Documentos de Académico

Documentos de Profesional

Documentos de Cultura

FP 1

Cargado por

Andy ArenasTítulo original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

FP 1

Cargado por

Andy ArenasCopyright:

Formatos disponibles

.

EV²

EL5 m

UP E Y

I N

A ALV DN N

R CO²

P AL26 m

R U RY D OL V B

P A R

WSUXILI ONT

0Ø A C ILS

10 0Ø OR ETA

5 LO D L

F SEE T INmA²

ILE² UR 2

TO 1 m P

U

PR

DS

0Ø

10

CK

S TORA R

A B E / XT OO

RAGA/ EE F²L

O E C 3m

ST ARFFI 28

O

.

EV²

EL5 m

DN Y

N

CO²

AL26 m

UP E UP B CE

IN V EN

P D RA VAL T

R

E M²

NF OO

U Y L ILE² CO R 3

3m

32MMØ PIPE S PR LIAR TRO TO 2 m G E

P W I N UN

0 Ø AUX CO ILS AL

T RI2Nm²

LO

Rm²

BB

Y

0

1 0Ø O ET R A E

IL ² U I SITO 5 LO

5 LO D TO 1 m RY

V

F SE E N12Tm²

A

P

U P

E1

PR F1I6Cm²

DS AR

E A O F

0Ø I N

10 AD

M

IT. ICmE

2 B

M. / /K F ² T&4 m²

N INGY F 18

E² RR I

M R R O

WD2 m ADNEEANTm²

I

PO )

(M1 m² NG /

P 150 E

E F² FIC

'SO

5m2

GM

N G

RI

N EEEA

. GI R

RM EN A

ER

WD2 m

²

. PO

EV²

EL 5 m

EA

AR

FLUSH ANCHOR OR Y NG²

OR I m

INE

AG 13

Y L

C-CLAMP FOR STEEL PE

RT

T

R4Am² ST

O

PR

TRUSS

om² O P

WS

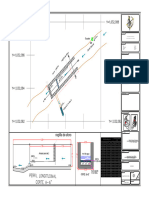

BOTTOM OF SLAB B 1

Ro2 m LA UP

ROUND BAR D

HANGER UP E UN 69

I N

A ALV EA O 1.0

MACHINE BOLT

P R AR GR

U RY D L V

HEXAGONAL NUTS H

W/ NUT TCm² 0Ø W

R

P A RO 10BELO

W/ WASHERS

PA 12

WSUXILI ONT DIS

OR

K

UP

FLAT BAR

0Ø A C ILS / WE

LOWER PIPE

10 0Ø OR ETA G C

NOTE: 5 LO D

F SEE S PR KINPA0 m²

AR S 15

D P

0Ø

CROSSMAIN AND BRANCHLINE PIPE

10

SHOULD BE MAXIMIZE TO THE CEILING LEVEL.

C

FD IPE

8 0Ø D P FDC E

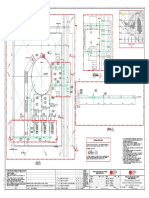

PIPE SIZE STEEL PLATE BAR ROD. DIA. MACHINE BOLT W/ NUT

N D 6 5X TAN 0Ø PIP ILE²

T

EA

X S D TO 3 m D AR

MM. IN. LOWER (THK X W) LOWER (THK X W) MM. IN. (DIA. x L) mm.

GR

OU 65WET 65X8TAN GU

AR2 m

²

50 2 3.2 X 25 MM 4.8 X 25 MM 9.5 3/8 9.5Ø x 100 MM. L X S

W

65 RY

CV

ELO

GV

65 2 1/2 3.2 X 25 MM 4.8 X 25 MM 9.5 3/8 9.5Ø x 115 MM. L

80 3 3.2 X 25 MM 4.8 X 25 MM 9.5 3/8 9.5Ø x 127 MM. L B D W SP

0 Ø D

100 4 3.2 X 25 MM 4.8 X 25 MM 9.5 3/8 12.0Ø x 165 MM. L 10DSP UN

O

150 6 4.8 X 32 MM 6.4 X 32 MM 12.0 1/2 12.0Ø x 216 MM. L GR

L OW Ø W

50 ELO

F B

TER

WA

WALL HANGER

Ø15x40mm LONG

PIPE EXPANSION BOLT

STEEL COLUMN

TO BE FILLED W/ NON-

STEEL PIPE SLEEVE W/ OR NAIL (TYPICAL)

