Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Dynamics ANSYS 7.0 Workshops

Cargado por

Maria Lavinia Iordache0 calificaciones0% encontró este documento útil (0 votos)

84 vistas74 páginasANSYS

Derechos de autor

© © All Rights Reserved

Formatos disponibles

PPT, PDF, TXT o lea en línea desde Scribd

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoANSYS

Copyright:

© All Rights Reserved

Formatos disponibles

Descargue como PPT, PDF, TXT o lea en línea desde Scribd

0 calificaciones0% encontró este documento útil (0 votos)

84 vistas74 páginasDynamics ANSYS 7.0 Workshops

Cargado por

Maria Lavinia IordacheANSYS

Copyright:

© All Rights Reserved

Formatos disponibles

Descargue como PPT, PDF, TXT o lea en línea desde Scribd

Está en la página 1de 74

DYNAMICS

for ANSYS 7.0

Workshop Supplement

Inventory Number: 001810

First Edition

ANSYS Release: 7.0

Published Date: March 14, 2003

Registered Trademarks:

ANSYS

is a registered trademark of SAS IP Inc.

All other product names mentioned in this manual are trademarks or registered trademarks of their respective

manufacturers.

Disclaimer Notice:

This document has been reviewed and approved in accordance with the ANSYS, Inc. Documentation Review and

Approval Procedures. This ANSYS Inc. software product (the Program) and program documentation (Documentation)

are furnished by ANSYS, Inc. under an ANSYS Software License Agreement that contains provisions concerning non-

disclosure, copying, length and nature of use, warranties, disclaimers and remedies, and other provisions. The

Program and Documentation may be used or copied only in accordance with the terms of that License Agreement.

Copyright 2003 SAS IP, Inc.

Proprietary data. Unauthorized use, distribution, or duplication is prohibited.

All Rights Reserved.

Workshop Supplement

DYNAMICS

D

Y

N

A

M

I

C

S

7

.

0

Workshop Supplement

March 14, 2003

Inventory #001810

WS-3

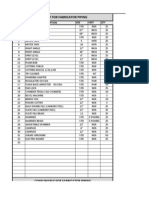

Table of Contents

Introductory Workshop

Galloping Gertie -------------------------------------------- W-5

Modal Analysis Workshop

Plate with a Hole -------------------------------------------- W-17

Modal Analysis Workshop

Model Airplane Wing -------------------------------------------- W-23

Harmonic Analysis Workshop

Fixed-Fixed Beam -------------------------------------------- W-27

Transient Analysis Workshop

Bouncing Block -------------------------------------------- W-35

Restarting a Transient Workshop

Bouncing Block -------------------------------------------- W-43

Response Spectrum Workshop

Workbench Table -------------------------------------------- W-49

Random Vibration Workshop

Model Airplane Wing -------------------------------------------- W-55

Pre-stressed Modal Analysis Workshop

Pre-Stressed Disc -------------------------------------------- W-61

Modal Cyclic Symmetry Workshop

Spiral Bevel Gear -------------------------------------------- W-67

Introductory

Workshop

Galloping Gertie

D

Y

N

A

M

I

C

S

7

.

0

Workshop Supplement

March 14, 2003

Inventory #001810

WS-6

Introductory Workshop

Galloping Gertie

Objective

To get an idea of the steps involved in a typical dynamic analysis.

The Tacoma Narrows bridge, also known as the Galloping Gertie

is famous for its spectacular collapse in 1940. In this workshop,

we will examine a model of the bridge and calculate its natural

frequencies and mode shapes. We will then simulate the wind

storm and vortex shedding that caused the bridges collapse by

doing a harmonic analysis.

D

Y

N

A

M

I

C

S

7

.

0

Workshop Supplement

March 14, 2003

Inventory #001810

WS-7

Introductory Workshop

Galloping Gertie

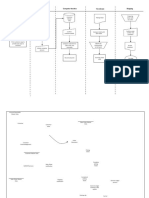

Instructions

1. Enter ANSYS in the working directory specified by your instructor.

2. Start by reading input from the file gallop.inp.

Utility Menu: File > Read Input from choose gallop.inp

This will create the model and perform a static analysis to prestress the bridge.

The next step is to do a modal analysis.

D

Y

N

A

M

I

C

S

7

.

0

Workshop Supplement

March 14, 2003

Inventory #001810

WS-8

Introductory Workshop

Galloping Gertie

3. Enter Solution and change analysis type to Modal:

Solution > Analysis Type > New Analysis choose Modal.

4. Set the following analysis options.

Solution > Analysis Type > Analysis Options...

accept the default (Block Lanczos)

10 modes to extract

10 modes to expand

Calculate element stresses

Include prestress effects press OK

Accept defaults on the next dialog (Options for Block Lanczos Modal Analysis)

5. Solve.

Solution > Solve > Current LS

D

Y

N

A

M

I

C

S

7

.

0

Workshop Supplement

March 14, 2003

Inventory #001810

WS-9

6. Plot the first few mode shapes.

General Postproc > Read Results > By Pick

General Postproc > Plot Results > Contour Plot > Nodal Solu ...

Introductory Workshop

Galloping Gertie

Mode 3 SX stress

Mode 1 SX stress

D

Y

N

A

M

I

C

S

7

.

