Documentos de Académico

Documentos de Profesional

Documentos de Cultura

PN54A001 Instalación de Heat Tracing

Cargado por

Pedro A. Santana H.Descripción original:

Título original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

PN54A001 Instalación de Heat Tracing

Cargado por

Pedro A. Santana H.Copyright:

Formatos disponibles

FlexiPanel

INSTALLATION PROCEDURES

WITH MAINTENANCE AND TROUBLE SHOOTING GUIDE INSPECTION REPORT FORMS

FlexiPanel Vessel Heating System

The following installation procedures are suggested guidelines for the installation of Thermons FlexiPanel system. They are not intended to preclude the use of other methods and good engineering or field construction practices. A copy of this manual accompanies each heater panel shipped. It is also available on the web at www.thermon.com.

FlexiPanel Attachment . . .

1. Plan for proper heater placement on the tank based on tank and heater sizes, tank obstructions, low liquid level and wiring routing requirements etc. FlexiPanels rely on good surface contact to maximize the heat transfer into the tank wall and product. Do not modify, overlap, cut or crease the heater. Heaters are typically bonded to the tank wall surface using adhesive supplied with the RTM Mounting Kit Part# W3073. An instruction sheet (Thermon dwg # 54A107S1) is supplied with the kit. The RTM Mounting Kit includes 2 each 10.3 oz tubes of RTV silicone sealant . One kit can install up to 8 square feet of heater. Additional tubes are available specify Part Number W20043 Silicone Sealant 10.3oz. Allow 0ne tube per 4 square feet of heater area. A roll of AL-20L tape is also included and installs up to 35 square feet of heater. Additional rolls of AL-20L are available specify Part Number W400080.

Receiving, Storing and Handling . . .

1. 2. Inspect materials for damage incurred during shipping. Report damages to the carrier for settlement. Shipping cartons are marked on the outside with the product description, sales order number and quantity. Compare information on shipping carton with packing slip and purchase order to verify receipt of correct shipment. Product should be stored indoors away from standing water; however, if outdoor storage is required, a protective covering should be used. Do not remove the heater from the carton until ready to install. Read all installation instructions prior to installing heater(s).

2.

3.

3.

4.

Surface Preparation/Layout . . .

1. Surface area where the FlexiPanel is to be installed must be reasonably clean. Remove dirt, rust and scale with a wire brush and oil and grease film with a suitable solvent. Mill varnish and protective coatings may be removed with a suitable stripper. FlexiPanels are typically 12 in width and vary in length up to 84. In general the heater is adhesively bonded to the lower exterior tank wall. The FlexiPanel should not extend above the vessels normal minimum liquid level as this will result in higher operating sheath temperatures at the exposed heater area. Space FlexiPanels evenly around circumference of vertical vessels and along lower area of horizontal vessels.

2.

Photo: RTM Mounting Kit

4.

FlexiPanel Testing . . .

1. Prior to installation check each heater for proper resistance. Resistance values for standard FlexiPanel heaters are enclosed. Nominal resistance is V2/P (Voltage squared divided by Power) Example - 120V@1000 Watt = 1202/1000 or 14.4 ohms. The resistance window is +/- 10%. (13.015.8 ohms) Prior to installation check each heater for insulation resistance. 1000 Vdc megohmeter check for insulation resistance between the power wires and ground wire. On steel tanks repeat test between the power wires and steel tank. 20 megohms minimum after 60 seconds. Repeat these tests after installing heaters and after the insulation has been installed. 2

2.

The outline of the heater is marked on the vessel using the marking pen. Load the adhesive tube into the caulking gun. Clip off end of threaded tip or puncture seal as applicable, install cartridge nozzle and cut off the nozzle tip for proper bead size. A bead of adhesive is applied to the silicone heater layer at 2 spacing. In a similar manner apply adhesive to the marked area on the tank wall. Using the notched spreader immediately spread the adhesive on the heater and tank not exceeding 1/32. Be sure the entire surface area is covered. Position the heater in place. Do not allow the adhesive to skin over. Compress heater firmly in place onto the tank wall using the roller. Work out any air bubbles by running the roller over the backside of the heater from the center outward. Secure the heater to the tank using aluminum tape as required. If spray on foam type insulation is to be used seal all the edges of the heater with AL-20L tape to prevent lifting. Allow 24 hours for adhesive to cure before energizing. The RTM Mounting Kit includes 8 each Caution Labels to be secure to the exterior of the insulating shell to identify the tank as electrically heat traced.

5.

3.

LATI TIO PRO ROC I N STA L LATIO N PROC E D U R E S

Final Connections . . .

