Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Handbook - Calculations0

Cargado por

paimpillyDescripción original:

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Handbook - Calculations0

Cargado por

paimpillyCopyright:

Formatos disponibles

Handbook - Calculations

1 of 1

http://www.esabna.com/EUWeb/FM_handbook/577fm8_1.htm

Covered

Electrodes

Calculating Filler Metal Consumption

Stainless

Steel

Products

The number of pounds of welding electrodes or welding wire necessary to complete a given weld joint may

be calculated by the formula:

Solid Wire

& Rod

Products

P =

WL

E

Where:

ESAB

TIG & MIG

Wires

Cored

Wire

Products

Pounds of electrode or wire required

W =

Weight per foot of weld metal

Length of weld (feet)

Deposition efficiency

Weight Per Foot of Weld Metal

Submerged

Arc

Products

Calculating the weight of weld metal requires that we consider the following items.

1. Area of the cross-section of the weld.

2. Length of the weld.

Hardsurfacing

Products

3. Volume of the weld in cubic inches.

Filler Metal

Consumption

4. Weight of the weld metal per cubic inch.

StubLoss

Correction

Calculations

Electrode/Wire

Consumption

Filler Metals

ASTM

Steels

Conversion

Tables

Weld Metal Cost

Worksheet

Weight/Foot

Weld Metal

Weight/Meter

Weld Metal

4/12/2012 2:30 PM

Handbook - Calculations

1 of 1

http://www.esabna.com/EUWeb/FM_handbook/577fm8_2.htm

Covered

Electrodes

In the fillet weld shown below, the area of the cross-section (the triangle) is equal to one half the base times

the height, the volume of the weld is equal to the area times the length, and the weight of the weld then, is

the volume times the weight of the material (steel) per cubic inch.

Stainless

Steel

Products

Solid Wire

& Rod

Products

(A) HEIGHT 0.5"

0.5"

(B) BASE

Volume of Weld = .5B x A x 12

Weight of Steel = .283 lb per cu. in.

Weight of Weld

= (0.5 x 0.5) x 0.5 x 12 x .283

= .424 lb.

CALCULATING THE WEIGHT PER FOOT OF A FILLET WELD

ESAB

TIG & MIG

Wires

This example is for a fillet weld with no reinforcement. Similar calculations can be made for butt or lap joints.

Deposition Efficiency

Cored

Wire

Products

The deposition efficiency of an electrode or welding wire indicates the portion of that product you can

expect to be deposited as weld metal. Losses due to slag, spatter, fume and in the case of semi automatic

or automatic welding processes, the ends cut before each weld and the wire left in the feed cable make no

process 100% efficient.

Submerged

Arc

Products

For estimates of electrode or wire consumption, the following average values of deposition efficiency may be used.

Deposition

Hardsurfacing

Products

Process

Filler Metal

Consumption

StubLoss

Correction

Calculations

Electrode/Wire

Consumption

Filler Metals

ASTM

Steels

Conversion

Tables

Efficiency

Submerged Arc

99%

Gas Metal Arc (98%A, 2%O2)

98%

Gas Metal Arc (75%A, 25%CO2)

96%

Gas Metal Arc (C02)

93%

Metal Cored Wires

93%

Gas Shielded Flux Cored Wires

86%

Self Shielded Flux Cored Wires

78%

Weld Metal Cost

Worksheet

* Shielded Metal Arc (Stick 12" long)

59%

* Shielded Metal Arc (Stick 14" long)

62%

Weight/Foot

Weld Metal

* Shielded Metal Arc (Stick 18" long)

66%

Weight/Meter

Weld Metal

* Includes 2" stub loss.

4/12/2012 2:30 PM

Handbook - Calculations

1 of 1

http://www.esabna.com/EUWeb/FM_handbook/577fm8_3.htm

Covered

Electrodes

It must be remembered that when deposition tests are performed in the laboratory, the deposition efficiency

is calculated by the formula:

Stainless

Steel

Products

Weight of metal deposited

Solid Wire

& Rod

Products

Deposition Efficiency

Weight of electrode consumed

ESAB

TIG & MIG

Wires

This does not take stub loss into consideration. The chart below shows how the laboratory established

efficiency is effected by the length of the stub.

Cored

Wire

Products

Stub Loss Correction Table

for Coated Electrodes

Submerged

Arc

Products

Hardsurfacing

Products

Electrode

Length

12"

(300 mm)

Electrode

Filler Metal

Consumption

StubLoss

Correction

14"

(350 mm)

Electrode

Calculations

Electrode/Wire

Consumption

Filler Metals

ASTM

Steels

Conversion

Tables

Weld Metal Cost

Worksheet

18"

(450 mm)

Electrode

2"

3"

4"

5"

Deposition (50 mm) (75 mm) (100 mm) (125 mm)

Efficiency STUB

STUB

STUB

STUB

60.0%

65.0%

70.0%

75.0%

80.0%

50.0%

54.2%

58.3%

62.5%

66.6%

45.0%

46.7%

52.5%

56.2%

60.0%

40.0%

43.3%

46.6%

50.0%

53.3%

35.0%

37.9%

40.8%

43.7%

46.6%

60.0%

65.0%

70.0%

75.0%

80.0%

51.4%

55.7%

60.0%

64.3%

68.5%

47.1%

51.1%

55.0%

56.9%

62.8%

42.9%

46.4%

50.0%

53.6%

57.1%

38.3%

41.0%

45.0%

46.2%

51.4%

60.0%

65.0%

0.0%

75.0%

80.0%

53.3%

57.7%

62.2%

66.6%

71.1%

50.0%

54.2%

56.3%

62.5%

66.6%

46.6%

50.5%

54.4%

56.3%

62.2%

43.3%

46.9%

50.5%

54.2%

57.7%

Weight/Foot

Weld Metal

Weight/Meter

Weld Metal

4/12/2012 2:28 PM

Handbook - Calculations

1 of 1

http://www.esabna.com/EUWeb/FM_handbook/577fm8_4.htm

Covered

Electrodes

Stainless

Steel

Products

Electrode or Welding Wire Consumption

Solid Wire

& Rod

Products

ESAB

TIG & MIG

Wires

1/8

(3.2)

