Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Access Steel - SX023a - Effective Section Properties of Steel Lipped Channel in Compression

Cargado por

gianniorlati1972Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Access Steel - SX023a - Effective Section Properties of Steel Lipped Channel in Compression

Cargado por

gianniorlati1972Copyright:

Formatos disponibles

Example: Calculation of effective section properties for a cold-formed lipped channel section in compression

CALCULATION SHEET

Document Ref: Title

SX023a-EN-EU

Sheet

of

Example: Calculation of effective section properties for a cold-formed lipped channel section in compression EN 1993-1-3 V. Ungureanu, A. Ruff D. Dubina

Date Date

Eurocode Ref Made by Checked by

Dec 2005 Dec 2005

Example: Calculation of effective section properties for a cold-formed lipped channel section in compression

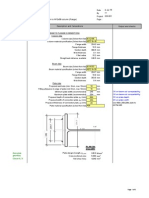

This example deals with the effective properties calculation of a coldformed lipped channel section subjected to compression.

For practical design of light gauge sections to EN1993, designers will normally use software or refer to manufacturers data. This example is presented for illustrative purposes

Basic Data The dimensions of the cross-section and the material properties are: Total height h = 200 mm Total width of upper flange

Created on Saturday, October 10, 2009 This material is copyright - all rights reserved. Use of this document is subject to the terms and conditions of the Access Steel Licence Agreement

b1 = 74 mm b2 = 66 mm

c = 20,8 mm r = 3 mm

Total width of bottom flange Total width of edge fold Internal radius Nominal thickness Steel core thickness Basic yield strength Modulus of elasticity Poissons ratio Partial factor

tnom = 2 mm

t = 1,96 mm

EN1993-1-3 3.2.4(3)

f yb = 350 N mm2

E = 210000 N mm 2

= 0,3

M0 = 1,0

EN1993-1-3 2(3)

The dimensions of the section centre line are:

Web height Width of upper flange Width of bottom flange Width of edge fold

hp = h tnom = 200 2 = 198 mm

bp1 = b1 tnom = 74 2 = 72 mm bp2 = b2 tnom = 66 2 = 64 mm cp = c tnom 2 = 20 ,8 2 2 = 19 ,8 mm

Example: Calculation of effective section properties for a cold-formed lipped channel section in compression

CALCULATION SHEET

Document Ref: Title

SX023a-EN-EU

Sheet

of

Example: Calculation of effective section properties for a cold-formed lipped channel section in compression EN 1993-1-3 V. Ungureanu, A. Ruff D. Dubina

Date Date

Eurocode Ref Made by Checked by

Dec 2005 Dec 2005

Checking of geometrical proportions The design method of EN1993-1-3 can be applied if the following conditions EN1993-1-3 are satisfied: 5.2

b t 60 c t 50 h t 500

b1 t = 74 1,96 = 37,75 < 60 OK c t = 20,8 1,96 = 10,61 < 50 OK h t = 200 1,96 = 102,04 < 500 OK

In order to provide sufficient stiffness and to avoid primary buckling of the stiffener itself, the size of stiffener should be within the following range:

0,2 c b 0,6

c b1 = 20,8 74 = 0,28 c b2 = 20,8 66 = 0,32

0,2 < 0,28 < 0,6 OK 0,2 < 0,32 < 0,6 OK

Created on Saturday, October 10, 2009 This material is copyright - all rights reserved. Use of this document is subject to the terms and conditions of the Access Steel Licence Agreement

The influence of rounding of the corners is neglected if:

r t5

r bp 0,10

r t = 3 1,96 = 1,53 < 5 OK

r bp1 = 3 72 = 0,04 < 0,10 OK r bp 2 = 3 64 = 0,05 < 0,10 OK

EN1993-1-3 5.1(3)

