Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Case Study On Bearing Failure

Cargado por

Ayush JAinDescripción original:

Título original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Case Study On Bearing Failure

Cargado por

Ayush JAinCopyright:

Formatos disponibles

BEARING FAILURE OF BITUMEN PUMP

13P14

EQPT NO

MODEL/MAKE

MECH. SEAL MAKE

MECH. SEAL TYPE

BEARING TYPE

SERVICE

TEMPERATURE

: 13P14

: M/S RUSSIAN

: M/S EPIL

: 1502-52 SPL

: 6216, 7414

: BITUMEN

: 220deg C

BEARING FAILURE OF BITUMEN PUMP

13P14

PAST HISTORY AND CHAIN OF EVENT :

13P14 PUMP OF BITUMEN PUMP HOUSE WAS EARLIER

GLAND PACKED TO ARREST LEAKAGE. AFTER

SUCCUSSEFUL

CONVERSION

AND

GOOD

PERFORMANCE OF MECH. SEAL IN 13P11 & 13P12

BITUMEN PUMPS , IT WAS DECIDED TO CHANGE THE

GLAND PACKING WITH SIMILLER MECH. SEAL IN THIS

PUMP ALSO.

13P14 PUMP WAS SENT TO WORKSHOP FOR

MODIFICATION AND SEAL INSTALLATION ON 29/2/99.

PUMP WAS OPENED IN WORKSHOP AND STEAM

JACKETING IN PUMP CASING DONE. DUE TO NON

RECEIPT OF MECH SEAL, PUMP WAS KEPT OPENED

FOR ALMOST 6 MONTHS.

BEARING FAILURE OF BITUMEN PUMP

13P14

ASSEMBLY OF PUMP WAS DONE ON 22/7/2000, AFTER

RECEIPT OF SEAL.

PUMP WAS STARTED ON 10/09/2000 AND PUMP THRUST

BEARING FAILED JUST AFTER 4 HOURS OF ITS RUN.

PUMP AGAIN SENT TO WORKSHOP AND ITS BEARINGS

WERE REPLACED & SEAL FITTED AFTER CLEANING.

PUMP AGAIN SENT TO SITE AND STARTED ON 25/09/2K

AND AFTER 3-4HRS OF ITS OPERATION, ITS THRUST

BEARINGS AGAIN FAILED.

PUMP AGAIN SENT TO WORKSHOP FOR BEARING

REPLACEMENT.

BEARING FAILURE OF BITUMEN PUMP

13P14

OBSERVATION MADE AT WORKSHOP AFTER

OPENING:

BOTH THE THRUST BEARINGS BRASS CAGES WERE

FOUND BROKEN AND ITS BALLS GOT DEFORMED.

ALL OTHER COMPONENTS OF PUMP AND SEAL WERE

FOUND INTACKED.

THERE WAS 10MM GAP FOUND ON OD OF RADIAL

BEARING AND ID OF BRG. HOUSING, RADIAL BEARING

WAS NOT RESTING AT ALL ON HOUSING.

ANALYSIS:

SLEEVING ON HOUSING WAS DONE ON RADIAL BEARING

PORTION , WHICH WAS CAME OUT WHILE REMOVAL OF

BEARING FROM HOUSING. AS PUMP WAS KEPT OPENED

AT WORKSHOP FOR ALMOST 6MONTHS ,

BEARING FAILURE OF BITUMEN PUMP

13P14

ANALYSIS:

SLEEVE WAS MISSED AND BOTH THE OCCASION

BEARING WAS FITTED WITHOUT SLEEVE. SINCE RADIAL

BEARING WAS NOT RESTING ON HOUSING TOTAL

RADIAL LOAD TRANSMITTED TO THRUST BEARINGS. AS

THRUST BEARINGS ARE DESIGNED FOR AXIAL LOAD

AND NOT FOR RADIAL LOAD , ITS WAS FAILED

IMMEDIATELY.

REPAIR /REPLACEMENT CARRIED OUT:

BEARING HOUSING WAS REPLACED WITH SPARE

BEARING HOUSING AND BOTH THE BEARINGS WERE

REPLACED. NOW PUMP IS RUNNING NORMAL

DAMAGE TO RETAINER

BEARING FAILURE OF BITUMEN PUMP

13P14

REPEATED BEARING FAILURE OF BARARI

PUMP 603P3

EQPT NO

MAKE

SERVICE

TEMPERATURE

BEARING

Past Failure Event:

1996

16/10/96

04/12/97

:603P3

:M/S KIRLOSKAR BROTHER

:TREATED EFFULENT

WATER (BOOSTER)

:AMBIENT

:3311,6311

-New pump provided in BARARI minor Pump

house for boosting up the fire water pressure.