0

Workshop Supplement

March 14, 2003

Inventory #001810

WS-10

7. Enter Solution and choose harmonic analysis.

Solution > Analysis Type > New Analysis

8. Set the following analysis options.

Solution > Analysis Type > Analysis Options...

Select the Mode superposition solution method

Defaults for all others (including subsequent dialog box)

9. Set frequency and substep options:

Solution > Load Step Opts > Time/Frequenc > Freq and Substps...

Harmonic frequency range = 0 to 0.4

Number of substeps = 40

Stepped boundary conditions

10. Set constant damping ratio = 0.01.

Solution > Load Step Opts > Time/Frequenc > Damping

Introductory Workshop

Galloping Gertie

D

Y

N

A

M

I

C

S

7

.

0

Workshop Supplement

March 14, 2003

Inventory #001810

WS-11

11. Apply a load vector for mode superposition

with a scale factor of 100.

Solution > Define Loads > Apply > Load Vector > For Mode Super

(close the warning message window)

12. Solve: Solution > Solve > Current LS

13. Save the ANSYS database for the Variable

Viewer in Step 14.

Utility Menu: File > Save as Jobname.db

14. Enter POST26 (TimeHist Postproc). The

Variable Viewer will start automatically.

Specify the results file name, i.e. gallop.rfrq,

by clicking on File > Open Results)

Select gallop.rfrq as the results file, then click [Open]

Select gallop.db as the ANSYS database, then click [Open]

Introductory Workshop

Galloping Gertie

D

Y

N

A

M

I

C

S

7

.

0

Workshop Supplement

March 14, 2003

Inventory #001810

WS-12

15. Create a scalar parameter to represent the center node: At command

line type in ncen = node(0,0,0) .

16. Define a variable (a vector) using the Variable Viewer that will contain

the UZ displacements of the center node:

Introductory Workshop

Galloping Gertie

a. Click on the Add Data button

b. Double click on Nodal Solution

and DOF Solution, select Z-

Component of displacement and

enter uz_mid for the Variable

Name, and then click [OK]

c. Enter ncen followed by [Enter] in

the ANSYS Picker Menu, then [OK]

D

Y

N

A

M

I

C

S

7

.

0

Workshop Supplement

March 14, 2003

Inventory #001810

WS-13

16. (contd).

The Variable Viewer should appear as follows:

Introductory Workshop

Galloping Gertie

D

Y

N

A

M

I

C

S

7

.

0

Workshop Supplement

March 14, 2003

Inventory #001810

WS-14

17. Graph the UZ-displacement vs frequency:

1. Select the line labeled uz_mid and then click on the Graph Data button

18. Close the Variable Viewer and then Exit ANSYS or go to step 19 if time

permits.

Introductory Workshop

Galloping Gertie

D

Y

N

A

M

I

C

S

7

.

0

Workshop Supplement

March 14, 2003

Inventory #001810

WS-15

Optional: Continue with the following steps to review the

deformed shape and stresses at 0.07 Hz frequency.

19. Read Input from gallop_more.inp.

20. Enter POST1, read results for load step 1 substep 7, and plot the deformed

shape and stress contours. Repeat for the imaginary part as well.

21. Exit ANSYS.

Real Part

Imaginary Part

Introductory Workshop

Galloping Gertie

SEQV stress

SEQV stress

Modal Analysis

Workshop

Plate with a Hole

D

Y

N

A

M

I

C

S

7

.

0

Workshop Supplement

March 14, 2003

Inventory #001810

WS-18

Description:

Determine the first 10 natural

frequencies of the plate with a hole

shown. Assume the plate to be

radially constrained at the hole. The

plate is made of aluminum, with the

following properties:

Youngs modulus = 10 x 10

6

psi

Density = 2.4 x 10

-4

lbf-sec

2

/in

4

Poissons ratio = 0.27

Modal Analysis Workshop

Plate with a Hole

D

Y

N

A

M

I

C

S

7

.

0

Workshop Supplement

March 14, 2003

Inventory #001810

WS-19

Instructions

1. Clear the database and read input from plate.inp to create the model geometry

and mesh.

Utility Menu: File > Clear & Start New press OK, then answer Yes

Utility Menu: File > Read Input from choose plate.inp

2. Define material properties.

Preprocessor > Material Props > Material Models

Double click through

Structural Linear Elastic Isotropic

EX = 10e6 (Youngs modulus in psi)

PRXY = 0.27 (Poissons ratio)

[OK]

Structural Density

DENS = 2.4e-4 (Density in lbf-sec

2

/in

4

)

[OK]

Exit the material GUI

Modal Analysis Workshop

Plate with a Hole

D

Y

N

A

M

I

C

S

7

.

0

Workshop Supplement

March 14, 2003

Inventory #001810

WS-20

3. Choose modal analysis.

Solution > Analysis Type > New Analysis choose Modal, then OK

4. Specify analysis options.

Solution > Analysis Type > Analysis Options

Use Block Lanczos method (default)

10 modes to extract

10 modes to expand

Yes to calculate element results press OK

Accept defaults on the next dialog box

5. Radially constrain the hole.

Utility Menu: Plot > Lines

Solution > Define Loads > Apply > Structural > Displacement > Symmetry B.C. > On Lines

Pick the lines around the hole and press OK in the Picker Menu

6. Start the solution.

Solution > Solve > Current LS

Check solution information in the /STAT window, then press OK

Modal Analysis Workshop

Plate with a Hole

D

Y

N

A

M

I

C

S

7

.

