Documentos de Académico

Documentos de Profesional

Documentos de Cultura

93 A 0 DC

Cargado por

Franklin Alarcon Silva0 calificaciones0% encontró este documento útil (0 votos)

5 vistas2 páginasFICHA TECNICA DE BRITE ZING

Título original

93a0dc_7c11d734111749329154f483c7c37a2d

Derechos de autor

© © All Rights Reserved

Formatos disponibles

PDF o lea en línea desde Scribd

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoFICHA TECNICA DE BRITE ZING

Copyright:

© All Rights Reserved

Formatos disponibles

Descargue como PDF o lea en línea desde Scribd

0 calificaciones0% encontró este documento útil (0 votos)

5 vistas2 páginas93 A 0 DC

Cargado por

Franklin Alarcon SilvaFICHA TECNICA DE BRITE ZING

Copyright:

© All Rights Reserved

Formatos disponibles

Descargue como PDF o lea en línea desde Scribd

Está en la página 1de 2

Special Spray Head

BRITE

ZING

Rust Protection That

Matches Galvanizing

URES - BENEFITS

Non-Clogging

Meets ASTM A780 Standard

Passes Inspection

99+% Pure Zinc

Lowest Contamination Risk

Look of Hot-Dip

Doesn't Look Repaired

One-Step Color Match

Save Time & Cost - One Operation

Ages Like Galvanized Repair is Camouflaged

Paintable — Excellent for Top-Coating

Weld-Thru Primer Protect Parts for Future Use

Proprietary Formula

One-Coat, Fast-Drying, Non-Sagging

Same-Day Shipping

Cost Savings, Lower Inventory

Galvanic Action

Better Self-Healing and Sealing

24-Hour Technical Support

Immediate Answers

Aerosol or Gallon

Good for Field or Shop Repair

Original Brite® Zinc

Proven, Established Industry Leader

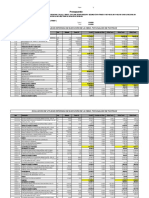

PART NO. DESCRIPTION PER CASE

B-100 12.5-Ounce Aerosol Spray Can 12

B-200 1-Gallon Can 1

SPOT-ON® Touch-Up Pen

Ph: 1.888.992.7483 © Fax: 313.883.4930

briteproducts.com

Sane

FINISH

USAGE

COVERAGE

FLASH POINT.

V.0.C. LBS./GAL.

TEMPERATURE

CONDUCTIVITY

DRY TIME

TOP-COATING

SHELF LIFE,

PACKAGING

SPECIFICATIONS

APPLICATION = Brushing

Aerosol

+ Spraying

Fluid pressure

Orifice of tip

Viscosity

+ Spraying.

Pump

Orifice of tip

Filter screens

Viscosity

PRODUCT DATA SHEET

Single pack, ready to apply, organic zinc compound with 70% zinc

dust in the dry file

Reflective, metallic sheen,

Zinc-tich top coat (or primer) for ferrous and non-fertous surfaces

Gallon: 570 S. F/Aerosol: 40 S. F per can at 1 mil dry film thickness.

55 degrees F. (TCC)

Gallon - 5.21/Aerosol - 5.18

45° to 100° F/Limits (once applied) - 45° to 450° F

73 million ohms per square at 3 mils dry (resistivity)

To touch, 15-30 minutes at 70 degrees F.

1 24-48 hours, depending on atrnospheric conditions, may be

top-coated with acrylic, enamel, silicones, latex or chlorinated rubber

type products. Lacquers or alkyd type should not be used

Aerosol - 12 months / Gallon — 5 years.

Gallons and 12.5-oz. aerosol cans.

Meets requirements of DOD-P-21035A; ASTM-A780-00; ASTM 8117

(1,000 hrs.) MIL-P-26915C; MIL-P-46105, TT-P641, SSPC PS-1, PS-14,

PS-20, PS-22, PS-29 and PS-30. California MIR compliance of 1.11

Use as received in can (str often),

Use as is. Shake well; invert can and clear nozzle after use.

{Low pressure type) Atomized air pressure 50 Ios.

15 - 20 Ibs.

80/1000ths

Reduce in ratio of 8 part:

{Airless type)

30-1/2" (1D) airless type

60? — 26/1000ths, Type of tip Tungsten carbide, reversing,

Complete removal is recommended. If used, 2 30 mesh is rinimurn

No reduction required

Brite Zinc to 1 part xylene or xylol.

Recommended. . Connect hose directly to pump, without filter assembly, ensuring a

hose length of SOft. max. Use least pressure possible. Start at 1500 Ibs.

and increase as required for good spraying properties.

GENERAL SURFACE PREPARATION

Following are recommended minimum requirements for substrate pre-treatment:

Grease or Oils. .....,... Solvent clean (SSPC-SP1)

Rust scale. ......... Power tool (SSPC-SP3)

Mil scale. Sandblast (SSPC-SP6)

SCOPE. Damaged areas caused by cutting, welding, drilling or abrasion.

