Documentos de Académico

Documentos de Profesional

Documentos de Cultura

The Revision Hydro-Electrometallurgy: Created By: Hesga Fadiastian (3334091321)

Cargado por

Hesga FadiastianDescripción original:

Título original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

The Revision Hydro-Electrometallurgy: Created By: Hesga Fadiastian (3334091321)

Cargado por

Hesga FadiastianCopyright:

Formatos disponibles

The Revision Hydro-Electrometallurgy

Created by: Hesga Fadiastian (3334091321)

DEPARTEMENT OF METALLURGICAL ENGINEERING FACULTY OF ENGINEERING UNIVERSITY OF SULTAN AGENG TIRTAYASA

2012

The Revision

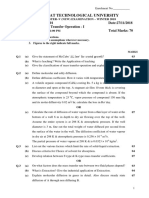

1. In Moa Bay Plant, Cuba

After the second filtration, we can get NiS and CoS. which it is generated in addition to the filtrate. The filtrate in here is H2SO4 . H2SO4 can we use again in leaching process for leaching agents. The filtrate can we use until the plant not produce 2. Hydrogen can occur in most metals research and development in a safe way to save the hydrogen as a fuel. Hydrogen is soluble in a variety of compounds consisting of nadir earth metals and transition metals and metal can be dissolved in the crystal and amorphous metals. The solubility of hydrogen in metals is caused by local distortions or impurities in the metal crystal.

3. In HPAL ( High Pressure Acid Leaching) used H2S for leaching agents and high pressure. Moa Bay Plant is the first industry used H2S to get Nickel and Cobalt since 1959 in Cuba. Advantage of HPAL are we can get concentrate without direct reduction so lower capital cost and more efficient for energy and we can get Nickel and Cobalt 90% .

4. In Sherrit Gordon Plant

The product of filtration except the solids is liquid 5. Kinetic Aspect Ammonia sulfate retards the rate of nickel precipitation from ammonical solution similar results were also repoted for copper but ammonia sulfate in system will prevent the precipitation cobalt. The solubility of cobalt at 175 C increase with increasing (NH4) 2SO4. Ammonium sulfate is present in solution prepared by ammonia leaching of sulfides. In the precipitation of nickel from ammonical nickel sulfate solution using nickel powder as a catalyst. The activation energy in the temperature range 150-175oC is 13,7 kkal/mol and in the temperature range 175-200oC is 5,7 kkal/mol. It appears that a low temperature the reaction is chemical control and at high temperature the reaction is diffusion controlled.

6. K = aH+ / (aM+ ).(aH2) log K = - log H2+ - log [M 2+] + log pH2 log K = - 2 pH log [M 2+] + log pH2 log [M 2+] = - 2 pH (log K log pH) 7. At slide number 15. 350 g/l ammonium sulfate. In this case ammonium sulfate as leaching agents. Leaching agents used in leaching proses. Ammonia sulfate retards the rate of nickel precipitation from ammonical solution similar results were also repoted for copper but ammonia sulfate in system will prevent the precipitation cobalt. The solubility of cobalt at 175 C increase with increasing (NH4) 2SO4. Ammonium sulfate is present in solution prepared by ammonia leaching of sulfides.

También podría gustarte

- SI Selected 11 Hyvarinen 2005Documento5 páginasSI Selected 11 Hyvarinen 2005Tomás HidalgoAún no hay calificaciones

- Hydrometallurgy 12Documento7 páginasHydrometallurgy 12mohamaddaneshvarAún no hay calificaciones

- Egorov 1Documento6 páginasEgorov 1santiAún no hay calificaciones

- Atmospheric Chloride Leaching of Base Metal SulphidesDocumento15 páginasAtmospheric Chloride Leaching of Base Metal SulphidesDennis Daniel Condori EspilcoAún no hay calificaciones

- Aluminum Sulfate As A Water Purifier Coagulant by Ni Luh Putu Agustina Putri 1713081015Documento8 páginasAluminum Sulfate As A Water Purifier Coagulant by Ni Luh Putu Agustina Putri 1713081015putrik agustinaAún no hay calificaciones

- P Block PresentationDocumento12 páginasP Block PresentationChinmayee JenaAún no hay calificaciones

- Iontech Paper 2 Flue DustDocumento6 páginasIontech Paper 2 Flue DustGeorgi SavovAún no hay calificaciones

- Baghalha Ve Papangelakis, 1998Documento8 páginasBaghalha Ve Papangelakis, 1998laguna028Aún no hay calificaciones

