [HOI

Y PUESTA EN MARCHA SKID DE MONITOREO, MEDICION Y

DESPACHO DE TURBO Ai - TRANSFERENCIA DE PATIO DE

2dea

TTANQUES A ZONA DE HPS = MALVINAS.

DOCUMENTO GENERAL TECNICO

1. OBJETIVO.

2. SELECCION Y DIMENSIONAMIENTO..

Sistoma de Gostin do Calidad

TABLA DE CONTENIDO

O12

REV

¥

PLUSPETROL PERO NA A

‘CORPORATION

PROYECTO: INGENIERIA, PROCURA, CONSTRUCCION, PRUEBAS FATISAT | HOU:

Y PUESTA'EN MARCHA SKID DE MONITOREO, MEDICION Y

DESPACHO DE TURBO Ai - TRANSFERENCIA DE PATIO DE

TTANQUES A ZONA DE HPS = MALVINAS.

3de3

THOUS:

DOCUMENTO GENERAL TECNICO

1. OBJETIVO

El presente documento tiene por objeto sustentar en la fase de Ingenieria para propuesta el dimensionamiento y

seleccién de los principales componentes que conformaran los Skids de Medicion y Despacho para el proyecto

“INGENIERIA, PROCURA, CONSTRUCCION, PRUEBAS FATISAT Y PUESTA EN MARCHA SKID DE

MONITOREO, MEDICION Y DESPACHO DE TURBO Ai - TRANSFERENCIA DE PATIO DE TANQUES A

ZONA DE HPS - MALVINAS” a ser suministrados a la compafiia Pluspetral Pera Corporation.

2, SELECCION Y DIMENSIONAMIENTO

Itro Micrénico DN 2” NPT, Modelo VFAP829, Marca PARKER-VELCON

De acuerdo al catélogo adjunto el modelo de Filtro seleccionado que tiene certificacién de disefo y

construccién segin El 1596, modelo VFAP829, la maxima capacidad del mismo es de hasta 100 GPM

siendo esta capacidad un 40% por encima del maximo flujo requerido por el proceso: 71,5 GPM. El

fabricante garantiza que para este flujo maximo de disesio del Filo se tiene una maxima caida de presion

menor 0 igual a 2 PSID cuando los elementos filtrantes estén limpios.

‘+ Medidor de Despizamiento Positive, Modelo GENESIS DN 2” ANSI 150, Marca Smith Meter-

TechnipFMC

Para el caso del Medidor de Desplazamiento Positive seleccionado moldeo GENESIS de DN 2" ANSI

150, el fabricante garantiza segiin catélogo adjunto, que el flujo maximo de disefio del Medidor es de 150

GPM; y de acuerdo a su curva de performance, para el maximo flujo del proceso para el cual ha sido

seleccionado: 71,5 GPM, la maxima caida de presién seria de 1 PSI. Por otro lado, para la condicién de

flujo minimo del proceso de 32,5 GPM, si se hubiera seleccionado un medidor de DN 3’, la incertidumbre

en la medici6n seria muy alta; ya qué estaria por debajo de la condicién minima para garantizar una

Linealidad 0 Exactitud en la medicién del +0.075%. Bajo este dimensionamiento preliminar el medidor

sseleccionado garantiza un funcionamiento normal para las condiciones del proceso requeridas.

+ Valvuta de Control de Flujo, Modelo Set-Stop 210 DN 2” ANSI 150, Marca Smith Meter-TechnipFMC

La Valvula de Control de Flujo modelo Set-Stop 210 de tamafio DN 2" ANSI 150 “Pasaje Normal"

seleccionada, muestra en las curvas de performance del catélogo adjunto que la maxima caida de presion

para un flujo maximo de 71,5 GPM seria de 2 PSI. Asi mismo, se puede verificar que si se hubiera

considerado una valvula de control de DN 3°, la curva estaria por encima de la maxima condicién de flujo

del sistema, ocasionando que la valvula de control cavite y opere en condiciones extremas que no

garantizarian el control del flujo y operacién normal del sistema.

