Documentos de Académico

Documentos de Profesional

Documentos de Cultura

M350 Wk6 Intro - Sensors

Cargado por

noobaznkidDescripción original:

Título original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

M350 Wk6 Intro - Sensors

Cargado por

noobaznkidCopyright:

Formatos disponibles

MECH 350 Instrumentation and Design of

Experiments

Basic Sensors

Page 147

Main topics:

Measured Parameters

Sensor Fundamentals

Contents

Sensor principles

Predominant sensor technologies

Overview of main sensor categories

Position / Speed

Stress / Strain

Temperature

Vibration / Acceleration

Sampling of Specialty sensors

Objectives

Understand the fundamentals of simple sensors,

including proximity sensor, potentiometers,

linear variable differential transformers, optical

encoders, strain gages, thermocouples, and

accelerometers.

Be able to identify suitable sensor technologies

for a given application.

Sensor Principles

Recall, from Lecture 1:

A sensor is a device that takes in information

from the outside world. Based on the

information, the sensor creates a signal on

which a system can base a decision.

A sensor, thus, has an input and an output

Usually, a sensor is tailored to a specific task

A sensor will measure some physical quantity

and convert it into some electrical signal (e.g.,

voltage, current)

Sensor Classifications

1. Position and Speed measurement: rate or

voltage of output signal changes with input

2. Stress and Strain measurement: applied

force results in changes in resistance

3. Temperature measurement: resistance or

voltage of output signal changes with temp.

4. Vibration and Acceleration measurement:

voltage created from piezoelectric materials

5. Pressure and Flow measurement: often

derived from sensors listed above.

Sensor Technology (1)

Mechanical sensor technology:

Centrifugal governor as rotational velocity

increases, outward movement of weights causes a

linear shaft movement closes steam valve

Bimetallic strip - differing coefficient of

expansion results in movement with temperature

standard household thermostat

Spring loaded valve / scale opposing pressure

or force can be read from a scale

Bourdon tube length and/or position changes

with pressure.

Pitot pressure tube fluid velocity based on

pressure; aircraft airspeed indicator

Sensor Technology (2)

Electrical sensor technology:

Resistive

change in length, L or cross-sectional area, A results in

changes in resistance for a given material resistivity,

Inductive - voltage based on time rate of change

of magnetic flux;

Movement of a magnetically permeable object

within the magnetic field of a coil

Movement of a magnet within a coil

A

L

R

Sensor Technology (3)

Electrical sensor technology (continued):

Capacitive energy stored between parallel

plates of a capacitor is related to distance between

plates and the plate geometry.

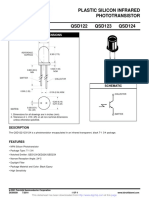

Optical Photodiodes and photoresistors are

affected by amount of light striking the sensing

surface

Piezoelectric sensors made of materials that

produce a voltage when subjected to strain; quartz

is most common.

1. Position and Speed

Position Measurements:

Proximity sensors create a change in state

(switch) or vary an analog output when close to,

but typically not touching an object.

Technology: Magnetic, capacitance, inductance.

Applications: counting objects, limiting travel of a

mechanism

Potentiometers resistance varies with angular

or linear positioning; 5k pot

Technology: resistance due to length of electrical travel

Applications: volume control, variable speed control

1. Position and Speed

Position Measurements:

Proximity sensors

Potentiometers

1. Position and Speed (cont.)

Speed Measurements:

Digital optical encoder using light, the sensor

converts rotary motion to digital pulses

Technology: LED and photodiode / photoresistor

Applications: speed of conveyor systems

Generator converts rotary motion to DC voltage

potential.

Technology: induced EMF by rotating armature

Applications: speed of moving or rotating machinery

1. Position and Speed (cont.)

Speed Measurements:

Digital optical encoder

Generator

2. Stress and Strain

Values of stress, derived from strain

Resistance strain gage resistance of a thin

metal foil grid changes with strain

Technology: electrical resistance

Applications: stress / force on any elastic member can

be measured planes, trains, automobiles

Load cell calibrated strain gages with circuitry in

a specified package

Technology: Resistance, piezoelectric

Applications: Instron and other tensile testing

equipment.

2. Stress and Strain

Resistance strain gage

Load cell

3. Temperature

Thermocouple voltage created by contacting

dissimilar metals varies with temperature

Technology: Seebeck (thermoelectric) effect

Applications: industrial temperature monitoring where

control and/or recording is required

Resistance Temperature Detector (RTD)

metallic coil wrapped on a ceramic core

Technology: Metallic resistance.

