Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Neyveli Control Valves

Cargado por

Raja RamachandranDerechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Neyveli Control Valves

Cargado por

Raja RamachandranCopyright:

Formatos disponibles

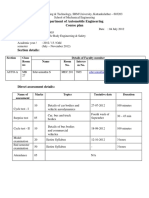

TYPES OF CONTROL VALVES USED BY BHEL

-TRICHY

SUPERHEATER SPRAY CONTROL VALVE

REHEATER SPRAY CONTROL VALVE

SOOT BLOWER PRESSURE REDUCING VALVE

FULL LOAD FEED WATER CONTROL VALVE

LOW LOAD FEED WATER CONTROL VALVE

DEARATOR LEVEL CONTROL VALVE

SUPERHEATER SPRAY CONTROL VALVE

The moderation of temperature of superheated steam is achieved by spraying water into the

steam . Quantity of spray is controlled by the spray control valve . Feed water at about 182

kg/sq.cm pressure and 240 C temperature is regulated and supplied to the system at a

pressure of 170 kg/sq.cm . It can be noticed that the pressure drop across the control valve is

only moderate . However , selection of control valve for this application should be done taking

the following factors into consideration .

Valve will be operating at minimum condition most of the time .As such the valve plug will be

close to the seat for a long period of time causing erosion of the seat and plug .So the

resultant valve offered should ensure around 15% opening at the minimum operating

conditions . Equal Percentage characteristic is needed for this service .

A cage design valve enables maximum pressure drop to take place in the cage rather than

in the seat and thus protects the seat ring . This ensures continuous trouble free

operation .

TYPICAL OPERATING PARAMETERS OF SH SPRAY CONTROL VALVE

Inlet pressure

: 182 kg/ sq.cm

Outlet pressure

: 170 kg/ sq.cm

Operating temperature : 240 Deg. C

Flow rate

: 34.5 Tons / Hr.

REHEATER SPRAY CONTROL VALVE

It handles a higher pressure drop when compared to the

superheater spray control valve.

In order to avoid cavitation , erosion , vibration and noise

associated with this service , a multi stage pressure

reducing valve is needed for this service .

Typical operating parameters are given below .

Inlet Pressure

: 170 kg/ sq.cm

Outlet Pressure

: 100 kg / sq.cm

Operating Temperature : 240 Deg C

Flow rate

: 15 tons / hr

SOOT BLOWER PRESSURE REDUCING VALVE

This control valve design requires high pressure- temperature class

design due to the very critical nature of the application.

Soot blowers are operated occassionally during the day . This leads to

temperature cycling of the valve . In addition to the temperature

cycles , high pressure drops create high noise levels and can cause

excesive wear and vibration to occur in the trim .

Hence a special low noise / anti-vibration trim with better noise

attentuation features is required for this application.

Typical operating parameters for this application

Inlet Presure

: 175 kg / sq.cm

Outlet Pressure

: 30 kg / sq.cm

Operating Temperature : 420 Deg. C

Flow rate

: 8 tons/ hr

FULL LOAD FEED WATER CONTROL VALVE

It handles a relatively large volume of flow . When the boiler is in full load

operation or near it , this valve will be in continuous operation . Since this valve

takes over from low load feed control valve after having achieved a steady

operation : the pressure drop across this valve is less .

A cage guided valve , 12 x 8 size , for this application ( for 210 MW/ 250 MW) and 16

x 12 size for 500 MW plant is used.

A Balanced trim construction enables to meet the high shut off requirements with

conventional actuators .

The valve design should handle large volume of flow ( higher Cv for given body size)

keeping flow velocities very much within limits.

Typical operating parameters for this valve are

Inlet Pressure

: 233 kg / sq. cm

Outlet Pressure

Operating Temperature

Flow quantity

: 228 kg / sq. cm

: 240 Deg . C

: 720 Tons / hr

LOW LOAD FEED WATER CONTROL VALVE

At boiler start up , the feed water is to be fed at low pressure and

consequently the low load feed control valve handles very high pressure

drops . Because of this high pressure drops ,there are chances for the feed

water to flash / cavitate .

