Documentos de Académico

Documentos de Profesional

Documentos de Cultura

F & G Detection and Protection

Cargado por

Ana MarksDerechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

F & G Detection and Protection

Cargado por

Ana MarksCopyright:

Formatos disponibles

Fire & Gas Detection

and Protection

Purpose:

Required for protection of

Personnel and assets.

Keys:

Hazardous Area

Gas Detection

Fire Detection

Fire Protection

Hazardous Area

-In Oil & Gas industry Combustible

Materials such as Hydrocarbons and

Hydrogen gas and Toxic gases such as

H2S are handled.

-Combustible materials become

Flammable in the presence of

atmospheric Oxygen.

-If Flammable material comes into

contact with an arc or spark or a hot

surface, an Explosion may occur.

Hazardous Area

-Exposure to Toxic Gas above certain

levels may be dangerous to human life.

-Therefore improperly handled

combustible or toxic material may

cause a loss of life and materials,

which has to be prevented by suitable

design practices..

-To prevent electrical devices from

causing an explosion due to generatoin

of an arc/ spark or hot surface, various

protection techniques are employed

viz. IS, Ex proof, Purging, Non

incendive, Increased Safety, Oil

Immersion, Encapsulation etc.

Gas Detection

Gas leak may occur due to:

- Operational Requirements

(Blowdown, Vents etc)

- Failure of Equipment and fittings

Type of Gas:

- Hydrocarbon

- Hydrogen

- Hydrogen Sulphide (Toxic)

Types of Gas Detectors:

- Catalytic Bead

- Infra Red (Point or Line of Sight)

- Electrochemical, Semiconductor

Fire Detection

Fusible Plugs(Non Electrical)

Flame Detector (UV, UV/IR)

Heat/ Thermal Detectors (Fixed,

Rate of Rise)

Smoke detectors

Fire Protection

Active Protection

Passive Protection

Active

-Sprinkler/ Deluge

-FM200/CO2/ Halon

-Foam

Passive

-Firewall

-Protective Coatings

Sprinkler/ Deluge

Fire Water System:

Two or three independently operated

fire water pumps are located

separately so that single fire incident

does not put all these pumps out of

action.

Sprinkler (Wet System)

-Pipework of Fire Water under

pressure with Quartzoid Bulbs

suitably placed along its length.

Deluge (Dry System)

-One Pipework of Pneumatic supply

with Quartzoid Bulbs suitably placed

along its length and Pressure Switch

sensor. Second Pipework of Fire

Water with a Deluge Valve that

opens upon sensing of Low pressure

in first network due to a broken bulb.

- Deluge Valve for each system is

located outside of but adlacent to the

protected area (e.g DV for Main

Deck is located on Cellar Deck and

vice versa.)

Clean Agent

Used to protect the areas where primary

risk is of Electrical fires. E.g Control

Room, Switchgear, battery room, turbine

enclosure etc

Discharge of Clean Agent is generally

activated by coincident Smoke detection.

Control Box containing the following is

placed at the entrance of the protected

enclosure:-

- Audible Alarm to indicate that CA will be

discharged after time delay of 20 seconds.

- Key Operated Switch to Inhibit the

discharge.

- Pushbutton for Local Manual Activation.

- Indicating Lamp for Inhibit condition

- Indicating Lamp for About to

Discharge.

- Indicating Lamp for System

Discharged.

Firewalls

Firewall is used to limit the

spread of fire from one area to

another. These prevent the

passage of smoke and flame as

well as prevent temperature rise

on the unexposed surface.

Designed as per SOLAS (Safety

of Life at Sea) regulations.

Alarms Annunciations

General Alarm:

- It is activated upon detection of fire,

gas, MAC or any ESD.

-Audio Visual alarm (Red flashing, 2

secs on/ 2 secs off).

Toxic Gas Alarm:

- It is activated upon detection of toxic

gas.

- It is a 1.4 sec ramp, sawtooth wave

(slow increasing, fast reducing).