- Falconbridge Electrowinning CellDocumento1 páginaFalconbridge Electrowinning CellYassine GouzzaliAún no hay calificaciones

- Chemistry Form 4 (Manufactured Substances in Industries)Documento24 páginasChemistry Form 4 (Manufactured Substances in Industries)Fariezuan HamidAún no hay calificaciones

- Grade 10 Lesson Note XXDocumento12 páginasGrade 10 Lesson Note XXKolaso KombasoAún no hay calificaciones

- Nitrgen Fertlisers-1Documento8 páginasNitrgen Fertlisers-1Imen KsibiAún no hay calificaciones

- The P-Block Elements - WatermarkDocumento28 páginasThe P-Block Elements - Watermarkaadidharaskar11Aún no hay calificaciones

- A Synergistic Solvent Extraction System For Separating Copper From Iron in High Chloride Concentration SolutionsDocumento5 páginasA Synergistic Solvent Extraction System For Separating Copper From Iron in High Chloride Concentration SolutionsPasha TanAún no hay calificaciones

- Activated Carbon BioleachingDocumento5 páginasActivated Carbon BioleachingL Sergio Quiroz CastilloAún no hay calificaciones

- Reaction TypesDocumento10 páginasReaction TypesaqibazizkhanAún no hay calificaciones

- Hydrogenation and Ring Opening of Naphthalene On Bulk and Supported Mo C CatalystsDocumento11 páginasHydrogenation and Ring Opening of Naphthalene On Bulk and Supported Mo C Catalystsioanaandra5690Aún no hay calificaciones

- v112n06p455 Sulfating RoastingDocumento6 páginasv112n06p455 Sulfating Roastingergfarad0% (1)

- Recycling of Metals From Spent CatalystDocumento6 páginasRecycling of Metals From Spent CatalystMohammad YoussefiAún no hay calificaciones

- Synthesisof2KAlSO42 12H2OfromwastecanDocumento7 páginasSynthesisof2KAlSO42 12H2Ofromwastecanzulfan jordanAún no hay calificaciones

- Role of Iron in CESL ProcessDocumento16 páginasRole of Iron in CESL Processkittens1234Aún no hay calificaciones

- Mo2C-HYDocumento11 páginasMo2C-HYioanaandra5690Aún no hay calificaciones

- MASS PRODUCTION OF LiAl ALLOYS BY THE STEPDocumento28 páginasMASS PRODUCTION OF LiAl ALLOYS BY THE STEPVenkiteshAún no hay calificaciones

- 4 CF 0Documento7 páginas4 CF 0reza haghjooAún no hay calificaciones

- Acterization and Flotation of Sulfur From Chalcopyrite Concentrate Leaching ResidueDocumento9 páginasActerization and Flotation of Sulfur From Chalcopyrite Concentrate Leaching ResidueSantiago TuestaAún no hay calificaciones

- Electrolytic IndustriesDocumento13 páginasElectrolytic IndustriesMarialie Enecio0% (1)

- Processing of Nickel Laterite Ores: A Review of Scientific LiteratureDocumento5 páginasProcessing of Nickel Laterite Ores: A Review of Scientific LiteratureCofe Milk100% (1)

- A Review of Niobium-Tantalum Separation in Hydro MetallurgyDocumento12 páginasA Review of Niobium-Tantalum Separation in Hydro Metallurgyduverney.gaviriaAún no hay calificaciones

- Chemistry Holidays Assignment: Form 4Documento39 páginasChemistry Holidays Assignment: Form 4Hafiz HakimiAún no hay calificaciones

- Gold Extraction With Halogens: J.-M. Lalancette, B. Dubreuil, D. Lemieux and C. ChouinardDocumento16 páginasGold Extraction With Halogens: J.-M. Lalancette, B. Dubreuil, D. Lemieux and C. ChouinardLudwig Kommer100% (2)

- Sphalerite Leaching With H2SO4 and NaNO3Documento11 páginasSphalerite Leaching With H2SO4 and NaNO3Ade SatriaAún no hay calificaciones

- Preparation and Characterization of Charcoals That Contain Dispersed Aluminum Oxide As Adsorbents For Removal of Fluoride From Drinking WaterDocumento11 páginasPreparation and Characterization of Charcoals That Contain Dispersed Aluminum Oxide As Adsorbents For Removal of Fluoride From Drinking WaterCamila NevesAún no hay calificaciones