0

Workshop Supplement

March 14, 2003

Inventory #001810

WS-21

7. Review results. Start by listing the frequencies.

General Postproc > Results Summary

8. Plot the first mode shape.

General Postproc > Read Results > First Set

General Postproc > Plot Results > Deformed Shape

Choose Def + undef edge and press OK

Modal Analysis Workshop

Plate with a Hole

Mode 1

D

Y

N

A

M

I

C

S

7

.

0

Workshop Supplement

March 14, 2003

Inventory #001810

WS-22

9. Plot and animate the next mode shape.

General Postproc > Read Results > Next Set

Utility Menu: Plot > Replot

Utility Menu: PlotCtrls > Animate > Mode Shape

10 frames

Time delay = 0.05

(accept all other defaults)

10. Repeat above step for subsequent mode

shapes.

Modal Analysis Workshop

Plate with a Hole

Mode 6

Modal Analysis

Workshop

Model Airplane Wing

D

Y

N

A

M

I

C

S

7

.

0

Workshop Supplement

March 14, 2003

Inventory #001810

WS-24

Description:

Determine the first five natural frequencies of the model airplane wing

shown. Assume the wing to be fully fixed at Z=0. The wing has the

following properties:

Youngs modulus = 38000 psi

Poissons ratio = 0.3

Density = 1.033 x 10

-3

slugs/in

3

= (1.033E-3)/12 lbf-sec

2

/in

4

Modal Analysis Workshop

Model Airplane Wing

D

Y

N

A

M

I

C

S

7

.

0

Workshop Supplement

March 14, 2003

Inventory #001810

WS-25

Instructions

1. Clear the database and read input from wing.inp to create the model

geometry and mesh.

2. Define material properties. Remember to use British in-lb-sec units.

3. Apply boundary conditions. Hint: Choose Apply Displacements on

Areas, pick the Z=0 area, and fix it in all DOF.

4. Extract (and expand) the first four natural frequencies using the

Block Lanczos method.

Modal Analysis Workshop

Model Airplane Wing

D

Y

N

A

M

I

C

S

7

.

0

Workshop Supplement

March 14, 2003

Inventory #001810

WS-26

5. Review all the mode shapes.

Modal Analysis Workshop

Model Airplane Wing

Mode 1

Mode 3

Mode 2

Mode 4

Harmonic Analysis

Workshop

Fixed-Fixed Beam

D

Y

N

A

M

I

C

S

7

.

0

Workshop Supplement

March 14, 2003

Inventory #001810

WS-28

Harmonic Analysis Workshop

Fixed-Fixed Beam

Description:

Determine the harmonic response of a steel beam carrying two

rotating machines which exert a maximum force of 70 lb at

operating speeds of 300 to 1800 rpm. The beam, 10 feet long, is

fully fixed at both ends, and the machines are mounted at its

one-third points. Assume a damping ratio of 2%.

D

Y

N

A

M

I

C

S

7

.

0

Workshop Supplement

March 14, 2003

Inventory #001810

WS-29

Instructions

1. Clear the database and read input from beam.inp to create the

beam model.

2. Specify harmonic analysis (full method) .

3. Fix the two ends of the beam and apply the two in-phase harmonic

forces of FY=70 lbs each at the 40-inch and 80-inch points along

the beam.

4. Specify a damping ratio of 0.02 (i.e. 2%).

Solution > Load Step Opts > Time/Frequenc > Damping

5. Specify 25 solutions between 5 and 30 Hz (300-1800 rpm).

Remember to step apply the loading.

Solution > Load Step Opts > Time/Frequenc > Freq and Substps

6. Obtain the harmonic solution.

Solution > Solve > Current LS

Harmonic Analysis Workshop

Fixed-Fixed Beam

D

Y

N

A

M

I

C

S

7

.

0

Workshop Supplement

March 14, 2003

Inventory #001810

WS-30

Harmonic Analysis Workshop

Fixed-Fixed Beam

7. In Time history post processor

plot UY displacements versus

frequency for the two nodes at

which the forces were applied.

NOTE: Use (Utility Menu > PlotCtrls >

Style > Graphs ) for changing graph

style / settings.

8. Find the critical frequency and

phase angle.

TimeHist Postpro > List Variables

D

Y

N

A

M

I

C

S

7

.

0

Workshop Supplement

March 14, 2003

Inventory #001810

WS-31

Harmonic Analysis Workshop

Fixed-Fixed Beam

9. In General Post processor review the deformed shape of the beam

at the critical frequency and phase angle.

1. Find the load step and substep for the critical frequency:

General Postproc > Result Summary

2. Issue the HRCPLX command to read in the results at the critical

frequency and phase angle:

HRCPLX,1,4,-25.3743

D

Y

N

A

M

I

C

S

7

.

0

Workshop Supplement

March 14, 2003

Inventory #001810

WS-32

Harmonic Analysis Workshop

Fixed-Fixed Beam

9. (continued).

3. Plot the UY displacement:

General Postproc > Plot Results > Contour Plot > Nodal Solu

plns,u,y

D

Y

N

A

M

I

C

S

7

.