Pump is taking suction from discharge of

603P2 pump.

-Thrust Bearing failed & oil seal damaged.

-Both the bearing (radial & thrust )

damaged,wear ring loose.

REPEATED BEARING FAILURE OF BARARI

PUMP 603P3

15/01/98

19/06/98

-Shaft key way damaged, welding & M/C done.

-Sleeve damaged, gland leak, sleeve made in

workshop.

10/06/99 -Thrust bearing seized & shaft damaged.

25/10/99 -Both the radial & thrust bearing damaged.

08/02/2000 -Bearing & oil seal damaged.both the bearing &

oil seal changed.

06/03/2000 -Bearing & oil seal damaged

Observation1. Bearing housing cover bush, provided for

fixing of

oil Seal,found detached from cover and got rotated.

2. Oil seal found damaged.

3. Radial bearing races found rubbed against rollers

4. Thrust bearing clearances increased.

5. Bearings got rotated and found loose on housing.

REPEATED BEARING FAILURE OF BARARI

PUMP 603P3

09/05/2000 -Overhauling done, bearing Replaced.

24/05/2000 -Bearing damaged.Bearing housing support

plate replaced with thicker plate and

perpendicularity maintained.

19/07/2000 -Bearing failed.Heavy love-joy coupling

replaced with lighter shim pack type coupling.

26/08/2000 -Bearing failed.Pump manufacturer M/s

Kirloskar Brother called and assembly done in

their presence.

18/09/2000 -Bearing failed.Elect.cabling checked, as motor

was tripping at high load.

FLAKING

REPEATED BEARING FAILURE OF BARARI

PUMP 603P3

23/09/2000

-Bearing damaged.foundation bolts

welding done.

10/10/2000

-Bearing failed. Foundation RCC

filling done, to strengthen the

base plate.

28/11/2000

-Bearing & oil seal damaged.Asked

operation to run the pump with

full opening of discharge valve.

08/01/2001

-Overhauling Done, bearing

changed.

REPEATED BEARING FAILURE OF BARARI

PUMP 603P3

29/01/2001 -Pump bearing again failed.Impeller diameter

checked with the data folder of the pump and

found that impeller OD is 14mm higher than

the rated diameter of the impeller

Impeller OD trimmed to required rated

diameter and pump was assembled with

trimmed impeller and new bearing.Now pump is

running since 05/02/2001.

Cause of failure:

Due to higher impeller diameter of the pump it was

developing high axial thrust, which was causing repeated

thrust bearing failure of the pump.

REPEATED BEARING FAILURE OF

BARARI PUMP 603P3

REPEATED BEARING FAILURE OF VDU PUMP 12P5S

EQPT. DETAIL :

Tag. No..

Eqpt. type

Make

Model

Service

Working temp.

Bearing - Thrust

- Radial

Capacity Rated

Minimum

:

:

:

:

:

:

:

:

:

:

12P5S Column bottom pump

Centrifugal pump

M/S Sulzer pump (I) ltd.

ZE-100-4500

Short residue

380-400 Deg. C.

7312 BG 2 nos

NU312

200 m3/hr

90 m3/hr

REPEATED BEARING FAILURE OF VDU PUMP 12P5S

PAST HISTORY AND CHAIN OF EVENTS:

Old Russian Pump 12P5S was replaced in year2000 revamp shutdown.

Pump 12P5S was attended due to bearing failure on 25/08/2000 and

following spares were replaced.

a- Bearing 7312 (2nos) & NU 312 (1 no)

b- Complete Mech. Seal .

Pump 12P5S was commissioned at 17.00hrs on 28/8/01.

At 19.00 hrs. pump bearing failed after a run of 2hrs. As per

production log book Pump bearing housing was found abnormally hot

& steam was coming out from CW out let line. Immediately pump

was stopped & 12P5A was put on service.

Pump 12P5S was opened and sent to work shop for maintenance. the

pump thrust and radial bearings were found badly damaged and

seized on shaft. The following spares were replaced.

REPEATED BEARING FAILURE OF VDU PUMP 12P5S

a.

b.

c.

d.

Bearing 7312 (2nos) & NU 312 (1 no)

Complete Mech. Seal .

Pump Shaft.

Bearing housing cover repaired

On 5/9/2001 at 9hrs pump was started and its bearings again failed

at 1645hrs. event before failure of the pump bearing is as follows

as per production log book.

Pump 12P5S started at 9hrs in presence of MLE. Informed to

SELE. Vibration checked by MLE and found normal at 9.15hrs.

12P5A stopped.

12P5S tripped at 10.10hrs. motor bearing temperature is also high.

12P5A started again.