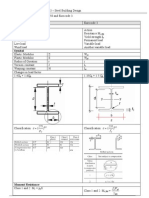

Gross section properties

Abr = t (2cp + bp1 + bp2 + hp ) = 1,96 (2 19,8 + 72 + 64 + 198) = 732 mm2

Position of the centroidal axis with regard to the upper flange:

z b1 =

[c (h

p

2 2 cp 2 ) + bp2 hp + hp 2 + cp 2 t

Abr

= 96,88 mm

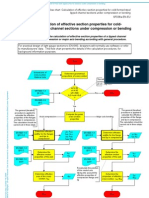

Effective section properties of the flanges and lips in compression

The general (iterative) procedure is applied to calculate the effective EN1993-1-3 properties of the compressed flange and the lip (plane element with edge 5.5.3.2 stiffener). The calculation should be carried out in three steps: Step 1: Obtain an initial effective cross-section for the stiffeners using effective EN1993-1-3 widths of the flanges determined by assuming that the compressed flanges are 5.5.3.2 (3) doubly supported, the stiffener gives full restraint ( K = ) and that design strength is not reduced ( com,Ed = f yb / M 0 ).

Example: Calculation of effective section properties for a cold-formed lipped channel section in compression

CALCULATION SHEET

Document Ref: Title

SX023a-EN-EU

Sheet

of

Example: Calculation of effective section properties for a cold-formed lipped channel section in compression EN 1993-1-3 V. Ungureanu, A. Ruff D. Dubina

Date Date

Eurocode Ref Made by Checked by

Dec 2005 Dec 2005

Effective width of the compressed flanges The stress ratio: = 1 (uniform compression), so the buckling factor is: k = 4 for internal compression element. EN1993-1-3 5.5.2 and EN1993-1-5 4.4

= 235 f yb

For the upper flange: The relative slenderness:

p,b1 =

bp1 t 28,4 k

72 1,96 = 0,789 28,4 235 350 4

0,789 0,055 (3 + 1) = 0,914 0,789 2

The width reduction factor is:

Created on Saturday, October 10, 2009 This material is copyright - all rights reserved. Use of this document is subject to the terms and conditions of the Access Steel Licence Agreement

1 =

p,b1 0,055(3 + ) p,b1

2

The effective width is:

beff1 = 1bp1 = 0 ,914 72 = 65,8 mm

be11 = be12 = 0 ,5beff1 = 0 ,5 65,8 = 32 ,9 mm For the bottom flange: The relative slenderness:

p,b2 =

bp2 t 28,4 k

64 1,96 = 0,702 28,4 235 350 4

0,702 0,055 (3 + 1) = 0 ,978 0,702 2

The width reduction factor is:

2 =

p,b2 0 ,055(3 + ) p,b2

2

The effective width is:

beff2 = 2 bp2 = 0 ,978 64 = 62 ,6 mm

be21 = be22 = 0,5beff2 = 0 ,5 62 ,6 = 31,3 mm

Example: Calculation of effective section properties for a cold-formed lipped channel section in compression

CALCULATION SHEET

Document Ref: Title

SX023a-EN-EU

Sheet

of

Example: Calculation of effective section properties for a cold-formed lipped channel section in compression EN 1993-1-3 V. Ungureanu, A. Ruff D. Dubina

Date Date

Eurocode Ref Made by Checked by

Dec 2005 Dec 2005

Effective width of the edge fold For the upper edge fold: The buckling factor is: if bp,c bp 0 ,35 : if 0 ,35 < bp,c bp 0 ,6 : k = 0,5

k = 0 ,5 + 0 ,83 3 (bp,c bp 0 ,35)

2

EN1993-1-3 5.5.3.2(5a)

bp,c bp1 = 19 ,8 72 = 0 ,275 < 0 ,35

so

k 1 = 0 ,5

The relative slenderness:

p,c1 =

cp t 28,4 k 1

19,8 1,96 = 0,614 28,4 235 350 0,5

EN1993-1-5 4.4

The width reduction factor is:

Created on Saturday, October 10, 2009 This material is copyright - all rights reserved. Use of this document is subject to the terms and conditions of the Access Steel Licence Agreement

1 =

p,c1 0,188 p,c1

2

0,614 0,188 = 1,13 but 1 so 1 = 1 0,614 2 EN1993-1-3 5.5.3.2(5a) 5.5.3.2(6)

The effective width is:

ceff1 = cp 1 = 19 ,8 1 = 19 ,8 mm

Effective area of the upper edge stiffener:

As1 = t (be12 + ceff1 ) = 1,96 (32 ,9 + 19 ,8) = 103,3 mm 2

For the bottom edge fold: The buckling factor is:

bp,c bp2 = 19 ,8 64 = 0 ,309 < 0 ,35

EN1993-1-3 5.5.3.2(5a) so k 2 = 0 ,5

The relative slenderness:

p,c2 =

cp t 28,4 k 2

19,8 1,96 = 0,614 28,4 235 350 0,5

EN1993-1-5 4.4

The width reduction factor is:

2 =

p,c2 0,188 p,c2

2

0 ,614 0 ,188 = 1,13 but 1 so 2 = 1 0 ,614 2

Example: Calculation of effective section properties for a cold-formed lipped channel section in compression

CALCULATION SHEET

Document Ref: Title

SX023a-EN-EU

Sheet

of

Example: Calculation of effective section properties for a cold-formed lipped channel section in compression EN 1993-1-3 V. Ungureanu, A. Ruff D. Dubina

Date Date

Eurocode Ref Made by Checked by

Dec 2005 Dec 2005

The effective width is:

ceff2 = cp 2 = 19 ,8 1 = 19 ,8 mm

EN1993-1-3 5.5.3.2(5a) 5.5.3.2(6)

Effective area of the bottom edge stiffener:

As2 = t (be22 + ceff2 ) = 1,96 (31,3 + 19 ,8) = 100 ,2 mm 2

EN1993-1-3 Use the initial effective cross-section of the stiffener to determine the 5.5.3.2(3) reduction factor, allowing for the effects of the continuous spring restraint. Step 2: The elastic critical buckling stress for the edge stiffener is:

cr,s =

Created on Saturday, October 10, 2009 This material is copyright - all rights reserved. Use of this document is subject to the terms and conditions of the Access Steel Licence Agreement

2 K E Is As

EN1993-1-3 5.5.3.2(7)

where: K is the spring stiffness per unit length, Is is the effective second moment of area of the stiffener. For the upper edge stiffener: The spring stiffness is: EN1993-1-3 5.5.3.1(5)

1 E t3 K1 = 2 3 2 4(1 ) b1 hp + b1 + 0,5 b1 b2 hp k f

with:

b1 distance from the web to the centre of the effective area of the stiffener in compression (upper flange)

b1 = bp1 be12 t be12 2 32,9 1,96 32,9 2 = 72 = 61,73 mm (be12 + ceff ) t (32,9 + 19,8) 1,96

b2 distance from the web to the centre of the effective area of the stiffener in compression (bottom flange)

b2 = bp2 be22 t be22 2 31,3 1,96 31,3 2 = 64 = 54,41 mm (be22 + ceff2 ) t (31,3 + 19,8) 1,96

Example: Calculation of effective section properties for a cold-formed lipped channel section in compression

CALCULATION SHEET

Document Ref: Title

SX023a-EN-EU

Sheet

of

Example: Calculation of effective section properties for a cold-formed lipped channel section in compression EN 1993-1-3 V. Ungureanu, A. Ruff D. Dubina

Date Date

Eurocode Ref Made by Checked by

Dec 2005 Dec 2005

kf =

As2 100 ,2 = = 0 ,97 for a member in axial compression As1 103,3

K1 = 0,331 N mm 2 The effective second moment of area:

2 3 2 c b t3 c t ceff1 ceff1 I s1 = e12 + eff1 + be12 t + ceff1 t eff1 12 12 2 2(be12 + ceff1 ) 2(be12 + ceff1 ) 4 I s1 = 3663 mm 2 2

so, the elastic critical buckling stress for the upper edge stiffener is

cr,s1 =

Created on Saturday, October 10, 2009 This material is copyright - all rights reserved. Use of this document is subject to the terms and conditions of the Access Steel Licence Agreement

2 0,331 210000 3663 = 309 N mm 2 103,3

For the bottom edge stiffener: The spring stiffness is:

E t3 1 K2 = 2 , 3 2 4(1 ) b2 hp + b2 + 0,5 b1 b2 hp kf

K 2 = 0,406 N mm 2 The effective second moment of area:

3 2 2 ceff2 be22 t 3 ceff2 t ceff2 ceff2 I s2 = + + be22 t + ceff2 t 12 12 2 2(be22 + ceff2 ) 2(be22 + ceff2 ) 4 I s2 = 3618 mm 2 2

so, the elastic critical buckling stress for the bottom edge stiffener is

cr,s2 =

2 0,406 210000 3618 = 350,7 N mm 2 100,2

Example: Calculation of effective section properties for a cold-formed lipped channel section in compression