0

Workshop Supplement

March 14, 2003

Inventory #001810

WS-33

Harmonic Analysis Workshop

Fixed-Fixed Beam

10. If time permits, repeat the analysis with forces that are 180 out of

phase.

D

Y

N

A

M

I

C

S

7

.

0

Workshop Supplement

March 14, 2003

Inventory #001810

WS-34

Harmonic Analysis Workshop

Fixed-Fixed Beam

10. (continued).

HRCPLX,1,21,-98.2155

plns,u,y

Transient Analysis

Workshop

Bouncing Block

D

Y

N

A

M

I

C

S

7

.

0

Workshop Supplement

March 14, 2003

Inventory #001810

WS-36

Description:

A 6x6x1-inch block is dropped on a 100-

inch long beam from a height of 100 inches.

Obtain a graph of the motion of the block as

it bounces on the beam. Assume a gap

stiffness of 2000 lb/in. The beam is fully

fixed at both ends, and the only load is

gravity, 386 in/sec

2

. The beam and the

block are made of the same material:

Youngs modulus = 1,000,000 psi

Density = 0.001 lbf-sec

2

/in

4

Poissons ratio = 0.3

Transient Analysis Workshop

Bouncing Block

D

Y

N

A

M

I

C

S

7

.

0

Workshop Supplement

March 14, 2003

Inventory #001810

WS-37

Instructions

1. Clear the database and read input from bounce.inp to build the

model.

2. Define a transient analysis (full method)

3. Fix the two ends of the beam in all directions.

4. Use APDL to calculate the integration time step (ITS):

kgap = 2000 - gap stiffness

mgap = 6*6*0.001 = 0.036 - mass of block

pi = acos(-1)

fgap = sqrt(kgap/mgap)/(2*pi) - gap frequency

its = 1/(fgap*30) - integration time step

Transient Analysis Workshop

Bouncing Block

D

Y

N

A

M

I

C

S

7

.

0

Workshop Supplement

March 14, 2003

Inventory #001810

WS-38

5. Solve using two load steps.

Load Step 1 (for non-zero initial acceleration):

Fix all nodes of the block in all dofs.

Apply an acceleration of 386 in/sec

2

In Solution Control menu,

Set analysis to large displacement transient.

Set time=0.001.

2 substeps

Request output of all results for all substeps on the results file

Static solution (time integration effects off) with Step applied load.

Set beta damping of .0003183.

SOLVE

Transient Analysis Workshop

Bouncing Block

D

Y

N

A

M

I

C

S

7

.

0

Workshop Supplement

March 14, 2003

Inventory #001810

WS-39

Load Step 2 ( transient):

Go back to solution control menu and

Time=1.5

Automatic time stepping on, with starting ITS = 0.02, minimum ITS =

its (from step 4) and maximum ITS = 0.02

Transient solution (time integration effects on)

Release the block

SOLVE

Transient Analysis Workshop

Bouncing Block

D

Y

N

A

M

I

C

S

7

.

0

Workshop Supplement

March 14, 2003

Inventory #001810

WS-40

Transient Analysis Workshop

Bouncing Block

6. Review results:

Plot the UY displacements of the beam mid-point and the block versus time.

Plot the FY reaction force at one of the constraints versus time.

Animate results over time. Note: To store all the frames needed for animation, you

may need to reduce the size of the graphics window.

D

Y

N

A

M

I

C

S

7

.

0

Workshop Supplement

March 14, 2003

Inventory #001810

WS-41

Transient Analysis Workshop

Bouncing Block

8. Do not exit ANSYS:

You will continue this workshop with a restart later on.

7. Animate results over time.

Note: To store all the frames

needed for animation, you

may need to reduce the size of

the graphics window.

/post1

/focus,,50,50

/dist,,70

/dsca,,1

/eshape,0

inres,nsol

set,first

pldisp

/noerase

*do,t,0.001,1.5,3/50

set,near,,,,t

pldisp

*enddo

/erase

Restarting a Transient

Workshop

Bouncing Block

D

Y

N

A

M

I

C

S

7

.

0

Workshop Supplement

March 14, 2003

Inventory #001810

WS-44

Restarting a Transient Workshop

Bouncing Block

Description:

Continue the bouncing block analysis from

the previous exercise. That analysis was

stopped at time=1.5. In this exercise we

will continue to follow the blocks motion

up to time=3.0.

The restart files needed (.r001 /.ldhi /.rdb )

are available from the previous workshop.

The results file from the previous transient

analysis is also available. ANSYS will

append the new results to this RST file as

load step 3.

Time = 1.5

D

Y

N

A

M

I

C

S

7

.

0

Workshop Supplement

March 14, 2003

Inventory #001810

WS-45

Instructions:

1. Continue the ANSYS session from the previous workshop.

2. Solution > Analysis Type > Restart

This will bring up a lister window showing a summary of the

restart files available. Choose the load step and substep number

from this summary.

3. In Solution Control menu under the Time Control section: change

TIME to 3.0 and select Time increment.

4. Solve.

Restarting a Transient Workshop

Bouncing Block

D

Y

N

A

M

I

C

S

7

.

0

Workshop Supplement

March 14, 2003

Inventory #001810

WS-46

Restarting a Transient Workshop

Bouncing Block

In Time History postprocessor graph the UY displacement of a

node on the block and a node on the beam again.