12P5S again started at 11.15hrs informed to MLE and SELE. 12P5A

also running.

12P5 stopped at 14.30hrs and the load checked from sub station

for 12P5A & 5S and found 250 & 260 A respectively. As per SELE

12P5S load not to be kept beyond 250Amp. So 12P5 restarted at

15.00hrs. all the 3pumps kept running.

REPEATED BEARING FAILURE OF VDU PUMP 12P5S

At 16.45hrs, 12P5S bearing housing found smoking,its lube oil

burnt out, oil cup was out and fumes were coming. Pump

stopped immediately in presence of SPNM(U). M/M & E/M

kept informed.

Observation

-Before opening of pump.

a) Lube oil was found burnt and having bearing wear particle.

b) Coupling DBSE is found 190mm against 180mm.

c) Coupling shims were found distorted and broken.

d) Coupling spaces was found damaged.

-After opening at work shop.

a)both the thrust and radial bearings are found damaged and

seized with shaft ( identical to earlier failure).

b)Shaft found 0.20mm bent at radial bearing seating.

REPEATED BEARING FAILURE OF VDU PUMP 12P5S

c)Bearing cover labyrinth found rubbed with bearing inner race

got damaged.

d)Mech. seal collar found rubbed with purge bush.

e)Deep rubbing marks on Wear ring observed and clearance

1.5mm and 1.0mm found in front & back respectively.

f)Throat bush clearance 1.0mm found.

g) Ovality of 0.05mm found in outer thrust bearing seating.

Repair replacement done.

1.All the thrust and radial bearing replaced with new one.

2.Bearing housing cover labyrinth repaired.

3.Bearing housing ovality removed and bearing center checked.

4.Pump shaft replaced with new one.

5.All the wear rings except case wear ring replaced and its

clearance maintained. Throat bush also replaced and

clearance maintained.

REPEATED BEARING FAILURE OF VDU PUMP 12P5S

6.Mech. Seal faces are lapped and reused as new bellow is

not available,

7.New coupling is issued and hub boring is done, which is to be

replaced along with its spacers.

Suspected cause of failure:

Thrust bearing failure may be due to following reason.

1.Lack of lubrication in housing.

2.Excessive hydraulic thrust on bearings.

3.Improper mounting of bearings.

4.Improper loading of thrust bearing during operation.

Lack of lubrication in housing.

The possibility of lack of lubrication is ruled out as after

failure of bearing there was oil found in housing and it has run

for approx.7 hrs.

REPEATED BEARING FAILURE OF VDU PUMP 12P5S

Excessive hydraulic thrust on bearings.

The pump is single stage and fitted with both side wear rings

and balancing holes and its clearances are also not abnormally

high, which can not create that much thrust load on bearing.

However during starvation of pump thrust balancing of rotor

will be disturbed.

Improper mounting of bearings.

As the pump has run for approx. 7hrs on load and no abnormal

sound or vibration was observed. This possibility may be ruled

out.

Improper loading of thrust bearing during operation

Due to high Distance between shaft ends 190mm (DBSE)

maintained, compared to recommended DBSE of 180mm,

coupling will cause pulling of pump rotor in motor side, which

will result in improper loading of outer thrust bearing.

REPEATED BEARING FAILURE OF VDU PUMP 12P5S

Improper loading of thrust bearing will cause sliding of rolling

elements. As sliding friction of bearing elements, will cause

high heat generation and continue rise in bearing temperature

and subsequent failure of thrust bearings. The failure of

thrust bearing will allow the pump rotor assembly moving in

pump side and it will cause rubbing of cover, purge bush and

case wear ring.

CCRU RGC TURBINE 15KT1

THRUST BEARING FAILURE

The Recycle Gas Compressor (15-K-1) of CRU is

driven by a back pressure type steam turbine.

EQPT. DETAIL :-

TAG NO.

MAKE

MODEL

SPEED

TYPE OF BLADE

STEM INLET PR.

STEAM OUT LET PR.

:

:

:

:

:

:

:

15KT1

EBARA JAPAN

SBHEG4-4

7446 RPM

4 STAGES CURTIS WHEEL

60 KG/CM2

4 KG/CM2

CCRU RGC TURBINE 15KT1

THRUST BEARING FAILURE

PAST HISTORY AND CHAIN OF EVENT

ON 28-2-01, 15K1 COMPRESSOR TRIPPED ON HIGH AXIAL

DISPLACEMENT.

ON 28-2-01, 19.10HRS COMP. ROLLED AFTER CHECKING.

TRIPPED AT 6000 RPM ON HIGH THRUST BEARING TEMP &

AXIAL DISPLACEMENT.

AFTER ANALYSIS THE PROBLEM, DECIDED TO OPEN THE

THRUST BEARING FOR CHECKING.