- CoagulantesDocumento48 páginasCoagulantesAna MaríaAún no hay calificaciones

- Mukongo d1 2009Documento26 páginasMukongo d1 2009Erick KazangaAún no hay calificaciones

- Leaching of A Roasted Copper Sulfide Ore PDFDocumento3 páginasLeaching of A Roasted Copper Sulfide Ore PDFJHPAún no hay calificaciones

- Chemistry Investigatory Project XIIDocumento24 páginasChemistry Investigatory Project XIISamaditya Jatar100% (11)

- Copper ElectroplatingDocumento21 páginasCopper ElectroplatingRahul PandeyAún no hay calificaciones

- Alafara NigeriaDocumento6 páginasAlafara NigeriaIrwan SyaifullohAún no hay calificaciones

- ChemDocumento22 páginasChemDivya RajendranAún no hay calificaciones

- Lec-02 PyrometallurgyDocumento21 páginasLec-02 PyrometallurgyTanvir HossainAún no hay calificaciones

- Chemical Reaction Aluminum and KohDocumento7 páginasChemical Reaction Aluminum and KohCarlosMarioGonzalezAún no hay calificaciones

- 10.1007@978-1-4614-2380-57 (Capitulo 7)Documento30 páginas10.1007@978-1-4614-2380-57 (Capitulo 7)ERICK JESUS MUÑOZ HERNANDEZAún no hay calificaciones

- The - Treatment - of - Arsenic - Bearing - Ores Alkaline PDFDocumento10 páginasThe - Treatment - of - Arsenic - Bearing - Ores Alkaline PDFSteven DziobaAún no hay calificaciones

- Calcium-Aluminothermal Production of Niobium and Mineral Composition of The Slag - GorkunovDocumento15 páginasCalcium-Aluminothermal Production of Niobium and Mineral Composition of The Slag - Gorkunovmaa bloAún no hay calificaciones

- Alkaline Sulfide Recovery of GoldDocumento13 páginasAlkaline Sulfide Recovery of GoldAFLAC ............100% (1)

- Chapter 2sulphuric Acid Manufacture Sept 2014Documento5 páginasChapter 2sulphuric Acid Manufacture Sept 2014kvk326Aún no hay calificaciones

- Leaching of Copper OxideDocumento6 páginasLeaching of Copper OxideWinmtyAún no hay calificaciones

- Synthesis of Common Alum: Chrome Alum KCR (So) - 12H ODocumento11 páginasSynthesis of Common Alum: Chrome Alum KCR (So) - 12H OidaayudwitasariAún no hay calificaciones

- Alat BahanDocumento21 páginasAlat BahanSandra ibrahimAún no hay calificaciones

- Propiedades y Usos de Fluxes en AluminioDocumento1 páginaPropiedades y Usos de Fluxes en AluminioninzauAún no hay calificaciones

- ProjectDocumento7 páginasProjectsivaAún no hay calificaciones

- Lead FinalDocumento26 páginasLead Finalthodeti babuAún no hay calificaciones

- FUNDAMENTALS OF ZINC RECOVERY FROM METALLURGICAL Wastes in The Enviroplas Process PDFDocumento14 páginasFUNDAMENTALS OF ZINC RECOVERY FROM METALLURGICAL Wastes in The Enviroplas Process PDFManojlovic Vaso100% (1)

- Extractive Metallurgy 3: Processing Operations and RoutesDe EverandExtractive Metallurgy 3: Processing Operations and RoutesAún no hay calificaciones

- Extractive Metallurgy 2: Metallurgical Reaction ProcessesDe EverandExtractive Metallurgy 2: Metallurgical Reaction ProcessesCalificación: 5 de 5 estrellas5/5 (1)

- Extractive Metallurgy 1: Basic Thermodynamics and KineticsDe EverandExtractive Metallurgy 1: Basic Thermodynamics and KineticsAún no hay calificaciones

- Organosilicon Reagents Synthesis and ApplicationsDe EverandOrganosilicon Reagents Synthesis and ApplicationsAún no hay calificaciones

- Group 7 PPAR LEC Assignment 4 Solubility and Distribution PhenomenaDocumento2 páginasGroup 7 PPAR LEC Assignment 4 Solubility and Distribution PhenomenaSam ChispaAún no hay calificaciones

- Rossing - Production ProcessDocumento27 páginasRossing - Production ProcessJan LubbeAún no hay calificaciones