CALCULATION SHEET

Document Ref: Title

SX023a-EN-EU

Sheet

of

Example: Calculation of effective section properties for a cold-formed lipped channel section in compression EN 1993-1-3 V. Ungureanu, A. Ruff D. Dubina

Date Date

Eurocode Ref Made by Checked by

Dec 2005 Dec 2005

Thickness reduction factor d for the edge stiffener For the upper edge stiffener: The relative slenderness:

EN1993-1-3 5.5.3.2(3) Figure 5.10d EN1993-1-3 5.5.3.1(7) EN1993-1-5 4.4(2)

d1 =

f yb cr,s1 = 350 309 = 1,064

The reduction factor will be: if d 0 ,65 if 0 ,65 < d < 1,38 if d 1,38

d = 1,0

d = 1,47 0 ,723d d = 0 ,66 d

so

0 ,65 < d1 = 1,064 < 1,38

Created on Saturday, October 10, 2009 This material is copyright - all rights reserved. Use of this document is subject to the terms and conditions of the Access Steel Licence Agreement

d1 = 1,47 0,723 1,064 = 0,701

For the bottom edge stiffener: The relative slenderness:

d2 =

f yb cr,s2 = 350 350 ,7 = 0 ,999

The reduction factor will be:

0 ,65 < d2 = 0 ,999 < 1,38

so

d2 = 1,47 0,723 0,999 = 0,748

EN1993-1-3 5.5.3.2(3) Figure 5.10e EN1993-1-3 5.5.3.2 (10)

Step 3: As the reduction factor for buckling of the stiffener is d < 1, iterate to refine the value of the reduction factor for buckling of the stiffener. The iterations are carried out based on modified values of obtained using:

com,Ed,i = d f yb M0 and

p,red = p d

The iteration stops when the reduction factor converges. For the upper edge stiffener: Initial values (iteration 1): Final values (iteration n):

d1 = 0,701

be12 = 32 ,9 mm ceff1 = 19,8 mm

d1 = d1,n = 0 ,683

be12 = be12,n = 36 mm ceff1 = ceff1,n = 19 ,8 mm

Example: Calculation of effective section properties for a cold-formed lipped channel section in compression

CALCULATION SHEET

Document Ref: Title

SX023a-EN-EU

Sheet

of

Example: Calculation of effective section properties for a cold-formed lipped channel section in compression EN 1993-1-3 V. Ungureanu, A. Ruff D. Dubina

Date Date

Eurocode Ref Made by Checked by

Dec 2005 Dec 2005

For the bottom edge stiffener: Initial values (iteration 1): Final values (iteration n):

d2 = 0,748

be22 = 31,3 mm ceff2 = 19 ,8 mm

d2 = d2,n = 0 ,744

be22 = be22,n = 32 mm ceff2 = ceff2,n = 19 ,8 mm

Final values of effective properties for flanges and lips in compression are: For the upper flange and lip:

d1 = 0,683

be12 = 36 mm

ceff1 = 19 ,8 mm

and be11 = 32,9 mm

Created on Saturday, October 10, 2009 This material is copyright - all rights reserved. Use of this document is subject to the terms and conditions of the Access Steel Licence Agreement

For the bottom flange and lip:

d2 = 0,744

be22 = 32 mm

ceff2 = 19 ,8 mm

and be 21 = 31,3 mm

t red,1 = t d1 = 1,96 0,683 = 1.34 mm t red,2 = t d2 = 1,96 0,744 = 1,46 mm

EN1993-1-3 5.5.3.2(12)

Effective section properties of the web The stress ratio: = 1 (uniform compression), so the buckling factor is: k = 4 for internal compression element. EN1993-1-3 5.5.2 and EN1993-1-5 4.4

= 235 f yb

The relative slenderness:

p,h =

hp t 28,4 k

198 1,96 = 2,171 28,4 235 350 4

2,171 0,055 (3 + 1) = 0,414 2 ,1712

The width reduction factor is:

p,h 0 ,055(3 + ) p,h

2

Example: Calculation of effective section properties for a cold-formed lipped channel section in compression