1. FlexiPanel heaters are supplied standard with a T&B 5232 liquidtight flex conduit fitting exiting the top of the heater cap. The liquidtight flexible conduit is supplied by others. Local junction boxes and thermostats are to be properly installed and supported. Connect conduit securely as required to keep enclosures dust-tight and water-tight. Area approved seal fittings when required are supplied by others. Carefully connect conduit to heater fitting without rotating the fitting. Use a wrench to keep the heater fitting from rotating while tightening . Use a wrench to keep the heater fitting from rotating. Tighten the cap nut first by hand and then with a second wrench with 25 ft-pounds of torque. Repeat heater resistance and insulation resistance tests after the heater is installed on the tank. This verifies the heater was not damaged during the heater installation. Make any corrections/ repairs/replacements. Tape or bond thermostat bulb or sensor onto the tank wall midway between heaters and away from any heat sinks at a level similar to the heaters. If a high temperature thermostat is used to monitor maximum bulk fluid temperature the thermostat bulb or sensor would be located on the tank wall similar to the control thermostat but at a higher temperature setpoint. If a high temperature thermostat is used to monitor maximum heater sheath temperature the thermostat bulb or sensor would be located directly on the backside of one heater in the circuit and set to a temperature above the normal operating temperature of the heater. 3. An overlimit or high temperature thermostat may be employed in the design to monitor the maximum allowable bulk fluid temperature or maximum allowable heater temperature. If designed to monitor the maximum bulk fluid temperature lower the setpoint of the high temperature thermostat below the actual fluid temperature to verify switch operation. The microswitch will produce an audible click sound and the heater current will be zero. Increase the setpoint to the design high temperature cutout setpoint. Note that the sensor is wall mounted and during normal operation this thermostat will always be in the closed position. If designed to monitor the maximum allowable heater temperature lower the setpoint of the high temperature thermostat below the actual heater operating temperature to verify switch operation. The microswitch will produce an audible click sound and the heater current will be zero. Increase the setpoint to the design high temperature cutout setpoint. Note that the sensor is mounted on the heater and during normal operation this thermostat will always be in the closed position. A liquid level below the heaters with the heaters energized is considered an upset condition and should be avoided or prevented unless the heating system has been specifically designed for this condition. In general the heater operating temperature is much higher without fluid to conduct heat away from the heater. Liquid level controls can be employed to cut off the power supply to the heating system during low liquid level conditions but this disables the heating system so it is best to consider the fluid level above the heaters as a system requirement for safe operation. 4. The 2002 NEC requires Ground Leakage Equipment Protective Devices on all heat tracing circuits. Exception: Ground Leakage Monitoring and Alarms may prevent the need for branch EPD breakers. Electrical Heat Tracing caution labels should be applied to the outer surface of the weather barrier at regular intervals around the tank. 8 labels are supplied with the RTM Mounting Kit. Part# 27200 provides a package of 25 labels.

2.

3.

4.

5.

Thermal Insulation . . .

1. The need for properly installed and well maintained thermal insulation cannot be overemphasized. Regardless of the type or thickness of insulation used, a protective barrier should be installed. This protects the insulation from moisture intrusion, physical damage and helps insure the proper performance of the heat tracing system. Seal around all penetrations through the thermal insulation. Repeat heater resistance and insulation resistance tests after the installation of the thermal insulation and weather barrier. This verifies the heater was not damaged during the insulation installation. Make any corrections/repairs/replacements.

2.

System Operation . . .

1. The heating system can be energized once the fluid level is above the heaters. Turn the circuit breaker on and with the control thermostat closed (set to a temperature higher than actual fluid temperature) record the voltage and current. Retain these readings as part of an ongoing maintenance program. Lower the setpoint on the control thermostat to below the actual fluid temperature to test that the thermostat will shut off the heaters. The microswitch will produce an audible click sound and the heater current will be zero. Set the control thermostat to the desired maintain temperature setpoint. 3 5.

2.

Once the heat tracing system has been installed, an ongoing preventative maintenance program should be implemented using qualified personnel. Support documentation should be maintained which provides general information and an operating history of the specific circuits in the system.

FlexiPanel Vessel Heating System

Insulation Resistance Test (IR Test)

Description An Insulation Resistance Test (Megger) checks the quality of the heaters insulating layers by measuring the electrical insulation resistance of the system. The higher the reading the better the insulation resistance. A low reading may indicate potential failure and allow replacement during routing maintenance. To obtain comparable results tests are done for the same duration usually 60 seconds. Check heater insulation resistance before installation, after installation, after insulation is installed as as part of an annual preventative maintenance program. Record data in a maintenance log. An IR test should also be done if any work is done on the tank insulation or if the tank has been subject to damage. The test is performed with an instrument Equipment called a megohmmeter or Megger. Thermon recommends performing the test at 1000 Vdc. 500 Vdc is the minimum acceptable test voltage. Tests are done with the heating equipment not Testing connected to a power supply. On an installed system use the connections at the local junction box or splice box .Disconnect the heater lead wires from the terminals and connect to Megger.

