Documentos de Académico

Documentos de Profesional

Documentos de Cultura

PipeLine Presentation

Cargado por

UNESDerechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

PipeLine Presentation

Cargado por

UNESCopyright:

Formatos disponibles

PIPELINE OPERATION

Navid Mostoufi

Properties of Fluids

Fluids are materials that deform by any tangential

form and the deformation is continuous.

Fluids are divided into gases and liquids.

Gases are compressible but liquids are practically

incompressible.

Liquids have specific volume but gases will fill out

any volume.

n

F

F

n

F

t

= Pressure ] [Pa P Stress Normal

A

F

n

=

] [

2

m

N

Stree Shear

A

F

t

t =

= Shear Stress

mm Hg 100 For example,

Hg mm 100 P

Hg mm 100 760 P

gage

abs

=

=

gage atm abs

P P P + =

. .

101325 Pa

1 atm

14.7 psi

PA

A

P

relative

=0

P

relative

> 0

P

relative

< 0

PB

B

Fluid density:

For liquids:

water

G S

= . .

For gases

air

gas

air

gas

M

M

RT PM

RT PM

G S = = =

/

/

. .

or

3

m

Kg

V

m

=

3

cm

g

or

2

ft

Lb

For liquids usually SG

20/20

or SG

20/4

is reported

Density of liquids decreases with temperature.

The exception is water for which the density

reaches its maximum at 4C.

Viscosity

V

F

H

moving

stationary

t =

A

F

In general:

dy

dv

t =

Unit of viscosity

s Pa

s m

Kg

m

s N

m

s m

m

N

.

.

.

/

2

2

= = =

=

In CGS system

( ) Cp p 100 = =

H

V

s Pa P . 1 . 0 1 =

s Pa cP . 10 1

3

=

In British system:

2

ft

s . lb

=

Viscosity of water at 20 C is 1 cP

t

Deformation rate

Bingham plastic

Pseudoplastic

Dilatant

Newtonian

Vapour Pressure

At the surface of the liquid, some molecules have

enough energy to overcome the intramolecular forces,

thus emerge the liquid surface and enter vapour

phase.

This is the reason for having vapour pressure for

liquids.

Cavitation

In the flow of liquids, there may be points in which

the pressure is less than the vapour pressure of the

liquid at the flow temperature. In such a situation,

small bubbles form at this point. This phenomenon

is called cavitation.

This is an undesired situation because when these

bubbles go to another point with a higher pressure,

they suddenly disappear which results in a pressure

impulse that could be destructive.

Fluid Statics

( )

x

y

z

P

a

x

P

a

y

P

a g

z

c

=

c

= +

c

P P P

dP dx dy dz

x y x

c c c

= + +

c c c

( )dz g a dy a dx a dP

z y x

+ =

Main equation of the static fluid

gdz dP a a a

z y x

= = = = 0

Stationary fluid:

In other words, the change in pressure is only in

the direction of gravitation.

Assuming constant density, integration results:

z g P A = A

Constant =

= + z g P

Constant

z

g

P

+

or

or

Z

g

P

+

is called piezometric head

gh P h = = 0

at P=0 if

Manometer

Manometer is an instrument that measures the pressure

through height of a liquid.

( )

gh P

z z g P P

gz P gz P

1 2 2 1

2 2 1 1

= A

=

+ = +

gh P 0 P

1 2

= =

: if

h

1

2

When the pressure to be measured is high, a

liquid with higher density could be used.

=

Hg

( )

( )

( ) ( )

gH gh

z z g z z g P P

z z g P P

z z g P P

2 2

2 3 2 1 2 1 3 1

2 3 2 3 2

1 2 1 2 1

+ =

+ =

=

=

o H

2

13.6

5

4

3

2

1

water

20cm

2cm

13cm

Oil

SG=0.9

SG=1.6

Air SG=0.0

Example:

Solution

( ) ( ) ( )

( ) ( ) ( )

( )

( )

( ) Pa

z z g

z z g z z g z z g

P P P P P P P P P P

w

w w w

343 13 . 0 81 . 9 1000 91 . 0

22 . 0 81 . 9 1000 6 . 1 2 . 0 81 . 9 1000

9 . 0

0 6 . 1

) (

4 5

3 4 2 3 1 2

5 4 4 3 3 2 2 1 5 1

= +

+ =

+

+ + =

+ + + =

Flow of Fluid

This happens when shear stress force is negligible

compared to other forces. In such condition, it is enough

to set viscosity to zero in the equations of motion.