ESCUTCHEON FOR COMBUSTIBLE MATERIALS PLASTIC WATERPROOF

B 6.5MM THK. X 50MM FINISHED SURFACE HEAT RESISTANT 100X6.25X75 LONG

B/2 X 50MM CAULKING COMPOUND STEEL BARS WELDED

A/4

50MMØ TO TO PIPE

100MMØ PIPE 2-15 X 50L BOLT W/

DOUBLE NUTS AND PIPE

LOCK WASHER

A

A/2

9.5MMØ (3/8)

ROD DIA. NUT W/ LOCK WASHER

CMU WALL

A/4

A/4

NUT W/ LOCK WASHER

PLASTIC WATERPROOF

OR PARTITION

CONCRETE SLAB

9.5MMØ (3/8)

A/2

2-15 X 50L BOLT W/ HEAT RESISTANT

A

DOUBLE NUTS AND ROD DIA. NOTES: CAULKING COMPOUND

LOCK WASHER SHAP ON TYPE

SLEEVE SHALL BE PROVIDED AROUND ALL PIPING EXTENDING OAKUM MASTIC PACKING

50MMØ TO 100MMØ ESCUTCHEON PLATE

A/4

6.5MM THK. X 50MM B/2 THRU WALLS & FOUNDATION.

PIPE (FOR FINISHED SURFACE)

X 50MM B A. MINIMUM CLEARANCE BETWEEN PIPES AND SLEEVES CONCRETE SPOUT

SHALL NOT BE LESS THAN 25mm. FOR PIPES 25mm

STEEL COLUMN THROUGH 90mm.&50mm. FOR PIPES 100mm. LARGER. CONCRETE WALL PORTABLE FIRE

B. THE CLEARANCE BETWEEN THE PIPE SLEEVE SHALL BE NOTE: FIN. FLOOR LINE EXTINGUISHER

FILLED W/ NON-COMBUSTIBLE FLEXIBLE MATERIALS SUCH

AS MINERAL WOOL FIBERGLASS OR EQUIVALENT PIPE SHALL PIPE SLEEVE SHALL HAVE A MINIMUM FIRE RATING SIMILAR

WHERE A = B 300MM LENGTH ALL THROUGH OUT PIPE SIZE OF 50Ø TO 100Ø NOT DECLARE FIRE RATING OF WALLS AND FLOORS. TO PENETRATED WALL.

C. FLOOR SLEEVES SHALL BE EXTENDED AT LEAST 75mm.

ABOVE THE TOP OF THE WEARING SURFAGE.

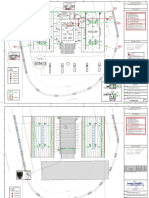

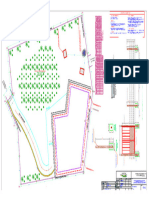

ARCHITECT/ ENGINEER PROJECT OWNER SHEET CONTENTS CADD BY REVISIONS CADD BY DATE SHEET NO.

GENERAL NOTES JAD

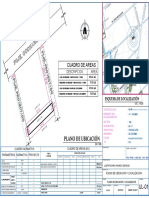

PROPOSED FIRE PROTECTION PLAN DATE

LEGEND

FOR 3-STOREY COMMERCIAL

PROFESSIONAL MECHANICAL ENGINEER

BUILDING MISCELLANEOUS DETAILS

09.13.22

CHECKED

FP

PTR NO :

PLACE ISSUED :

PRC NO :

TIN NO : LOCATION : DATE

0 1

DATE ISSUED :

También podría gustarte

- Plan Especifico Vial Palian - Uñas PDFDocumento1 páginaPlan Especifico Vial Palian - Uñas PDFMary Yoana CRAún no hay calificaciones

- PL - Arquitectura General Gasocentro-Adg-01Documento1 páginaPL - Arquitectura General Gasocentro-Adg-01Richard ChbAún no hay calificaciones

- Fsñ-004 (2juegos) Formato A1Documento1 páginaFsñ-004 (2juegos) Formato A1dustinAún no hay calificaciones

- Perfil MecanicoDocumento1 páginaPerfil MecanicoRoberto Carlos Campos MitoAún no hay calificaciones

- 02 Planta y Elevacion FrontalDocumento1 página02 Planta y Elevacion FrontalJonathan GutierrezAún no hay calificaciones

- Evs-09 (2 Juegos) Formato A1Documento1 páginaEvs-09 (2 Juegos) Formato A1dustinAún no hay calificaciones

- DWG SHX002 570 05 1002 - 1BDocumento1 páginaDWG SHX002 570 05 1002 - 1BHarry Ccayascca FloresAún no hay calificaciones