+ Valvula Shut-Off o SDV, Modelo 200-30A DN 2” ANSI 150, Marca Smith Meter-TechnipFMC

La Shut-Off o SDV modelo 200-30A de tamafio DN 2” ANSI 150 seleccionada, para el Cv y maximo flujo

de disefio definido en el catélogo adjunto: 130 GPM; cubre el flujo maximo de 71,5 GPM requerido por el

proceso y estaria operando al 55% de su Cv. Sila seleccién se hubiera hecho con una valvula de tamario

DN 3" con un flujo maximo de disefio de 420 GPM, para el maximo flujo de operacién del proceso, la

vlvula estaria operando menos del 20% de su Cv, lo que provocaria que la valvula no opere normal

‘ocasionando cavitacién e inseguridad en su funcién de cierre de por emergenci

Sistoma do Goston do Caiad 000120

pes

eT ecenit

Beta rcnely

Ue oy

Died

Poe

Preeti

Se ec ciir)

vec ENGINEERING YOUR SUCCESS.

Phe/sepator

Pec loerttisn)

atysepte

‘pe

(oettisen

(Compl ih

‘eis

elsepetor

pes

hay neser (oer tse)

CONTENTS

‘Small Housings Carts & Refuelers,

VF-31E

19

Horizontal Filter/Separator

VF-609, i ,

11581 Qualified HV Series for

VP-61, VF-B1E, VF-62 08 Fixed installations . 23

Vertical Filter Vessel Horizontal Filter/Separator

Vel-Max® VX Serie: HV Series for Fixed Installation

at Military Faciities. 25

S.E11541 Qualified Horizontal Aquacon® Vessels

11596 Qualified HA Series

Vertical Filter/Separator for Aircraft Fueling Trucks,

M1581 Qualified WV Series..17 Hydrant Carts and Cabinets

Horizontal Filter/Separator

11581 Qualified Horizontal Vessels for CDF®

HV & HVS Series for Hydrant Monitor - £11596 Qualified HM

Series 29

Vertical Clay Vessels

VC Series

Bulk Fuel Filtration Skids

27

keeper

apes

pert)

‘ypleat Type SL Locations

(Ghaeterminedby end-user)

Aiport

JFS2500,

Function of Filter/Separator

‘Accessories.

Recommended Manual Drain

Hooku

Auto Air Eliminator & Relief Valve

36

Hook-Up.

‘Typical Float Control & Slug

Valve Hook-up..

Monitor Interlock Operating

Principle.

‘The Importance of Spiders.

Adapters/Hardware

Nut & Washers..

Vessel Quote Request Form

‘ovata Cart

& E11541

EI 1596 design requirements for L

jet fuel include: sloped deck plates,

Conridge spacing and spider vam

pists. Consul Fernie

STANDARD DESIGN FEATURES ‘RECOMMENDED OFTIONAL

* ASME Code construction to

any pressure

Filter vessels VEAP814 through 1&5 © Pressure Relief Valve

‘VFAP44, such as the VFAPS14150

shown at right, have through:

bolt covers, NPT connections, * Pleated cellulose media

andinclude fittings for drain, * El qualified epoxy coated

pressure gauge and air vent, interior, primed exterior

VBAPI614 and larger vessels, such * Buna-N O-ring cover seals

as the VEAP2044150 shown at far * 3° slope deck plate

right, ate provided with swing bolt

closure, RF flange connections

and fittings for pressure gauge, air

eliminator, pressure relief valve

and drain valve.

* Drain Valve(s)

* Sampling Probes

+ ASME Code Stamp

16

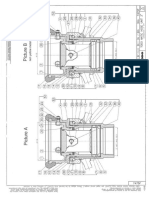

DIMENSIONS

Clearance Required to Remove Cartridges.