OBSERVATION

THRUST PAD (ACT.SIDE) FOUND COMPLETELY WIPED OFF.

NO OTHER ABNORMALITY OBSERVED.

CCRU RGC TURBINE 15KT1

THRUST BEARING FAILURE

REPAIR REPL. DONE

ALL THE 6NOS ACTIVE SIDE THRUST PADS REPLACED.

COMPLETE LUBE OIL REPLACED AND FILTER CHANGED.

SOLO RUN OF TURBINE CHECKED.

TURBINE ROLLED ON 6-3-01 AND FOLLWING

PARAMETER WERE OBSERVED

AXIAL DISP.

TH. BEARING TEMP

CHEST PR.

1ST STAGE PR.

:

:

:

:

0.23/.19

85,91,85OC

25 KG/CM2

19 KG/CM2

FROM 1ST WEEK OF MAY THESE READINGS HAVE STARTED

INCREASING WITH OUT ANY CHANGE IN OPERATING

PARAMETER

CCRU RGC TURBINE 15KT1

THRUST BEARING FAILURE

ON 29-6-01 TURBINE TRIPPED, DUE TO HIGH

THRUST BRG. TEMP. AND AXIAL THRUST. DECIDED

TO OPEN THE TURBINE.

OBSERVATION MADE AFTER OPENING:

THRUST(ACT.SIDE) FOUND DAMAGED.

3RD & 4TH ROW BLADES OF TURBINE FOUND 80% CHOCKED

DUE TO SEVERE SILICA DEPOSITION.

DIAPHRAGM NOZZLES WERE FOUND ERODED.

REPAIR REPL. DONE

ROTOR AND DIAPHRAGM OF TURBINE WERE CLEANED BY

HYDRO-SAND BLASTING .

ERODED PORTION OF DIAPHRAGM NOZZLES WERE WELD

BUILD UP AND GRINDED OFF.

ACTIVE SIDE THRUST BEARING REPLACED WITH NEW

ONE.

CCRU RGC TURBINE 15KT1

THRUST BEARING FAILURE

AFTER REPAIR / REPLACEMENT TURBINE ROLLED

ON 12-7-01 AND TURBINE IS RUNNING WITH

FOLLOWING PARAMETER.

AXIAL DISP.

TH.BEARING TEMP.

CHEST PR.

1ST STAGE PR.

:

:

:

:

(-)0.02/(+).01

50,51,53 DEG. C

21KG/CM2

13 KG/CM2

THRUST BEARING FAILURE OF CCRU RGC

TURBINE 15KT1

REASON OF REPEATED FAILURE OF THRUST BEARING:

Brief on Existing system

The HP steam requirement of CRU RGC turbine (Ebara

make) is met partly from captive generation with the

balance (about 45%) thru import from TPS. The

turbine is designed for an inlet steam temperature of

420oC @60 Kg/cm2g. However, the actual steam

temperature remains in the range of 360-370oC.

Reasons of failures

The rise in thrust bearing temperature and high axial

displacement of turbine rotor were due to deposition on

the moving and static blades of the turbine.

The suspected reasons for metal erosion of turbine

diaphragm nozzles is the supply of steam at lower

temperature and impurities present in it

THRUST BEARING FAILURE OF CCRU RGC

TURBINE 15KT1

Prevention of silica deposits

The most significant factor in corrective action is the

maintenance of low silica concentration on BFW that in

turn will ensure less than 0.02 ppm silica in HP steam.

Industrial experience shows that deposition difficulties

due to silica will not generally develop if steam silica

content is held below 0.02 ppm.

We have also seen that the silica finds its way to steam

(at definite distribution ratio) and silica rejection by

steam is drastic at exhaust steam specific volume of 0.6

cu ft/lb and above

.

Based on the above discussion, the actions to avoid

recurrence of heavy silica deposition on CRU RGC steam

turbine blades can be summarised as follows :

THRUST BEARING FAILURE OF CCRU RGC

TURBINE 15KT1

a) Lab test on regular basis for DM water and BFW

separately to monitor silica concentration. This will also

help detection of possible contamination of condensate

thru tube leaks of STG condensers.

b) The exhaust at the turbine to be maintained at

4.0+kg/cm2g on sustained basis to retard silica rejection

by steam. All the MP to LP PRDS are being checked for

performance so that LP steam header pressure is always

maintained.

c) Action being initiated for providing improved insulation

to ensure steam availability to RGC at design level.

Steam generator at 15 F-1 of CRU are being looked into

for ascertaining reasons for low superheat temperature

of steam generated.