In reality, all fluids are viscous. However, in some cases,

such as external flows or flow over surfaces, the effect of

viscosity could be neglected.

Inviscid flow

In inviscid flow, viscosity has no or negligible effect on flow.

Viscous flow

Effect of viscosity could not be neglected in

such flow.

For example, in flow of fluid in the pipes and

in boundary layer the effect of viscosity has to

taken into account.

Reason: The fluid sticks to the surface

because it is viscous.

There is energy loss in viscous flow.

Viscous flow could be either laminar or turbulent.

In laminar flow, the fluid does not mix with

neighboring layers.

In turbulent flow, fluid particles have random motion

and pressure and velocity change randomly.

There are 3 important parameter for

determining the flow:

Length: Larger, results in turbulence (i.e., pipe diameter

or boundary layer thickness)

Velocity: Higher velocity results in turbulence.

Kinematic viscosity: Lower kinematic viscosity results in

turbulence.

v

VL

= Re

If Re is low the flow is laminar.

If Re is high the flow is turbulent.

For example, for flow in pipes, if Re<2100, the flow is laminar.

If Re is close to the limit, the flow is transient.

2

2

2

2

1

1

2

1

h

g

P

g 2

V

h

g

P

g 2

V

+

+ = +

+

Sum of the 3 terms is called Total Head

h

g

P

+

Piezometric head

2

2

V

P + Stagnation Pressure

P

Bernoulli Equation

Static pressure

v

2

2

V

P +

2

2

V

P

Measurement of fluid velocity using Pitot tube

( )

1 2 1

2 1

2

1

P P

2

V

g

P

g

P

g 2

V

+

1

2

v

Where can we use Bernoullis equation?

-External flows in which viscosity could be neglected.

-Determining the height of water jet out of firefighting

hose.

-Calculating the force exerted on a window by wind.

-Internal flows of short distance

-Pressure drop when cross section is changed.

Differential Form of

Equations of Motion

0 =

|

|

.

|

\

|

c

c

+

c

c

+

c

c

+

c

c

+

c

c

+

c

c

+

c

c

z

V

y

V

x

V

z

V

y

V

x

V

t

z

y

x

z y x

Total derivative:

0 =

|

|

.

|

\

|

c

c

+

c

c

+

c

c

+

z

V

y

V

x

V

Dt

D

z

y

x

0 . = V +

c

c

+

c

c

+

c

c

= V

V

Dt

D

k

z

j

y

i

x

Equation of Continuity

Euler Equation

When the flow is inviscid, the viscous forces

are neglected (

ij

=0)

g P

Dt

DV

+ V =

In 3 directions:

z

z

y

y

x

x

g

z

P

Dt

DV

g

y

P

Dt

DV

g

x

P

Dt

DV

+

c

c

=

+

c

c

=

+

c

c

=

|

|

.

|

\

|

c

c

+

c

c

+

c

c

+ +

c

c

=

|

|

.

|

\

|

c

c

+

c

c

+

c

c

+ +

c

c

=

|

|

.

|

\

|

c

c

+

c

c

+

c

c

+ +

c

c

=

2

z

2

2

z

2

2

z

2

z

z

2

y

2

2

y

2

2

y

2

y

y

2

z

2

2

x

2

2

x

2

x

x

z

V

y

V

x

V

g

z

P

Dt

DV

z

V

y

V

x

V

g

y

P

Dt

DV

z

V

y

V

x

V

g

x

P

Dt

DV

In vector form:

g V P

Dt

DV

+ V + V =

2

Navier-Stokes Equations

If fluid is:

-Newtonian (such as air, water, oil)

-Isotropic

-incompressible (V.V=0)

Integral Form of

Equations of Motion

Constant density

2 2 1 1

v A v A =

Single input, single output, constant velocity

2 2 2 1 1 1

v A v A =

Conservation of Mass

} }

+

c

c

=

. .

^

. .

