Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Manual de Operacion

Cargado por

Xavier Hernandez100%(1)100% encontró este documento útil (1 voto)

206 vistas41 páginasFresadora

Derechos de autor

© © All Rights Reserved

Formatos disponibles

PDF o lea en línea desde Scribd

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoFresadora

Copyright:

© All Rights Reserved

Formatos disponibles

Descargue como PDF o lea en línea desde Scribd

100%(1)100% encontró este documento útil (1 voto)

206 vistas41 páginasManual de Operacion

Cargado por

Xavier HernandezFresadora

Copyright:

© All Rights Reserved

Formatos disponibles

Descargue como PDF o lea en línea desde Scribd

Está en la página 1de 41

i

CONTENTS

1. SAFETY INSTRUCTION

2. APPLICATION

3, STRUCTURE

4. OPERATION

5. MAIN PARAMETER

6. LUBRICATION

1.TRANSPORT, INSTALLATION AND TRIAL RUN

8. MAINTENANCE

9, UNIVERSAL SWIVEL HEAD ADJUSTMENT

10, EXPLOSION DIAGRAM

1. SAFETY INSTRUCTION

1, Read and understand the entire instruction manual before ope

ne

machine

i 2, Always wear approved safty gogglesface shields while using the

machine

4. Make sure the machin is properly grounded.

4 Before operating the machine, remove te, rings, watches, other

jewel, pu the long fai safc ha ring operation. Do not west

loves and koep the sleeves and edges of he work uniform tight

5 Keep he floor around the machine clean and fc of scrap material oi

sd prea

6 Keep machine guards in plac at all times duing operation, 1f

removed for maintenance puposs, use exzeme caution and replace the

guard immedi

17. Do nat over reach, Mainain a balanead stance a

operator donot fil olan aginst blades o othe moving pas

4. Adjust oF mainuin the machine when disconnecting with power

spel.

9. Use the right tol Dost fore ato o tachment to da job which

times so that

it was not designed for.

10, Make sure the switch of the motor is inthe OFF postion before

comecting the machine with the power svpply.

11. Keep visitors safety distance away from the work area,

12, Never attempt to operate or adjust machine when program i not

understood,

1B. Keep fingers away trom revolving parts and cutting tools while

‘operating, machine.

‘pease carefully read the operation manual fo instalation and operation

‘of the achine,

| Check the locking handles and electrical equipments are normal, si

pounding wie comets wih round relly

2. APPLICATION

‘hw machine can be wid fr ming spur scar and tlic eins)

gens, various opiral sures for example tes of rit dil, and sso

all any angle surice through sviveling the fot haf sphere of ming

fen (The milling hes consti by two 45" ides) Tes Kel machine

tool fr machine, nsrument, moter and 9 on

14, Do not attempt o adjust or remove tools daring operation.

15, Always keep cutters sharp

16. Keep your hands away fom he high sped tring, handed.

17.Must pour the machine cil into the gear box when il is lower

than oll gauge

18.It is forbidden to process flammable and aplosive metal, for

‘ample : pure sluminum, magnesium and soon.

19.The machine should never be used in lammable, explosive or

humid environment

20, The machine should be disassembled and arsembled supported by

the lifting mechanism wit suficient bearing capacity

21, Make sur thatthe operating site should kept well ventilated. Ie is

recommended that ventilation equipment should be provided on the

‘operating sie

22. Failureto comply withall these warnings may ease serous injury.

3. STRUCTURE

| Themachine consis of bse, clu, 0 Sv

"element ube sadae and colt, (ig)

4. OPERATION

ead, am, electrical

—4.1spndte ig. 1)

|The power of apndl ie pased through gor onthe motor and. siding

| gos tothe double ape gars ofthe spindle,

4. Speed change ofthe spindle: Tum the sped change handle ofthe

gearbox according to diferent working conditions to select target

"Caution: Stop motor before changing speed

4.12 When milling, ty to reduc the length ofthe ran and tol, and

“ghten all moving pats which it docs requie movement fr example: am,

4.13 When horizontal miling

13:1 Try to lean the table md mice part towards the

ohn

4.132 Try to install miling cater towards the rootage of milling rank handle aucomaticaly disengage when the table vertically

tar.

42 peat change of table feed

42.1 Feoding box

Feeding box is nstaliod under the saddle tas eight ifferentfesting

speed by tuning the sped change handle @. I's eay to operate them.