FlexiPanel Cat. # RT-521 RT-522 RT-1021 RT-1022 RT-2022 RT Special RTF-1236 RTF-1260 RTF-1282 RTF-1284 RTF-2260 RTF-2284 RTF Special FlexiPanel Cat. # Nominal Service Voltage (VAC) 120 240 120 240 240 Up to 600V 120 120 120 120 240 240 Up to 600V Nominal Service Voltage (VAC) Nominal Power (Watts) 500 500 1000 1000 2000 Up to 2 W/in2 300 500 300 500 500 500 Up to 0.7 W/in2 Nominal Power (Watts)

Testing insulation layer between heater element and heater ground. Connect one lead to the heater power wires and the other lead to the heater ground wire. Set the voltage to 1000Vdc. Turn the Megger on. Apply test voltage for one minute. The minimum insulation resistance reading is 20 megohms. If the heater is installed on a nonmetallic tank the testing is complete. To test the insulation layer between heater element and metal tank r emove the negative lead from the ground wire and connect to the metal tank surface. Set the voltage to 1000Vdc. Turn the Megger on. Apply test voltage for one minute. The minimum insulation resistance reading is 20 megohms. Results For readings below 20 megohms recheck testing Test Results procedure. Look for correct connections and settings and that the heater is isolated from other electrical connections. Check for evidence of excess moisture, corrosion or damage to the heater or wiring. . Damaged heaters should be replaced. Insulation failure can result from excessive heat or cold, dirt, moisture, oil, corrosive vapors, vibration, aging, nicked wires or mechanical or electrical damage.

Dimensions (Inches) 12 x 24 12 x 24 12 x 42 12 x 42 12 x 84 As Specified 12 x 36 12 x 60 12 x 84 12 x 84 12 x 60 12 x 84 As Specified Dimensions (Inches)

Minimum -10% 25.9 103.7 13.0 51.8 25.9 -10% 43.2 25.9 43.2 25.9 103.7 103.7 -10% Minimum -10%

Nominal Resistance 28.8 115.2 14.4 57.6 28.8 As Specified 48.0 28.8 48.0 28.8 115.2 115.2 As Specified Nominal Resistance

Maximum +10% 31.7 126.7 15.8 63.4 31.7 +10% 52.8 31.7 52.8 31.7 126.7 126.7 +10% Maximum +10%