. 0

s c v c

vdA n dV

t

Example: Water flows with a constant velocity of 3 m/s into

a nozzle as shown in the figure. What is the velocity of the

fluid at the outlet? Calculate the volumetric flow rate.

s m

v A Q

/ 0236 . 0

4 / 1 . 0 3

3

2

1 1

=

=

=

t

s m

A

A

v v

v A v A

/ 75

4 / 02 . 0

4 / 1 . 0

3

2

2

2

1

1 2

2 2 1 1

=

= =

=

t

t

Example: Water flows through an equipment

as shown below. Determine the rate of

accumulation of water in the equipment.

3 3 3 2 2 2 1 1 1

. .

^

. .

0

. 0

v A v A v A

dt

dm

vdA n dV

t

s c v c

+ + =

+

c

c

=

} }

s kg

dt

dm

dt

dm

/ 3 . 30

01 . 0 1000 20 12 04 . 0 1000 0

2

=

+ + = t

For Steady Uniform Flow

- Flow is constant with tim

- Single input, single output

- Constant properties at input and output

losses gz

p v

A v gz

p v

A v W

s

+

|

|

.

|

\

|

+ +

|

|

.

|

\

|

+ + =

-

1

1

1

2

1

1 1 1 2

2

2

2

2

2 2 2

2 2

Equation of Energy

- In calculation of pump/turbine work or

heat exchanged during the flow

- Relating pressure and velocity when

effect of viscosity is not negligible

f

s

h z z

g

p

g

p

g

v v

g m

W

+ + +

=

-

-

1 2

1

1

2

2

2

1

2

2

2

1 1 1 2 2 2

A v A v m = =

-

g

v

K

g

u u

g m

Q

h

f

2

2

1 2

=

+ =

-

-

- Neglecting energy loss

- No work given to (taken from) the fluid

- Incompressible flow

Equation of energy reduces to equation of

Bernoulli:

1

1

2

1

2

2

2

2

2 2

z

g

p

g

v

z

g

p

g

v

+ + = + +

Multi input/output

3 1 3

3

2

3

1

1

2

1

2 1 2

2

2

2

1

1

2

1

2 2

2 2

+ + + = + +

+ + + = + +

f

f

h z

g

p

g

v

z

g

p

g

v

h z

g

p

g

v

z

g

p

g

v

Existence of pump and/or turbine

( ) ( )

( )

f T P

f T P

P T

P T s

h h h z z

g

v v

g

p p

h z

g

p

g

v

h z

g

p

g

v

h

h h

g m

W W

g m

W

= +

+ + + + = + + +

=

=

-

- -

-

-

1 2

2

1

2

2 1 2

2

2

2

2

1

1

2

1

2

2 2

Example: Water flows from a reservoir through a pipe

of 0.8 m diameter to the river with a turbine on the flow.

If the level of water in the reservoir is 30 m higher than

the river, flow of water is 3 m

3

/s and efficiency of the

turbine is 80%, calculate the power of turbine. Assume

that the friction loss of the pipe is K=2.

s m

A

Q

V / 968 . 5

4 / 8 . 0

3

2

=

= =

t

g

v

K z

g

p

g

v

h z

g

p

g

v

h

T P

2 2 2

2

2

2

2

2

1

1

2

1

+ + + + = + + +

0

0

0

0

0 0

kW W

Q gh W

m h

h

T T

T

T

T

622 622000

8 . 0 3 4 . 26 81 . 9 1000

4 . 26

81 . 9 2

968 . 5

2 30

2

= =

=

=

=

+ =

-

q

Example: Determine the flow rate of the water in the

venturi tub shown below. Neglect all losses.

D

1

=10 cm, D

2

=5 cm.

m

g

p p

g gz p z g p

p p

b a

12 . 15

2 . 1 6 . 13 ) 2 . 1 (

2 1

2 1

=

+ + = + +

=

1 2

2 2 1 1

4V V

A V A V

=

=

( )

s m V

g

V V

z z

g

p p

g

V V

/ 45 . 4

0 12 . 15

2

16

2

0

1

2

1

2

1

1 2

1 2

2

1

2

2

=

+

=

+

Equation of Energy:

s kg

Q m

s m

V A Q

/ 35 035 . 0 1000

/ 035 . 0 45 . 4 1 . 0

4

3 2

1 1

= =

=

= =

=

-

t

2

1 1 1

2

2 2 2

v A v A F =

Steady-state, single input and output

Mass balance:

2 2 2 1 1 1

v A v A m = =

-

So:

( )

1 2

v v m F =

-

Momentum Equation

Example: Water with a flow of 0.01 m

3

/s

passes through a bend as shown blow.