42.2 Longitudinal eed of able

“Two hingwhecls are at two ends of the tbl

Power fee handle @ control the power elutch work or nt) sin he

side of beable conros he able ae, "igh nd “stop. The sop

Mock @ is djs and locked to the wrget postion.

4423 Gros fend of table Cros eed handle of ables in onto the

swe.

423.1 Manual fed

. 423111 Power feed handle ® isin the neural poston.

42.1.2 Tum te bandwhe! in front of he sda, the tbl wil move

. foroward backward

42.3.2 Power fed

“Table will move forward or backward when adjusting power fed

hundle © up or down.

“WARNING:

‘When chaning table feeding oped, he power chic must ben nal

poston.

42321 Fintadjus handle @ and © in petal position

42.322 The feeding moor runs ile

42323 ju speed change handle @ o selec target pee

42324 Then adjust bande © or © to tage cretion finaly

443 Power vertical fed ttre ison the lof the knee. (XQ6226B

only)

‘44 The kawe travels restricted inthe extreme postion by meas of lini

:

WARNING:

The table can not vertically feed in vertical direction when the

‘handle is foked. The locking handle and vertical movement of

fmerloc.

“Must losen the locking handle before vertical feed,

Disengage the locking handle when vertically feeding.

‘Shut off machine inmmedatly if malfunction occurs and ask

10 repair it

BEARING CHART (Fig2)

5.MAIN PARAMETER

i Wane | ‘Modal 7 ‘Moser

i Besrg ees az 7 ) Abr

2 on i [Mies vetal ing aa oma"

3 61908 + be

+ — 7 Spindle per 5000

z ‘O08 7 Spindle speed amber tens

6 ow 1

7 ORE T Spindle speed range—s06ont7, {160048 1920r.

8 rae 2 ‘Bistnce berwen spindle a

9 FHSAC 7 sd oaton od cote 0~44men-0~17 816

10 Bearing TaBACS 2 -

Distance between

Tr Tes SNOT 7 120mm ~ 6nd -U2"~

spindle and table

Bearing TaCZ +

5 Bearing Gia RZ T Swivel sage of =

i ewig i808 z lig Bes

5 om T E 7 aie

oie 120mm %26mm-0" 10-1

16 ewig Gino aR 2 5 (270amx260mm special)

7 ‘Bearing e907 z

a ‘om 2800-23-12" C11"

16 Being wRz 3 ee

9 Dexia 062 7 =

20 Bearing oe r .

2 Beating ao r e ecu) aa

2 Beating 61908 z ost

2 Bearing 206, 2

ars

2 Beating 190428 é

3 Bearing or T 160

6 Bean coed T 1700 (XQ62268)

6. LUBRICATION

6.1 Lubvicting of must be clean, nonscd, snkydrous and no bard solid

6.2. Gear box, feeding box ar lubricated with engine oil (No.6 cil)

our oil after checking the oils lower than il gauge on tin

CChange oil anes 3 monts for new machine, change ol once 6 months

Ie.

6.3Lubricate lead saddlesable guideways, saddle-knee

_Bideways, knce column guisewsy' with No.46 engine el four times every

shit,

64 Lubricate spindle rolling bearings and gear in heedstock with

NOS MoS2-Li grease. Change the grease once a year for spindle rolling

bearings.

‘Change the grease once fal a year forthe gear of

665 Hand pump is installed on left of the sad, it is centealization

lubrication forthe saddle and pars ofthe table. Pll tout twice every shi.

our ail nto hand pump on time, and check the oil is lower than oil

ge.

headstock,

7. TRANSPORT, INSTALLATION AND TRIAL RUN

“The tempersture range of transportation and storage of the machin is

between 2510-4557,

711 Transportation

‘Must load or unload machine complying with outer sgn onthe packing

box. Any impactor vibration is prohibited. Must open the box carefilly,

‘there it wil seatch the paint on the machine surface. After opening the

‘box, check all the accessories according to the packing list, check whether

there is something wrong or damaged, please inform dealer or manufacturer

‘ntme in order osoive it wel, then convey the machine with fori. Please

set a steol wire rope according to Fig when conveying the machine with

crane, and insert some pads or soft cloth between the machine surface and

the tel wire rope, and ask for help if necessary during the transportation,

Caution:

1. The stecLwire rope should not couch machine surface, cach hand

lever, handle and handwheel Do put wood block oF soft eloth on the

interface between the steckwire rope and the machine edge fo avoid

damaging the paint

2, Move worktable tothe front end of the knee before conveying the

machine withthe crane, and keep the two ends of table on the knee have

the same length, tighten the longitudinal & cross locking handles at the

same time,

172 tostalaion

In order to keep machine steady and high machining precision, must

install machine on the concrete foundation, which should be built according

to the dimension ofthe foundation Fig, The foundation should be Bilton

solid sll. The machine will be put on the foundation after itis already dry,

then fx the bolts on the concrete, must correct it carefully, make sure its

level and the allowance is under 0,04/1000 mm in cress and longitudinal

directions after ighting the bolts.

13 Teal nn

173.1 Before tral ru, please clean te antiust oll on some pats ofthe

‘machine carefully, hen coat thin bricating lon the outer surface.

73.2 Loosen locking handle in three directions (X, Y, Z) of machine

before the ial run

73,3 Pour lubrication ol into the gearbox, then do an overall check,

734 Check whether each handwhes! and handle of machine is reliable

snd flexible,

73.5 Please check whether the main motor turns right and whether the

feed motor phase sequence is consistent withthe main motor afer starting

the spindle,

‘74 Teil ron First start to run ile atthe lowest speed for more than 30,

minutes, then increase the speed sep by sep and check whether the speed

change structure is exible & reliable.

Caution: Care mast be tsken when loading or unloading the

‘machine during the transportation.

8, MAINTENANCE,

8.1 Toble-sadde guideways gib adjustment Fig.5)

8.1.1 Remove al it (om sre)

8.1.2 Loosen the setzcrew ofthe gis small end.

3.1.3 Turn the adjusting corew of the gids big end clockwise while

moving the table until sight drag ie fe.

8.1.4 Tighten the setscrew of small end.

82 Saddlo-knee guideway gib adjustment.

82.1 Remove all i (fom area),

8.2.2 Remove chip wiper guards and wiper,

182.3 Loosen te stserew of the gb’ smal end.

824 Tum adjusting serew of big end clockwise while moving the

sada until slight drag is fl

825 Tighten the setcrew of small end

8.26 Replace chip wiper guards and wiper.

83 Adjust the backlash of the knee-column guideways with setscrew

"1" and"2" while moving knee wat slight drag is fl, tighten the knee with

the locking handle "3" when ke rach target position. ig)

8.4 Lead screw backlash adjusment. Fg.)

8.4.1 Adjust setscrew "2" fneecssary until 0.1-0.12mm is gotten.

84.2 Tighten the locking screw "I" on seserew "2" finally.

8.5 Ram guideways gib adjustment

am gudeways gib adjustment i the sime as table» sade gudeways

adjustment

£6 Troubleshooting

‘The following chart contins some typical probable toubies of

‘operation according 19 the possible cause(s)and remedies for each tem,

‘TROUBLE POSSIBLE CAUSES REMEDY

1LPoor contet om the

Spline doer not rotate | wie

2Poor motor

heck the site.

Repair oF renew motor,

‘he ewich Knob ind

ater in rong pon.

Gib tips to teh.

‘Tanlefecds in versen, | improper tackash of |1.Releae gi

rou longitudinal post | crews [Agjst them

unsediy. snot wo brent |e lubicton,

f.necamp.

Vinetve when [2Selct proper cuing

smachining. lye ccording to

Bearing ia gear bor

pore lLonteinsuriient, —/.Pour

Spindle bearings |.Grene is isumicent. [LM grease,

too bet Fx to Adjustment the bearing

188 Preventive Maintenance

To ensure the accuracy of the machine and prolong life of the

‘machine we offer the following preventive maintenance chars.

Frequens ea

Lt necessary fo ol each Inbrenon point before

operon.

fat is mocetary to release the clamps clens and Inrite table

Per operation.

JAswitch off power source before Invng.

Daly

[Check al the gibe and adjust them if weeny.