CALCULATION SHEET

Document Ref: Title

SX023a-EN-EU

Sheet

of

Example: Calculation of effective section properties for a cold-formed lipped channel section in compression EN 1993-1-3 V. Ungureanu, A. Ruff D. Dubina

Date Date

Eurocode Ref Made by Checked by

Dec 2005 Dec 2005

The effective width of the web is:

heff = hp = 0 ,414 198 = 82 mm

he1 = he2 = 0,5heff = 0 ,5 82 = 41 mm Effective section properties Effective cross-section area: Aeff = t [be11 + be21 + he1 + he2 + (be12 + ceff1 ) d1 + (be22 + ceff2 ) d2 ]

Aeff = 436,7 mm 2

Position of the centroidal axis with regard to the upper flange:

2 2 ceff2 he2 he1 ceff1 d1 + t ceff2 d2 hp + hp (be22 d2 + be21 ) + he2 hp + 2 2 2 2 = Aeff

Created on Saturday, October 10, 2009 This material is copyright - all rights reserved. Use of this document is subject to the terms and conditions of the Access Steel Licence Agreement

z G1

z G1 = 98,44 mm Position of the centroidal axis with regard to the bottom flange:

z G2 = hp z G1 = 198 98 ,44 = 99 ,56 mm

Example: Calculation of effective section properties for a cold-formed lipped channel section in compression

Example: Calculation of effective section properties for a cold-formed lipped channel section in compression SX023a-EN-EU.doc

Quality Record

RESOURCE TITLE Example: Calculation of effective section properties for a cold-formed lipped channel section in compression

Reference(s) ORIGINAL DOCUMENT Name Created by Technical content checked by Editorial content checked by Technical content endorsed by the following STEEL Partners: 1. UK

Created on Saturday, October 10, 2009 This material is copyright - all rights reserved. Use of this document is subject to the terms and conditions of the Access Steel Licence Agreement

Company BRITT Ltd. Timisoara, Romania BRITT Ltd. Timisoara, Romania

Date 05/12/2005 08/12/2005

V. Ungureanu, A. Ruff D. Dubina

G W Owens A Bureau B Uppfeldt C Mller J Chica G W Owens

SCI CTICM SBI RWTH Labein SCI

12/4/06 12/4/06 11/4/06 11/4/06 12/4/06 11/9/06

2. France 3. Sweden 4. Germany 5. Spain Resource approved by Technical Coordinator TRANSLATED DOCUMENT This Translation made and checked by: Translated resource approved by:

Page 10

También podría gustarte

- Axially Loaded Columns - Base Plate DesignDocumento2 páginasAxially Loaded Columns - Base Plate DesignaomareltayebAún no hay calificaciones

- Wind Load Bs 6399Documento1 páginaWind Load Bs 6399Kutty MansoorAún no hay calificaciones

- 115-Eurocode Design - Cantilever DeflectionDocumento1 página115-Eurocode Design - Cantilever Deflectionrodriguez.gaytanAún no hay calificaciones

- Must To Know Formulas (NMAT)Documento2 páginasMust To Know Formulas (NMAT)CatAún no hay calificaciones

- Pad Foundation Design To Bs 81101997Documento23 páginasPad Foundation Design To Bs 81101997Anonymous 66uWhphVAún no hay calificaciones

- A Critical Review On The Shear Lag Effect of Steel Channel Sections Subject To Tensile LoadingDocumento9 páginasA Critical Review On The Shear Lag Effect of Steel Channel Sections Subject To Tensile LoadingGRENZE Scientific Society100% (2)

- Equilibrium of Rigid BodiesDocumento22 páginasEquilibrium of Rigid BodiesSpiro DourbalyAún no hay calificaciones

- Beam-Column Connection To BS5950Documento6 páginasBeam-Column Connection To BS5950Mitra RampersadAún no hay calificaciones

- Purlin DesignDocumento28 páginasPurlin DesignFatih Genc100% (2)

- EC2 Beam Section DesignDocumento3 páginasEC2 Beam Section Designikanyu79100% (1)

- Design Input:: Design Sheet Title: Design of Anchor Bolts & Base Plate For A Fixed Base Column Ameya STDDocumento4 páginasDesign Input:: Design Sheet Title: Design of Anchor Bolts & Base Plate For A Fixed Base Column Ameya STDSuryaSinghAún no hay calificaciones