Calculate the forces experienced by each

support. Neglect the shear forces on the wall.

s m

A

Q

v

s m

A

Q

v

/ 96 . 7

04 . 0

4

01 . 0

/ 99 . 1

08 . 0

4

01 . 0

2

2

2

2

1

1

=

= =

=

= =

t

t

Calculating P

1

( ) ( ) Pa v v p

g

p

g

v

g

p

g

v

29700 99 . 1 96 . 7

2

1000

2

2 2

2 2 2

1

2

2 1

2

2

1 1

2

1

= = =

+ = +

Calculating Rx from

momentum equation

In x-direction:

( )

( )

N R

R

v v m R A p

x

x

x x x

169

99 . 1 0 01 . 0 1000 08 . 0

4

29700

2

1 2 1 1

=

=

=

-

t

( )

N R

v v m R

y

y y y

6 . 79 ) 0 96 . 7 ( 01 . 0 1000

1 2

= =

=

-

Calculating Ry from

momentum equation

In y-direction:

Flow in

Pipes

( )

(

(

|

.

|

\

|

|

.

|

\

|

A

=

A

=

2

2

2 2

1

4 4 R

r

L

P R

R r

L

P

V

z

Laminar flow:

Solution of Navier-Stokes equation

max .

2

1

z z

V V =

( )

|

.

|

\

|

A

= = =

L

P R

r V V

z Z

4

0

2

max ,

( )

|

.

|

\

|

A

= = =

}

L

P R

R

rdr r V

A

Q

V

z

R

z

t

t

8

2

2

2

0

Definition of friction factor

g

V

D

L

f

g

p

h

f

2

.

2

=

A

=

Darcy-Weisbach equation for laminar flow

Re

64 64

= =

VD

f

Power-law velocity distribution

10 9 7 6

10 2 10 10 10 4 Re

6 6 5 3

n

>

Usually n=7

n

R

r

V

V

1

max

1

|

.

|

\

|

=

Turbulent Flow:

Moody Diagram

|

|

.

|

\

|

+ =

f

D

f Re

523 . 2

7 . 3

/

ln 86 . 0

1 c

g

V

D

L

f h

f

2

2

=

3 type of problems:

Q D, , ,c v

D h

f

, , , c v

Q h

f

, , , c v

Known Required

h

f

Q

D

First type of problem could be easily solved without

iteration. Problems type 2 and 3 need iterative

calculation.

2 5

8 3

2 5

8 3

10 / 10

10 3 Re 10

03 . 0

2 . 5

4 . 9

75 . 4

2

25 . 1

5 . 0

2

5 . 0

5

10 / 10

10 3 Re 10

2

9 . 0

5

2

55 . 0

2100 Re

17 . 3

7 . 3

/

ln 965 . 0

62 . 4

7 . 3

/

ln 07 . 1

< <

< <

3

< <

< <

(

(

|

|

.

|

\

|

+

|

|

.

|

\

|

=

>

(

(

|

|

.

|

\

|

+

|

|

.

|

\

|

=

(

(

|

|

.

|

\

|

+ =

D

f f

f

f

D

f

gh

L

Q

gh

LQ

D

h gD

L D

L

h gD

Q

Q

D D

D g

L Q

h

c

c

v c

v c

v c

The units could be wither British or SI

Swamee & Jane equations for solving pipe flow

problems without iteration

Minor Losses

The main losses in pipes are due to friction. In the

connections and fittings, there are losses due to change

in velocity and flow direction which result in pressure

drop. These losses are called minor losses.

g 2

V

K h

2

f

=

Globe Valve

Angle Valve

Sometimes it is common to use equivalent length

instead of loss factor K.

f

D

K L

g 2

V

D

Le

f

g 2

V

K

e

2 2

=

=

For example, pressure loss of a discharge to

atmosphere (K=1) of a 20 cm diameter pipe with a

friction factor of 0.02 is equivalent to the pressure

loss of 10 m of this pipe.

For a piping system whose length is about 10 times its

diameter, minor losses are the main source of pressure

drop.