ane

haan bk

weenie | so | 14 | 1] 2 |en| 3 [ov|oen| ae | 2 | rs [ton] en | - | - | 2

ro

vearase | 150 | a [+ [2 [en] a fermlson|ror| 2 | re [rox] om | - | - fas] n

waver | 200 [i [4 [4 | te | 06 [arvalsor] se [2 fawn) @ | om | rm [rev | soo | 22

vwearreas | 00 faa | « [1 | te | 16 [sar |sor| eo | « [ame] 9 [rm | mm [rar] seo | a5

veapreze [aso [oe [|r| te [11 | se [sar] ea [| « | 20 [ran] x | on [20m | seo | a2

veneao2s | 600 | 2a | « [1 | 20 [ren |eon|esr| eo | «| aa | v3 [re | rm | 26 | ro00] 67

vwearaoce | 200 ae | @ [1 | 20 [ren [ren [aor] vie] @ | 28 | 18 [rm | rm | 2 | 00) ae

wiapzeze | 1200 | 20 [2] | 28 | 2s [ae fern | 77 |e [este |e |e | a8 | 1500) 15

vwearasaa | 1000 | «« [12] 1 | ae | a0 [orm [row] ton] e [oe [ ve | 9 | | as [1000 | 165

vwarasaz | 700 | a | 12 [1 [oor] 26 [esr] e¢ | 10m] 10 | ae | 23 [ran | ton] a [2050 | 208

wiapanes | ae00 | [er] [eeu] 2s | oo [ern | ro | 12 [sa | 2 | 19 | 13 [sau |e | 400

Flow rates are for pleated paper carrdgex. For higher viscosity flvds, consult your Parker ABD Representative

2 VEAPSeres Filters are designed to accommodate our standard 6 in. O.D, 34m ID, 14% in. long cartridges that are stacked one, two,

orthree high Many cartridges are available in longer length hat eliminate tacking. For example a 44 inch long FO-G44PLFTM could

be used in place of tee 14% Inch long cartridges This make for easier and lew expensive changeots.

5 Anumber of threaded base filter cartridges (e FO-G44PLFSTS) are available, which alow for ease cartridge changeout and removal

‘fparticulate matter fom the deckplates The threaded base cartridges mount on the 60007 Adapters.

4 Dimensions shown ar for etimating purpose oly, Fr evact disensons, obtain cried drawing

5. VEAPIG and VEAP2O Series esels have flat covers, VEAPI6 Series vessels donot have hydraulic ft jacks.

16

SPECIFICATIONS

» 3 TechnipFMC

and 3" Steel Meters

Bulletin $S01060 Issue/Rey. 1.2 (7/20)

and 3

Relying on nearly a century of experience

in the petroleum measurement world, TechnipF MC.

has designed the Genesis Series PD meters for

biofuel blending and other refined products, offering

Longevity and application versatility that out-measures

the competition. Some market applications include

gasoline and oxygenates, ethanol, biodiesel and

jot fue.

+ Improved Flow Range’ — Standard linear + Fully Sealed Design ~ Eliminates the possibilly

performance of 15:1 turndown with an optional

‘30:1 and 50:1 turndown, which makes the Genesis

‘Series ideal fr terminal blending and low flow

applications.

+ Integrated Electronic Output — Meter is

‘characterized from the factory allowing for

improved linearity and reproducibility across

the application range with no need for a

‘separate pulse transmitter.

+ Long Service Life - Horizontal shaft design

with ceramic hybrid ball bearings and (PEEK™)

polyetheretherketone wear strips to significantly

reduce wear on blade tip thus ensuring long

lfelreduced maintenance requirements,

+ Reliable Design ~ Reduced mechanical parts from

traditional positive displacement meter by over 40%

as well as an adjustable measuring chamber and

block design to eliminate the need for han fitted

parts,

Reference the parformance chart fr flow range and viscosity range.

‘of VOC emissions and maintenance requirements

ff packing glands and gear trains which minimizes

total cost of ownership,

Compact Design — In-ine installation envelope

Is simple with no special piping offsets.

Integrated Temperature Option - Meter includes

‘an optional integrated temperature well with internal

wiring to the HRE board and separate external

Weights and Measures test well,

NACE MRO175 compliant forall pressure

containing wetted components.

