Documentos de Académico

Documentos de Profesional

Documentos de Cultura

ASCO 2905 Pub5540 Revd

Cargado por

Jonathan MirandaTítulo original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

ASCO 2905 Pub5540 Revd

Cargado por

Jonathan MirandaCopyright:

Formatos disponibles

2000 SERIES

Data Sheet Model 2905

The ASCO Model 2905 are resistive,

AC load banks designed for operation

indoors when up to 700 kW of resistive

load is required.

LOAD BANK RATINGS Control Power

Standard capacity ratings of: The load bank requires a 120V, single phase, source for control circuit operation. An

integral control power transformer is available as an option.

• 700 kW

Standard load step resolution of 5 kW.

Operator Controls

The standard local mode is manual control via "digital toggle" switches. The local mode

Standard three phase voltage ratings of: features full digital monitoring and individual load steps with LED indications. The

• 240/480-60Hz integral control panel is provided for load bank operation and includes the necessary

controls and status indicators.

Please consult factory for non-standard

ratings. The optional remote control mode is via the hand-held touchscreen controller. It features

a 4.3" color touchscreen housed in a rugged and easy to grip industrial grade enclo-

sure. Load selection can be the sum of the entire load string (up to 25 load banks) or

Cooling Blower Motor Control individual units within that string. Extremely fast and reliable CANbus communication

The motor obtains power from either the protocol is used in the SIGMA LT for networking. CANbus protocol reduces network sag

power source under test (motor connected which is typically found in RS232 network load banks. A USB port is provided for data

to load bank main load bus) or from a download and software updates.

remote source (external power source). Construction

When operating from the power source

under test, the motor circuit connects the The 2905 is constructed using heavy gauge aluminized steel per ASTM A463. It is designed

motor for high or low voltage. for continuous indoor operation. Two (2) moveable and two (2) fixed casters are provided

for easy mobility. Handles, lifting eyes, and forklift pockets are provided on the load bank for

Cooling System transport. All exterior fasteners are stainless steel.

Proper cooling is provided by integral Finish

blower motor. The blower motor circuit

is fuse and overload protected. The 2905 has a high quality baked polyester powder coated finish with a film thickness

of 2.8 +/- 0.4 mils per coat. The standard color is gray (ANSI 61).

Two Year Warranty Included

The equipment is covered by an industry exclusive 24-month parts and labor warranty.

Model 2905 Specifications

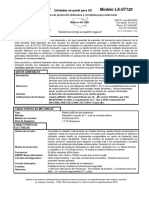

Resistor Elements 60.50 [1537.00]

57.25 [1454.00]

33.50 AIR EXHAUST

ASCO load banks use helically wound [851.00]

chromium alloy Helidyne elements. Ele-

ments are supported by ceramic insula- CONTROL

PANEL

tors on internal frame supports. These

elements are designed to operate at

approximately 1/2 of their maximum CENTER OF

continuous wire rating.

GRAVITY

Elements are positioned within the cool- 75.00

[1905.00]

ing airstream for optimal performance. ! WARNING

PROTECTIVE COVERS MUST BE CLOSED

ON UNUSED CAM LOCKS

240V: MINIMUM OF 6 CABLES PER PHASE

480V: MINIMUM OF 3 CABLES PER PHASE

Changes in resistance due to temperature

300 AMPS MAX PER CAM LOCK

1262041-1

HINGED PHASE A

1262041-3

PHASE B

1262041-4

PHASE C

1262041-5

LOWER PANEL

are minimized by maintaining conservative 41.70 [1059.18]

watt densities. GND

GND

1262041-2

TO C.G.

The overall load tolerance of the 2905 load

bank is -0, +5%. This ensures that adver-

tised kW is delivered at rated voltage. FORKLIFT

CHANNELS

The elements are continuously rated at 15.77 [400.56]

TO C.G. RECESSED LOAD 26.51 [673.35]

CONNECTION PANEL

the specific voltage. Tests at lower volt-

TO C.G.

ages, with a corresponding reduction in

All dimensions are in inches [millimeters].

overall rating, may be carried out. Power is Specifications subject to change without notice.

proportional to voltage squared.

