Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Epsilon 3542

Cargado por

Didier MaréchalDescripción original:

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Epsilon 3542

Cargado por

Didier MaréchalCopyright:

Formatos disponibles

3542 Axial Extensometers

General purpose extensometers for axial tensile, compression and cyclic testing. Gage lengths from 0.5 to 2 inches (and 10 to 50 mm) and measuring ranges from 5% to 100% strain.

Features

MODEL

Epsilon

Technology Corp

O R D E R I N G I N F O R M AT I O N

May be left on through specimen failure. Full bridge, 350 ohm strain gaged design for compatibility with nearly any test system. All models can measure in both tension and compression and can be used for cyclic testing. Mechanical overtravel stops in both directions. Most standard units meet existing ASTM class B-1 and ISO 9513, class 0,5 requirements for accuracy. Measuring ranges greater than 50% will meet these class requirements in lower calibration ranges. Hardened tool steel knife edges are easily replaced. A spare set comes with every extensometer. High and low temperature options extend operation from as low as -265 C (-450 F) to +175 C (350 F). Includes high quality foam lined case. Replaceable arms and spacers for ease of repair. This also allows changing the gage length for different test requirements. Rugged, dual flexure design for strength and improved performance. Much stronger than single flexure designs, this also allows cyclic testing at higher frequencies. Standard quick attach kit allows one hand mounting to specimens.

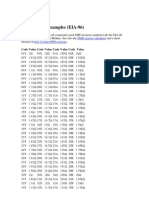

Model 3542 Available Versions: ANY combination of gage length, measuring range and temperature range listed below is available, except as noted. Available in intermediate gage lengths on special order.

Gage Length

U.S.A.

-0050 -0064 -0100 -0140 -0200

0.500 0.640 1.000 1.400 2.000 10.0 mm 12.5 mm 25.0 mm 50.0 mm

Measuring Range

METRIC

3542 with a 50 mm gage length and 5% measuring range.

3542 with a 2 gage length and 25% measuring range.

3542 axial model used simultaneously with a 3575 transverse model.

3542 with 10 mm gage length and 10% measuring range.

These extensometers are designed for testing a wide range of materials, including metals, plastics, composites and ceramics. All will work in both tension and compression. The dual flexure design makes them very rugged and insensitive to vibrations, which permits higher frequency operation. They come standard with Epsilons quick attach kit, making it easy to mount the extensometer on the test specimen in seconds with one hand. The quick attach kit can be removed, allowing mounting of the extensometer with springs or rubber bands. The Model 3542 extensometers are strain gaged devices, making them compatible with any electronics designed for strain gaged transducers. Most often they are connected to a test machine controller. The signal conditioning electronics for the extensometer is typically included with the test machine controller or may often be added. In this case the extensometer is shipped with the proper connector and wiring to plug directly into the electronics. For systems lacking the required electronics, Epsilon can provide a variety of solutions, allowing the extensometer output to be connected to data acquisition boards, chart recorders or other equipment. See the electronics section of this catalog for available signal conditioners and strain meters.

-010M -012M -025M -050M

-005 -010

% STRAIN

LINEARITY

-020 -025 -050 2 -100

5% 10% 20% 25% +50%/-10% +100%/-5%

0.10%

0.15%

Model Number 3542 - __ __ __ __ - __ __ __ - __ __

Temperature Range

S P E C I F I C AT I O N S

5 to 10 VDC recommended, 12 VDC or VAC max. 2 to 4 mV/V, nominal, depending on model 0.10% to 0.15% of full scale measuring range, depending on model Temperature Range: Standard (-ST) is -40 C to +100 C (-40 F to 210F) Cable: Integral, ultra-flexible cable, 8 ft (2.5 m) standard Standard Quick Attach Kit: Fits round samples up to 1.0 inch diameter (25 mm) and flats to 0.5 inch thick by 1.25 inch wide (12 mm by 31 mm) Operating Force: 30 g typical

OPTIONS

Excitation: Output: Linearity:

1 Not available in one-half inch, 10 or 12.5 mm gage lengths.

-LT -ST -HT1 -HT2 -LHT

-265 C to 100 C (-450 F to 210 F) -40 C to 100 C (-40 F to 210 F) -40 C to 150 C (-40 F to 300 F) -40 C to 200 C (-40 F to 400 F) -265 C to 200 C (-450 F to 400 F)

2 For 2 inch and 50 mm gage lengths, linearity is 0.2% typical, (ASTM class B-2).

Example: 3542-0100-020-LT: 1.000 inch gage length, 20% measuring range, low temperature option (-450 F to 210 F)

Contact Epsilon for your special testing requirements.