Specifications

Accuracy

Applicable to various refined products from ethanol to

biodiesel, upto 20 cSt in viscosity, For products above

this range, consult factory for evaluation

‘5-150 gpm

18.570 pm

7-214 ph

3-450 gpm

11-570 bm

4-214 oph

33.500 gpm

127-1,900 1pm 15:1

48-774 bp

47-500 gpm

631,900 lpm 30:1

24-714 bph

10.500 gpm

38-1900 pm 50:1

14-714 bph

Gallon Registration:

2" ~ 100, 200, 500, 1,000 (Pulses/Gallon)

3" - 100, 200, 500 (Pulses/Gallon}

1-73

+10.10% +-0.02% 301

+H0.15% +-0.02% sot

HH 0078% +1-0.01%

40.10% — +1-0.02%

+h 015% 40.02%

Barrel Registration:

= 5,000, 10,000, 20,000, 50,000 (Pulses/Barret)

3" ~ 1,000, 2,000, 5,000, 10,000, 20,000 (Pulses/Barrel)

3-100 (PulsesiLiter)

Dekalitre Registration

= 200, 500, 1,000, 2,000, 5,000 (Pulses/Dekalitre)

3" ~ 100, 200, 500, 1,000 (Pulses/Dekalitre)

Cubic Meter Registration:

~ 20,000, 50,009, 100,000, 200,000, 500,000

(Pulses/Cubic Meter)

= 5,000, 10,000, 20,000, 50,000, 100,000

(Pulses/Cubic Meter)

2 Reteranca he medelng code to Select the appleaon viscsty rage

2 Bulletin $S0%060 Iesue/Rev. 1.2 (7120)

Ce 5 eS

Dvsion VPED*

ASME

STASME 150. Steel 285 1.95519 Section VII

Dvsion /PED*

N50, PN 16 232 1,800 18 PED"

N50,PN25 Steol_ 962 2.600 25 PED

DN75,PN16 Stool 232 1.600 18 PED

DN75,PN25 Steel 362 2,500 25 PED

BED required fr all European countries.

Input Current: Quiescent Current (No Load): 27 mA @

10 Veo, 20 mA @ 24 Veo, 20 mA @ 30 Ve

Power Consumption: < 850 mW plus load

Output Signal

10 Vde Input Power Supply

No Load: 9.7 + 0.3 Vp-p square wave

270 0 Load: 7.6 + 0.3 Vp-p square wave (minimum)

24 Ve Input Power Supply:

No Load: 23.7 + 0.3 Vp-p square wave

270 © Load: 16 + 0.3 Vp-p square wave (minimum)

30 Vde Input Power Supply

No Load: 28.7 0.3 Vp-p square wave

270.0 Load: 21 + 0.3 Ve-p square wave (minimum)

Output Source Current (A & B @ 270 Load).

70 mA@ 10 Ve, 130 mA @ 24 Vado, 160 mA @ 30 Vdc

‘Output Current per Channel (A & B):

Maximum Sink Current: 300 mA @ 30 Vde

Maximum Source Current: 80 mA @ 30 Vac

Signal Cable

‘Threeewire shielded for single-channe| transmission.

Sue Distance

#20 AWG Up to 2,000 ft (610 m)

#IBAWG Up to 3,000 ft. (915 m)

#16 AWG Up to 5,000 ft. (1,525 m)

Class 1, Zone 1 AEx d IIB TS IP65

Brazil INMETRO UL BR 19.0082X

Ex db IIB TS GalGb -40°C s Tamb < +70°C

European Union (EU)

DEMKO O9ATEX 0903808X

Exd IIB TS GalGb IP85 Tamb = -40°C to +70°C

NTEP Certificate of Conformance: CC 10-032

‘Canadian NOAAV-2421

cortficate

‘Australia NMI 5/6B/221

Brazil INMETRO Dimel No. xexx (PENDING)

Pressure Safety Requirements

PED ~ Pressure Equipment Directive (Europe)

‘CRN Canadian Registration Number -0F10768.23456,

Electromagnetic Compatiblty

European Union: EMC Compliance by Councit Directive

EMC Directive 2014/30/EU

EEN 6126-1: Electrical equipment for measurement,

contol and laboratory us.

ven renrady sce 268

Materials of Construction

Bearings

ste

HovainglGover

wetes

Fastener

Measuring

‘Chamber

coin Rotor

CSIR Carton Steet

Carbon StesliCast Iron

Carbon Stealicast Iron

Castiron

Hara Anodized Aluminum wi

PEEK" wear stips

Hardened Stainless Steol

Hardened Stainless Stool

Ceramic Hybrid Sanioss Stel

GFLT Low Temp Viton F

Stans Stel Carbon Stee

Bulletin SSO1060 Iesue/Rev. 1.2(7120) 3

The following guide defines the correct Genesis Meter for a given application and the respective catalog code.