Safety Features Ambient Temperature Testing and Standards

A differential pressure switch is provided The 2905 load bank is designed for con- ASCO load banks comply with NEMA,

to detect air loss. The switch is inter- tinuous duty cycle with no limitations. The NEC, and ANSI standards. Quality control

locked with the load application controls ambient temperatures range is -20°F to system is certified to ISO9001 standards.

to prevent load from being supplied if 120°F (-28°C to 50°C).

cooling air is not present. Weight and Dimensions

An overtemperature switch is provided to Environment

Dimensions (approx. in/mm) Weight

sense the load bank exhaust in the heater The 2905 is self-contained portable load (approx.

Length Width Height lb/kg)

case assembly. The switch is interlocked bank designed for operation and storage

with the load application controls to pre- indoors. 60.5/1537 33.50/851 75/1905 1150/522

vent load from being supplied if an over-

temperature condition is present. Power Terminals

Major fault protection is provided by Input connections are quick connect style Support

branch circuit fuse protection. receptacles mounted on the side of the SIGMA software can be updated

load bank. free of charge through the ASCO

The load contactors are interlocked with

the fan controls to ensure load can be website at the following link.

Optional Accessories

applied only when the fan is running.

• 4.3" Color Touchscreen Hand-Held

The blower circuit is protected by fuses Controller

and overload relays. • 5 m Interconnection Cable

Internal access is restricted by bolt on (other lengths available)

exterior panels. • 20' Load Cable Set with Connectors

The air intake on the 2905 is designed to Documentation -

prevent objects greater than 0.50" diam- Operating Manual

eter from being ingested into the unit.

A comprehensive operator's manual is

Vertical air discharge is directed away supplied electronically via a USB drive.

from personnel. Optional SIGMA LT Hand-Held Terminal.

Sections include: Safety, Installation,

The exterior of the load bank has appro- Operation, Maintenance, and Trouble-

priate warning and caution statements on shooting.

access panels.

ASCO Power Technologies loadbanks.ascopower.com • LBsales@ascopower.com

6255 Halle Drive, Cleveland, Ohio 44125, U.S.A. customercare@ascopower.com • 1-216-573-7600

©2020 ASCO Power Technologies. Publication 5540 • Rev. D

También podría gustarte

- Mantenimiento de redes eléctricas subterráneas de baja tensión. ELEE0109De EverandMantenimiento de redes eléctricas subterráneas de baja tensión. ELEE0109Aún no hay calificaciones

- Abb Catalogo InterruptoresDocumento28 páginasAbb Catalogo InterruptoresTesel IndustrialAún no hay calificaciones

- Montaje de redes eléctricas subterráneas de alta tensión. ELEE0209De EverandMontaje de redes eléctricas subterráneas de alta tensión. ELEE0209Aún no hay calificaciones

- Joslyn - VBM - Vbu - Joslyn T&B PDFDocumento12 páginasJoslyn - VBM - Vbu - Joslyn T&B PDFEdwin QuispeAún no hay calificaciones

- Plantas Electricas SelmecDocumento12 páginasPlantas Electricas SelmecDaniel López Olivera100% (1)

- Celdas IberapaDocumento13 páginasCeldas IberapaFlogisto79100% (3)

- Hci444d EspañolDocumento8 páginasHci444d EspañolChristian Rivera FloverAún no hay calificaciones

- Catalogo CeldasDocumento31 páginasCatalogo Celdasvanessa quispeAún no hay calificaciones

- Fo211R07 SERIE SLA 2CDocumento2 páginasFo211R07 SERIE SLA 2CMauricio MoralesAún no hay calificaciones