Applications: faster response and/or greater accuracy

than thermocouple devices; limited to 600

o

C

3. Temperature

Thermocouple

Unsheathed Thermocouple

Resistance Temperature

Detector (RTD)

4. Vibration and Acceleration

Accelerometers used to determine the rate of

change in velocity of an object.

Technology: inertial mass and displacement of mass

compared to surroundings; (position sensors)

Applications: seismic activity, car crash testing,

pedometer, suspension damping effectiveness,

camcorder image stabilization, Wii remote

Often used to measure continuous mechanical

vibrations bearings in machinery, resonant

frequency of structures.

4. Vibration and Acceleration

Accelerometers

5. Pressure and Flow

Pressure:

Displacement used as basis of measurement

Technology: strain gauge or piezoelectric (dynamic)

Applications: industrial pressure monitoring of fluids in

storage vessels or within a process

Flow:

Venturi / Orifice plate pressure differential

Turbine / rotary paddle wheel flow meters

Laser Doppler velocimeter (LDVs) change in

reflected wavelength from particles in fluid

5. Pressure and Flow

Pressure:

Piezoelectric

Pressure Transducer

Flow:

Specialty Sensors

Mass Airflow sensor automotive intake; vane

meter or hot wire sensor

Oxygen sensor ceramic and platinum; senses

O

2

concentration in the exhaust vs. outside air

Capacitive touch sensor appliance and other

touch control with no physical switch movement

Specialty Sensors (cont.)

PIR (Passive Infrared) Motion sensor converts

infrared radiation into electrical signal

Microelectromechanical systems (MEMS)

micromachined silicon; acceleration, pressure

Light / Image sensors photoelectric, CCD

others - http://en.wikipedia.org/wiki/List_of_sensors

Sensor Technology Comparison

Mechanical sensors:

(+) Reliability, simplicity, cost

(-) Limited applications, slow response, transducer

complexity, measurand recording

Electrical / Electronic sensors:

(+) Diversity of application, easily

scalable/customizable, ease of signal conditioning,

production repeatability, cost, remote monitoring,

data capture,

(-) Cost (if low volume), electrical noise, susceptible to

electrical spikes, temperature effects.

Homework Use pages 147 thru 188 as a guide

Choose two of the applications listed below and provide

answers to the following:

a) Identify the physical quantities that need to be measured

and why they are important.

b) Identify the sensor category and sensor technology that

could be used. Be sure to explain your reasoning.

c) Discuss any limitations and/or trade-offs that are involved.

Applications: Home burglar system, combined household heating

and cooling system, television with attached Nintendo Wii

console, automobile drivetrain, hospital recovery room, weather

forecasting data center.

Note: There are many other sensors in addition to those presented

in this lecture. Grading will be based on thoroughness.

También podría gustarte

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceCalificación: 4 de 5 estrellas4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeCalificación: 4 de 5 estrellas4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDe EverandShoe Dog: A Memoir by the Creator of NikeCalificación: 4.5 de 5 estrellas4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDe EverandGrit: The Power of Passion and PerseveranceCalificación: 4 de 5 estrellas4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)De EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Calificación: 4 de 5 estrellas4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe EverandThe Little Book of Hygge: Danish Secrets to Happy LivingCalificación: 3.5 de 5 estrellas3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe EverandNever Split the Difference: Negotiating As If Your Life Depended On ItCalificación: 4.5 de 5 estrellas4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureCalificación: 4.5 de 5 estrellas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryCalificación: 3.5 de 5 estrellas3.5/5 (231)

- Rise of ISIS: A Threat We Can't IgnoreDe EverandRise of ISIS: A Threat We Can't IgnoreCalificación: 3.5 de 5 estrellas3.5/5 (137)

- The Emperor of All Maladies: A Biography of CancerDe EverandThe Emperor of All Maladies: A Biography of CancerCalificación: 4.5 de 5 estrellas4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaCalificación: 4.5 de 5 estrellas4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersCalificación: 4.5 de 5 estrellas4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealDe EverandOn Fire: The (Burning) Case for a Green New DealCalificación: 4 de 5 estrellas4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyCalificación: 3.5 de 5 estrellas3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnDe EverandTeam of Rivals: The Political Genius of Abraham LincolnCalificación: 4.5 de 5 estrellas4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDe EverandThe Unwinding: An Inner History of the New AmericaCalificación: 4 de 5 estrellas4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreCalificación: 4 de 5 estrellas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Calificación: 4.5 de 5 estrellas4.5/5 (121)

- The Perks of Being a WallflowerDe EverandThe Perks of Being a WallflowerCalificación: 4.5 de 5 estrellas4.5/5 (2104)