This code is part of the ordering information and should be included on the purchase order.

(WeaIGSONS«3- st-15-B- 2- P- 0- oF- 200-6 -

=_ |

2-2 UC - ULICUL,

az visser Carat

A-ANEIECE

“Type ofateriat P_PEDIATEXRECEC

— IN RTEMECExard NE

uote

“End Connection Size T-INMeTRO

415-ASME 150

SO ASHE 900

te DENS 3 Baral

“Flow Range Tun Down O- Belae

@_ anton

B15" H— HectoLitre

cso mse,

bua!

Viscosity

tomcat gest cnn So

patestiowest econ

Seo emtioat eS dossoo= 200

cosine 50m

“cover Ports orate. s0000

cure oa0oca— 20000

osanoo= soane

Temperature Probe {0200 100,000

aqme oo | zoo a p00

= Reaues

+ Rofaroncs product spcfcation for appleable combination of OuputResluten and Uns for ach meters

+ PED requited fora European Counties.

4 15-1 Tumown sto nl option for Canaan Mears on viscostes blow 20 cSt

4 Bulletin $S07060 Iesue/Rev. 1.2 (7120)

Dimensions

mm (Inches)

Front View

OQ Ow -

vs

:

|

lel sua

+ 20

: é JO

© 2" NPS ASME 150 Class

, :

— oa

L

Note: Dimensions ~ Inches to the nearest tenth (milimeters to the nearest whole mm), each independently dimensioned from

respective engineering drawings.

(BS 8S 60" 15st 1st tag zeros ta 3190

(419) (215) (175) (394) (330) (348) (283) (70) (70) 4)._——(95)_—(178)_——(88).

Bulletin SSO1060 Tesue/Rev. 1.2(7120) 5

Horizontal Flow

Standard Flow Otecon

Vertical Flow

Terminal Connections: CN1

Terminal? + 10-30 Vale

Terminal 2 “A* Signal (Leading)

Terminal 3 “B" Signal (Lagging)

Terminal 4 Logic Common (Ground)

Terminal §

Terminal 6 | No electical connection on circuit boar

Terminal 7 | Tes canbe used for wing connections

ortiesns (ox RTD junction, ete.)

Terminal 8

‘S801080 Wesson 12 (720)

odolng cod, Cover Pats, dat.

canadien ta ange i a any pans onl i fone anf eens ae oe

‘a Grenwea marta aceones ners news ay tw nen harged we ge

‘02 Wogner Avenue

Poievesseso00

13489 Lonoed Re Sram steer

TechnipEMG-com aun, fres 7044 USA 2507 Elowte Comany

y TechnipFMC SPECIFICATIONS

Bulletin $$03009 Issue/Rev. 1.1 (10/17)

+ Simple contro loop

+ Control loop needle valves fr tuning

+ Low pressure drop

+ Separate opening and closing speed control -

+ Compound spring Operation

“+ Horizontal or vertical applications: The Smith Meter Model 210 Valve is a Smith Meter 200

+ Fullrange of optional contro functions Series Valve with two solenoid controls (see Figure 1)

+ 2" Reduced Port Valve ~ Ideal for renewable fuels: ‘The normally-open (N.O.) and normally-closed (N.C.)

blending, controling fow down to 3 GPM. solenoids, located in the upstream and downstream portons

“+ Failto close design of the control loop, respectively, control the operation of

the valve, With both solenoids energized, high upstream

pressure is blocked allowing the product inthe cover to

No.

why & gitSyg | venttofow downstream pressure, opening the main ve

aa ler’ | Conversely, do-onorgizing both solenoids allows high

Upstream pressure to close the valve.