Quick attach kit wire forms for large specimens Connectors to interface to nearly any brand test equipment Shunt calibration module (see page 96) Adapter kits to change gage lengths Specialty knife edges (see page 97)

Rubber Band and Spring Attach Options

18.9 .75 [ 84.3 to 211 ] 3.32 to 8.32

40.6 1.60

[ 10 mm ] .500 inch gage length

18.9 .75

3542 LOW MEASURING RANGE

66 2.60

[ 97 to 211.3 ] 3.82 to 8.32

Extensometers for Composites Compression Testing

3542 with 2 gage length and +50/-10% measuring range.

3542 with 25 mm gage length and 10% measuring range.

Models 3542 and 3442 extensometers can be furnished to clip directly onto composites compression fixtures, such as for ASTM D695. These use specially made quick attach kit wire forms for the customers fixture. Consult the factory for specifics. See also the Model 3442 Miniature Extensometer.

3542 with composites compression fixture for ASTM D695.

Using springs (included).

Standard Quick Attach Wire Forms (Included)

Using rubber bands (included).

40.6 1.60

18.9 .75 [ 97 to 211.3 ] 3.82 to 8.32

[ 50 mm ] 2 inch gage length

3542 HIGH MEASURING RANGE

[ 50 mm ] 1 inch gage length

3542 MEDIUM MEASURING RANGE For round samples. For flat samples.

DIMENSIONS: [mm] inches

10

11

También podría gustarte

- Weld Like a Pro: Beginning to Advanced TechniquesDe EverandWeld Like a Pro: Beginning to Advanced TechniquesCalificación: 4.5 de 5 estrellas4.5/5 (6)

- SMD Resistor ExamplesDocumento5 páginasSMD Resistor Examplesmarcbuss100% (1)

- Tension Capacity of PileDocumento8 páginasTension Capacity of Pilenimal179100% (1)

- Commisionign HVAC ChecklistDocumento10 páginasCommisionign HVAC ChecklistCarolina HernándezAún no hay calificaciones

- Aerospace MaterialsDocumento68 páginasAerospace MaterialsAykut Üçtepe100% (1)

- How To Build Pyramids and Other Orgone GeneratorsDocumento6 páginasHow To Build Pyramids and Other Orgone GeneratorsGuy Jones100% (2)

- Datasheet Sensor Bently 3300 XL 8mmDocumento14 páginasDatasheet Sensor Bently 3300 XL 8mmCharles Matos0% (1)

- Electromagnetic CompatibilityDocumento12 páginasElectromagnetic Compatibilityoadipphone7031Aún no hay calificaciones

- 3500 91 Egd Communication Gateway Module Datasheet 0Documento6 páginas3500 91 Egd Communication Gateway Module Datasheet 0dikastaloneAún no hay calificaciones

- ASTM C158-02 (2012) Strength of Glass by Flexure (Determination of Modulus of Rupture)Documento9 páginasASTM C158-02 (2012) Strength of Glass by Flexure (Determination of Modulus of Rupture)Cristian Perez100% (1)

- Din862 863Documento1 páginaDin862 863Catalin Lazar0% (1)

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionDe EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionCalificación: 4.5 de 5 estrellas4.5/5 (3)

- Deaton FE Slab DesignDocumento57 páginasDeaton FE Slab DesignMohamed AliAún no hay calificaciones

- FM200Documento23 páginasFM200Ahmed SherifAún no hay calificaciones

- Extenso MetersDocumento22 páginasExtenso MetersJavierAún no hay calificaciones

- Miniature Averaging Axial ExtensometersDocumento2 páginasMiniature Averaging Axial ExtensometersNabilah Abu BakarAún no hay calificaciones

- 3300 Proximity Transducer System: DescriptionDocumento18 páginas3300 Proximity Transducer System: DescriptionSuvek KumarAún no hay calificaciones

- 3300 XL 11mm Proximity Transducer System: DescriptionDocumento21 páginas3300 XL 11mm Proximity Transducer System: DescriptionOmer ZamanAún no hay calificaciones

- 3300XL 11mm PDFDocumento22 páginas3300XL 11mm PDFinelecstarAún no hay calificaciones

- Economical, Miniature Limit Switch Boasting Rigid ConstructionDocumento5 páginasEconomical, Miniature Limit Switch Boasting Rigid ConstructionRajeev Saini100% (1)

- J400 Series Switch (B-07)Documento16 páginasJ400 Series Switch (B-07)marklam1985Aún no hay calificaciones

- Probe 3300xl 8mm PtsDocumento29 páginasProbe 3300xl 8mm Ptsknsvel2000Aún no hay calificaciones

- DS100 7 Eng Mut2200elDocumento16 páginasDS100 7 Eng Mut2200elAhmed IsmailAún no hay calificaciones