Abandon Platform:

-It is manually activated by a rotary

switch located in control room, near

survival craft, helideck.

-Audio Visual Alarm (Blue lamp, Siren

tone)

Mimic Display:

It provides the operator with

information on type and location of a

hazard. The system gives a

geographical layout of installations

including the following items:

Fire, Smoke, Flammable Gas, Toxic

Gas, Fire Extinguishing apparatus

status, ESDs, MAC

También podría gustarte

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryCalificación: 3.5 de 5 estrellas3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Calificación: 4.5 de 5 estrellas4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDe EverandGrit: The Power of Passion and PerseveranceCalificación: 4 de 5 estrellas4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe EverandNever Split the Difference: Negotiating As If Your Life Depended On ItCalificación: 4.5 de 5 estrellas4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe EverandThe Little Book of Hygge: Danish Secrets to Happy LivingCalificación: 3.5 de 5 estrellas3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaCalificación: 4.5 de 5 estrellas4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeCalificación: 4 de 5 estrellas4/5 (5795)

- Rise of ISIS: A Threat We Can't IgnoreDe EverandRise of ISIS: A Threat We Can't IgnoreCalificación: 3.5 de 5 estrellas3.5/5 (137)

- Her Body and Other Parties: StoriesDe EverandHer Body and Other Parties: StoriesCalificación: 4 de 5 estrellas4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreCalificación: 4 de 5 estrellas4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyCalificación: 3.5 de 5 estrellas3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersCalificación: 4.5 de 5 estrellas4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDe EverandShoe Dog: A Memoir by the Creator of NikeCalificación: 4.5 de 5 estrellas4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe EverandThe Emperor of All Maladies: A Biography of CancerCalificación: 4.5 de 5 estrellas4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDe EverandTeam of Rivals: The Political Genius of Abraham LincolnCalificación: 4.5 de 5 estrellas4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceCalificación: 4 de 5 estrellas4/5 (895)

- The Perks of Being a WallflowerDe EverandThe Perks of Being a WallflowerCalificación: 4.5 de 5 estrellas4.5/5 (2104)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureCalificación: 4.5 de 5 estrellas4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDe EverandOn Fire: The (Burning) Case for a Green New DealCalificación: 4 de 5 estrellas4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)De EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Calificación: 4 de 5 estrellas4/5 (98)

- The Unwinding: An Inner History of the New AmericaDe EverandThe Unwinding: An Inner History of the New AmericaCalificación: 4 de 5 estrellas4/5 (45)

- Play Skit For KidsDocumento2 páginasPlay Skit For KidsAna MarksAún no hay calificaciones

- Offshore Safety Case TrainingDocumento114 páginasOffshore Safety Case Traininganil56394439100% (1)

- RP 92002Documento34 páginasRP 92002kirandevi1981Aún no hay calificaciones

- Monte Carlo Simulation Formula in ExcelDocumento11 páginasMonte Carlo Simulation Formula in ExcelAna MarksAún no hay calificaciones

- UAE LyricsDocumento1 páginaUAE LyricsAna Marks100% (1)

- Manual TecnicoDocumento66 páginasManual Tecnicojavier andres urbina diaz100% (1)

- Hmi CNG SpecDocumento15 páginasHmi CNG SpecSantosh MordeAún no hay calificaciones

- 01-01-1865-D ELDS Technical Manual Iss13Documento221 páginas01-01-1865-D ELDS Technical Manual Iss13Alberyt099Aún no hay calificaciones

- Leak Detection Safeguarding Stamicarbon's High Pressure Urea VesselsDocumento8 páginasLeak Detection Safeguarding Stamicarbon's High Pressure Urea Vesselsvaratharajan g rAún no hay calificaciones

- Mesqac 2010 Rev.01Documento55 páginasMesqac 2010 Rev.01akivko100% (1)

- 6158 IEC Safe Iec Basic PDFDocumento11 páginas6158 IEC Safe Iec Basic PDFMarijan Utroša100% (1)