THRUST BEARING FAILURE OF CCRU RGC

TURBINE 15KT1

CHOKAGE OF BLADES

EROSION ON DIAPHRAGM

También podría gustarte

- Asset Integrity Management A Complete Guide - 2020 EditionDe EverandAsset Integrity Management A Complete Guide - 2020 EditionAún no hay calificaciones

- Troubleshooting Rotating Machinery: Including Centrifugal Pumps and Compressors, Reciprocating Pumps and Compressors, Fans, Steam Turbines, Electric Motors, and MoreDe EverandTroubleshooting Rotating Machinery: Including Centrifugal Pumps and Compressors, Reciprocating Pumps and Compressors, Fans, Steam Turbines, Electric Motors, and MoreAún no hay calificaciones

- TilTing Pad Radial BeaRings PDFDocumento28 páginasTilTing Pad Radial BeaRings PDFmrbookaniAún no hay calificaciones

- Tilting Pad BearingDocumento11 páginasTilting Pad BearingDharmendra JainAún no hay calificaciones

- Boiler FD Fan, Bearing Failure Case StudyDocumento9 páginasBoiler FD Fan, Bearing Failure Case StudyAli Shujah Jafri100% (2)

- Bearing Failure PDFDocumento5 páginasBearing Failure PDF01666754614100% (2)

- Superior Turbine Solutions rotor repair and machining servicesDocumento26 páginasSuperior Turbine Solutions rotor repair and machining servicesramnadh803181100% (1)

- Analysis of Process Fan Failure & Bearing Housing Case - StudyDocumento16 páginasAnalysis of Process Fan Failure & Bearing Housing Case - Studytylerdurdane100% (1)

- Bearing Defect Inspection Based On Machine VisionDocumento20 páginasBearing Defect Inspection Based On Machine VisionArun Kumar100% (1)

- 'TP-800B' Overhauling of Steam TurbineDocumento35 páginas'TP-800B' Overhauling of Steam TurbinewasayAún no hay calificaciones

- Steam Turbine ValvesDocumento2 páginasSteam Turbine ValvesWalter Joseph100% (1)

- Evaluation of Tilting Pad Thrust Bearings PDFDocumento10 páginasEvaluation of Tilting Pad Thrust Bearings PDFVILLANUEVA_DANIEL2064Aún no hay calificaciones

- FAN Presentation 06.04.11Documento52 páginasFAN Presentation 06.04.11Senthil KumarAún no hay calificaciones

- Tilting Pad Bearing PreloadDocumento3 páginasTilting Pad Bearing Preloadrafay0saeed100% (2)

- Bearing Instal at Ion and Maintenance GuideDocumento130 páginasBearing Instal at Ion and Maintenance GuideTeodoru Horia Adrian75% (4)

- Reciprocating Compressor Condition Monitoring: © 2010 General Electric Company. All Rights ReservedDocumento22 páginasReciprocating Compressor Condition Monitoring: © 2010 General Electric Company. All Rights ReservedPablo Alcayaga Penros100% (3)

- Bearing Failure 1Documento8 páginasBearing Failure 1Kumar SwamiAún no hay calificaciones

- Centrifugal Pump OverloadingDocumento2 páginasCentrifugal Pump OverloadingAbdul AlimAún no hay calificaciones

- PA Fan High VibrationsDocumento14 páginasPA Fan High VibrationsVIBHAVAún no hay calificaciones

- Bowed Rotor Straightening WebVersion Dec 29 2010Documento2 páginasBowed Rotor Straightening WebVersion Dec 29 2010elrajilAún no hay calificaciones

- A Review of Tilting Pad Bearing TheoryDocumento31 páginasA Review of Tilting Pad Bearing TheoryJose Luis RattiaAún no hay calificaciones

- Waukesha Bearings - Modular TPT Bearings - MS - A4Documento32 páginasWaukesha Bearings - Modular TPT Bearings - MS - A4rafay0saeedAún no hay calificaciones

- OnM Best Practices MPPGCLDocumento42 páginasOnM Best Practices MPPGCLJithinAbraham100% (1)

- Internal Bearing CleardssanceDocumento3 páginasInternal Bearing Cleardssancejicki09Aún no hay calificaciones

- 03 Product OverviewDocumento44 páginas03 Product OverviewMamdouh ElhanafyAún no hay calificaciones

- Turbine FundamentalDocumento18 páginasTurbine FundamentalHamid ArizAún no hay calificaciones

- Bearing Fits PDFDocumento11 páginasBearing Fits PDFkarthiblackAún no hay calificaciones

- SKF Bearing Failure and CausesDocumento44 páginasSKF Bearing Failure and CausescazacuphAún no hay calificaciones

- Cause and Prevention For Steam Turbine BDocumento10 páginasCause and Prevention For Steam Turbine Brudi setiawanAún no hay calificaciones