- Hall Effect GT1Documento2 páginasHall Effect GT1Luz RiosAún no hay calificaciones

- Datasheet TYPE 2822.2823Documento1 páginaDatasheet TYPE 2822.2823diegoAún no hay calificaciones

- RTD & Thermocouple Industrial Sensor AssembliesDocumento10 páginasRTD & Thermocouple Industrial Sensor Assembliesparameswararaob6482Aún no hay calificaciones

- fdb2 - Fire and Damper PDFDocumento4 páginasfdb2 - Fire and Damper PDFcandratrikusumaAún no hay calificaciones

- FN3280Documento4 páginasFN3280prykAún no hay calificaciones

- 3542 ExtensometerDocumento2 páginas3542 ExtensometerGMAR ComercializadoraAún no hay calificaciones

- Euromag Mut2200el SensorDocumento12 páginasEuromag Mut2200el Sensorn_zeinoun100% (1)

- MAgnetrol 75 Seires LEvelDocumento8 páginasMAgnetrol 75 Seires LEvelmarcoo8Aún no hay calificaciones

- Sanitary TurbinaDocumento4 páginasSanitary TurbinaCindy MateusAún no hay calificaciones

- DRC Packaged Encoders SST Data SheetDocumento4 páginasDRC Packaged Encoders SST Data SheetElectromateAún no hay calificaciones

- 3300xl ProbesDocumento35 páginas3300xl ProbesbudlrcAún no hay calificaciones

- PDF 100812100836 552363Documento20 páginasPDF 100812100836 552363Alrich BalanayAún no hay calificaciones

- DRUCK PTX 600 SeriesDocumento4 páginasDRUCK PTX 600 SeriesFraFraFra87Aún no hay calificaciones

- HiaDocumento4 páginasHiappanagos5664Aún no hay calificaciones

- EI Bimetal Thermometer: Data SheetDocumento5 páginasEI Bimetal Thermometer: Data SheetfreddyheavymetalAún no hay calificaciones

- Product Information Clip-On Extensometer 5025-1, 8040-1 and 7537-1Documento3 páginasProduct Information Clip-On Extensometer 5025-1, 8040-1 and 7537-1Diego AvendañoAún no hay calificaciones

- 08 925 Clip On Extensometer 5025 1 PI enDocumento3 páginas08 925 Clip On Extensometer 5025 1 PI enDiego AvendañoAún no hay calificaciones

- 3300 XL 11mm Proximity Transducer System: DescriptionDocumento21 páginas3300 XL 11mm Proximity Transducer System: Descriptionhussein javanAún no hay calificaciones

- Sensor de TemperaturaDocumento4 páginasSensor de TemperaturaDaniel NogueiraAún no hay calificaciones

- "MPF" Modular Pressure Transmitter: ApplicationsDocumento4 páginas"MPF" Modular Pressure Transmitter: Applicationsgrincheu70Aún no hay calificaciones

- Datasheet El Bimetal Thermometer 1Documento4 páginasDatasheet El Bimetal Thermometer 1Cezarina FrunzeanuAún no hay calificaciones

- Temperature Gauges CatalogueDocumento20 páginasTemperature Gauges CataloguesnehalAún no hay calificaciones

- Product CatalogueDocumento146 páginasProduct CatalogueSkazemi7Aún no hay calificaciones

- TLH PDFDocumento2 páginasTLH PDFTravis WoodAún no hay calificaciones

- 4000 Strain GageDocumento2 páginas4000 Strain GageamssanchezAún no hay calificaciones

- Nuflo Ez-InDocumento8 páginasNuflo Ez-InAnonymous Wu6FDjbAún no hay calificaciones

- EI Bimetal Thermometer: Data SheetDocumento5 páginasEI Bimetal Thermometer: Data SheetAntonella EspinozaAún no hay calificaciones

- 501 453racDocumento1 página501 453racshrieersAún no hay calificaciones

- Turbine Meter NufloDocumento8 páginasTurbine Meter NufloJaime SeguraAún no hay calificaciones

- Vibration TransducerDocumento13 páginasVibration TransducerLawren IgnatiusAún no hay calificaciones

- Catalogo Termometro BimetalicoDocumento8 páginasCatalogo Termometro BimetalicoNahbi Emilio PerezAún no hay calificaciones

- d222 en 02 Borehole Rod ExtensometersDocumento4 páginasd222 en 02 Borehole Rod ExtensometersViorel LeopaAún no hay calificaciones

- SST500 Inlinometer ManualDocumento8 páginasSST500 Inlinometer ManualIan JonesAún no hay calificaciones