Single Heater / Phase to Phase or Phase to Neutral

Power Supply 208V/240V N 120V/277V

SCH TICS WI R I N G SCH E MATICS

120 volt Power Supply

Control thermostat

C NC

Bulb

28.8 OHMS / 500 wa tts

FLE XIPA NEL

28.8 OHMS / 500 wa tts

Multiple Heater / Phase to Phase or Phase to Neutral

Power Supply 208V/240V N 120V/277V

28.8 OHMS / 500 wa tts

PARALLEL WIRING

Control thermostat

C NC

Bulb

120 volt Power Supply 125 WATTS

FLE XIPANEL

125 WA TTS

28.8 OHMS + 28.8 OHMS = 57.6 OHMS

FLE XIPANEL

SER IES WIR ING

Multiple Heater / Contactor / Phase to Phase Heaters / Phase to Neutral Control

Power Supply

N A B

R EF: OHMS LAW

208V/240V HEATER

V 2 /R=W

Contactor

FLE XIPA NEL

FLE XIPA NEL

Control thermostat

C NC

Bulb

120V COIL

Sample Circuit - Control Thermostat and High Temperature Cutout Thermostat

Power Supply

N A B

208V/240V HEATER

Contactor

FLE XIPA NEL

FLE XIPA NEL

Control Thermosta t

C NC

Bulb

High Temp Thermostat

C NC

120V Coil

FlexiPanel Vessel Heating System

Maintenance and Troubleshooting Guide

The following information is intended to assist you in maintaining and troubleshooting electric tank and vessel heating systems. The primary objective is to enhance your understanding of the elements of a successful heat tracing installation. Of these elements, one of the most important is thermal insulation. Before calling your heat-tracing vendor make a visual inspection of the installation; perhaps the thermal insulation is wet, damaged or missing. Also, consider that repairs or maintenance of in-line or nearby equipment may have resulted in damage to the heating equipment. These are common causes of heat tracing problems, and they are often overlooked. Other possible causes are listed below with their symptoms and remedies. Note: If you suspect that an electric heating circuit is damaged, we recommend a dielectric insulation resistance (megger) test be performed with a 1000 Vdc megohmmeter. See page 4 of this manual. Readings can be logged on Part 2 of the Thermon Inspection Report Form brochure. Periodic testing with accurate records will establish a normal range of operation, and dielectric insulation resistance readings, which deviate from the normal range, can quickly reveal a damaged circuit. SYMPTOM heat/No I. No heat/No current POSSIBLE CAUSE A. Loss of Power (Voltage) REMEDY Restore power to the heating circuit. (Check circuit breaker and electrical connections.) Adjust set point. May require manual reset to re-enable heating circuit. Check set point. (Identify cause of high temperature- review design, check liquid level.) Repair or replace circuit.1 Repair sensor or controller.2

B. Controller set point too low C. High-temperature limit switch activated

D. Open series heating circuit E. Controller Failure

Thermal Insulation . . . An Integral Part of Every Heat Tracing System

The value of properly installed and well-maintained thermal insulation cannot be overemphasized. Without the insulation, the heat losses are generally too high to be offset by a conventional heat tracing system. Before the thermal insulation is installed on the tank or vessel, the heating circuit should be tested for dielectric insulation resistance. This will ensure that the heater has not been damaged while exposed on the uninsulated tank. There are many different tank insulation materials, each of which has advantages in particular applications. The temperature ratings of some of the common insulation materials are listed below in order of their efficiency (from the most to least effective), based on equivalent thicknesses: Polyurethane foam (1800F - 2500F) Fiberglass (3750F 5000F) Cellular Glass (4000F) Calcium Silicate (12000F+) Rigid Flexible Rigid Rigid

SYMPTOM System Temperature Il. Low System Temperature POSSIBLE CAUSE A. Controller Set Point Too Low REMEDY Adjust set point.

B. Temperature sensor located too Relocate sensor. close to heater or other heat source; may be accompanied by excessive cycling of control relays/contacts. C. Insulation material and/or Replace insulation; thickness different than designed. Increase insulation thickness (if dry); Consider increasing voltage3 for higher heater output; Add additional heaters. D. Ambient temperature lower than Add additional heaters; designed Consider increasing voltage3; Add additional insulation. E. Lower Voltage (Check at power Connection point) F. Liquid Level below heaters (Heaters cycling or deenergized) if tied into LLL switch) 6 Adjust voltage3 to meet design requirements. Increase liquid level; Lower heater location below low liquid level.

Regardless of the type or thickness of insulation used, a protective barrier should be installed. This protects the insulation from moisture intrusion and physical damage, and helps ensure the proper performance of the heat tracing system. Insulating materials such as fiberglass and calcium silicate are very susceptible to water absorption, which dramatically increases the heat lost. They should be replaced if they become wet.

NTEN AN TROU TIN GU M AI NTENA N CE AN D TROU B LE SHOOTIN G GU I DE

SYMPTOM System Temperature I I I. High System Temperature POSSIBLE CAUSE A. Controller on continuously REMEDY Adjust set-point or replace sensor.2 Replace sensor or controller.

2

Footnotes . . . 1 FlexiPanel heaters must usually be replaced if defect not found in heater wires . Note: FlexiPanel heaters may use an internal thermal cutout that will result in a open circuit if activated due to temperatures above the rated set point. This may be normal. Check system design. Mechanical thermostat sensors cannot be repaired or replaced; RTD or thermocouple sensors may be replaced. Some controllers have replaceable contacts/relays, or may require a manual reset if a trip-off condition on the heating circuit was detected. The operation of most electric heating circuits is dramatically affected by changes in the supply voltage. Before making any changes, consult the heater manufacturer with information on the alternate voltages available, otherwise, heater failure and/or electrical safety hazard may result is some situations. Verify voltage prior to energizing heating system. Higher voltages can result in heater failure and/or an electrical safety hazard may result in some situations. A liquid level below the heaters is considered an upset condition and should be avoided or prevented unless the heating system has been specifically designed for this condition.

B. Controller failed with contacts closed C. Sensor located near heat sink.

Relocate sensor to an area representative of overall tank conditions.

D. Backup heating circuit controller on continuously

Adjust set-point or replace backup controller. 4

SYMPTOM IV. Cycling IV. Excessive Cycling POSSIBLE CAUSE A. Temperature sensor located too close to heater or other heat source; may be accompanied by low system temperature. B. Connected voltage too high (See item C) C. Heater output too high REMEDY Relocate sensor.

Lower voltage4

Install lower-output heater or lower voltage.