- Example Calculation of Effective Section Properties For A Cold-Formed Lipped Channel Section in BendingDocumento10 páginasExample Calculation of Effective Section Properties For A Cold-Formed Lipped Channel Section in Bendingcbler100% (10)

- Moment Connection - Flush End Plate-19.01.06Documento48 páginasMoment Connection - Flush End Plate-19.01.06kalpanaadhi83% (6)

- Access Steel Data Sheets BindedDocumento154 páginasAccess Steel Data Sheets BindedblueswanAún no hay calificaciones

- OptistructDocumento85 páginasOptistructSahithyananda ShashidharAún no hay calificaciones

- Wind Loads UK Portal Frame WEDocumento31 páginasWind Loads UK Portal Frame WEmandregomes100% (1)

- Mathcad - Baseplate Design - 8Documento6 páginasMathcad - Baseplate Design - 8Monotobo X MakinaAún no hay calificaciones

- Composite Beam Design ExampleDocumento7 páginasComposite Beam Design ExampleAlphyl Balasabas100% (2)

- Flitch BeamDocumento4 páginasFlitch BeamOlanrewaju OkunolaAún no hay calificaciones

- Mathcad - BASEPLATE DESIGN - 10 PDFDocumento6 páginasMathcad - BASEPLATE DESIGN - 10 PDFMonotobo X MakinaAún no hay calificaciones

- Common Rafters: Job No: Job Name: Date: Drawing Ref: Prepared By: Checked By: Site Ref: OtherDocumento8 páginasCommon Rafters: Job No: Job Name: Date: Drawing Ref: Prepared By: Checked By: Site Ref: Otherstarsplesh100% (1)

- Standard Lighting Column FoundationsDocumento2 páginasStandard Lighting Column FoundationsEm MarAún no hay calificaciones

- 2-Way Spanning Insitu Concrete Slabs To Bs 81101997 (Table 3.14)Documento4 páginas2-Way Spanning Insitu Concrete Slabs To Bs 81101997 (Table 3.14)alialiAún no hay calificaciones

- Deflection Limits - EurocodeDocumento1 páginaDeflection Limits - EurocodeielleAún no hay calificaciones

- Design of Cold Formed Steel Members 2003 LibroDocumento246 páginasDesign of Cold Formed Steel Members 2003 LibroFelipeAún no hay calificaciones

- BS 5268-6.2-2001 Structural Use of Timber PDFDocumento24 páginasBS 5268-6.2-2001 Structural Use of Timber PDFAlf Esparon100% (1)

- RT Level Iii TestDocumento4 páginasRT Level Iii Testsusanweb0% (1)

- Composite Slab ReportDocumento10 páginasComposite Slab ReportAhmed Moustafa AboelelaAún no hay calificaciones

- BS 6399-1996 Loading For Building-Part3 Imposed Roof Loads PDFDocumento31 páginasBS 6399-1996 Loading For Building-Part3 Imposed Roof Loads PDFSenthooran MahendranAún no hay calificaciones

- DPM FluentDocumento182 páginasDPM Fluentபார்த்தசாரதி சுப்ரமணியன்Aún no hay calificaciones

- Shear KeyDocumento14 páginasShear KeyMbalekelwa MpembeAún no hay calificaciones

- Design of Column For Axial Loads and BendingDocumento6 páginasDesign of Column For Axial Loads and BendingGihan ChathurangaAún no hay calificaciones

- Composite SlabDocumento13 páginasComposite Slabkosithuag50% (2)

- Tedds RC Beam Design 2Documento3 páginasTedds RC Beam Design 2Hor Ka WaiAún no hay calificaciones

- Example Design of A Cold-Formed Steel Lipped Channel Wall Stud in CompressionDocumento4 páginasExample Design of A Cold-Formed Steel Lipped Channel Wall Stud in CompressionOprisor Costin100% (1)

- Example Calculation of Alpha-Cr PDFDocumento9 páginasExample Calculation of Alpha-Cr PDFHerdean RemusAún no hay calificaciones

- BRC Wire MeshDocumento12 páginasBRC Wire MeshDharnendra P BhavsarAún no hay calificaciones