- DWG SHX002 570 05 1002 - 1B PDFDocumento1 páginaDWG SHX002 570 05 1002 - 1B PDFHarry Ccayascca FloresAún no hay calificaciones

- LAM3 PlantasDocumento1 páginaLAM3 PlantasRocio Segura MejiaAún no hay calificaciones

- FSÑ-02 (2juegos) Formato A1Documento1 páginaFSÑ-02 (2juegos) Formato A1dustinAún no hay calificaciones

- K1A Layout1Documento1 páginaK1A Layout1Sencic Innovacion ConstructivaAún no hay calificaciones

- JDH1 01 016 SZC ST5 ST SDW 0105 00Documento1 páginaJDH1 01 016 SZC ST5 ST SDW 0105 00Ubaidullah KhanAún no hay calificaciones

- CSRC001 000 01 DR It 000007Documento1 páginaCSRC001 000 01 DR It 000007German Taipe PalaciosAún no hay calificaciones

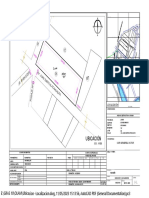

- Ubicacion Localizacion El Tambo-1Documento1 páginaUbicacion Localizacion El Tambo-1jhonAún no hay calificaciones

- PMT Coltabaco P1Documento1 páginaPMT Coltabaco P1Marco Antonio Gasca DuranAún no hay calificaciones

- Zona de RestaurantesDocumento1 páginaZona de RestaurantesBethsy MoranAún no hay calificaciones

- Fsñ-03 (2juegos) Formato A1Documento1 páginaFsñ-03 (2juegos) Formato A1dustinAún no hay calificaciones

- Plano de Ubicacion y Localizacion GeoreferenciadaDocumento1 páginaPlano de Ubicacion y Localizacion GeoreferenciadaAugusto Obeso AlcántaraAún no hay calificaciones

- Proyecto Detalles (1) P TerrenoDocumento1 páginaProyecto Detalles (1) P TerrenoAntonio SantillánAún no hay calificaciones

- Mapa Carretero YucatánDocumento1 páginaMapa Carretero YucatánJosé Luis Gordillo Rubio100% (1)

- A-07 - Planta General Piso 05Documento1 páginaA-07 - Planta General Piso 05JaramjcAún no hay calificaciones

- Planos Arquitectonicos PlantasDocumento1 páginaPlanos Arquitectonicos PlantasGrecia ParetasAún no hay calificaciones

- CSRC001 000 B1 DR Me 000002Documento1 páginaCSRC001 000 B1 DR Me 000002Alain Dax Sanchez AriasAún no hay calificaciones

- 7.0 Señalizacion Huachenca Asd-Ps-01Documento1 página7.0 Señalizacion Huachenca Asd-Ps-01Alexander Chavez VergaraAún no hay calificaciones

- Plano de Drenaje PluvialDocumento1 páginaPlano de Drenaje PluvialVismarkVillegasRocha0% (1)

- Lote 2Documento1 páginaLote 2jesus condor mateoAún no hay calificaciones

- Plano Ubicacion-UbicacionDocumento1 páginaPlano Ubicacion-UbicacionYury Huamani gallegosAún no hay calificaciones

- Croquis de UbicacionDocumento1 páginaCroquis de UbicacionDarwin Toledo Espino100% (1)

- Blocs Ultimo PidoDocumento1 páginaBlocs Ultimo PidoVania csAún no hay calificaciones

- Canal Bledonia 1 NuevoDocumento1 páginaCanal Bledonia 1 Nuevohernaninfante16Aún no hay calificaciones

- Plan de Desarrollo Urbano Municipal: de San Pedro Garza García, N.L. 2030Documento1 páginaPlan de Desarrollo Urbano Municipal: de San Pedro Garza García, N.L. 2030varicochaAún no hay calificaciones

- CERCO GEOREFERENCIADO (ENRIQUE) - Model - pdf24Documento1 páginaCERCO GEOREFERENCIADO (ENRIQUE) - Model - pdf24Jose Fernando Mendocilla IbañezAún no hay calificaciones

- MwslsklwqsDocumento1 páginaMwslsklwqsa00825732Aún no hay calificaciones

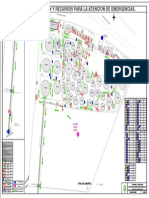

- Recursos Atencion Contingencias Act24012022 Plano Emergencia 1Documento1 páginaRecursos Atencion Contingencias Act24012022 Plano Emergencia 1PROFINE LIMITADAAún no hay calificaciones