D. Fluid level below heater

Increase fluid level above heaters.5 Lower maintain temperature; Lower voltage; Design for lower watt density heater; Increase setpoint for high temp cut out.

E. Wall thickness larger than design allowance (Not an issure for steel wall)

FlexiPanel Vessel Heating System

INSULATION

JUNCTION BOX THERMOSTAT POWER IN

HEATER LOW LIQUID LEVEL ABOVE HEATERS

TEMPERATURE SENSOR

SAMPLE INSTALLATION HORIZONTAL TANK

HEATER

JUNCTION BOX THERMOSTAT POWER IN TEMPERATURE SENSOR LOW LIQUID LEVEL ABOVE HEATERS

SAMPLE INSTALLATION VERTICAL TANK

THERMON . . . The Heat Tracing Specialists 100 Thermon Dr. PO Box 609 San Marcos, TX 78667-0609 Phone: 512-396-5801 Facsimile: 512-396-3627 800-820-HEAT www.thermon.com In Canada call 800-563-8461

STANDARD DWG NO: 54A001 R2

Thermon Manufacturing Co.

Printed in U.S.A.

INSULATION

FlexiPanel Vessel Heating System

Inspection Report Form For Electric Tank Heating

Part 1

Page _____of_____

LOCATION

SYSTEM

REFERENCE DRAWING(S)

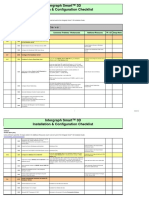

CIRCUIT INFORMATION BKR PANEL NO. BKR POLE(S) NO. HEATER JUNCTION BOX # # HEATERS PER JUNCTION BOX HEATER CONTROLLER HIGH LIMIT CONTROLLER (IF ANY) GROUND FAULT PROTECTION (TYPE) GROUND FAULT TRIP SETTING

DATE

COMMENTS AND ACTIONS

INSPECTION REPORT FORMS

Inspection Report Form For Electric Tank Heating

Part 2

Page _____of_____

QUANTITY/TYPE/LOCATION/RESISTANCE HEATER MODEL PART NUMBER LOCATION RESISTANCE

INSULATION RESISTANCE TESTING (BEFORE INSULATING) HEATER # TEST VOLTAGE MEGGER VALUE

INSULATION RESISTANCE TESTING (AFTER INSULATING) HEATER # TEST VOLTAGE MEGGER VALUE

HEATER SUPPLY VOLTAGE VALUE AT POWER SOURCE VALUE AT FIELD CONNECTION

HEATER CIRCUIT CURRENT READING AMP READING GROUND FAULT CURRENT

FlexiPanel Vessel Heating System

Inspection Report Form For Electric Tank Heating

Part 3

Page _____of_____

THERMAL INSULATION

DAMAGED INSULATION OR LAGGING WEATHER SEAL GOOD INSULATION OR LAGGING MISSING PRESENCE OF MOISTURE CAUTION LABELS INSTALLED

HEATING SYSTEM COMPONENTS

ENCLOSURES, BOXES SEALED SIGN OF CORROSION HEATER WIRE CONNECTIONS PRESENCE OF MOISTURE

HEATING AND/OR HIGH LIMIT CONTROLLER

MODEL CONTROLLER SET POINT(S) OPERATING PROPERLY

PERFORMED BY DATE APPROVED BY DATE

COMPANY COMPANY

INSPECTION REPORT FORMS

NOTES:

También podría gustarte

- Blast Furnace - April 2014: SR - No Checklist Frequency Shift Checklist Instrumentation Maintenance Plan For The month-BFDocumento11 páginasBlast Furnace - April 2014: SR - No Checklist Frequency Shift Checklist Instrumentation Maintenance Plan For The month-BFShiva Prakasam PernetiAún no hay calificaciones

- Edi Training MaterialDocumento18 páginasEdi Training MaterialPrasad RajAún no hay calificaciones

- Csi Hand Book PDFDocumento125 páginasCsi Hand Book PDFAnonymous tricks100% (1)

- Primavera P6 vs SAP PS: Comparing Project Management SoftwareDocumento4 páginasPrimavera P6 vs SAP PS: Comparing Project Management SoftwareKusam AvinashAún no hay calificaciones

- Local Employment Policy Handbook PDFDocumento135 páginasLocal Employment Policy Handbook PDFrodi_dumitru5709Aún no hay calificaciones

- Large Crude Oil Storage Tank Trac-Loc Installation ... - Pentair ThermalDocumento2 páginasLarge Crude Oil Storage Tank Trac-Loc Installation ... - Pentair ThermalBarmar SbahiAún no hay calificaciones