- Reverse and Rim and Face AlignmentDocumento37 páginasReverse and Rim and Face AlignmentvenkeekuAún no hay calificaciones

- Turbines and GoverningDocumento31 páginasTurbines and GoverningKVV100% (2)

- Vibration Product Training: Gearbox TutorialDocumento10 páginasVibration Product Training: Gearbox TutorialMuhammad afzalAún no hay calificaciones

- Hydrostatic Journal BearingDocumento18 páginasHydrostatic Journal Bearingapi-19775783100% (1)

- Thermal expansion of boilers explainedDocumento5 páginasThermal expansion of boilers explainedThusitha DalpathaduAún no hay calificaciones

- Troubleshooting VTP Vertical Turbine PumpDocumento20 páginasTroubleshooting VTP Vertical Turbine PumpKrrish100% (1)

- Maintenance of Journal (Babbitt) BearingsDocumento34 páginasMaintenance of Journal (Babbitt) BearingsNilav KumarAún no hay calificaciones

- Solid Particle Erosion and Mechanical DamageDocumento5 páginasSolid Particle Erosion and Mechanical DamageCarlos ToscanoAún no hay calificaciones

- Turbine FundamentalsDocumento102 páginasTurbine FundamentalsAkshayAún no hay calificaciones

- Steam Turbines FundamentalsDocumento51 páginasSteam Turbines Fundamentalssevero97100% (1)

- Hydrostatic Journal BearingDocumento14 páginasHydrostatic Journal Bearingapi-19775783100% (4)

- A Study On Failure of Mechanical PumpDocumento34 páginasA Study On Failure of Mechanical PumpAzif Ali MoothantevileyilAún no hay calificaciones

- Classifying Bearings and Selecting the Right TypeDocumento8 páginasClassifying Bearings and Selecting the Right TypeMohamed Sadek100% (1)

- Shaft fits and tolerances chart for radial and thrust bearingsDocumento1 páginaShaft fits and tolerances chart for radial and thrust bearingsSahil KumarAún no hay calificaciones

- Glycol Re-Boiler Tube Damage Case StudyDocumento17 páginasGlycol Re-Boiler Tube Damage Case StudyMohd Shafuaaz KassimAún no hay calificaciones

- Boost Boiler Efficiency With an Air PreheaterDocumento44 páginasBoost Boiler Efficiency With an Air PreheaterAtef BouabdallahAún no hay calificaciones

- Sam Turbo Pump Type ArsDocumento21 páginasSam Turbo Pump Type ArsNor Azman SaaidAún no hay calificaciones

- 1702021839325 overspeed trip case studyDocumento17 páginas1702021839325 overspeed trip case studyMahmoud AbdellatifAún no hay calificaciones

- First Inspection Report Details Engine Repair NeedsDocumento36 páginasFirst Inspection Report Details Engine Repair NeedsCwsAún no hay calificaciones

- Fir Engine TP-542 FMX - 440Documento21 páginasFir Engine TP-542 FMX - 440CwsAún no hay calificaciones

- Sam Industries PumpDocumento52 páginasSam Industries PumpHunney KotiyaAún no hay calificaciones

- Ahmed A'Nasser Handover 22 November PDFDocumento3 páginasAhmed A'Nasser Handover 22 November PDFmohamed hamedAún no hay calificaciones

- Install, Operate and Maintain SAM Turbo PumpDocumento40 páginasInstall, Operate and Maintain SAM Turbo Pumpsanjayagrawal70-1Aún no hay calificaciones

- Pump failure report of 05PC-114ADocumento3 páginasPump failure report of 05PC-114ANupesh katreAún no hay calificaciones

- Ahmed A'nasser Hitch ReportDocumento3 páginasAhmed A'nasser Hitch Reportmohamed hamedAún no hay calificaciones

- Job Report: Overhauling of Waste Water Pump (WP-111)Documento8 páginasJob Report: Overhauling of Waste Water Pump (WP-111)msaqibraza93Aún no hay calificaciones

- Case Study Pumps 1Documento36 páginasCase Study Pumps 1Aravazhi Ramasami Thangaraj100% (1)

- Klasa EngleskiDocumento7 páginasKlasa EngleskiZdravko PeranAún no hay calificaciones

- SB SBH Series Blender IMDocumento22 páginasSB SBH Series Blender IMJOSE BARONAún no hay calificaciones

- Job Report: Overhauling of Waste Water Pump (WP-111)Documento6 páginasJob Report: Overhauling of Waste Water Pump (WP-111)msaqibraza93Aún no hay calificaciones