- Plano de Desague: Primer NivelDocumento1 páginaPlano de Desague: Primer NivelJaren Smith Alfaro FloresAún no hay calificaciones

- Plano de GeoreferenciacionDocumento4 páginasPlano de GeoreferenciacionJhon Tamara RamirezAún no hay calificaciones

- 2do PisoDocumento1 página2do PisoChristian BCFAún no hay calificaciones

- AzoteaDocumento1 páginaAzoteaChristian BCFAún no hay calificaciones

- 6 - PLANO BASE PROVINCIA DE TRUJILLO VERSION - JUNIO - 2023-ModelDocumento1 página6 - PLANO BASE PROVINCIA DE TRUJILLO VERSION - JUNIO - 2023-ModelSarita SánchezAún no hay calificaciones

- OM28 JP Propuesto PDFDocumento1 páginaOM28 JP Propuesto PDFmarco calvoAún no hay calificaciones

- GL2-000-PL-AR-00 - Layout General - Rev.ADocumento1 páginaGL2-000-PL-AR-00 - Layout General - Rev.AEste VillalobosAún no hay calificaciones

- Bloque BusessDocumento1 páginaBloque BusessJuan Carlos Escobar CondoriAún no hay calificaciones

- Vivienda Unifamiliar AlbañileriaDocumento1 páginaVivienda Unifamiliar AlbañileriaLucio Rios SaldañaAún no hay calificaciones

- CONEXIONES DOMICLIARIAS 2-Layout1Documento1 páginaCONEXIONES DOMICLIARIAS 2-Layout1Fredy RodriguezAún no hay calificaciones

- 1.0 Plano de Ubicacion y Localizacion-U y LDocumento1 página1.0 Plano de Ubicacion y Localizacion-U y LFrank Espinoza LeónAún no hay calificaciones

- ARQ - MAGDALENA - F1.pdf GOM Signed Signed Signed SignedDocumento1 páginaARQ - MAGDALENA - F1.pdf GOM Signed Signed Signed SignedMishelle AsimbayaAún no hay calificaciones

- Red Interna 2Documento1 páginaRed Interna 2Paola EstefaniaAún no hay calificaciones

- Surtidor Bio Petrol (Santos Dumont) PDFDocumento6 páginasSurtidor Bio Petrol (Santos Dumont) PDFLuis Fernando Vega BasmaAún no hay calificaciones

- Ubicacion - Localizacion - GRAS 10Documento1 páginaUbicacion - Localizacion - GRAS 10constructora casa verdeAún no hay calificaciones

- Finales Anteproyecto Atami Lote Hoja 34 Por TerrazasDocumento1 páginaFinales Anteproyecto Atami Lote Hoja 34 Por TerrazasNelsonSinuhDiazAún no hay calificaciones

- 04 Plano CercoDocumento1 página04 Plano CercoLorena Bresli Muñoz MaraviAún no hay calificaciones

- Hnos Sanchez Pomalaza-Layout3Documento1 páginaHnos Sanchez Pomalaza-Layout3Jamie JosAún no hay calificaciones

- Plano San Salvador de Jujuy 2017Documento1 páginaPlano San Salvador de Jujuy 2017JAIME lealAún no hay calificaciones

- Planos Constructivos - Edificio Uso Mixto - Linda Flor Solis Reyes PDFDocumento27 páginasPlanos Constructivos - Edificio Uso Mixto - Linda Flor Solis Reyes PDFLinda Flor100% (1)

- Plano PararrayoDocumento1 páginaPlano PararrayoELvis C DavlAún no hay calificaciones

- 1207 - 7-35 - Planta LayoutDocumento1 página1207 - 7-35 - Planta LayoutStefano Torres GodoyAún no hay calificaciones

- Detalles (Puentes, Camaras) - 14Documento1 páginaDetalles (Puentes, Camaras) - 14Gabriel Romero MamaniAún no hay calificaciones

- Coaching Samurai: ECONOMÍA, FINANZAS, EMPRESA Y GESTIÓNDe EverandCoaching Samurai: ECONOMÍA, FINANZAS, EMPRESA Y GESTIÓNAún no hay calificaciones

- Educar y convivir en la cultura globalDe EverandEducar y convivir en la cultura globalCalificación: 5 de 5 estrellas5/5 (2)

- Coeducando para una ciudadanía en igualdadDe EverandCoeducando para una ciudadanía en igualdadCalificación: 5 de 5 estrellas5/5 (1)