- Column Base Plate (Eurocode)Documento4 páginasColumn Base Plate (Eurocode)_at_to_Aún no hay calificaciones

- Proracun - Example Cold Formed SteelDocumento10 páginasProracun - Example Cold Formed SteelpedjaAún no hay calificaciones

- SX028a-EN-EU-Example - Design Resistance of A Screwed Connection of Cold-Formed Members PDFDocumento4 páginasSX028a-EN-EU-Example - Design Resistance of A Screwed Connection of Cold-Formed Members PDFWAún no hay calificaciones

- MRI Lecture NotesDocumento33 páginasMRI Lecture NotesArungoud PoshalaAún no hay calificaciones

- RCC51 Column Load Take-Down DesignDocumento7 páginasRCC51 Column Load Take-Down DesignBst PerchatAún no hay calificaciones

- Composite Beams & Columns To Eurocode 4Documento155 páginasComposite Beams & Columns To Eurocode 4dfdfdfasd324sad100% (2)

- Example Composite Floor SlabDocumento13 páginasExample Composite Floor SlabZamfira Octavian100% (2)

- Simply Supported Primary Composite BeamDocumento17 páginasSimply Supported Primary Composite BeamPaul Marceti100% (2)

- Steel Joints According To Eurocode 3Documento21 páginasSteel Joints According To Eurocode 3alfonxxlAún no hay calificaciones

- Cold Formed BendingDocumento8 páginasCold Formed BendinggeorgeispasoiuAún no hay calificaciones

- 05 - Example Sway StabilityDocumento10 páginas05 - Example Sway StabilityAlex TimocAún no hay calificaciones

- Eurocode Side BarsDocumento6 páginasEurocode Side BarsraymondAún no hay calificaciones

- Ec3 Kolon HesabıDocumento5 páginasEc3 Kolon HesabınaimalimliAún no hay calificaciones

- NCCI: Determination of Non-Dimensional Slenderness of I and H SectionsDocumento11 páginasNCCI: Determination of Non-Dimensional Slenderness of I and H SectionslingchenhAún no hay calificaciones

- Fin Plate ConnectionDocumento70 páginasFin Plate Connectionfloi dAún no hay calificaciones

- SX033b-En-EU-Example - Truss or Post End ConnectionDocumento8 páginasSX033b-En-EU-Example - Truss or Post End ConnectionWAún no hay calificaciones

- 11 Continuous BeamsDocumento55 páginas11 Continuous BeamsMelinda GordonAún no hay calificaciones

- Agricultural Buildings Designed To BS 5502-22Documento3 páginasAgricultural Buildings Designed To BS 5502-22fAún no hay calificaciones

- Worksheet CBSE Class 10 LightDocumento6 páginasWorksheet CBSE Class 10 Lightroythomasc50% (4)

- Simply Supported Secondary Composite BeamDocumento11 páginasSimply Supported Secondary Composite BeamgeorgeispasoiuAún no hay calificaciones

- Bending Strength: Overall Buckung Check L R - R at - o - 5 X 7 o o o - . o T Y - 5 T F - o / ' UDocumento8 páginasBending Strength: Overall Buckung Check L R - R at - o - 5 X 7 o o o - . o T Y - 5 T F - o / ' UReef20Aún no hay calificaciones

- BS and ECDocumento9 páginasBS and ECNGUYENAún no hay calificaciones

- Access Steel - SF038 - Effective Section Properties of Lipped Steel ChannelsDocumento3 páginasAccess Steel - SF038 - Effective Section Properties of Lipped Steel Channelsgianniorlati1972Aún no hay calificaciones

- Advantages CFSTDocumento14 páginasAdvantages CFSTprajjwal patidarAún no hay calificaciones

- BS 5950-2000 Example 001Documento5 páginasBS 5950-2000 Example 001Anitha Hassan KabeerAún no hay calificaciones

- Tying Resistance of A Fin Plate ConnectionDocumento9 páginasTying Resistance of A Fin Plate ConnectionSam Samoura0% (1)

- LT Buckling Beam Design - Simple Method - 2upDocumento5 páginasLT Buckling Beam Design - Simple Method - 2upberto2008Aún no hay calificaciones