- Sivacon: Centro de Control de Motores 8PT Homologado, en Técnica ExtraíbleDocumento8 páginasSivacon: Centro de Control de Motores 8PT Homologado, en Técnica ExtraíbleJobita JMAún no hay calificaciones

- WEG - Interruptores en Caja Moldeada DWBDocumento56 páginasWEG - Interruptores en Caja Moldeada DWBMarcelo LescanoAún no hay calificaciones

- Es Irb-Ecowatt PDFDocumento7 páginasEs Irb-Ecowatt PDFLuis Leiva SanchezAún no hay calificaciones

- Weg Interruptores DWB en Caja Moldeada Iec50070311Documento60 páginasWeg Interruptores DWB en Caja Moldeada Iec50070311luisAún no hay calificaciones

- ITW GSE AXA 2400 ES 6 Paginas SeparadasDocumento6 páginasITW GSE AXA 2400 ES 6 Paginas SeparadasEmerson BarajasAún no hay calificaciones

- Seccionador Encapsulado RM6Documento8 páginasSeccionador Encapsulado RM6Raúl BermúdezAún no hay calificaciones

- LA-ST180 EspanolDocumento2 páginasLA-ST180 EspanolEzequiel PeñaAún no hay calificaciones

- Brochure - Keor - T - Es 3f 10 Kva - 60 KvaDocumento12 páginasBrochure - Keor - T - Es 3f 10 Kva - 60 KvaFernando CespedesAún no hay calificaciones

- Centro de Control de Motores CCM de Bajo Voltaje Reliagear™Documento60 páginasCentro de Control de Motores CCM de Bajo Voltaje Reliagear™Sabastian SebastianAún no hay calificaciones

- Transformadores Secos BTDocumento4 páginasTransformadores Secos BTmariojrm74Aún no hay calificaciones

- Cut OutDocumento16 páginasCut OutJhonathan STAún no hay calificaciones

- DWB - Interruptores en Caja MoldeadaDocumento60 páginasDWB - Interruptores en Caja Moldeadajunior_jazzzAún no hay calificaciones

- Keor T: SAI de 10 A 120 kVADocumento14 páginasKeor T: SAI de 10 A 120 kVATyrell SnowAún no hay calificaciones

- 1 - Capacitación VWP01 Rev.0Documento363 páginas1 - Capacitación VWP01 Rev.0Felipe Serrano GonzalezAún no hay calificaciones

- Abb Compass TripticoDocumento2 páginasAbb Compass TripticoDaniel GarcíaAún no hay calificaciones

- Spec NDR-480 SerieDocumento2 páginasSpec NDR-480 SerieRicardo CalixtoAún no hay calificaciones

- Estabilizador Rackeable Matscom 2.5KDocumento6 páginasEstabilizador Rackeable Matscom 2.5KEduardo RodriguezAún no hay calificaciones

- Bancosdecapacitoresis 140814172521 Phpapp02Documento24 páginasBancosdecapacitoresis 140814172521 Phpapp02Janpier Franco Pizarro Nonalaya100% (1)

- Brochure Keor-T UPS LegrandDocumento16 páginasBrochure Keor-T UPS LegrandDaniel HernandezAún no hay calificaciones

- Interruptores ElectromagneticosDocumento306 páginasInterruptores ElectromagneticosCarlos Zevallos CRAún no hay calificaciones

- Español Pi144gDocumento9 páginasEspañol Pi144gCristhian ChoqueAún no hay calificaciones

- WEG DWB 50070311 Es PDFDocumento56 páginasWEG DWB 50070311 Es PDFHugo MenéndezAún no hay calificaciones

- Celdas Aislamiento MixtoDocumento6 páginasCeldas Aislamiento MixtoJean AvalosAún no hay calificaciones

- LA-ST60 EspanolDocumento2 páginasLA-ST60 EspanolEzequiel PeñaAún no hay calificaciones

- FT Regulador TR 5kVA 1F-120VCADocumento2 páginasFT Regulador TR 5kVA 1F-120VCAdulcesinestesiaAún no hay calificaciones