- Finite Volume Discretization of Governing Equation On Collocated Grid With Heat SourceDocumento10 páginasFinite Volume Discretization of Governing Equation On Collocated Grid With Heat SourceAyush JAinAún no hay calificaciones

- Modeling and Simulation of Gas, Oil and Water Flow in A Catenary-Shaped RiserDocumento17 páginasModeling and Simulation of Gas, Oil and Water Flow in A Catenary-Shaped RiserAyush JAinAún no hay calificaciones

- Erosion Effect Over VelocityDocumento7 páginasErosion Effect Over VelocityAyush JAinAún no hay calificaciones

- Running in Parallel Luc Chin IDocumento13 páginasRunning in Parallel Luc Chin INashrif KarimAún no hay calificaciones

- Numerical investigation of erosion threshold velocity in a pipe with sudden contractionDocumento22 páginasNumerical investigation of erosion threshold velocity in a pipe with sudden contractionAyush JAinAún no hay calificaciones

- Thick Walled CylindersDocumento9 páginasThick Walled CylinderskabangiAún no hay calificaciones

- DPM U BendDocumento13 páginasDPM U BendharabnezhadAún no hay calificaciones

- System Coupling Users GuideDocumento144 páginasSystem Coupling Users GuidegarystevensozAún no hay calificaciones

- Thick-Walled Cylinders and Press Fits StressesDocumento17 páginasThick-Walled Cylinders and Press Fits StressestooocooolAún no hay calificaciones

- Photovoltaic Principles (NREL) PDFDocumento71 páginasPhotovoltaic Principles (NREL) PDFED DK KAAún no hay calificaciones

- Parallelism in StructureDocumento3 páginasParallelism in StructureAyush JAinAún no hay calificaciones

- NS EquationDocumento11 páginasNS EquationAyush JAinAún no hay calificaciones

- Bioinformatics Drug DesignDocumento62 páginasBioinformatics Drug DesignAyush JAinAún no hay calificaciones

- How Photovoltaic Cells Convert Sunlight into Electricity Using the Photovoltaic EffectDocumento1 páginaHow Photovoltaic Cells Convert Sunlight into Electricity Using the Photovoltaic EffectAyush JAinAún no hay calificaciones

- Analysis of DO Sag For Multiple Point Sources: Department of Mathematics, Galgotias University, Greater Noida, IndiaDocumento7 páginasAnalysis of DO Sag For Multiple Point Sources: Department of Mathematics, Galgotias University, Greater Noida, IndiaprateekbaldwaAún no hay calificaciones

- Photoelectric EffectDocumento4 páginasPhotoelectric EffectAyush JAinAún no hay calificaciones

- Dielectric MaterialsDocumento7 páginasDielectric MaterialsAyush JAinAún no hay calificaciones

- DAAD IIT Master Scholarships for GermanyDocumento3 páginasDAAD IIT Master Scholarships for GermanyTarun SachdevaAún no hay calificaciones

- About Ancient BharatDocumento0 páginasAbout Ancient BharatKundan KumawatAún no hay calificaciones

- FAQDocumento9 páginasFAQAyush JAinAún no hay calificaciones

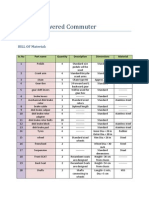

- BOM - Human Powered CommuterDocumento2 páginasBOM - Human Powered CommuterAyush JAinAún no hay calificaciones

- Suspension Design AnalysisDocumento8 páginasSuspension Design AnalysisPrithvish M GowdaAún no hay calificaciones

- Recent Trends in Wind Energy by Ayush JainDocumento3 páginasRecent Trends in Wind Energy by Ayush JainAyush JAinAún no hay calificaciones

- Mechanical, Aeronautical & Manufacturing Rankings 2011: Rank Title Country Academic Employer Citations ScoreDocumento10 páginasMechanical, Aeronautical & Manufacturing Rankings 2011: Rank Title Country Academic Employer Citations ScoreAyush JAinAún no hay calificaciones

- For Academic Customers: Site Creation Request FormDocumento7 páginasFor Academic Customers: Site Creation Request FormAyush JAinAún no hay calificaciones

- Parallel PortDocumento1 páginaParallel PortAyush JAinAún no hay calificaciones

- AjDocumento4 páginasAjAyush JAinAún no hay calificaciones

- HT12D PDFDocumento11 páginasHT12D PDFSwarnalatha ChinnathuraiAún no hay calificaciones

- Theory of Chemical Kinetics and Charge Transfer Based On Nonequilibrium ThermodynamicsDocumento17 páginasTheory of Chemical Kinetics and Charge Transfer Based On Nonequilibrium ThermodynamicsYoana Yoa YoaAún no hay calificaciones