‘SURFACE PREPARATION On areas to be repaired, by brush or spray, apply at least two coats,

& APPLICATION to achieve a 25 to 3.0 mils, dry film thickness, Where feasible, first coat

should be applied within two hours of the damage to the galvanized

surface to prevent oxidation of exposed areas. On areas damaged by

welding, remove any weld spatter by wire brushing or equivalent be-

fore use of Brite Zinc, Repair material should extend at least 3" beyond

the edges of darnaged areas, to ensure continuity of galvanic action,

WELD-AID PRODUCTS

14650 Dequindre, Detroit, MI 4

}8212, USA - Ph: 1.800.935.3243 - Fax: 313.883.4930 - www.weldaid.com

También podría gustarte

- MEJORAS INFRAESTRUCTURA L1 METRO LIMADocumento8 páginasMEJORAS INFRAESTRUCTURA L1 METRO LIMAFranklin Alarcon SilvaAún no hay calificaciones

- Certificado de TrabajoDocumento2 páginasCertificado de TrabajoFranklin Alarcon Silva50% (2)

- Reporte Semanal de ObraDocumento16 páginasReporte Semanal de ObraFranklin Alarcon SilvaAún no hay calificaciones

- Organigrama de ObraDocumento1 páginaOrganigrama de ObraFranklin Alarcon SilvaAún no hay calificaciones

- Unidad 1 - Gestión Integral de ProyectosDocumento66 páginasUnidad 1 - Gestión Integral de ProyectosFranklin Alarcon SilvaAún no hay calificaciones

- Expedientes técnicos túnel BenavidesDocumento24 páginasExpedientes técnicos túnel BenavidesFranklin Alarcon SilvaAún no hay calificaciones

- 1 Presupuesto - Tramo 1. Evaluacion.01.12.20Documento4 páginas1 Presupuesto - Tramo 1. Evaluacion.01.12.20Franklin Alarcon SilvaAún no hay calificaciones

- Acta de Entrega de MaterialesDocumento2 páginasActa de Entrega de MaterialesFranklin Alarcon SilvaAún no hay calificaciones

- Metrado en Formato (Autoguardado)Documento21 páginasMetrado en Formato (Autoguardado)Franklin Alarcon SilvaAún no hay calificaciones

- Listado de Equipos Calidad IcDocumento1 páginaListado de Equipos Calidad IcFranklin Alarcon SilvaAún no hay calificaciones

- 03.0 Cronograma de TECSIDELDocumento3 páginas03.0 Cronograma de TECSIDELFranklin Alarcon SilvaAún no hay calificaciones

- 06.0 Reporte Recepcion en ObraDocumento1 página06.0 Reporte Recepcion en ObraFranklin Alarcon SilvaAún no hay calificaciones

- Listado InstrumentacionDocumento4 páginasListado InstrumentacionFranklin Alarcon SilvaAún no hay calificaciones

- Tabla Equipos BenavidesDocumento4 páginasTabla Equipos BenavidesFranklin Alarcon SilvaAún no hay calificaciones

- Acta de EntregaDocumento2 páginasActa de EntregaFranklin Alarcon SilvaAún no hay calificaciones

- Acta de EntregaDocumento2 páginasActa de EntregaFranklin Alarcon SilvaAún no hay calificaciones

- Propuesta Dossier FinalDocumento48 páginasPropuesta Dossier FinalFranklin Alarcon SilvaAún no hay calificaciones

- Listado de Equipos Calidad IcDocumento1 páginaListado de Equipos Calidad IcFranklin Alarcon SilvaAún no hay calificaciones

- Oe 03 Desmontaje de EstructurasDocumento5 páginasOe 03 Desmontaje de EstructurasHumberto Israel SanchezAún no hay calificaciones

- 1.-Presupuesto - MacusaniDocumento2 páginas1.-Presupuesto - MacusaniFranklin Alarcon SilvaAún no hay calificaciones

- Acta de Entrega de MaterialesDocumento2 páginasActa de Entrega de MaterialesFranklin Alarcon SilvaAún no hay calificaciones

- Ppto CUZCO FINALDocumento4 páginasPpto CUZCO FINALFranklin Alarcon SilvaAún no hay calificaciones

- Matriz de Comunicaciones IRZADocumento12 páginasMatriz de Comunicaciones IRZAFranklin Alarcon SilvaAún no hay calificaciones

- Informe Semanal 47Documento13 páginasInforme Semanal 47Franklin Alarcon SilvaAún no hay calificaciones

- 1 Presupuesto - Tramo 1. Evaluacion.01.12.20Documento4 páginas1 Presupuesto - Tramo 1. Evaluacion.01.12.20Franklin Alarcon SilvaAún no hay calificaciones

- Plan de inspección para reparación de enrocado y murosDocumento1 páginaPlan de inspección para reparación de enrocado y murosFranklin Alarcon SilvaAún no hay calificaciones

- Requerimiento de 11.11.2019Documento3 páginasRequerimiento de 11.11.2019Franklin Alarcon SilvaAún no hay calificaciones

- Matriz de Comunicaciones IRZADocumento12 páginasMatriz de Comunicaciones IRZAFranklin Alarcon SilvaAún no hay calificaciones

- CR00 04 ES PR 0551 - 00 Reparacion ConcretoDocumento9 páginasCR00 04 ES PR 0551 - 00 Reparacion ConcretoFranklin Alarcon SilvaAún no hay calificaciones

- Lookahead Semanal - 51Documento75 páginasLookahead Semanal - 51Franklin Alarcon SilvaAún no hay calificaciones