- 03-CCM-BT-INST.-ELECTRICAS CelDocumento35 páginas03-CCM-BT-INST.-ELECTRICAS CelDiego Figueroa SanchezAún no hay calificaciones

- Subestación Compacta FPower FPEDocumento4 páginasSubestación Compacta FPower FPEitcmscribAún no hay calificaciones

- v10x e Manual Controlador Potencia Pcw-Pcwe SpanishDocumento4 páginasv10x e Manual Controlador Potencia Pcw-Pcwe SpanishVicente AlfonzoAún no hay calificaciones

- Catalogo AkkuDocumento8 páginasCatalogo AkkuDennis Brenes RodríguezAún no hay calificaciones

- Ie340 Puente Montajes ContactoresDocumento1 páginaIe340 Puente Montajes ContactoresDinastíaAún no hay calificaciones

- Triptico Bcos de Capacitores en BT Single Oct 2011Documento6 páginasTriptico Bcos de Capacitores en BT Single Oct 2011Jose ManuelAún no hay calificaciones

- Ie312 Abb Nuevos ContactoresDocumento2 páginasIe312 Abb Nuevos ContactoresDinastíaAún no hay calificaciones

- Final Dte PDFDocumento46 páginasFinal Dte PDFCharleeAún no hay calificaciones

- Generac-Industrial-Power Brochure SpanishDocumento18 páginasGenerac-Industrial-Power Brochure SpanishRicardo TitoAún no hay calificaciones

- Presentación VEI - UNIFLUORCDocumento50 páginasPresentación VEI - UNIFLUORCWilliam Dante Mescco SaireAún no hay calificaciones

- LA ST240 EspañolDocumento2 páginasLA ST240 Españoljose ivanAún no hay calificaciones

- Conectores BS 2019Documento2 páginasConectores BS 2019Ana UicabAún no hay calificaciones

- Spec - RS-50 SerieDocumento1 páginaSpec - RS-50 SerieCARLOSAún no hay calificaciones

- FT Regulador 60kVA 3F-240-120VCA GAB-EXTDocumento2 páginasFT Regulador 60kVA 3F-240-120VCA GAB-EXTdulcesinestesiaAún no hay calificaciones

- Transformador Trifasico de Distribucion en Aceite 15 50 KvaDocumento2 páginasTransformador Trifasico de Distribucion en Aceite 15 50 KvaCesar Huayllapuma Ramirez0% (1)

- DE17FMX 5NBar1250 120-144Documento25 páginasDE17FMX 5NBar1250 120-144Rose CantuAún no hay calificaciones

- 2 - TTDocumento2 páginas2 - TTCesar Huayllapuma RamirezAún no hay calificaciones

- JOSLYN VBM Información TécnicaDocumento6 páginasJOSLYN VBM Información TécnicaJORG ESTRADAAún no hay calificaciones

- Folleto 3M Bornas EPDMDocumento4 páginasFolleto 3M Bornas EPDMcphcricriAún no hay calificaciones

- Es Cvab-N EcowattDocumento11 páginasEs Cvab-N Ecowattfeluco.martin.96Aún no hay calificaciones

- LA-ST120 Espanol 2021.Documento2 páginasLA-ST120 Espanol 2021.Ezequiel PeñaAún no hay calificaciones

- Secos Baja TensionDocumento3 páginasSecos Baja TensionRoger FloresAún no hay calificaciones

- 1660 CodensaDocumento3 páginas1660 CodensaTatiana RoaAún no hay calificaciones

- WEG DWB 50070311 EsDocumento64 páginasWEG DWB 50070311 EsDiego Alexaner Pulido CruzAún no hay calificaciones

- Caracteristicas de LA-ST60Documento2 páginasCaracteristicas de LA-ST60Guillermo NaranjoAún no hay calificaciones

- ShneiderDocumento8 páginasShneiderDilham BerrioAún no hay calificaciones