[check all the backlash betnen serena and

Monthly

check seca wie, plus switches at leat once 4 year

ro ave toreing or weering

9. UNIVERSAL SWIVEL. HEAD ADJUSTMENT

921 Horizontal ad vera poston of te pind (Fig 8) |

9.1 Spindles inthe orient oson whe fra an hind boxes

of te swivel has al at an ane 0

91.2 The spindle is in the vertical poston when foward box

revlvesto the angle 180"

9.13 To expand the mechinng range to rise the spindle at is ia

from norma positon by revolving hind box an

Forward and hind boxes must postion precisely with positioning pin

hile the swivel hesd is in the horizontal or vertical pesiton, in order to

‘nsure vertical and horizontal precision of the spindle to uble, the

positioning pin must be put into locating hole only, otherwise dont force it

Imo the locating hole t avoid damaging the junetion plane.

9:2 Right and let tlt of the spindle 9)

Hind box ofthe swivel head revolves an angle 90" clockwise or counter=

clockwise. The machine will expand the longitudinal working range.

193 Revolve the spindle in horizontal plane. (Fig 10)

“The spindle with the support may be revolved in horizontal plane for

enhancing rigidity of tol bar. When adjusting, must revolve forward box

and hind box to the different direction The angle of the spindle is decided

by adjustment of forward box and hind box. The adjustable angle is

calealated. by the following char.

‘The formula for calculation is:

cot B =2c08 8 -1 a= igh

© ——Angle which is between the axis of spindle and cross

movement of table,

—— Forward box Angle

a—— Hind box Angle

For example:

1)eut4s* —Dextrorotation

Hind Box © 24° 28 11" (coumerclociawise)

Forward Box 65° 31° 49" (clockwise)

2)et30" Levorotation

Hind Box © 15° 32" 32° (clockwise)

Forward Box 42" 56' 29" (counterclockwise)

CAUTION: Dont loosen the locknut of the swivel head too loose

to prevent the swivel head from falling down quickly to damage the table

snd pats.

wear) s 4

30

0500

KY

cin

Adjusting seven,

Fig.5

Fig.6

Pig.d 7

Fig

ind bor Forward tor

or

ACCURACY LIST

\ [no Teme “rtsangs | MRE

pets Sighs of verted a soon | oor

8 1 [eon ot ce owns | Rawson | 55

a . aa

Totes so lam | ace esa

2 Vs iongindint | 8S] onc

7 ae Ta coe

a [ote fomess 0061000 | poh.

fiesta Teatro lle woos foo

5 |eetorminteent [ean te | ot

a sox wn

4 fosccaite emernan ne vans | ot

ee Stmemeaeie | tame | ccd

7 paiva maeERE —Towsaw | acy

| rovetinte two [acon [anesam [ot

rrinteowienwtee | ningmaima | 4) | oy

Pet feng amet

: eg oe

fo] Prmieicemessintnains [ose |) a

ax | Pallciybeteenrbe — Jacoss Jsooure | ct

romero ese [biota [baoven0 | 5 2

PACKING LIST

NO.

NAME

‘MODEL

Quiy

Machine

‘Milling chuck

sets

Toner hexagon spanner

56. 8512

Bach 1

‘Sleeve miling arbor

18040/32

Nut washer

MI6 16

‘Tool bar

‘Adapter shaft

Support

Wreneh

SE-10 $16-18 S21~24]

Deawbar

Foundation bot

MI6x450

Hexagonal socket yl

head serews

12x30

Spanner

2124

Operation manual

‘Accuracy test list

Packing list

10, EXPLOSION DIAGRAM

01. Column & base part

02 Knee part (A)

(2, Knee part (B)

Power lifting & falling structure

03, Table pat

04, Feeding box part

05, Ram part

06, Universal swiveling head part

09, Hanger part

01 Column & Base part

~~

[01 Column & base part

Of Column & base part

ie. fi wo]

oer Ajesting 02 2

1002 n r

1008 ile 3

oe Teporsion i

1008 10 Retaining ring :

108 ae shaft n

Sat t TXT Ore pen bard ate 7

a ; “HOY 40 Coolant ump 7

a 4 Uaioe int +

1010 2 =e £

ott TITRE fe, sock heed ale . voting sTeee 2

Ti cette 7 Taneeting sibe 7

101s Tiek bad sree o Fined eat 5

a ee + TIS for. eockt bead bale 5

a ee + Coolant t

106 Back plate n Gover alate .

1017 TEKIN Grae recessed pan head seren ie .

HEX Hex eect be T

an - Flat water

o1018 * 7

coro Tos Henan bale +] HOXH Haren 1

yore Spring shor t ey "

ion . o

overs Ti pee 2

vor HL ster 2

e035 over t

oan Wien ine ni

ovr? om .