D

Y

N

A

M

I

C

S

7

.

0

Workshop Supplement

March 14, 2003

Inventory #001810

WS-47

Restarting a Transient Workshop

Bouncing Block

In the general postprocessor animate the bouncing of the block

again.

Animate results over time. Note: To store all the frames needed for

animation, you may need to reduce the size of the graphics window.

Time = 1.5 to 3

Response Spectrum

Workshop

Workbench Table

D

Y

N

A

M

I

C

S

7

.

0

Workshop Supplement

March 14, 2003

Inventory #001810

WS-50

Description:

Determine the displacements

and stresses in a workbench

table due to the acceleration

spectrum shown below.

A

c

c

e

l

e

r

a

t

i

o

n

Frequency

20 80 200 300

217 217

79.5

150.2

Response Spectrum Workshop

Workbench Table

D

Y

N

A

M

I

C

S

7

.

0

Workshop Supplement

March 14, 2003

Inventory #001810

WS-51

Response Spectrum Workshop

Workbench Table

Instructions

1. Clear the database and read input

from table.inp to create the model

geometry and mesh.

2. Obtain a modal solution (15

modes) and view the first few

mode shapes. Be sure to request

element stress calculations.

Mode 1 Mode 2

D

Y

N

A

M

I

C

S

7

.

0

Workshop Supplement

March 14, 2003

Inventory #001810

WS-52

Response Spectrum Workshop

Workbench Table

3. Do a spectrum analysis for the

given acceleration spectrum

applied in the global X direction.

Use the SRSS method of mode

combination.

4. Review displacements and table

top stresses for each load step.

pldisp,2

plns,u,x

plns,s,1

D

Y

N

A

M

I

C

S

7

.

0

Workshop Supplement

March 14, 2003

Inventory #001810

WS-53

5. If time permits, repeat the analysis with the spectrum applied in the Y

direction, then in the Z direction.

Response Spectrum Workshop

Workbench Table

Random Vibration (PSD)

Workshop

Model Airplane Wing

D

Y

N

A

M

I

C

S

7

.

0

Workshop Supplement

March 14, 2003

Inventory #001810

WS-56

Random Vibrations Workshop

Model Airplane Wing

Description:

Determine the displacements and stresses of the model airplane

wing due to an acceleration PSD applied to the base of the wing in

Y direction. Assume the wing to be fully fixed at Z=0.

A

c

c

e

l

e

r

a

t

i

o

n

(

G

2

/

H

z

)

Frequency (Hz)

20 100 400 600

0.1 0.1

0.025

0.075

D

Y

N

A

M

I

C

S

7

.

0

Workshop Supplement

March 14, 2003

Inventory #001810

WS-57

Random Vibrations Workshop

Model Airplane Wing

Instructions

1. Clear the database and read input

from wing.inp to create the model

geometry and mesh.

2. Define material properties.

Youngs modulus = 38000 psi

Poissons ratio = 0.3

Density = 1.033E-3/12 lbf-sec2/in4

3. Apply boundary conditions. Hint:

Choose Apply Displacements on

Areas, pick the Z=0 area, and fix it in

all DOF.

4. Extract (and expand) the first 15

natural frequencies using the Block

Lanczos method.

5. Review mode shapes.

Mode 1

D

Y

N

A

M

I

C

S

7

.

0

Workshop Supplement

March 14, 2003

Inventory #001810

WS-58

6. Perform a PSD Spectrum analysis using the acceleration PSD

shown.

Hint: Be sure to use G

2

/Hz as the units of the PSD.

7. Specify excitation in the Y direction (by applying unit

displacements in the Y direction at the base nodes).

8. Compute Participation factors.

9. Use PSD mode combination method and SOLVE.

Random Vibrations Workshop

Model Airplane Wing

D

Y

N

A

M

I

C

S

7

.

0

Workshop Supplement

March 14, 2003

Inventory #001810

WS-59

Random Vibrations Workshop

Model Airplane Wing

10. In the general postprocessor look at the relative displacements/ stresses (

Load step 3).

Can you directly use stress contours for, say SZ, to compare to yield stress?

What is in load step 1?

Are equivalent/principal stresses derived from 1 sigma component stresses valid?

D

Y

N

A

M

I

C

S

7

.

0

Workshop Supplement

March 14, 2003

Inventory #001810

WS-60

Random Vibrations Workshop

Model Airplane Wing

11. In Time History Postprocessor create the response PSD for UY at one of

the nodes of the wingtip. Plot on log-log scale.

Hint: When you get into time history postprocessor first issue Store Data and

accept the default. This is required for computing Response PSD.

NODE 182

Pre-stressed Modal

Workshop

Pre-Stressed Disc

D

Y

N

A

M

I

C

S

7

.

0

Workshop Supplement

March 14, 2003

Inventory #001810

WS-62

Modal Analysis Workshop

Pre-stressed Disc

Description:

Determine the first ten natural frequencies and mode shapes of the

perforated aluminum disc shown. The disc is constrained at the central

hole both in the radial and out-of-plane directions. A pre-stress exists due

to a radial pressure load of -20 lbs/inch at the perimeter. Properties of the

disc are as follows:

Youngs modulus = 1.0 x 10

7

psi

Density = 2.3 x 10-4 lbf-sec2/in4

Poissons ratio = 0.27

D

Y

N

A

M

I

C

S

7

.