00

Stage Tipt

Second High Flow Rate

Low Flow Star

oe to: Tare ral sso py copoly woe

Se ai aie eee oe

‘Figur Mode 210 Vale Schematic mayo oy resign

Energizing just the N.O. solenoids locks fuid in the valve

‘cover, which locks the valve poppet ina fixed position,

‘to maintain a constant flow rate as long as operating condi-

tions do not change. When operating conditions change,

‘causing a change in flow rate for that fixed valve opening,

the flow controller signals the appropriate solenoid to open

momentarily to readjust flow rate back to its set value. When

the set flow rate changes (e.g. from low flow start to high flow

limit, or during multi-step valve shutdown), the appropriate

solenoid is signalled to open untl flow rate adjusts to the new

set value. See Figure 2 for atypical tuck loading flow rate

sequence

Located between each solenoid and the main valve port

is a valve response control device, typically a needle valve.

This device Is used to ine tune the opening and closing rate

of the valve, as well as providing total control loop isolation

{or ease of service. Adjustment of these devices control the

flow to the cover chamber, permitting adjustments based on

product viscosities and pressures.

Reverse Flow and Pressure Relief

Reverse flow through the valve will occur if the pressure

‘downstream ofthe valve exceeds the pressure upstream of

the valve by 2 to 6 psig depending on valve size. This may

be desirable to provide pressure relief due to thermal expan-

sion forthe piping downstream of the valve, however, proper,

thermal reief analysis for the system is required. When the

pressure downstream of the valve is greater than the pressure

Upstream of the valve, fluid will flow from the downstream

side to the upstream side through the valve seat. The exact

pressure at which this will occur is dependent on the size and

‘configuration of the valve, as well as, the specific hydraulic

‘environment in which it's installed.

‘The 808/07A is a combination of check valve/pressure relict,

‘This option is available for the 210 series valve and when

installed, does not allow reverse flow through the main valve

seat but instead provides an adjustable pressure reli valve

(07A) which relieves downstream pressure in excess of the

setting to the upstream side of the valve through the valve

Tree

maybe deat.

Fortemperstreoutde teas range, cons factory.

Pobtatoroatyone (PTFE)

Standar

Opfiona for 4 ana 6 ony)

‘Stale sta bal valves anclor ing and tog avalable

2 Bulletin SS03009 esuelRev. 1.1 (10/17)

PED requvemests nt apptiatins to lquts win maximum vapor pressure of Sa abow

PED rues forall European countries. Equipment must be ranuaciures by or Elerbek, Germany fc.

Class 300 ASME, 300 psi (20.7 bar)

“20°F to 200°F

1 (Low Swe) Buna e200

20°F io 200°F

Sinan (20° 19990)

(OpieRal) @HOVAETEDHR 220 vac 150 He

oe

‘evoe

Low Swell

Carbon Steel." Buna’,

Main Valve Cast Stee! Carbon S Viton or

Ductile Ion Buna.N

Viton,

Solenoid Stainless I

coaeala easy Starnes Stool Buna

Nestle PTFE

Neede steer Steer Yow

‘Tubings

and Steer Steer -

Fitings

oor Chrome Piatod

Bally Stoo? Steel Bal/Stesl — PTFE*

cy

* 138

a 260

Pressure ratings are based on tamperaties of 20°F to 100°F (28°C to 38°). Fer apetaton at higher temperatures, the maximum wadeng assure

mosphere pressure, at macmum allowable temperate

Flow Rate (Limin)

40 100 250 500 1.000 2500 5.000 10,000 20.000,

8 120

6 17

Ve 100

2 80

ap

0 wa

‘

6 40

4

20

2

°

10 so 028 4 G78 1000 2 8 4 5678 10,000

Notes: Assumes that a dual spring is used in 4” and 6" valves.