For a piping system whose length is about 50 times its

diameter, the share of minor losses is pressure drop is

comparable to the length of the pipe.

For a piping system whose length is about 100 times its

diameter, the main source of pressure drop is the length

of the pipe and minor losses could be neglected.

Pumping of Fluids

Pumping is required for overcoming pressure loss in

transferring liquid.

It is also necessary for transferring the liquid to a higher

level.

f p 1 2

2

1

2

2 1 2

h h Z Z

g 2

V V

g

P P

= +

Head of a pump could be obtained from the equation of energy.

p

s

p

d

z

d

Z

s

Discharge Head

fd d

2

d d

d

h Z

g 2

V

g

P

h + +

=

Total Head

( ) ( )

fs fd s d

2

s

2

d s d

s d p

h h Z Z

g 2

V V

g

P P

h h h

+ + +

|

|

.

|

\

|

+

|

|

.

|

\

|

=

=

Suction Head

fs s

2

s s

s

h Z

g 2

V

g

P

h + +

=

NPSH have to be always positive. This means that the liquid

pressure in the suction of the pump has to be greater than the

vapour pressure of the pumping liquid for the liquid not to be

vaporized in the pump, thus, preventing cavitation.

Since h

fs

increases with liquid flow, NPSH reduces with

increasing the flow rate.

Net Positive Suction Head (NPSH)

g

P

h

h Z

g

V

g

P P

NPSH

v

s

fs s

v s

=

+ +

=

2

2

4

Q

NPSH

NPSHR

NPSHA

NPSHA should be at least 2-3 m higher than NPSHR. For

large pumps, this difference could be even higher.

Pump Curve

Operating point of the pump

Operating point

OP with controller

Design

Q

H

S

H

P

Normal

Pump Power

Q . gH Q . P P

P

= A =

Theory

P

P

P

P

Q gH P

P

q

=

q

=

Considering motor

efficiency.

M P

P

M

P

M

Q gH P

P

q q

=

q

=

Pumping efficiency is

around 70%.

Serial Pumps

Parallel pumps

Centrifugal pumps

Centrifugal pumps

Centrifugal pumps

Axial flow pumps

Impellers

Impellers

Mixed flow impeller

Positive displacement pumps

Positive displacement pumps

Positive displacement pumps

Pigging

Cleaning the pipeline.

Dewatering the line (condensate)

Separating products

Inline inspection

Pigging

Pigs

Pigs

Pigs

Pigs

Pig Launcher

Pig Receiver

También podría gustarte

- Steel Pipe Leak Repair ClampDocumento1 páginaSteel Pipe Leak Repair Clampjohn3791Aún no hay calificaciones

- Calculation of Air Content (P/V Plot)Documento2 páginasCalculation of Air Content (P/V Plot)Vimin PrakashAún no hay calificaciones

- Cat 390d Excavator Hydraulic Systempdf PDFDocumento10 páginasCat 390d Excavator Hydraulic Systempdf PDFSebastian Dube100% (1)

- Ansi Bolting Chart 1/2" To 4": Nominal Pipe SizeDocumento8 páginasAnsi Bolting Chart 1/2" To 4": Nominal Pipe SizeUNESAún no hay calificaciones

- Line List PDFDocumento4 páginasLine List PDFAroon CheAún no hay calificaciones

- Gas Pipeline Hydraulic Analysis CalculationDocumento10 páginasGas Pipeline Hydraulic Analysis Calculationbalakrishna100% (3)

- Design Code Requiring Surge AnalysisDocumento3 páginasDesign Code Requiring Surge AnalysisSharun SureshAún no hay calificaciones

- Pipe Thickness CalculationDocumento1 páginaPipe Thickness Calculationananyo_senguptaAún no hay calificaciones

- Kamos Gasket RTJDocumento7 páginasKamos Gasket RTJCahya Adi YeftaAún no hay calificaciones

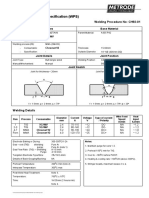

- Welding Procedure Specification (WPS)Documento3 páginasWelding Procedure Specification (WPS)Jignasa ShahAún no hay calificaciones

- TBE Inlet Separator V 2100 FLNG2Documento6 páginasTBE Inlet Separator V 2100 FLNG2halipzramlyzAún no hay calificaciones