- Paras Polycab Private Limited: Quality Products Professional Team Renowned BrandDocumento36 páginasParas Polycab Private Limited: Quality Products Professional Team Renowned BrandRaghavendra YedidaAún no hay calificaciones

- BRSM Form 009 VRMDocumento17 páginasBRSM Form 009 VRMAnonymous q8lh3fldWMAún no hay calificaciones

- PVRVDocumento4 páginasPVRVbkkbrazil100% (1)

- Intergraph Smart Interop Publisher: System RequirementsDocumento8 páginasIntergraph Smart Interop Publisher: System RequirementsRamilAún no hay calificaciones

- Coatings Word June 2011Documento52 páginasCoatings Word June 2011sami_sakrAún no hay calificaciones

- 01-01-1865-D ELDS Technical Manual Iss13Documento221 páginas01-01-1865-D ELDS Technical Manual Iss13Alberyt099Aún no hay calificaciones

- Weighbridge TSDocumento6 páginasWeighbridge TSNiroop RajAún no hay calificaciones

- Service Receipt Sheet ReviewDocumento1 páginaService Receipt Sheet ReviewAndika JuliandahriAún no hay calificaciones

- WPS Sa 517Documento2 páginasWPS Sa 517DHANANNJAI SINGH -Aún no hay calificaciones

- PD2021-Plant Design Workflow Using Autodesk Plant Design Suite UltimateDocumento12 páginasPD2021-Plant Design Workflow Using Autodesk Plant Design Suite UltimatekalaiAún no hay calificaciones

- Intergraph Smart Interop Publisher Mapping ResolutionDocumento9 páginasIntergraph Smart Interop Publisher Mapping ResolutionQiuniuAún no hay calificaciones

- Dunning MailDocumento9 páginasDunning MaildamljanovicAún no hay calificaciones

- RF Device: GUI DevicesDocumento11 páginasRF Device: GUI Deviceschinmay patilAún no hay calificaciones

- Prima Catalouge 6 Pgs-MinDocumento6 páginasPrima Catalouge 6 Pgs-MinVarun KapoorAún no hay calificaciones

- INTRODUCTION To FINOLEX Finolex Group Was EstablishedDocumento24 páginasINTRODUCTION To FINOLEX Finolex Group Was EstablishedpraveennakkinaAún no hay calificaciones

- Import Customizing StepsDocumento12 páginasImport Customizing StepsVenkat GudipatiAún no hay calificaciones

- Work Procedure Bitumen Mastic FlooringDocumento6 páginasWork Procedure Bitumen Mastic FlooringSWARUP MONDALAún no hay calificaciones

- AVK Pneumatic Gate Valves BrochureDocumento2 páginasAVK Pneumatic Gate Valves BrochureCuong Nguyen ChiAún no hay calificaciones

- Make To Order (MTO) and Make To Stock (MTS) - ERP Operations - SCN WikiDocumento2 páginasMake To Order (MTO) and Make To Stock (MTS) - ERP Operations - SCN WikiSudeep JainAún no hay calificaciones

- Oil Well Flowline Pipe & FittingsDocumento7 páginasOil Well Flowline Pipe & FittingsPahala2016 toga100% (2)

- VD V013 ZPM Pro 1507Documento105 páginasVD V013 ZPM Pro 1507abdulAún no hay calificaciones

- Z Phy Inv DocumentDocumento13 páginasZ Phy Inv Documentapi-3703552Aún no hay calificaciones

- Electronic Leak Detectors and Valve Testers ENGDocumento2 páginasElectronic Leak Detectors and Valve Testers ENGShubham ChauhanAún no hay calificaciones

- SchneiderDocumento4 páginasSchneiderkarunya31Aún no hay calificaciones

- Volume - IIDocumento585 páginasVolume - IIRaji VargheseAún no hay calificaciones

- Datasheet Pressure Indicating Controller PDFDocumento5 páginasDatasheet Pressure Indicating Controller PDFHimawan Sigit NugrohoAún no hay calificaciones

- AGIP STD - Valves Specification SheetDocumento1 páginaAGIP STD - Valves Specification Sheethalim_kaAún no hay calificaciones

- Khadimally RT011215Documento33 páginasKhadimally RT011215jkj_13874Aún no hay calificaciones

- Anchor Pattern Planning Chart TSM: 8 APPC7001Documento1 páginaAnchor Pattern Planning Chart TSM: 8 APPC7001sathiaselanpasskerenAún no hay calificaciones

- SPLMV9Install ChecklistDocumento3 páginasSPLMV9Install Checklistanon_908554203Aún no hay calificaciones

- Donaldson FiltersDocumento2 páginasDonaldson FiltersAnonymous ieWpd823LgAún no hay calificaciones