0

Workshop Supplement

March 14, 2003

Inventory #001810

WS-63

Instructions

1. Clear the database and read input from disc.inp to create the model

geometry and mesh.

2. Apply displacement constraints: UZ=0 and symmetry b.c. (for radial

constraints) at the central hole. Hint: You will need to use two

menus:

Solution > Define Loads >Apply > Structural > Displacement > On Lines for the UZ

constraint

Solution > Define Loads > Apply > Structural > Displacement > Symmetry B.C. > On Lines

for symmetry b.c.

To pick the lines easily, switch to front view and use Circle picking.

Modal Analysis Workshop

Pre-stressed Disc

D

Y

N

A

M

I

C

S

7

.

0

Workshop Supplement

March 14, 2003

Inventory #001810

WS-64

Modal Analysis Workshop

Pre-stressed Disc

3. Apply the radial load as pressure on

the lines at the perimeter : -20

pounds/inch on the outer edges of the

disc.

Hint: Stay with the front view, use

Circle picking to pick the entire disc,

then use Circle unpicking to unpick all

except the outer edges.

4. Activate pre-stress effects (using the

Analysis Options dialog box), obtain a

static solution, and review results.

plns,s,1

D

Y

N

A

M

I

C

S

7

.

0

Workshop Supplement

March 14, 2003

Inventory #001810

WS-65

Modal Analysis Workshop

Pre-stressed Disc

5. Switch to modal analysis,

activate pre-stress effects

(again), and extract the first 10

modes of the pre-stressed disc

using the Block Lanczos method.

6. Review the mode shapes.

7. If time permits, do a second,

stress-free modal analysis (with

pre-stress effects off) and

compare results. Shown to the

right is the first mode shape for

each case. Can you guess which

one is pre-stressed?

FREQ = 73.484

FREQ = 1.582

Modal Cyclic Symmetry

Workshop

Spiral Bevel Gear

D

Y

N

A

M

I

C

S

7

.

0

Workshop Supplement

March 14, 2003

Inventory #001810

WS-68

Description:

Determine the first two natural frequencies

of nodal diameter 2 for the spiral bevel

gear shown. Assume a free-free condition

(i.e., no displacement constraints).

Material properties of the gear are as

follows:

Youngs modulus = 2.9 x 10

7

psi

Density = 7.324 x 10

-4

lbf-sec

2

/in

4

Poissons ratio = 0.32

Modal Cyclic Symmetry Workshop

Spiral Bevel Gear

Courtesy: Sikorsky Aircraft

D

Y

N

A

M

I

C

S

7

.

0

Workshop Supplement

March 14, 2003

Inventory #001810

WS-69

Instructions

1. Clear the database and read input from

bevel.inp to create the basic sector and define

material properties.

2. Issue the CYCLIC command to automatically

detect the low and high edge components using

BEVEL as the Root name for the components

( Preprocessor > Modeling > Cyclic Sector > Cyclic

Model > Auto Defined )

Modal Cyclic Symmetry Workshop

Spiral Bevel Gear

D

Y

N

A

M

I

C

S

7

.

0

Workshop Supplement

March 14, 2003

Inventory #001810

WS-70

3. Display the current cyclic status:

Preprocessor > Modeling > Cyclic Sector > Cyclic Model > Status

Modal Cyclic Symmetry Workshop

Spiral Bevel Gear

D

Y

N

A

M

I

C

S

7

.

0

Workshop Supplement

March 14, 2003

Inventory #001810

WS-71

4. Define a modal analysis with the following options:

Block Lanczos method

Extract two modes in the frequency range 100 to 10,000

Expand 2 modes

5. Solve for nodal diameter range 2 to 2:

1. Solution > Solve > Cyclic Options

2. Solution > Solve > Current LS

Modal Cyclic Symmetry Workshop

Spiral Bevel Gear

D

Y

N

A

M

I

C

S

7

.

0

Workshop Supplement

March 14, 2003

Inventory #001810

WS-72

6. Expand results to all 53 sectors ( General Postproc > Cyclic Analysis > Cyc

Expansion ). Then read in the results of the first mode shape (General Postproc

> Read Results > First set ). Plot the nodal solution for UZ displacements.

NOTE: The /CYCEXPAND command actually creates new elements and

nodes for all 53 sectors.

Modal Cyclic Symmetry Workshop

Spiral Bevel Gear

/gline,1,-1

plns,u,z

D

Y

N

A

M

I

C

S

7

.

0

Workshop Supplement

March 14, 2003

Inventory #001810

WS-73

7. Plot the vector sum displacement.

Modal Cyclic Symmetry Workshop

Spiral Bevel Gear

plns,u,sum

D

Y

N

A

M

I

C

S

7

.