- MDPE Work ProcedureDocumento18 páginasMDPE Work ProcedureANURAG YADAVAún no hay calificaciones

- Valve CV Sizing Liquids GasesDocumento24 páginasValve CV Sizing Liquids Gasesmath62210Aún no hay calificaciones

- Chlorine ManualDocumento26 páginasChlorine ManualsuguchemAún no hay calificaciones

- Design Calculations For Pressure VesselsDocumento51 páginasDesign Calculations For Pressure VesselsFuehrerAún no hay calificaciones

- BOPs and Accumulator SizingDocumento2 páginasBOPs and Accumulator SizingSudish BhatAún no hay calificaciones

- Pipe CalcDocumento1 páginaPipe CalcFikri AlhabsyiAún no hay calificaciones

- Pipe Wall Thickness CalculationDocumento1 páginaPipe Wall Thickness Calculationfarhad soopithodiAún no hay calificaciones

- Basic PipingDocumento48 páginasBasic Pipingmackoi BalaresAún no hay calificaciones

- Weld End Preparation at Unequal Wall ThicknessesDocumento4 páginasWeld End Preparation at Unequal Wall ThicknessesDesmond ChangAún no hay calificaciones

- API - Solid Bed AdsorbersDocumento70 páginasAPI - Solid Bed AdsorbersJunaid BaigAún no hay calificaciones

- Water SoftenersDocumento11 páginasWater Softenersadel rihanaAún no hay calificaciones

- Aspen Plus Model For Oil Shale RetortingDocumento28 páginasAspen Plus Model For Oil Shale RetortingMatteo TorinoAún no hay calificaciones

- Properties of Water WorksheetDocumento3 páginasProperties of Water WorksheetTaylor Delancey100% (1)

- PV Elite 2016Documento6 páginasPV Elite 2016RizhwanAún no hay calificaciones

- Natural Gas Transmission Pipeline Temperature Drop CalculationDocumento5 páginasNatural Gas Transmission Pipeline Temperature Drop CalculationCarina QuibinitAún no hay calificaciones

- Pressure Safety Valve Sizing Calculations Vapour or Gas ReliefDocumento3 páginasPressure Safety Valve Sizing Calculations Vapour or Gas ReliefDhananjay NilkuteAún no hay calificaciones

- LNG EconomicsDocumento20 páginasLNG EconomicsAtul TandonAún no hay calificaciones

- Ojt Narrative ReportDocumento10 páginasOjt Narrative ReportAllen Marie RaotraotAún no hay calificaciones

- Thermal Optimization of Ammonia Production ProcessDocumento17 páginasThermal Optimization of Ammonia Production ProcessGarvit Chopra100% (4)

- BD CAL FPSO (HULL) 014 002+M40218 014 002JS 轮机主要设备计算书Documento17 páginasBD CAL FPSO (HULL) 014 002+M40218 014 002JS 轮机主要设备计算书Ben Wong100% (1)

- CalcvesselDocumento11 páginasCalcvesselHami Keserci100% (1)

- Steam Consumption of Heat Exchangers - International Site For Spirax Sarco (Calorifier)Documento7 páginasSteam Consumption of Heat Exchangers - International Site For Spirax Sarco (Calorifier)Prak RemAún no hay calificaciones

- Overfill ProtectionDocumento4 páginasOverfill Protectionahmad santosoAún no hay calificaciones

- Multiphase Pumps Technical Notes SummaryDocumento42 páginasMultiphase Pumps Technical Notes Summaryazraq68100% (1)

- استاندارد برای رنگ آمیزی igsDocumento35 páginasاستاندارد برای رنگ آمیزی igstaherikhareAún no hay calificaciones

- Spec Sheet - Flare Stack DesignDocumento2 páginasSpec Sheet - Flare Stack DesignScylarAún no hay calificaciones

- AL-2208-6'' Pig Launcher Engineering and Fabrication - KNOCDocumento5 páginasAL-2208-6'' Pig Launcher Engineering and Fabrication - KNOCCaptainToniesAún no hay calificaciones

- Pressure Vessel, Boiler, Storage Tanks and Heat Exchanger in Oil, Gas Project. Storage Tanks Heat ExchangerDocumento1 páginaPressure Vessel, Boiler, Storage Tanks and Heat Exchanger in Oil, Gas Project. Storage Tanks Heat ExchangerValli RajuAún no hay calificaciones