- Pds Project SetupDocumento3 páginasPds Project SetupSRIKANTHAún no hay calificaciones

- Rei Vol IiDocumento142 páginasRei Vol IiDineshAún no hay calificaciones

- Catalogue of 3051SFCDocumento50 páginasCatalogue of 3051SFCKarthikeyan LakshminarayananAún no hay calificaciones

- Manpower ListDocumento4 páginasManpower ListgkAún no hay calificaciones

- Technocommercial SheetDocumento7 páginasTechnocommercial SheetRaja Rao KamarsuAún no hay calificaciones

- LPG Energy IntegrationDocumento6 páginasLPG Energy IntegrationBandaru KiranAún no hay calificaciones

- Lco Tank Relief Valve (2016.04.11.) - For ApprovalDocumento87 páginasLco Tank Relief Valve (2016.04.11.) - For ApprovalEnoch TwumasiAún no hay calificaciones

- Activate PPO and Sync BP to Cust/VendorDocumento12 páginasActivate PPO and Sync BP to Cust/VendorHARIAún no hay calificaciones

- PDSInstall ChecklistDocumento41 páginasPDSInstall ChecklistKannaphat Wattanaphan100% (1)

- PDFDocumento7 páginasPDFAngling DharmaAún no hay calificaciones

- RF Prog Guideline SapnetDocumento33 páginasRF Prog Guideline SapnetJohn NederpelAún no hay calificaciones

- Design code for sour hydrocarbon liquid and vapour pipingDocumento6 páginasDesign code for sour hydrocarbon liquid and vapour pipingprathameshAún no hay calificaciones

- Cameron Scanner 2000 Microefm Well Testing Solution BrochureDocumento8 páginasCameron Scanner 2000 Microefm Well Testing Solution BrochureAnom Haryanto100% (1)

- Complete ALE WorkingDocumento23 páginasComplete ALE WorkingjeetchauhanAún no hay calificaciones

- List of Selected Projects 480Documento20 páginasList of Selected Projects 480vijay2293Aún no hay calificaciones

- Procedure For Fire Water Max. Demand Calculation: Quality Management System DocumentDocumento4 páginasProcedure For Fire Water Max. Demand Calculation: Quality Management System DocumentmAún no hay calificaciones

- Flarenet Model Setup: Fan, YiDocumento11 páginasFlarenet Model Setup: Fan, YiShamsMohdAún no hay calificaciones

- MIL-PRF-131 (Formerly Mil-B-131)Documento6 páginasMIL-PRF-131 (Formerly Mil-B-131)Anonymous 1c48fy0Aún no hay calificaciones

- PDS Express Project CreationDocumento83 páginasPDS Express Project Creationnjtz55Aún no hay calificaciones

- PMC - POS Split Scope of WorkDocumento10 páginasPMC - POS Split Scope of Workgigiphi100% (1)

- SD GTS Integration: Community WIKI SAP CommunityDocumento5 páginasSD GTS Integration: Community WIKI SAP CommunitySUDHIRAún no hay calificaciones

- KEC-KMe ManualDocumento5 páginasKEC-KMe Manualhossimo33Aún no hay calificaciones

- JOHN WOOD Water HeaterDocumento6 páginasJOHN WOOD Water HeaterkapokAún no hay calificaciones

- Intellitrol SpecsDocumento5 páginasIntellitrol SpecsDuncan McIntyreAún no hay calificaciones

- Norma Nema 250 PDFDocumento39 páginasNorma Nema 250 PDFmoraima zorrillaAún no hay calificaciones

- Burndy Grounding CatalogDocumento133 páginasBurndy Grounding CatalogRoman PaduaAún no hay calificaciones

- Street Area Lighting Pole Selection Guide PDFDocumento118 páginasStreet Area Lighting Pole Selection Guide PDFPedro A. Santana H.Aún no hay calificaciones

- Manual Promass 84fDocumento74 páginasManual Promass 84fPedro A. Santana H.Aún no hay calificaciones

- Musso Circuito ElectricoDocumento228 páginasMusso Circuito ElectricoPedro A. Santana H.Aún no hay calificaciones

- Celdas Abb Se CVXDocumento110 páginasCeldas Abb Se CVXPedro A. Santana H.Aún no hay calificaciones

- Engineering Drawing Handbook PDFDocumento120 páginasEngineering Drawing Handbook PDFRobert Nixon100% (1)

- Placenta Previa Case StudyDocumento59 páginasPlacenta Previa Case StudySiergs Smith GervacioAún no hay calificaciones