- Her Body and Other Parties: StoriesDe EverandHer Body and Other Parties: StoriesCalificación: 4 de 5 estrellas4/5 (821)

- Pspice Lab #3: DC Characteristics of A Bipolar Transistor (BJT)Documento4 páginasPspice Lab #3: DC Characteristics of A Bipolar Transistor (BJT)sabitavabiAún no hay calificaciones

- Siei PDPDocumento28 páginasSiei PDPRoxana NegoitaAún no hay calificaciones

- TH L32a10s2Documento124 páginasTH L32a10s2Nilo Magno0% (1)

- Tda 7350 PDFDocumento22 páginasTda 7350 PDFGustavo MathiasAún no hay calificaciones

- Semi-Integrated SOG/TEOS Etchback Process For Multimetal Submicron DevicesDocumento4 páginasSemi-Integrated SOG/TEOS Etchback Process For Multimetal Submicron DevicesJohn KikidisAún no hay calificaciones

- Thesis Book - Abhijit Das (1501083)Documento60 páginasThesis Book - Abhijit Das (1501083)kazi ahadAún no hay calificaciones

- Gas LasersDocumento53 páginasGas LasersDheeraj100% (1)

- Lecture 1Documento52 páginasLecture 1Lokendra AgarwalAún no hay calificaciones

- Biasing For Zero Distortion: Using The EKV/BSIM6 ExpressionsDocumento6 páginasBiasing For Zero Distortion: Using The EKV/BSIM6 ExpressionsLaurMateiAún no hay calificaciones

- Instructions Manual EVR IMEV900002Documento20 páginasInstructions Manual EVR IMEV900002Ivan Dario QuirogaAún no hay calificaciones

- Infineon SPP - I - A15N60C3 DS v03 - 03 EN 53478Documento15 páginasInfineon SPP - I - A15N60C3 DS v03 - 03 EN 53478Jeferson TorresAún no hay calificaciones

- Opa 1637Documento35 páginasOpa 1637GAJENDRA KUMAR CHANDNIHAAún no hay calificaciones

- Marcel - Dekker.protective - Relaying.theory - And.applications.2nd - Ebook TLFeBOOKDocumento426 páginasMarcel - Dekker.protective - Relaying.theory - And.applications.2nd - Ebook TLFeBOOKMahesh Singh94% (17)

- Laser Beam WeldingDocumento45 páginasLaser Beam WeldingAhmed El Morsy0% (1)

- Arkan Kovan ABudllahDocumento13 páginasArkan Kovan ABudllahYasir Yasir KovanAún no hay calificaciones

- Silicon Infrared PhototransistorDocumento4 páginasSilicon Infrared Phototransistorapi-306843506Aún no hay calificaciones

- ATmega16 or 32 Mini User ManualDocumento12 páginasATmega16 or 32 Mini User ManualShivanshscribdAún no hay calificaciones

- Videocon InvertersDocumento2 páginasVideocon InvertersVignesh Mahalingam100% (1)

- MYP Year III Mathematics Unit 2 GRASPS TaskDocumento4 páginasMYP Year III Mathematics Unit 2 GRASPS TaskHamdan mohammedAún no hay calificaciones

- Scarab 2Documento12 páginasScarab 2ibneuronaAún no hay calificaciones

- Assignment2 - Network TheoryDocumento13 páginasAssignment2 - Network TheoryMaulesh GandhiAún no hay calificaciones

- 7PA26 27 30 Catalog SIP E6Documento5 páginas7PA26 27 30 Catalog SIP E6tduskoAún no hay calificaciones

- Inverter 2000 Rev DDocumento2 páginasInverter 2000 Rev DdiabolousxAún no hay calificaciones

- IRTS Studying For The HARECDocumento40 páginasIRTS Studying For The HARECserepezAún no hay calificaciones

- Wideband Rec FDocumento9 páginasWideband Rec FMontaha BouezzeddineAún no hay calificaciones

- Beta Ratio Effects: Skewed Inverters (Sutherland99) - If R UnskewedDocumento1 páginaBeta Ratio Effects: Skewed Inverters (Sutherland99) - If R UnskewedCarlos SaavedraAún no hay calificaciones

- EC208 Analog Communication EngineeringDocumento2 páginasEC208 Analog Communication EngineeringtrismaheshAún no hay calificaciones

- Intek H520 Plus ENG PDFDocumento57 páginasIntek H520 Plus ENG PDFjosemarquesAún no hay calificaciones

- 132 - 136 Dinda Fadhya Darmidjas 21060118130105Documento8 páginas132 - 136 Dinda Fadhya Darmidjas 21060118130105Dinda FadhyaAún no hay calificaciones