The internals of the valves are to be carefully selected to meet these severe

service conditions . The trim is made of hardened stainless steel / SS316 with

Stellite overlay .

A cage guided 6 x 4 size ( for 210 / 250 MW units ) and 8 cage guided

valve for 500 MW plant is used .

Typical operating parameters of this control valve are given below .

Inlet Pressure

; 233 kg / sq. cm

Outlet pressure

: 100 kg / sq.cm

Operating Temperature

: 240 Deg. C

Flow quantity

: 200 tons / hr

DEARATOR LEVEL CONTROL VALVE

The purpose of this valve , as the name implies , is to maintain a correct level

in the deaerator . This valve performs its function by varying condensate flow

into the deaerating vessel in response to load and a level signal . The service

conditions confronting these valves vary directly with the plant load .

The service conditions faced are mild when compared to spray control

valves and low load feed water control valve .

A cage guided valve is recommended for this application .

Typical operating parameters for this valve are

Inlet Pressure

: 19.6 kg / sq.cm

Outlet Pressure

: 13.8 kg/ sq.cm

Operating Temperature

: 49.2 Deg. C

Flow rate

: 523.3 Tons/ hr

También podría gustarte

- Vehicle DynamicsDocumento4 páginasVehicle DynamicsRaja RamachandranAún no hay calificaciones

- Vehicle Body EnggDocumento6 páginasVehicle Body EnggRaja RamachandranAún no hay calificaciones

- Automotive Transmission Systems: Course Plan and SyllabusDocumento5 páginasAutomotive Transmission Systems: Course Plan and SyllabusRaja RamachandranAún no hay calificaciones

- Machines and MechanismDocumento3 páginasMachines and MechanismRaja RamachandranAún no hay calificaciones

- Lesson Plan on Global Warming and Climate ChangeDocumento2 páginasLesson Plan on Global Warming and Climate ChangeRaja RamachandranAún no hay calificaciones

- Thermodynamics - Sunil PDFDocumento5 páginasThermodynamics - Sunil PDFRaja RamachandranAún no hay calificaciones

- Thermodynamics - SunilDocumento5 páginasThermodynamics - SunilRaja RamachandranAún no hay calificaciones

- Manufacturing TechnologyDocumento7 páginasManufacturing TechnologyRaja RamachandranAún no hay calificaciones

- Faculty of Engineering Course Plan for Theory of Automotive EnginesDocumento7 páginasFaculty of Engineering Course Plan for Theory of Automotive EnginesRaja RamachandranAún no hay calificaciones

- Non Traditional Machining TechniquesDocumento4 páginasNon Traditional Machining TechniquesRaja RamachandranAún no hay calificaciones

- Mechanics of SolidsDocumento2 páginasMechanics of SolidsRaja RamachandranAún no hay calificaciones

- Department of Automobile Engineering Course PlanDocumento4 páginasDepartment of Automobile Engineering Course PlanRaja RamachandranAún no hay calificaciones

- CE1017 Lesson PlanDocumento5 páginasCE1017 Lesson PlanRaja RamachandranAún no hay calificaciones

- Sources and Types of Municipal Solid WastesDocumento2 páginasSources and Types of Municipal Solid WastesRaja RamachandranAún no hay calificaciones

- CE1206 Lesson PlanDocumento2 páginasCE1206 Lesson PlanRaja RamachandranAún no hay calificaciones

- CE1006 Lesson PlanDocumento2 páginasCE1006 Lesson PlanRaja RamachandranAún no hay calificaciones

- CE1136 Lesson Plan88Documento3 páginasCE1136 Lesson Plan88Raja RamachandranAún no hay calificaciones

- Sources and Types of Municipal Solid WastesDocumento2 páginasSources and Types of Municipal Solid WastesRaja RamachandranAún no hay calificaciones

- CE1006 Lesson Plan7Documento2 páginasCE1006 Lesson Plan7Raja RamachandranAún no hay calificaciones

- CE1017 Lesson Plan18Documento3 páginasCE1017 Lesson Plan18Raja RamachandranAún no hay calificaciones

- CE1017 Lesson PlanDocumento5 páginasCE1017 Lesson PlanRaja RamachandranAún no hay calificaciones