- Solids Level Measurement Application Guide en 78224 PDFDocumento144 páginasSolids Level Measurement Application Guide en 78224 PDFwalcalAún no hay calificaciones

- LAST CARGOES AND CLEANINGDocumento1 páginaLAST CARGOES AND CLEANINGAung Htet KyawAún no hay calificaciones

- Material Safety Data Sheet: WWW - Smartlab.co - IdDocumento8 páginasMaterial Safety Data Sheet: WWW - Smartlab.co - Idlalan suparlanAún no hay calificaciones

- Perforamance Based AssessmentDocumento2 páginasPerforamance Based AssessmentJocelyn Acog Bisas MestizoAún no hay calificaciones

- Cap 716 PDFDocumento150 páginasCap 716 PDFjanhaviAún no hay calificaciones

- A. Kumar Aswamy Job Offer LetterDocumento1 páginaA. Kumar Aswamy Job Offer LetterHimanshu PatelAún no hay calificaciones

- TSS-TS-TATA 2.95 D: For Field Service OnlyDocumento2 páginasTSS-TS-TATA 2.95 D: For Field Service OnlyBest Auto TechAún no hay calificaciones

- EP Series User Manual PDFDocumento40 páginasEP Series User Manual PDFa.elwahabAún no hay calificaciones

- GSIS vs. de LeonDocumento9 páginasGSIS vs. de Leonalwayskeepthefaith8Aún no hay calificaciones

- HierbasDocumento25 páginasHierbasrincón de la iohAún no hay calificaciones

- Montgomery County Ten Year Comprehensive Water Supply and Sewerage Systems Plan (2003)Documento228 páginasMontgomery County Ten Year Comprehensive Water Supply and Sewerage Systems Plan (2003)rebolavAún no hay calificaciones

- Space Analysis in Orthodontic: University of GlasgowDocumento16 páginasSpace Analysis in Orthodontic: University of GlasgowNizam Muhamad100% (1)

- Supply Chain Management of VodafoneDocumento8 páginasSupply Chain Management of VodafoneAnamika MisraAún no hay calificaciones

- Rudraksha - Scientific FactsDocumento20 páginasRudraksha - Scientific FactsAkash Agarwal100% (3)

- Piping Material Classes GuideDocumento98 páginasPiping Material Classes GuideLuis Pottozen VillanuevaAún no hay calificaciones

- Cement ReportDocumento86 páginasCement ReportSohaibAún no hay calificaciones

- Myth and Realism in The Play A Long Day's Journey Into Night of Eugene O'neillDocumento4 páginasMyth and Realism in The Play A Long Day's Journey Into Night of Eugene O'neillFaisal JahangeerAún no hay calificaciones

- EEDMATH1 - Teaching Mathematics in The Primary Grades Beed 2E Learning Activity PlanDocumento3 páginasEEDMATH1 - Teaching Mathematics in The Primary Grades Beed 2E Learning Activity PlanBELJUNE MARK GALANANAún no hay calificaciones

- Urban Drainage Modelling Guide IUD - 1Documento196 páginasUrban Drainage Modelling Guide IUD - 1Helmer Edgardo Monroy GonzálezAún no hay calificaciones

- Critical Criminal Justice IssuesDocumento132 páginasCritical Criminal Justice IssuesAnnamarella Amurao CardinezAún no hay calificaciones

- Q1 Tle 4 (Ict)Documento34 páginasQ1 Tle 4 (Ict)Jake Role GusiAún no hay calificaciones

- XDocumento266 páginasXTrần Thanh PhongAún no hay calificaciones

- Venus in MulaDocumento2 páginasVenus in MulaGovind BallabhAún no hay calificaciones

- Aging and Elderly IQDocumento2 páginasAging and Elderly IQ317537891Aún no hay calificaciones

- g21 Gluta MsdsDocumento3 páginasg21 Gluta Msdsiza100% (1)

- NFPA 72 Fire Alarm TrainingDocumento376 páginasNFPA 72 Fire Alarm TrainingFavori gcbAún no hay calificaciones

- Completed Manuscript 1 5Documento52 páginasCompleted Manuscript 1 5SAMANTHA LACABAAún no hay calificaciones

- Ensure Even Preload with Proper Tightening Tools and SequenceDocumento2 páginasEnsure Even Preload with Proper Tightening Tools and SequenceMachineryengAún no hay calificaciones

- Analisis Dampak Reklamasi Teluk Banten Terhadap Kondisi Lingkungan Dan Sosial EkonomiDocumento10 páginasAnalisis Dampak Reklamasi Teluk Banten Terhadap Kondisi Lingkungan Dan Sosial EkonomiSYIFA ABIYU SAGITA 08211840000099Aún no hay calificaciones