0

Workshop Supplement

March 14, 2003

Inventory #001810

WS-74

8. Execute the ANCYC traveling wave animation:

Utility Menu > PlotCtrls > Animate > Cyc Traveling Wave

No. of frames to create = 25

Time delay = 0.1

Animation Mode = Forward-Reset-Forward

Nodal Solution Data

DOF solution

USUM

[OK]

Modal Cyclic Symmetry Workshop

Spiral Bevel Gear

También podría gustarte

- Dynamics 7.0: Training ManualDocumento4 páginasDynamics 7.0: Training ManualMaria Lavinia IordacheAún no hay calificaciones

- Dynamics 70 WorkshopsDocumento74 páginasDynamics 70 WorkshopsZain Ul Islam ButtAún no hay calificaciones

- Equipment Inspection ReportDocumento2 páginasEquipment Inspection ReportZain Ul Islam ButtAún no hay calificaciones

- PS JA 03 Planning EngineerDocumento2 páginasPS JA 03 Planning EngineerZain Ul Islam ButtAún no hay calificaciones

- PS-JA-01 Manager Plant ServicesDocumento3 páginasPS-JA-01 Manager Plant ServicesZain Ul Islam ButtAún no hay calificaciones

- PS-FRM-02 Contract Review ChecklistDocumento1 páginaPS-FRM-02 Contract Review ChecklistZain Ul Islam ButtAún no hay calificaciones

- PS JA 02 Project ManagerDocumento3 páginasPS JA 02 Project ManagerZain Ul Islam ButtAún no hay calificaciones

- Storage Tanks OverviewDocumento3 páginasStorage Tanks OverviewZain Ul Islam ButtAún no hay calificaciones

- Solidworks AssignmentsDocumento14 páginasSolidworks AssignmentszemanicAún no hay calificaciones

- Vibration Mechanism of A Mistuned Bladed-Disk: Y.J. Yan, P.L. Cui, H.N. HaoDocumento14 páginasVibration Mechanism of A Mistuned Bladed-Disk: Y.J. Yan, P.L. Cui, H.N. HaoZain Ul Islam ButtAún no hay calificaciones

- 11TPC 188queauDocumento1 página11TPC 188queausirishadeepthi9840Aún no hay calificaciones

- Tool Kit For Fabricator Piping: S.No Size Unit QTY DecriptionDocumento7 páginasTool Kit For Fabricator Piping: S.No Size Unit QTY DecriptionZain Ul Islam ButtAún no hay calificaciones

- Darcy Weisbach FormulaDocumento3 páginasDarcy Weisbach Formulasairam2234Aún no hay calificaciones

- 11TPC 188queauDocumento1 página11TPC 188queausirishadeepthi9840Aún no hay calificaciones

- 3month Look Ahead PlanDocumento1 página3month Look Ahead PlanZain Ul Islam ButtAún no hay calificaciones

- Usa Recognition ListDocumento23 páginasUsa Recognition ListPavitra JayaramanAún no hay calificaciones

- An Interview With Wal-Mart CEO H. Lee Scott: Amanda Little Startling Call For Mandatory CapsDocumento6 páginasAn Interview With Wal-Mart CEO H. Lee Scott: Amanda Little Startling Call For Mandatory CapsZain Ul Islam ButtAún no hay calificaciones

- Powering Pakistan One Stop ServiceDocumento2 páginasPowering Pakistan One Stop ServicemirfanbilalAún no hay calificaciones

- ZUIB Cover LetterDocumento1 páginaZUIB Cover LetterZain Ul Islam ButtAún no hay calificaciones

- Building A World-Class PMODocumento29 páginasBuilding A World-Class PMOZain Ul Islam ButtAún no hay calificaciones

- WallmartDocumento59 páginasWallmartZain Ul Islam ButtAún no hay calificaciones

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeCalificación: 4 de 5 estrellas4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe EverandThe Little Book of Hygge: Danish Secrets to Happy LivingCalificación: 3.5 de 5 estrellas3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceCalificación: 4 de 5 estrellas4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeDe EverandShoe Dog: A Memoir by the Creator of NikeCalificación: 4.5 de 5 estrellas4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDe EverandGrit: The Power of Passion and PerseveranceCalificación: 4 de 5 estrellas4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureCalificación: 4.5 de 5 estrellas4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)De EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Calificación: 4 de 5 estrellas4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnDe EverandTeam of Rivals: The Political Genius of Abraham LincolnCalificación: 4.5 de 5 estrellas4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe EverandNever Split the Difference: Negotiating As If Your Life Depended On ItCalificación: 4.5 de 5 estrellas4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDe EverandThe Emperor of All Maladies: A Biography of CancerCalificación: 4.5 de 5 estrellas4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryCalificación: 3.5 de 5 estrellas3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaCalificación: 4.5 de 5 estrellas4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersCalificación: 4.5 de 5 estrellas4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealDe EverandOn Fire: The (Burning) Case for a Green New DealCalificación: 4 de 5 estrellas4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyCalificación: 3.5 de 5 estrellas3.5/5 (2219)

- Rise of ISIS: A Threat We Can't IgnoreDe EverandRise of ISIS: A Threat We Can't IgnoreCalificación: 3.5 de 5 estrellas3.5/5 (137)

- The Unwinding: An Inner History of the New AmericaDe EverandThe Unwinding: An Inner History of the New AmericaCalificación: 4 de 5 estrellas4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreCalificación: 4 de 5 estrellas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Calificación: 4.5 de 5 estrellas4.5/5 (119)

- The Perks of Being a WallflowerDe EverandThe Perks of Being a WallflowerCalificación: 4.5 de 5 estrellas4.5/5 (2099)

- Her Body and Other Parties: StoriesDe EverandHer Body and Other Parties: StoriesCalificación: 4 de 5 estrellas4/5 (821)