- Basics of Instrumentation Fire GasDocumento20 páginasBasics of Instrumentation Fire Gasabdullah100% (1)

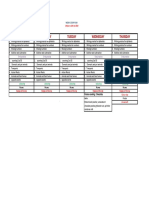

- Coloring: Oral Exam Revision Exam Revision Oral Exam Oral Exam Portion Written Exam PortionDocumento2 páginasColoring: Oral Exam Revision Exam Revision Oral Exam Oral Exam Portion Written Exam PortionAna MarksAún no hay calificaciones

- Proud Tree 20190722 4 1skedtvDocumento5 páginasProud Tree 20190722 4 1skedtvAna MarksAún no hay calificaciones

- Literacy 2 Three Letter Words - 16 PDFDocumento24 páginasLiteracy 2 Three Letter Words - 16 PDFAna MarksAún no hay calificaciones

- TUV - FS ENgr-PHRA-DubaiDocumento5 páginasTUV - FS ENgr-PHRA-DubaiAna MarksAún no hay calificaciones

- Oral Oral Exam Revision Fireless Cooking Oral Exam Oral Exam Portion Written Exam PortionDocumento2 páginasOral Oral Exam Revision Fireless Cooking Oral Exam Oral Exam Portion Written Exam PortionAna MarksAún no hay calificaciones

- Weekly Plan 1 April TO 5 April 2018: Oral Oral Oral OralDocumento2 páginasWeekly Plan 1 April TO 5 April 2018: Oral Oral Oral OralAna MarksAún no hay calificaciones

- Weekly Plan June 10 - 14, 2018: Sunday 10-06-18 Monday 11-06-18 Tuesday 12-06-18 Wednesday 13-06-18 Thursday 14-06-18Documento1 páginaWeekly Plan June 10 - 14, 2018: Sunday 10-06-18 Monday 11-06-18 Tuesday 12-06-18 Wednesday 13-06-18 Thursday 14-06-18Ana MarksAún no hay calificaciones

- Oral Oral Oral Oral Fireless Cooking Burger Ingredients: Sunday Monday Tuesday Wednesday ThursdayDocumento2 páginasOral Oral Oral Oral Fireless Cooking Burger Ingredients: Sunday Monday Tuesday Wednesday ThursdayAna MarksAún no hay calificaciones

- Weekly Plan Mar 5 To Mar 9Documento2 páginasWeekly Plan Mar 5 To Mar 9Ana MarksAún no hay calificaciones

- Sunday Monday Tuesday Wednesday Thursday: Oral Practice Oral Practice Oral Practice Oral Practice Oral PracticeDocumento1 páginaSunday Monday Tuesday Wednesday Thursday: Oral Practice Oral Practice Oral Practice Oral Practice Oral PracticeAna MarksAún no hay calificaciones

- Weekly Lesson Plan Jan 8-12Documento1 páginaWeekly Lesson Plan Jan 8-12Ana MarksAún no hay calificaciones

- Weekly Lesson Plan-1Documento1 páginaWeekly Lesson Plan-1Ana MarksAún no hay calificaciones

- Weekly Plan - ClassDocumento1 páginaWeekly Plan - ClassAna MarksAún no hay calificaciones

- lESSON PLAN 24THDEC TO 28TH DEC JAYA PDFDocumento1 páginalESSON PLAN 24THDEC TO 28TH DEC JAYA PDFAna MarksAún no hay calificaciones

- Weekly Plan - 10thdec To 14th DecDocumento1 páginaWeekly Plan - 10thdec To 14th DecAna MarksAún no hay calificaciones

- JJ Lesson Plan 22-25Documento1 páginaJJ Lesson Plan 22-25Ana MarksAún no hay calificaciones

- Weekly Plan 12 March To 16 MarchDocumento1 páginaWeekly Plan 12 March To 16 MarchAna MarksAún no hay calificaciones

- MIL-HDBK-217F N2 Parts Count AnalysisDocumento13 páginasMIL-HDBK-217F N2 Parts Count AnalysisAna MarksAún no hay calificaciones