- 1st Mar'14Documento1 página1st Mar'14Avinash KumarAún no hay calificaciones

- Petrofac E&C Oman LLC Petroleum Development Oman Datasheet For Globe Valves Rabab Harweel Integrated Project Petrofac Job No.: Es-00002 Pdo Contract No. C311-321Documento21 páginasPetrofac E&C Oman LLC Petroleum Development Oman Datasheet For Globe Valves Rabab Harweel Integrated Project Petrofac Job No.: Es-00002 Pdo Contract No. C311-321raj_hp2000Aún no hay calificaciones

- Lab 5 Reservoir Fluid StudiesDocumento10 páginasLab 5 Reservoir Fluid StudiesIrwan JanuarAún no hay calificaciones

- Pipe Stress Analysis Training Complete CourseDocumento24 páginasPipe Stress Analysis Training Complete CourseFábio GamaAún no hay calificaciones

- TorquingDocumento7 páginasTorquingVicky KumarAún no hay calificaciones

- Liquid Pipeline HydraulicsDocumento74 páginasLiquid Pipeline HydraulicsSimon Kapoma100% (1)

- Quick Opening ClosuresDocumento4 páginasQuick Opening ClosuresJuan CarvajalAún no hay calificaciones

- Calculate Bund Wall Volume for Crude Oil TankDocumento1 páginaCalculate Bund Wall Volume for Crude Oil Tankharsh_1582Aún no hay calificaciones

- P&I Diagram For Butane and Propane Transfer From Ship To IPPL TankDocumento1 páginaP&I Diagram For Butane and Propane Transfer From Ship To IPPL TankPrakash JoshiAún no hay calificaciones

- 1 Process VesselsDocumento4 páginas1 Process VesselsARIANA NICOLE RELIGIOSOAún no hay calificaciones

- Indus - PGD Process Design EngineeringDocumento2 páginasIndus - PGD Process Design EngineeringAmarjeet SandhuAún no hay calificaciones

- Choosing API 650 and API 620 TanksDocumento7 páginasChoosing API 650 and API 620 TanksrajachemAún no hay calificaciones

- 5'' 19.5 - G105 NC50 6.625-3.25Documento1 página5'' 19.5 - G105 NC50 6.625-3.25Hamza LahbibenAún no hay calificaciones

- Test Separator Trailer Prices 2013Documento3 páginasTest Separator Trailer Prices 2013hermit44535Aún no hay calificaciones

- Pipeline Elastic Bending Radius CalculationDocumento2 páginasPipeline Elastic Bending Radius CalculationvictorjosenAún no hay calificaciones

- What Is Differences Between ASME 31.1 & 31Documento2 páginasWhat Is Differences Between ASME 31.1 & 31Cheehoong YapAún no hay calificaciones

- Pipe Wall Thickness Calculation ASME B31.3 Straight PipeDocumento5 páginasPipe Wall Thickness Calculation ASME B31.3 Straight Pipeaike_5Aún no hay calificaciones

- Data Sheet For Mixer M34Documento5 páginasData Sheet For Mixer M34bingminAún no hay calificaciones

- SaipemDocumento48 páginasSaipemaldiemozAún no hay calificaciones

- HDPE Blow Molding Properties OverviewDocumento2 páginasHDPE Blow Molding Properties Overviewtayyabmubarik2417Aún no hay calificaciones

- Da and Dhda Datasheet Master - XLSM - Hpu-Dhda118-4.1 Rev1Documento3 páginasDa and Dhda Datasheet Master - XLSM - Hpu-Dhda118-4.1 Rev1jujuroyaleAún no hay calificaciones

- 3512B B 861bkW 1155bhp 1200rpmDocumento6 páginas3512B B 861bkW 1155bhp 1200rpmFernandez Gonzalo100% (1)

- Sa-516 70 TDCDocumento2 páginasSa-516 70 TDCshazan100% (1)

- TSV and PSV PDFDocumento5 páginasTSV and PSV PDFMetoo ChyAún no hay calificaciones

- Ch15 TestingDocumento37 páginasCh15 TestingKamlesh KumarAún no hay calificaciones

- 06 Differential EquationsDocumento36 páginas06 Differential EquationsViji55555Aún no hay calificaciones