- Atlas TechNotes - Complete Set Rev Nov 2011Documento50 páginasAtlas TechNotes - Complete Set Rev Nov 2011caod1712Aún no hay calificaciones

- Testing of Rigid Plastic ContainersDocumento22 páginasTesting of Rigid Plastic ContainersBhupendra Singh100% (12)

- Flight Equations of Motion for 6 DOF Aircraft ModelDocumento24 páginasFlight Equations of Motion for 6 DOF Aircraft ModelNeetu SharmaAún no hay calificaciones

- Zetex HandbookDocumento8 páginasZetex HandbookbolermAún no hay calificaciones

- Introduction to Catalysis LectureDocumento22 páginasIntroduction to Catalysis LectureVhyiitrii Shanqk Peñjhaqa Haatii100% (1)

- Teacher Guide Activity 2 AccelerationDocumento4 páginasTeacher Guide Activity 2 AccelerationCanada Railway TimesAún no hay calificaciones

- WMM Plant CalibrationDocumento5 páginasWMM Plant CalibrationAnonymous zyIPjL9vAún no hay calificaciones

- Data Sheet Monocristalino Chint Astronergy PDFDocumento2 páginasData Sheet Monocristalino Chint Astronergy PDFPaulo SousaAún no hay calificaciones

- Solution Manual-Chemical Engineering Thermodynamics - Smith Van NessDocumento621 páginasSolution Manual-Chemical Engineering Thermodynamics - Smith Van NessSurya Budi Widagdo87% (184)

- 4363 111 Machine Design IDocumento6 páginas4363 111 Machine Design Iyogesh_b_k100% (2)

- LECTURE 3 - Shear Stress & Allowable StressDocumento15 páginasLECTURE 3 - Shear Stress & Allowable StressIhab OmarAún no hay calificaciones

- 960 Physics (PPU) Semester 2 Topics-SyllabusDocumento7 páginas960 Physics (PPU) Semester 2 Topics-SyllabusJosh, LRT0% (1)

- Calculation of Electrical Induction Near Power LinesDocumento22 páginasCalculation of Electrical Induction Near Power LinesalpcruzAún no hay calificaciones

- Diagnostic Fracture Injection Tests in Ultra Low Perm FormationsDocumento6 páginasDiagnostic Fracture Injection Tests in Ultra Low Perm FormationsBolsec14Aún no hay calificaciones

- PNA Chemistry Expedite 8900 User's GuideDocumento114 páginasPNA Chemistry Expedite 8900 User's GuideJohnAún no hay calificaciones

- Partial Differential Equations Formula SheetDocumento3 páginasPartial Differential Equations Formula SheetnewyorkstudyAún no hay calificaciones

- Cementing EquipDocumento12 páginasCementing Equipzbhdzp100% (1)

- Information Folder LUCCON PDFDocumento9 páginasInformation Folder LUCCON PDFASHOKKUMAR EAún no hay calificaciones

- Love My LifeDocumento5 páginasLove My LifeLinda Veronica0% (1)

- Heat Exchangers Types & Applications, LMTD Derivation & ProblemsDocumento11 páginasHeat Exchangers Types & Applications, LMTD Derivation & Problemsananth2012Aún no hay calificaciones

- Molykote Greases For Subsea ApplicationsDocumento1 páginaMolykote Greases For Subsea ApplicationsProject Sales CorpAún no hay calificaciones

- Stainless Steel PropertiesDocumento3 páginasStainless Steel Propertieskiwanis_lamAún no hay calificaciones

- Tutorial 16 - CEL - BottleDocumento14 páginasTutorial 16 - CEL - BottleRezaAún no hay calificaciones

- 08 Energy 03 Complementary Strain Energy PDFDocumento2 páginas08 Energy 03 Complementary Strain Energy PDFjack_hero_56Aún no hay calificaciones

- Basic Hazen Williams FormulaDocumento28 páginasBasic Hazen Williams FormulaDhimas IriantoAún no hay calificaciones

- Elders Ray SYstemsDocumento7 páginasElders Ray SYstemssagarmkale4395Aún no hay calificaciones

- Principles of CT and CT TechnologyDocumento15 páginasPrinciples of CT and CT TechnologyLida Velasquez SierraAún no hay calificaciones

- L-3/T-2/CE Date: 07/08/2016Documento30 páginasL-3/T-2/CE Date: 07/08/2016নীল জোছনা0% (1)

- Mark S. Gockenbach - Mathematica Tutorial - To Accompany Partial Differential Equations - Analytical and Numerical Methods (2010) (p120)Documento120 páginasMark S. Gockenbach - Mathematica Tutorial - To Accompany Partial Differential Equations - Analytical and Numerical Methods (2010) (p120)Galeotto Marzio100% (1)