- T3701a DFEDocumento10 páginasT3701a DFEAnca SimaAún no hay calificaciones

- Example: Calculation of Effective Section Properties For A Cold-Formed Lipped Channel Section in BendingDocumento10 páginasExample: Calculation of Effective Section Properties For A Cold-Formed Lipped Channel Section in BendingVarga ZoranAún no hay calificaciones

- Calculation Sheet: Esign Xample Esign of A Lipped Channel in An Exposed FloorDocumento8 páginasCalculation Sheet: Esign Xample Esign of A Lipped Channel in An Exposed FloorMoonzeAún no hay calificaciones

- Beam UnrestrainedDocumento9 páginasBeam Unrestrainedgorgika papandAún no hay calificaciones

- UK Afternoon WorkshopDocumento50 páginasUK Afternoon WorkshopanhkhoacgAún no hay calificaciones

- Schwer - Florence - Axisymmetric Compression of A Mohr-Coulomb Medium Around A Circular HoleDocumento13 páginasSchwer - Florence - Axisymmetric Compression of A Mohr-Coulomb Medium Around A Circular Holegianniorlati1972Aún no hay calificaciones

- Units SlidesDocumento18 páginasUnits Slidesabegarza1Aún no hay calificaciones

- Access Steel - SF038 - Effective Section Properties of Lipped Steel ChannelsDocumento3 páginasAccess Steel - SF038 - Effective Section Properties of Lipped Steel Channelsgianniorlati1972Aún no hay calificaciones

- Geometric Shapes and TransformationsDocumento10 páginasGeometric Shapes and TransformationsisidroAún no hay calificaciones

- Dynamics - of - Circular - Motion - Ch8 - LectureDocumento79 páginasDynamics - of - Circular - Motion - Ch8 - LecturedonaldAún no hay calificaciones

- Atwood MachineDocumento4 páginasAtwood MachineanisahAún no hay calificaciones

- SmawDocumento78 páginasSmawBrijraj PandeyAún no hay calificaciones

- Orthogonal Trajectories in Cartesian CoordinatesDocumento35 páginasOrthogonal Trajectories in Cartesian CoordinatesWASEEM_AKHTER100% (1)

- Crystal StructureDocumento16 páginasCrystal StructurejyotiblossomsAún no hay calificaciones

- Ib Physics 2024 ChecklistDocumento29 páginasIb Physics 2024 Checklistellie du123Aún no hay calificaciones

- Chem 156.1 Experiment 5 - Determination of Partial Molar VolumesDocumento4 páginasChem 156.1 Experiment 5 - Determination of Partial Molar Volumesティン ヨロベAún no hay calificaciones

- 0620 w15 QP 33Documento12 páginas0620 w15 QP 33Mohamad SalahAún no hay calificaciones

- Dual Nature of Radiation and MatterDocumento36 páginasDual Nature of Radiation and Matterggle82338Aún no hay calificaciones

- Pharmaceutical Chemistry Answer Key Blue PacopDocumento30 páginasPharmaceutical Chemistry Answer Key Blue PacopJeannie UyAún no hay calificaciones

- Question 1142815Documento8 páginasQuestion 1142815phantomghost6413Aún no hay calificaciones

- Metallic BondDocumento10 páginasMetallic BondAbhishek NayakAún no hay calificaciones

- Year 10 Physics Holiday PackDocumento10 páginasYear 10 Physics Holiday Packivan micoAún no hay calificaciones

- Molecular Chemical Bonding NotesDocumento2 páginasMolecular Chemical Bonding NotesMeera KumarAún no hay calificaciones

- 4 TH BatchDocumento37 páginas4 TH Batchanil kumarAún no hay calificaciones

- Compressor MaterialsDocumento4 páginasCompressor MaterialsAhmed HassanAún no hay calificaciones

- 83 WorksheetDocumento2 páginas83 WorksheetRishabh DhaulakhandiAún no hay calificaciones

- JurnalDocumento96 páginasJurnalDheva NiaAún no hay calificaciones

- Numc PDFDocumento18 páginasNumc PDFMadhur MayankAún no hay calificaciones

- Superparamagnetic Materials: Seminar I - 4th Year (Old Program)Documento12 páginasSuperparamagnetic Materials: Seminar I - 4th Year (Old Program)Reena SiwachAún no hay calificaciones