- NAVIGAT 2500 CompassNet Feb 21 Web VersionDocumento4 páginasNAVIGAT 2500 CompassNet Feb 21 Web VersionaryobsAún no hay calificaciones

- Radio Interference PDFDocumento76 páginasRadio Interference PDFBorut ZaletelAún no hay calificaciones

- Career Objective:: Chandru.K Contact No: E-MailDocumento3 páginasCareer Objective:: Chandru.K Contact No: E-MailChand RuAún no hay calificaciones

- End Sem - Solution & Marking SchemeDocumento41 páginasEnd Sem - Solution & Marking SchemeHaryanvi ChhoraAún no hay calificaciones

- General Information: Shutdown SISDocumento5 páginasGeneral Information: Shutdown SISwagner_guimarães_1Aún no hay calificaciones

- gr10 Ta Science 2018 Term - 2Documento13 páginasgr10 Ta Science 2018 Term - 2S. JATHUAún no hay calificaciones

- RU EngineeringDocumento11 páginasRU EngineeringjoycechicagoAún no hay calificaciones

- IRSE News 278 Jun 21Documento40 páginasIRSE News 278 Jun 21Julian Hanggara AdigunaAún no hay calificaciones

- FC Vs FBDocumento8 páginasFC Vs FBMiguel SanchesAún no hay calificaciones

- Meditaciones Diarias THOMAS PRINTZDocumento100 páginasMeditaciones Diarias THOMAS PRINTZCristian Andres Araya CisternasAún no hay calificaciones

- BlackHat Europe 09 Damele A G Advanced SQL Injection WhitepaperDocumento37 páginasBlackHat Europe 09 Damele A G Advanced SQL Injection WhitepaperPradeep ChauhanAún no hay calificaciones

- Medal Log 20230820Documento11 páginasMedal Log 20230820Pedro HenriqueAún no hay calificaciones

- Open Fabric 1200 Launch SlidesDocumento10 páginasOpen Fabric 1200 Launch SlidesLaboriosaAún no hay calificaciones

- Alg Linear Axminusbeqc All PDFDocumento20 páginasAlg Linear Axminusbeqc All PDFNurulAún no hay calificaciones

- QB SetDocumento30 páginasQB SetAhyyaAún no hay calificaciones

- Chuyển đổi báo cáoDocumento12 páginasChuyển đổi báo cáo21OT112- Huỳnh Gia KiệtAún no hay calificaciones

- Sample Paper PVTC: Building Standards in Educational and Professional TestingDocumento7 páginasSample Paper PVTC: Building Standards in Educational and Professional Testingsamey21Aún no hay calificaciones

- All NudgeMail Commands Jan 27 Sheet1Documento3 páginasAll NudgeMail Commands Jan 27 Sheet1Lucas BelloliAún no hay calificaciones

- 4-20mA Radar Level Sensor Spec SheetDocumento2 páginas4-20mA Radar Level Sensor Spec SheetShrikant KambleAún no hay calificaciones

- Current-Controlled Sawtooth Generator: Active and Passive Electronic Components September 2004Documento6 páginasCurrent-Controlled Sawtooth Generator: Active and Passive Electronic Components September 2004AquariusAún no hay calificaciones

- System Flow Diagram and Level O-OE - SDocumento3 páginasSystem Flow Diagram and Level O-OE - Ssunil bhandariAún no hay calificaciones

- Gsm/Gprs/Gps Tracker User Manual: PrefaceDocumento13 páginasGsm/Gprs/Gps Tracker User Manual: PrefaceMichel PaisibleAún no hay calificaciones

- Emotionally Adaptive Driver Voice Alert System For Advanced Driver Assistance System (ADAS) ApplicationsDocumento4 páginasEmotionally Adaptive Driver Voice Alert System For Advanced Driver Assistance System (ADAS) ApplicationsBaptist LAún no hay calificaciones

- Pearson's Product-Moment Correlation Coefficient - Is A Measure of The Linear Strength of The Association Between Two Variables - It IsDocumento2 páginasPearson's Product-Moment Correlation Coefficient - Is A Measure of The Linear Strength of The Association Between Two Variables - It IsMaryJoyce PalmaAún no hay calificaciones

- AMOS-820 Linux BSP v3.0.2 Quick Start Guide v1.00 20160627Documento24 páginasAMOS-820 Linux BSP v3.0.2 Quick Start Guide v1.00 20160627asad_masharfeh7401100% (1)

- Chapter 1: Data Warehousing:: Dept of CSE, KLESCET - Shrikant AthanikarDocumento23 páginasChapter 1: Data Warehousing:: Dept of CSE, KLESCET - Shrikant AthanikarshreyaAún no hay calificaciones

- Speed Control of BLDC Motor Using PI andDocumento20 páginasSpeed Control of BLDC Motor Using PI andamn04feb0% (1)

- PVTsim Hands-On Webinar Handout - Introduction To EoS ModelingDocumento22 páginasPVTsim Hands-On Webinar Handout - Introduction To EoS ModelingsabrineAún no hay calificaciones

- IDC Whitepaper Demonstrating Business ValueDocumento15 páginasIDC Whitepaper Demonstrating Business ValueRamon MateoAún no hay calificaciones

- Stalker ScriptDocumento2 páginasStalker Scriptapi-528387861Aún no hay calificaciones