- Ds100-5-Eng (Mut2200el)Documento12 páginasDs100-5-Eng (Mut2200el)JAIME HERNANDEZ HERNANDEZAún no hay calificaciones

- 34 ST 03 64Documento36 páginas34 ST 03 64Manzoor-ul- HassanAún no hay calificaciones

- cs51 Sensor SDDocumento2 páginascs51 Sensor SDghmp123Aún no hay calificaciones

- F310 Load and Torque CellDocumento2 páginasF310 Load and Torque CellAsad HafudhAún no hay calificaciones

- Debitmetru ElectromagneticDocumento32 páginasDebitmetru ElectromagneticNistor PaulAún no hay calificaciones

- ElcometerDocumento6 páginasElcometerroohollah13Aún no hay calificaciones

- C LineDocumento16 páginasC LineSunil Kumar VishwakarmaAún no hay calificaciones

- Millermatic 140 Spec SheetDocumento4 páginasMillermatic 140 Spec SheetPaisaje SilenciosoAún no hay calificaciones

- AD01166M NUFLO Liquid Turbine Flow Meters Data SheetDocumento8 páginasAD01166M NUFLO Liquid Turbine Flow Meters Data SheetdediekosAún no hay calificaciones

- Transmitter SML 10Documento2 páginasTransmitter SML 10alamsyah_syamAún no hay calificaciones

- How to prepare Welding Procedures for Oil & Gas PipelinesDe EverandHow to prepare Welding Procedures for Oil & Gas PipelinesCalificación: 5 de 5 estrellas5/5 (1)

- AY 2015-16cvbbnjDocumento245 páginasAY 2015-16cvbbnjSyed Abdul AzizAún no hay calificaciones

- Standard Terms & Conditions of Sale Pre-Engineered BuildingsDocumento18 páginasStandard Terms & Conditions of Sale Pre-Engineered BuildingsHongducBuiAún no hay calificaciones

- Add A Thermometer To Your Digital Multimeter - Embedded LabDocumento13 páginasAdd A Thermometer To Your Digital Multimeter - Embedded LabGourmand OishiiAún no hay calificaciones

- XCMG Construction Machinery Co., LTDDocumento4 páginasXCMG Construction Machinery Co., LTD余Aún no hay calificaciones

- Manual de Instruções John Deere D170 (56 Páginas)Documento2 páginasManual de Instruções John Deere D170 (56 Páginas)Antonio CostaAún no hay calificaciones

- ARSTRUCTS Chapter1Documento15 páginasARSTRUCTS Chapter1Aila MaeAún no hay calificaciones

- Head & Combo: Manual 1.0Documento11 páginasHead & Combo: Manual 1.0NielsvdorstAún no hay calificaciones

- Foundation Construction Challenges at 100 11th Avenue in Manhattan - Secant Pile Wall by Andrew Cushing, Et. Al.Documento8 páginasFoundation Construction Challenges at 100 11th Avenue in Manhattan - Secant Pile Wall by Andrew Cushing, Et. Al.Andrew CushingAún no hay calificaciones

- One Pipe Steam DesignDocumento44 páginasOne Pipe Steam Designreyes hernandezAún no hay calificaciones

- PDFDocumento255 páginasPDFwrite2arshad_mAún no hay calificaciones

- Gate Ee 1991Documento7 páginasGate Ee 1991Bhavani Chandra UniqueAún no hay calificaciones

- Grabi Al Jubail ProfileDocumento130 páginasGrabi Al Jubail ProfileSlid ISO100% (1)

- Product Catalogue: Your Specialist in Flow DrillingDocumento64 páginasProduct Catalogue: Your Specialist in Flow DrillingВасяAún no hay calificaciones

- Wheels & BrakesDocumento14 páginasWheels & BrakesJoshua Saldana VélezAún no hay calificaciones

- TDS Tixatrol STDocumento2 páginasTDS Tixatrol STJose E BatistaAún no hay calificaciones

- RIL AGM Presentation SlidesDocumento44 páginasRIL AGM Presentation SlidesDeshGujaratAún no hay calificaciones

- 048Documento6 páginas048kokykarkarAún no hay calificaciones

- Getting Started With Java: Atul PrakashDocumento20 páginasGetting Started With Java: Atul PrakashOwsozeroAún no hay calificaciones

- RAB PE20Tx1set Amo, 60HP (1) Cetakan 50kg (400 Balok 16 Can) + Ice Storage 50TDocumento3 páginasRAB PE20Tx1set Amo, 60HP (1) Cetakan 50kg (400 Balok 16 Can) + Ice Storage 50THidayat SyamsiAún no hay calificaciones

- Flabeg Solar enDocumento11 páginasFlabeg Solar enZeec NoorAún no hay calificaciones