ooze Bonde «

oar Teching sien z

|02 Knee part

02 Knee part

02 Knee part (a)

02 Knee part (A)

“02001 AWE2S Bal rob 1 Lid

a = : ote 7

08 Handle Laver 1 if

ie 1080 ai

1008 ‘WEX20 Setscrow with tat end 1 Jew Ls

ene = iC 02092. Distance sleeve T

02007 ‘Shaft 1 eee 1

02008, TUXG Hen, eetucren with flat end 7 1

wate Terie 1 at ;

andle oeat i oc ivan for a

‘a2015 WOX12 Hex. eocket bead 1 “one? WEXE Rex taper end setscrey T

om a £ 2108 are T

07018 ene $2104 4x30 Wrist T

30 Sa i aE ae i

‘02021 é at “ - 02108 T

02022 a 2 ne = * . 02109 7

‘02024 = Ls ont

02026, five kt O21

02027 Niper T kd :

02 Knee part (A)

02 Knee part (A)

we Teas of ee we 7 ihe ae a

om Ta Brel for bale 1 a oo 7

0 1 00 WOKE Tan Hit we eee —

1 08 THRE ove racueed pb a

HX Si Z 07033 Pressure plate

2 07034 7

TOT he, seket bad ble . ne i

10 Masher - 02038 Niper 7

1 08) are pe 7

H 08 a 7

H 039 HOG fer Het t

H 2000 Hox Oi op 7

30X62X16 Bearinn 4 02041 5X50 Oylinder pin a

Prenure cover H om Clean sal 7

TaN ar eee veer fal Ma 3s ce Sere i

20 Flatt 1 ee tele 1

Elevating eer 1 -| 22045, cy 7

Xi6 He 4 ms Wout ae |

Ht E031 op 1 0 tale :

a oie edie arp Hi

‘Stanchion, 1 2049 Cover plate 2

TEED fe, eset 1 aes edie 7

1 2051 Sate 1

s on Dat Fit hy 1

ito aiden H ess TRIO Hn oper en steer 7

ter 1 2044 1

Tex sine 4 085 1

‘luteh : 02086 ‘WX10 Wer. socket head bolt =

aia u es? ing blag 1

Tanied an 1 088 Boxes? tearing 1

02 Knee part © 02 Knee part @

Power lifting&falling structure Power lifting&falling structure

02 Knee part (B)

Power lifting&falling structure

02 Xnee part (B)

Power lifting&falling structure

“3A 0, T5ke Hoter 7 07030 ‘Sout a

z oo Sonia é

@ 02040 Tarai T

1 oa Te er :

i ir tar .

7 oe eae 3

= i EECE :

om . wow fark 7

sre TK a ‘ i San mare :

oa ea Brine H ee

ov cata i ce :

0 Bins Ta z cnr c 2

ro i om Brena fy ;

a i tre en ;

ae Tint 7 wr ST ;

or se z sr WT er te ta TE 7

02 Knee part ®)

03 Table part

Power lifting&fal i

ling structure

03 Table part

2}

|

a

o

2

6

<

2

3

03 Table part

03 Table part 03 Table part

st — % t a

essa i a0 5

weit i om 7

nie | t 82 1

oes i 3809_| We ere vot 2

wa 7 aa & 1

7 oy Tit tar i

ble ela i eau 5 :

WHEKUOXIS AAjorts 7 03037 HOXI6 Her. socket head bolt 13

7 aa Sa 1

1 wen Ba Plt z

Tae SRi8 Portlet te a

a es CO ar z

HR anaes 5 es : :

os 1980 — cas ;

THA anes] inbeating pe T og Bevel gear :

oie 7] ae Baers Ta i

WX! Elbow : OEE x

pee 7

Tie eo a :

7p or i

a i

[ie me z

20m TONES tn eta Bead Bo a

pone BS ta a

2s tbe i

3 [wt Can re ves |

[air Sie tat i

z [i Sa 7

Et , cecil

|

part 03 Table part

wy we as ee a

7 on dial 2

Den Spit eter i on Taling er z

‘E Plane washer z Cu 8204-7 Bear ing T|

iar i ‘on TAS tree tr sie <

Taek bat 1 oH tas oft i

TOE foree tos Fe 7] [tae 246 tivet a

TORT Btrroy sth hor seh 7 om eae i

TE Saft etnies 7 oa eed seer 7

tear 1 on 2 ay 7

aa 7 ce i

TT Boron te H om 7

RAO Grip i a0 i

i oat 1

Thee bos i on :