- Site Waste Management Plan Waste Data FormDocumento2 páginasSite Waste Management Plan Waste Data FormAna MarksAún no hay calificaciones

- Sensors: Review On Smart Gas Sensing TechnologyDocumento22 páginasSensors: Review On Smart Gas Sensing TechnologyMahdi koolivandAún no hay calificaciones

- TP201.3 Determination of 2 Inch WC Static Pressure Performance of Vapor Recovery Systems of Dispensing FacilitiesDocumento18 páginasTP201.3 Determination of 2 Inch WC Static Pressure Performance of Vapor Recovery Systems of Dispensing FacilitiesCésar Oswaldo Aguilera OjedaAún no hay calificaciones

- Final Report EK210Documento11 páginasFinal Report EK210Jordan MarabelloAún no hay calificaciones

- Vapormate Application Guide903 119147Documento13 páginasVapormate Application Guide903 119147parejayaAún no hay calificaciones

- Unit Iii Chemical Hazards Control Measures For Chemical Hazards, Combustible Gases, Toxic Gases, Oxygen and Management of GasesDocumento23 páginasUnit Iii Chemical Hazards Control Measures For Chemical Hazards, Combustible Gases, Toxic Gases, Oxygen and Management of GasesMani VedhaAún no hay calificaciones

- General Monitors - S5000 - Manual-ENDocumento101 páginasGeneral Monitors - S5000 - Manual-ENJuan Carlos Trucios MitmaAún no hay calificaciones

- Documentation For Underground Car ParksDocumento15 páginasDocumentation For Underground Car ParksVasil StamenovAún no hay calificaciones

- Dispenser Pan Sensors & Containment Sump Sensors: Installation GuideDocumento14 páginasDispenser Pan Sensors & Containment Sump Sensors: Installation GuideShalvaTavdgiridzeAún no hay calificaciones

- Minor Project - 1 ReportDocumento17 páginasMinor Project - 1 ReportDeepak KumarAún no hay calificaciones

- Datasheet-EnglDocumento4 páginasDatasheet-EnglApolo HpAún no hay calificaciones

- HGD-2000 Catalog V1.2Documento1 páginaHGD-2000 Catalog V1.2Dewytt Jhordan Cordoba CubillosAún no hay calificaciones

- 1LAB 000611 Online Dissolved Gas Monitoring (Introducing The CoreSenseTM...Documento19 páginas1LAB 000611 Online Dissolved Gas Monitoring (Introducing The CoreSenseTM...SFGRISELDA SANCHEZAún no hay calificaciones

- ABB Gas Detector Relay Model 11Documento9 páginasABB Gas Detector Relay Model 11Felipe FlorezAún no hay calificaciones

- Types of Sensors With Their Circuit Diagrams: What Is Sensor?Documento48 páginasTypes of Sensors With Their Circuit Diagrams: What Is Sensor?dereje gerluAún no hay calificaciones

- MQ-2 HanweiDocumento4 páginasMQ-2 HanweiFabio Duque GiraldoAún no hay calificaciones

- # 127Documento6 páginas# 127Olegs AndreAún no hay calificaciones

- Macurco Gas Detectors: Installation and Operating InstructionsDocumento1 páginaMacurco Gas Detectors: Installation and Operating InstructionsLarryAún no hay calificaciones

- MaviGard New Products May 06Documento16 páginasMaviGard New Products May 06Adrian OprisanAún no hay calificaciones

- Unit 1 & 2 HSE Mgt. in PetroDocumento22 páginasUnit 1 & 2 HSE Mgt. in PetroRitesh PoudiyalAún no hay calificaciones

- Water-Waste Water InternationalDocumento57 páginasWater-Waste Water Internationaljegva7875Aún no hay calificaciones

- 47K GBDocumento32 páginas47K GBBryan WahyuAún no hay calificaciones

- Training Presentation PellistorsDocumento26 páginasTraining Presentation PellistorsdeboAún no hay calificaciones