- CE1020 Lesson Plan333Documento2 páginasCE1020 Lesson Plan333zaidAún no hay calificaciones

- Lesson Plan-CE1016 - Structural Design - Steel Academic Year 2015-16 (Semester Commencing in June 2015)Documento3 páginasLesson Plan-CE1016 - Structural Design - Steel Academic Year 2015-16 (Semester Commencing in June 2015)Raja RamachandranAún no hay calificaciones

- CE1006 Lesson PlanDocumento2 páginasCE1006 Lesson PlanRaja RamachandranAún no hay calificaciones

- CE1008 Lesson PlanDocumento3 páginasCE1008 Lesson PlanRaja RamachandranAún no hay calificaciones

- Lesson 1493762094Documento1 páginaLesson 1493762094Raja RamachandranAún no hay calificaciones

- CE1008 Lesson PlanDocumento3 páginasCE1008 Lesson PlanRaja RamachandranAún no hay calificaciones

- Lesson 1493761977Documento1 páginaLesson 1493761977santhi saranyaAún no hay calificaciones

- Faculty Name: Sucheta Panda: Total Number of Hours 48Documento1 páginaFaculty Name: Sucheta Panda: Total Number of Hours 48Raja RamachandranAún no hay calificaciones

- Lesson Plan Branch-Mca 3 Semester Operating SystemDocumento1 páginaLesson Plan Branch-Mca 3 Semester Operating Systemsanthi saranyaAún no hay calificaciones

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeCalificación: 4 de 5 estrellas4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)De EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Calificación: 4 de 5 estrellas4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe EverandNever Split the Difference: Negotiating As If Your Life Depended On ItCalificación: 4.5 de 5 estrellas4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDe EverandShoe Dog: A Memoir by the Creator of NikeCalificación: 4.5 de 5 estrellas4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe EverandThe Emperor of All Maladies: A Biography of CancerCalificación: 4.5 de 5 estrellas4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceCalificación: 4 de 5 estrellas4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe EverandThe Little Book of Hygge: Danish Secrets to Happy LivingCalificación: 3.5 de 5 estrellas3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnDe EverandTeam of Rivals: The Political Genius of Abraham LincolnCalificación: 4.5 de 5 estrellas4.5/5 (234)

- Grit: The Power of Passion and PerseveranceDe EverandGrit: The Power of Passion and PerseveranceCalificación: 4 de 5 estrellas4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaCalificación: 4.5 de 5 estrellas4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryCalificación: 3.5 de 5 estrellas3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDe EverandOn Fire: The (Burning) Case for a Green New DealCalificación: 4 de 5 estrellas4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureCalificación: 4.5 de 5 estrellas4.5/5 (474)

- Rise of ISIS: A Threat We Can't IgnoreDe EverandRise of ISIS: A Threat We Can't IgnoreCalificación: 3.5 de 5 estrellas3.5/5 (137)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersCalificación: 4.5 de 5 estrellas4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaDe EverandThe Unwinding: An Inner History of the New AmericaCalificación: 4 de 5 estrellas4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyCalificación: 3.5 de 5 estrellas3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreCalificación: 4 de 5 estrellas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Calificación: 4.5 de 5 estrellas4.5/5 (119)

- The Perks of Being a WallflowerDe EverandThe Perks of Being a WallflowerCalificación: 4.5 de 5 estrellas4.5/5 (2099)

- Her Body and Other Parties: StoriesDe EverandHer Body and Other Parties: StoriesCalificación: 4 de 5 estrellas4/5 (821)

- 01 Boq 220KV - Gis - Karanjde - Price Schedule (Consolidated)Documento4 páginas01 Boq 220KV - Gis - Karanjde - Price Schedule (Consolidated)Akd DeshmukhAún no hay calificaciones

- CMO Aluminium Tank Vent Check Valve With Overflow PipeDocumento2 páginasCMO Aluminium Tank Vent Check Valve With Overflow Piped13g0bcAún no hay calificaciones

- Pulverizador 4730Documento858 páginasPulverizador 4730Fernando Sabino100% (3)

- Cutting Speeds & RPM CalculationsDocumento7 páginasCutting Speeds & RPM Calculationsyanuar_adhiAún no hay calificaciones