- The Homeopathic Law of Similarity Dr. Von GrauvoglDocumento118 páginasThe Homeopathic Law of Similarity Dr. Von GrauvoglLeandro DazaAún no hay calificaciones

- AOAC Method Ascorbic Ac 967 21 PDFDocumento2 páginasAOAC Method Ascorbic Ac 967 21 PDFEdgardo Sanchez GutierrezAún no hay calificaciones

- Aromatic Waters - Liniments Lab NotesDocumento9 páginasAromatic Waters - Liniments Lab NotesElaine Sombrano100% (7)

- Is 14948 2001Documento15 páginasIs 14948 2001Kumar AbhishekAún no hay calificaciones

- Mass Transfer MaterialDocumento133 páginasMass Transfer MaterialYumnaAún no hay calificaciones

- Access To Success: Form One Annual Examinations Chemistry TIME: 2:30 Hours InstructionsDocumento7 páginasAccess To Success: Form One Annual Examinations Chemistry TIME: 2:30 Hours InstructionsShani Ahmed Sagiru100% (1)

- DILL CH - 15 Solutions and MixturesDocumento11 páginasDILL CH - 15 Solutions and MixturesMohamed MahmoudKhattabAún no hay calificaciones

- ExerciseDocumento48 páginasExerciseYash MohtaAún no hay calificaciones

- All About LeachingDocumento3 páginasAll About Leachinganon_850753764Aún no hay calificaciones

- STP of Etratab BolusDocumento5 páginasSTP of Etratab BolusBejoy KarimAún no hay calificaciones

- Denim Lca 3Documento7 páginasDenim Lca 3Haleema ManzoorAún no hay calificaciones

- Membrane Separation Process-Week 10Documento52 páginasMembrane Separation Process-Week 10baymaxxxxxAún no hay calificaciones

- Sampling Methods and Sample Laboratory Preparation at The Department of Archaeological Sciences, University of Bradford (United Kingdom)Documento7 páginasSampling Methods and Sample Laboratory Preparation at The Department of Archaeological Sciences, University of Bradford (United Kingdom)sri hartini hariaaAún no hay calificaciones

- Bonding AsDocumento97 páginasBonding AsRosina KaneAún no hay calificaciones

- Hydrated and Anhydrous SubstancesDocumento22 páginasHydrated and Anhydrous SubstancesFree FireAún no hay calificaciones

- Different Extraction Methods and Antioxidant Properties of Thyme (Thymus Vulgaris L.) HerbDocumento7 páginasDifferent Extraction Methods and Antioxidant Properties of Thyme (Thymus Vulgaris L.) HerbDIey ChokiEyAún no hay calificaciones

- Colloidal State & Surface ChemistryDocumento29 páginasColloidal State & Surface ChemistrydhiralAún no hay calificaciones

- Microsponges: A Futuristic Approach For Oral Drug DeliveryDocumento18 páginasMicrosponges: A Futuristic Approach For Oral Drug DeliveryIIrsandi JohanAún no hay calificaciones

- Building MaintenanceDocumento13 páginasBuilding MaintenanceChinmoy DasAún no hay calificaciones

- Food Chemistry: Qiuhui Hu, Yun Hu, Juan XuDocumento6 páginasFood Chemistry: Qiuhui Hu, Yun Hu, Juan XuM Nurshaffriaal RusdiAún no hay calificaciones

- BRB Silanil 258Documento2 páginasBRB Silanil 258m daneshpour100% (1)

- Phytochemical Analysis and Antifungal Activity of Moringa OleiferaDocumento4 páginasPhytochemical Analysis and Antifungal Activity of Moringa OleiferaEllymar DuqueAún no hay calificaciones

- Gujarat Technological UniversityDocumento2 páginasGujarat Technological UniversityShivam PanchalAún no hay calificaciones

- A Level Chemistry Practical RevisionDocumento1 páginaA Level Chemistry Practical RevisionKaruvarakkalAún no hay calificaciones

- As Chemistry Notes All in OneDocumento230 páginasAs Chemistry Notes All in OneMildred MunatsiAún no hay calificaciones

- PEG 3350 & Electrolytes For Oral Solution USPDocumento5 páginasPEG 3350 & Electrolytes For Oral Solution USPASHOK KUMAR LENKAAún no hay calificaciones

- Chapter 7 Science of CryobiologyDocumento27 páginasChapter 7 Science of CryobiologyAmir IqbalAún no hay calificaciones