Tair ive i 3108 ;

TORR Bree einen 1 ‘2108 i

co 1 ai i

Tar Fe 1 oat 7

TERT Ware vith hon kee Tee | 007 ;

TERRY Gail wine 7 om z

Testioiar 8 7 oa ;

Tine 7 aaie :

WRT ested nT TE 7 om i

Tring ver 7 aia i

Speer H om ;

aie 7 caine 1

‘ 7] ans iw

Tee ei aren 7 one 7

03 Table part

mers

4x63

axes be

ox o3

xen

ox os

axes

wxos

cos

24X03" Gu pipe

14x03 bu pie

f

04 Feeding box part

Be

04 Feeding box part 04 Feeding box part

NE ESTEE

04 Feeding box part 04 Feeding box part

%

wat

oun

cuca

7

00s

408

0?

oe

a4

om

uit

om

oie

om

we

on

oun ‘eth

oe TWX Setvores vith slotted Tat wd

oH 15 Shaft ret

wa

7

| om

oun

ons

one

om

oe

ours a SK¢ Rivet

04 Feeding box part

te Tem of Hee wy

a HHI? Setaeron vith elatied lat ond t

oar MBXEE Sree wer im t

om az

oun o

out z

015, =z Bearing 7

48 TE hate retanieg Fe €

0437 on .

08 Elesing ine 2

0438 BOU-RL Bearing ni

4 ‘eller r

at Gearing beak t

wae ¢

owe 0

ous 55 r

ous TST Hee soot heed bolt r

oH Spline abate 7

ou tear 7

ou om 1

uso esr o

4st wr r

oust ence n

om cover 7

om Wine safe 7

ss t

st 2 t

oo Seaer t

ost Tore veal T

04 Feeding box part

cs i

THD Setveren ith

oo TKO § Ge

win

cen

Tearing book

WATET Su

“G Aetainiog ria for |

06-2 Geena

Gear

Tearing aah

TAeI8 Ona

Shaft

BX per in

Fate

Shing fork

TE Shaft retaining

05 Ram part

05 Ram part

05 Ram part 05 Ram part

05 Ram part 05 Ram part

ro 7 ma ;

sant —| ET ae aa ra +

coer Ta Pie 7 wa z

ra Tee 7 cat ;

oss ae “ west t

cae sti i tee ‘iin ma ;

sor av a oo eae Pratap i

ose TOAWETS i 897 Haare ring :

ome Toeer i cst cf 7

ost i a9 cig ig oe ;

ost 1 oa a er 1

oan a ar Bete vesting i

ost 1 caer inh

ost i ose tr ;

oan 7 set TE Flr t

‘ai ‘ 7 oe ;

ett | free vt sete © oF arr er i

om SIKH Ten we z sr ;

‘ai Tera a 0 i

ost Tass a om 1

eat Tat 7 oo 1

‘st Tet 7 st 1

oes aa i ‘at ;

cee Seer sate i cst 1

m7 wipe i ast ;

cae Tae pit 1 on TR Fora er i

st mare . 8 TB tere ;

tai Tar 3 oat axies One 1

8 Eft 3 tat cig :

05 Ram part

% Tene of Te wy

oo EXE Seterer with elotied FAC ood

00 ‘Spline sate

co oxi

00 Spline hath

Tr etsining ina for tole

a ee

Gis Besrine

Teteraal goer

EEA Irae vive

Wate re

Spline bash

ie

rate bor

0X0 Parallel ey

TEX Sloted counteraueh {lat bend sere

05 Ram part

eee of ie

‘netion

if ting fork

12 Shaft retaining Fie

Sheen

enetion plate

Sifting fork

06 Universal swiveling

head part

08 tniversal

smivel ing head part

sor

oor

om

oot

fi

z,8 /\

e/ \

<3)