- 2488 2Documento2 páginas2488 2hogoyoAún no hay calificaciones

- Steam Room Construction & Generator Sizing GuideDocumento2 páginasSteam Room Construction & Generator Sizing GuideasdthuAún no hay calificaciones

- Catalogue Pipe Hangers SupportsDocumento111 páginasCatalogue Pipe Hangers SupportsIlija Runjajic100% (1)

- Attention: Installation GuideDocumento2 páginasAttention: Installation GuideDaniel EcheverriaAún no hay calificaciones

- Student Housing Unit in A Oor Area Without Corridors: ArticleDocumento8 páginasStudent Housing Unit in A Oor Area Without Corridors: ArticleShólànké Ezekiel ShówúnmiAún no hay calificaciones

- Railways - Section 1Documento38 páginasRailways - Section 1ajaydevmalikAún no hay calificaciones

- Modelling of Bridges For Inelastic Analysis: Saiidi@unr - EduDocumento80 páginasModelling of Bridges For Inelastic Analysis: Saiidi@unr - Eduhasan aziziAún no hay calificaciones

- Pressure Vessels Lectures 87Documento1 páginaPressure Vessels Lectures 87Adeel NizamiAún no hay calificaciones

- Domestic Gas PipingDocumento2 páginasDomestic Gas Pipingvalentinlupascu33Aún no hay calificaciones

- Case Histories of Failure of Deep Excavation. Examination of Where Things Went Wrong: Nicoll Highway Collapse, SingaporeDocumento8 páginasCase Histories of Failure of Deep Excavation. Examination of Where Things Went Wrong: Nicoll Highway Collapse, SingaporeThaungMyintAún no hay calificaciones

- Project fixture inventory and drainage designDocumento8 páginasProject fixture inventory and drainage designArch Ronel Magistrado DescargaAún no hay calificaciones

- Stability of Structures Z.J. Bazant and L. Cedolin OUP, Oxford, 1991, 70, ISBN 0 19 505529 2 - 1992Documento2 páginasStability of Structures Z.J. Bazant and L. Cedolin OUP, Oxford, 1991, 70, ISBN 0 19 505529 2 - 1992ciscoAún no hay calificaciones

- Soil Investigation Report: Item Page NoDocumento6 páginasSoil Investigation Report: Item Page NoWai LinnAún no hay calificaciones

- JD 950 enDocumento196 páginasJD 950 ensnorider11Aún no hay calificaciones

- Design of CorbelDocumento3 páginasDesign of CorbelAkshay KumarAún no hay calificaciones

- Alberta Building Code Guide to Energy Efficient Home ConstructionDocumento45 páginasAlberta Building Code Guide to Energy Efficient Home ConstructionAl7amdlellah100% (2)

- Motor Hyundai D4eb-Diesel 2.2Documento91 páginasMotor Hyundai D4eb-Diesel 2.2Igatech Diesel82% (11)

- Cement Mortar LiningsDocumento8 páginasCement Mortar LiningsAshok NarayanAún no hay calificaciones

- Acrow Bridge Table Form (Press)Documento32 páginasAcrow Bridge Table Form (Press)alaaAún no hay calificaciones

- Sound Proofing MaterialsDocumento7 páginasSound Proofing MaterialsLikitha GangaramAún no hay calificaciones

- Electrical Wiring WorkbookDocumento40 páginasElectrical Wiring Workbookrob yeley100% (2)

- Abbreviations and Symbols For Hvac&R Drawings: Iranian Petroleum StandardsDocumento12 páginasAbbreviations and Symbols For Hvac&R Drawings: Iranian Petroleum StandardsRoel FranciscoAún no hay calificaciones

- T & C Fastener Co, LTD.: Certified Material Test ReportDocumento1 páginaT & C Fastener Co, LTD.: Certified Material Test Reportlady romeroAún no hay calificaciones

- CV Curriculum Vitae Mechanical EngineerDocumento3 páginasCV Curriculum Vitae Mechanical Engineerkalpesh yadavAún no hay calificaciones

- Fem PPT 1Documento41 páginasFem PPT 1RAHUL CRAún no hay calificaciones