Test fis kerosene with 0.82 sp. gr. 2¢P or mPars

‘The 2" and 2" RP (Reduced Port Valve) have negiglble pressure crop below $0 GPM when the valve isnot fow limiting

Pilots and Tubing ro a Pilots

=

my

riots ana —-|

nl

Lr \S

cauzne © rams) = Seis) UN) UHC] STO) GOMTH) 30

F —tH0(am) M180) eset) 40ctoa) 8 ety 8097) 4.08)

T8506) tat ass) ese) ac este ascii scar

© frou) 7955) storm) atten) 2s s1e) s(t) 8.5160

ORnimar, soma rms

+1 Pos and tubing Wi be witha dnerslons

Bulletin $S02009 fssuelRew 1.1 (10/17) 3

Revisions inched in $803008 lesuaiRev. 14 (107

Page 2 Revers flow and possi rol! inomaten sed.

“oa eons cranes Prin

Yo tage wh notes nd ay uaa pst hl vy

‘toc Orne he ante asso orally te eo preston when ay hve bot anges on mer bg MTS

‘erat nan etic Far neat cr cre efron vt ur ste at soem a ci onthe era Uk

he lr essa ero

‘TechnipFMC.com

FMCTechnologies.com/MeasurementSolutions

erecmipf 017 —seo300 ue 1. (847)

Tecripe ic

Fie Teetnoogles

esaurerent Salons

$00 Norn Sam Houston Parkway West,

Suze 100

Houston, Texas 77067 USA

Poste 260 2190

USA Operation

1802 Wagner Avenue

Ene, Pomeylania 15510 USA

Pari bra p@e 500

(Germany Operation

‘Sinister nb

Regonstasso 1

25874 Clerk, Conmany

Piste sion 204

» 3 TechnipFMC

SPECIFICATIONS

Bulletin $$03034 Issue/Rev. 0.2 (8/12)

+ Simple construction — reduces maintenance costs,

downtime,

‘may be combined with other Smith Meter® Pilots to

provide multiple control functions.

+ Explosion-proof solenoid — ULL. listed and CSA

approved.

‘The Smith Meter® Model 200-300 is normally closed valve

that opens, only when the upstream line pressure in the

main valve cover chamber is allowed to vent through the

normally closed, elecrically-actuated solenoid valve located

in the downstream of the valve, With the cover chamber

pressure reduced, the force created by differential pressure

‘across the diaphragm less the pressure over the seat area

and the valve spring tension opens the valve (Figure 1).

This allows the upstream line

pressure to pressurize the valve cover chamber through

the upstream side ofthe plot loop, thereby closing the

valve and stopping product flow, An adjustable sensitivity

valve located in the upstream side of the plot loop serves

as a closing speed control (Figure 2, page 2).

Model 13

Needle Vale

(Sensiiviy)

308

Tim

Flow

Low Pressure

Model 13

Noodle Valve Qe

‘Semi

ose

7200

Flow

Low Pressure

Figure 2 ~ Valve Closed Position

|

200-300 is ideally suited for use with the Smith

Meter® Model DE-1, Dual Electric Air Release Head for low

Viscosity less than 200 SSU) air elimination applications:

where it is desirable to stop product flow when the

presence of air is detected in a metering system.

‘Any number of control pilots can be combined to provide

‘multiple control functions, Typical combinations include rate

of low control (Models 40A or 42A), back pressure control

(Model 60A), and pressure reducing control (Model 50B),

The Model 200-304 incorporates a bare 202 diaphragm

actuated valve, a Model 09SC strainer, a Model 13 needle

valve, and a two-way normally closed Model 30 solenoid

valve, The valve is available in sizes 2" through 6”

imPea= Te

2 Presse rang are based on temperatures of 20°F to 100°F (28°C 0

38°C) Fersparaton at higher leporaies th maximum working pressure

maybe doratad

53. PEDreuiomerss nt apptatons to fq ith rainum vapor posses

5 bar above atmosphere pressure, t maximum alowabl ameratue

4 PED reed for ll Euopesn count Equprent mt be maruactted

by Eleroek Germany ft.

5 For lemparatre cutsse tase ranges, con facto.

2 Bullotn SS03024 Issue/Rev 0.2 (8/12)

‘Above 200 SSU, consult factory

Pressure Rating/Connections*>*

(Class 150 ASME, 285 psi (19.6 ba),

‘Class 300 ASME, 300 psi (20.7 bar).