- Mechanical Engineering Fluid Flow ExamplesDocumento22 páginasMechanical Engineering Fluid Flow ExamplesKevin RamosAún no hay calificaciones

- Guide Differential Equations FlowDocumento36 páginasGuide Differential Equations FlowNagendra Samavedula JbpAún no hay calificaciones

- Whole Quran On A Single FileDocumento604 páginasWhole Quran On A Single Fileapi-19772922Aún no hay calificaciones

- BSW, BS,,AF, BA and Metric Tool SizeDocumento4 páginasBSW, BS,,AF, BA and Metric Tool SizeUNES100% (1)

- تارتارينيDocumento15 páginasتارتارينيUNESAún no hay calificaciones

- Learning AcssesDocumento27 páginasLearning AcssesUNESAún no hay calificaciones

- Mechdat 1Documento1 páginaMechdat 1UNESAún no hay calificaciones

- Wall Thickness Inches (Millimeters)Documento12 páginasWall Thickness Inches (Millimeters)ues2705Aún no hay calificaciones

- Thank You For Taking The Assignment-4. Assignment-4: Unit 5 - Week 4Documento4 páginasThank You For Taking The Assignment-4. Assignment-4: Unit 5 - Week 4srinuAún no hay calificaciones

- BFD Corrective - Action - SheetDocumento2 páginasBFD Corrective - Action - SheetJian MinAún no hay calificaciones

- Measuring Gases: Kinetic Theory and Gas LawsDocumento25 páginasMeasuring Gases: Kinetic Theory and Gas Lawsastromaze10Aún no hay calificaciones

- Manual Bomba SheppardDocumento10 páginasManual Bomba SheppardJuan Jose PerdomoAún no hay calificaciones

- Heat Recovery from Boiler Blow DownDocumento6 páginasHeat Recovery from Boiler Blow DownnrvamsiAún no hay calificaciones

- Material Control - Database-1Documento5 páginasMaterial Control - Database-1phani prabhakarAún no hay calificaciones

- Sok0929245 PDFDocumento17 páginasSok0929245 PDFLeonardo Basante HerreraAún no hay calificaciones

- Tugas I - FTF - Annisa Vada Febriani - 2307054003Documento23 páginasTugas I - FTF - Annisa Vada Febriani - 2307054003annisavada02Aún no hay calificaciones

- Experiment No. ME 153 05Documento7 páginasExperiment No. ME 153 05Ryan CalicaAún no hay calificaciones

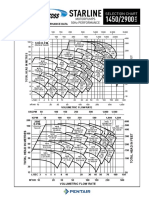

- Starline centrifugal pump performance chartDocumento122 páginasStarline centrifugal pump performance chartThomas KamongAún no hay calificaciones

- Gas Turbine ProtectionDocumento29 páginasGas Turbine ProtectionMohammed Hamza Ahmed100% (1)

- TIU Well Testing LectureDocumento32 páginasTIU Well Testing LectureMarco PlaysAún no hay calificaciones

- Assignment 2Documento2 páginasAssignment 2Venkitaraj K PAún no hay calificaciones

- Henry's LawDocumento6 páginasHenry's LawEn Csak0% (1)

- ES0153-75440100-DBR-0003 Dust ExtractionDocumento19 páginasES0153-75440100-DBR-0003 Dust Extractionraaj bharathAún no hay calificaciones

- Cause & Effect Diagram: Dissolved Gas Flotation Unit, Lku-CDocumento1 páginaCause & Effect Diagram: Dissolved Gas Flotation Unit, Lku-CwipaAún no hay calificaciones

- BN TB Cu Aircooled Had .5 6Documento32 páginasBN TB Cu Aircooled Had .5 6oonAún no hay calificaciones

- Joule ThomsonDocumento10 páginasJoule Thomsonanoopkmr18120% (1)

- Fluid Mechanics: 2CL303 6 Semester Civil EngineeringDocumento14 páginasFluid Mechanics: 2CL303 6 Semester Civil EngineeringkiranAún no hay calificaciones

- Lab # 2 Introduction To Steam BoilerDocumento3 páginasLab # 2 Introduction To Steam Boilerjawad100% (2)

- ID PerencanaanDocumento126 páginasID PerencanaanProyek MotamassinAún no hay calificaciones