anes

Plus

or

xe8 Taper pin with

0

oie

om

om

ons

617

one

Spacer

onz0

evel eer

oma

oar

io

7

HOKE Hex socket

0808

XE Hen

one

ry

26 chock washer

06 Universal s

veling head part

TSXATHTE Dagar eantaet ba

om

on

oie Fiat ey

Sate

Wendie

WoT _Felot ek

TGS Taper pin with ecron treed ood

HO Talet bolt

TEXT Setcran vith slotted toner oe

over

5 tater

Beer

“EXESRTS fogalareontact tal beatin

Ex

EE haer

08 Usiversal swiveling head part

500 Distinee sleeve

t0%85306 Biverial erlindeieat-raller beavin

689 ‘Slansine rine

s

Snindle

fey

HOXIG Hor eeotet teed bolt

Sa. 55

4

{WSEI? Slotted covntareush Flat Rend

09 Hanger part 09 Hanger part

También podría gustarte

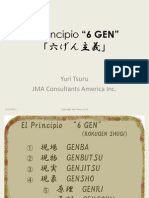

- 6 GenDocumento25 páginas6 Genivantorr2009100% (7)

- Master Hidraulica Esp GatesDocumento388 páginasMaster Hidraulica Esp GatesRoberto Carlos CarrizoAún no hay calificaciones

- Tipos de TornosDocumento8 páginasTipos de TornosNicolas Torres100% (3)

- Wila PDFDocumento108 páginasWila PDFXavier HernandezAún no hay calificaciones

- Iso 14000 ResumenDocumento4 páginasIso 14000 ResumenXavier HernandezAún no hay calificaciones

- GatesDocumento95 páginasGatesToñito NavaAún no hay calificaciones

- Transform AdoresDocumento8 páginasTransform AdoresDynks00Aún no hay calificaciones

- Simbologia de NormasDocumento59 páginasSimbologia de NormasXavier HernandezAún no hay calificaciones

- Manual de CNCDocumento70 páginasManual de CNCJorge Hugo Quezada Carrillo100% (9)

- Normalizacion y AcotacionDocumento27 páginasNormalizacion y AcotacionXavier HernandezAún no hay calificaciones

- Roscas Metricas e InglesasDocumento14 páginasRoscas Metricas e InglesasJohan HernandezAún no hay calificaciones

- Codigos para Torno CNCDocumento7 páginasCodigos para Torno CNCXavier HernandezAún no hay calificaciones

- Calibrador VernierDocumento65 páginasCalibrador VernierXavier HernandezAún no hay calificaciones

- Sensores100 PDFDocumento36 páginasSensores100 PDFLeonel SalaberryAún no hay calificaciones

- Descripcion de Los Impactos AmbientalDocumento6 páginasDescripcion de Los Impactos AmbientalXavier HernandezAún no hay calificaciones

- Regla de La Mano DerechaDocumento6 páginasRegla de La Mano DerechaXavier Hernandez0% (1)

- Manuel de OperacionDocumento40 páginasManuel de OperacionXavier HernandezAún no hay calificaciones

- FAG-Montaje y Desmontaje de RodamientosDocumento114 páginasFAG-Montaje y Desmontaje de Rodamientosgabonilsen100% (2)

- Tabla de Aceros AISI - SAEDocumento11 páginasTabla de Aceros AISI - SAEMauricio_Parra_1594100% (1)

- Catalogo Tubos y Perfiles AcerosDocumento19 páginasCatalogo Tubos y Perfiles AcerosYover PlacidoAún no hay calificaciones

- Manual de Rodamiento, Cara y EspaldaDocumento18 páginasManual de Rodamiento, Cara y EspaldaXavier Hernandez100% (1)

- Manual de OperacionDocumento20 páginasManual de OperacionXavier HernandezAún no hay calificaciones

- Manuel de OperacionDocumento55 páginasManuel de OperacionXavier HernandezAún no hay calificaciones

- Catalogo Bin ZelDocumento59 páginasCatalogo Bin ZelXavier HernandezAún no hay calificaciones

- Manual Del PropietarioDocumento112 páginasManual Del PropietarioXavier HernandezAún no hay calificaciones

- RHN WireRopeHoistsCatalogDocumento11 páginasRHN WireRopeHoistsCatalogJuan Camilo Tejada OrjuelaAún no hay calificaciones

- Iso 14000 ResumenDocumento4 páginasIso 14000 ResumenXavier HernandezAún no hay calificaciones

- Manual de OperacionDocumento46 páginasManual de OperacionXavier HernandezAún no hay calificaciones

- FlujogramacionDocumento31 páginasFlujogramacionALI JAWAHARLAL MAYORGA HUERTAAún no hay calificaciones