Buna-N 20°F to 200°F (-28°C 10 83°C)

LS (Low Swell) Buna’ -20°F to 200°F (-28°C to 93°C)

30 Vac, 50 He

420, 60 Hz

aaiiis

12 Vee 10%

2ANide 10%

For other votages, consult factory

8

10 95 40 95 at

3) (241) (102) @41) (105)

135 ss 49 95 (45

(943) (241) (124) 241) (114)

119 100 66 12555

432) (454) (279) (188) (18) (40)

Note: Dnensions ~ inches tothe neret tnt imate to the nearest whale

‘rm, sach independent dimensioned rem rspoctve engineering drawings.

1 Pl an bing wl be wid hese dimensions

82 (97)

135(61)

257 (116)

BE ~~

2021203 CastSteel Bronze, Stainless. Low Swell

Steel, Carbon Buna’, Vion,

Steal, Ductle Fon or Sune-N.

098C Carbon Steel 304 Stainless -

Steal Mesh

Needle Carbon Steel Stainless, Carbon PTFE

ave Stoo!

Model 13

30A 400 Staines Viton

Stee!

Standard Carbon Stee!

Optional 300 Series

Stainless

Stee!

+ Standard

5 Palyeatvoroatylne PTFE}.

°

Bulletin $0904 TseueRav, 0.2 (8/12)

3

evans ted S50004 a, 82785

Page 2 Revaas rere aed PD oro: Reread matt once reno sal an, "Na Bess Ey Cote’, rm Mose 22203 Pag Powe Rag

‘re aa Ono ose

2018 - pad ang a tat oman,

‘espa otana un wc hans ae ts an ut an par a wae Macs Pear rN

USA Operation

1802 Wagner Avenue

Er, Ponmeyiania 1510 USA

Tempra ivi 646985000

Fite Teemncagies

Messuremert Satstons, In {Germany Operaton

"htc0Cocswoos Road Smut eter mb

fechnipFMC.com Buiaing Sot Regentsvase

TechnlPEMG. oust, Texas 77044 USA BstraElarbek Germany

Ce raemoris ia Argtesened, SSD eas 8282) Post zeiso1.000 Pree ano1.2089

También podría gustarte

- PMAL-474-PL-Y-061 B - PID S.Medicion Despacho Jet A1 MalvinasDocumento1 páginaPMAL-474-PL-Y-061 B - PID S.Medicion Despacho Jet A1 MalvinascasandraAún no hay calificaciones

- Pmal-474-Dc-K-061 A - D.i&c Flow ComputerDocumento1 páginaPmal-474-Dc-K-061 A - D.i&c Flow ComputercasandraAún no hay calificaciones

- PMAL-474-3D-C-061 Maquetas 3D Del Skid de Medición & Despacho de Turbo A1Documento1 páginaPMAL-474-3D-C-061 Maquetas 3D Del Skid de Medición & Despacho de Turbo A1casandraAún no hay calificaciones

- PSTPE05522 - Doc General Tecnico Skid Medicion Turbo A1 - PLUSPETROL PDFDocumento22 páginasPSTPE05522 - Doc General Tecnico Skid Medicion Turbo A1 - PLUSPETROL PDFcasandraAún no hay calificaciones

- PMAL-474-PL-K-101 - 0 - Arquitectura de ControlDocumento1 páginaPMAL-474-PL-K-101 - 0 - Arquitectura de ControlcasandraAún no hay calificaciones

- Mecanico General Skid Medicion&Despacho Jet A1 Malvinas PPC - PSTPEDocumento1 páginaMecanico General Skid Medicion&Despacho Jet A1 Malvinas PPC - PSTPEcasandraAún no hay calificaciones

- Draw 7475F V 1Documento1 páginaDraw 7475F V 1casandraAún no hay calificaciones

- IVU Actividad5a HectorLuisMarquezDocumento2 páginasIVU Actividad5a HectorLuisMarquezcasandraAún no hay calificaciones

- Mapa Conceptual de Las Especialidades de La Carrera-1Documento2 páginasMapa Conceptual de Las Especialidades de La Carrera-1casandraAún no hay calificaciones