.027

Pounds/Foot (Kilos/meter) of Electrode or Wire

Required per Lineal Foot or (Meter) of Weld

SM AW-Stick GM AW-Solid

FCAW-Gas

M etal Cored

Electrodes

Wires

Shielded

Wires

(.040) .043 (.064) .028 (.042) .032 (.048) .029 (.043)

3/16

(4.7)

.060

(.089)

.097

(.144)

.063

(.094)

.070

(.104)

.065

1/4

(6.3)

.106

(.158)

.171

(.254)

.112

(.167)

.125

(.186)

.115

(.171)

5/16

(7.9)

.166

(.247)

.268

(.399)

.175

(.260)

.195

(.290)

.180

(.268)

L

L

Cored

Wire

Products

(9.5)

.239

(.356)

.385

(.573)

.252

(.375)

.282

(.420)

.260

(.387)

1/2

(12.7)

.425

(.632)

.686 (1.020)

.447

(.665)

.50

(.744)

.462

(.688)

(.988) 1.071 (1.594)

5/8

(15.8)

.664

3/4

(19.1)

.956 (1.423) 1.542 (2.295) 1.010 (1.503)

(25.4) 1.698 (2.527)

Square

Butt

Joint

2.739 (4.076) 1.787 (2.659)

.781 (1.162)

.722 (1.074)

1.125 (1.674) 1.039 (1.546)

2.0 (2.976) 1.846 (2.747)

Filler Metal

Consumption

3/16

(4.7)

1/4

(6.3)

A

1/16"

Electrode/Wire

Consumption

Weld Metal Cost

Worksheet

Weld Metal

Required

lbs/ft (kg/m )

Joint Dimensions - Inches (m m )

T

B

A

Calculations

Conversion

Tables

.699 (1.040)

Electrode Consumption (contd.)

StubLoss

Correction

Filler Metals

ASTM

Steels

(.097)

3/8

Submerged

Arc

Products

Hardsurfacing

Products

Weld M etal

Required

lbs/ft (kg/m)

Fillet Size

in. (mm)

L

Horizontal

Fillet

Welds

5/16

1/16

(1.6)

1/16

(1.6)

3/32

1/16

(2.4)

(1.6)

3/32

(2.4)

3/8

(9.5)

Stick Electrodes

Required

lbs/ft (kg/m )

.093

(.138)

.150

(.223)

.115

(.171)

.185

(.275)

.142

.137

(.211)

(.204)

.229

.220

(.341)

(.327)

.165

(.245)

.266

(.396)

7/16 (11.1)

(7.9)

1/2 (12.7)

Weight/Foot

Weld Metal

Weight/Meter

Weld Metal

4/12/2012 2:27 PM

Handbook - Calculations

1 of 1

http://www.esabna.com/EUWeb/FM_handbook/577fm8_6.htm

Covered

Electrodes

Weld Metal Cost Worksheet Instructions

Stainless

Steel

Products

To help you quantify your specific cost of weld metal deposited, ESAB has developed the weld metal cost

worksheet. Directions will assist you in calculating your specific cost to deposit weld metal while comparing

it to alternative methods or product.

1. Indicate the complete descriptions of the proposed and present products at (1) and (2).

Solid Wire

& Rod

Products

2. Secure the following information for the formulas (3), and write the data in the proper blanks in the

proposed method and present method columns (4).

A. Labor and Overhead

ESAB

TIG & MIG

Wires

Actual labor and overhead rate of your customer. If this figure is unknown, select a reasonable rate

for your area. This figure will be the same in the proposed and present method columns.

B. Deposition Rate in Pounds Per Hour

Cored

Wire

Products

The deposition rate is the actual weight of weld metal which can be deposited in one hour at a given

welding current at 100% operating factor. In other words, it is the amount of weld metal which could

be deposited in one hour if the welder could weld for a full hour without stopping.

Submerged

Arc

Products

Hardsurfacing

Products

C. Operating Factor

Filler Metal

Consumption

StubLoss

Correction

Operating factor is the percentage of a welders working day that is actually spent welding. It is the

arc time divided by the total hours worked multiplied by 100 and expressed as a percentage. A 30%

(.30) operating factor means that only 30% of the welders day is actually spent welding. If the

customers operating factor is not known, assume a 30% operating factor for SMAW, and a 45%

operating factor for semi-automatic GMAW and FCAW. For automatic GMAW and FCAW, an

operating factor of 60% to 80% may be assumed.

D. Electrode Cost Per Pound

Calculations

Electrode/Wire

Consumption

Filler Metals

ASTM

Steels

Conversion

Tables

Select the quantity price bracket in which the customer now purchases his filler metal. If unknown,

select the price bracket you think applicable and use for both the present and proposed calculations.

Weld Metal Cost

Worksheet

Weight/Foot

Weld Metal

Weight/Meter

Weld Metal

Continued on next page...

6

4/12/2012 2:21 PM

Handbook - Calculations

1 of 1

http://www.esabna.com/EUWeb/FM_handbook/577fm8_7.htm

Covered

Electrodes

E. Deposition Efficiency

The deposition efficiency is the relationship of the electrode used to the amount of the weld metal

deposited expressed in percent, or:

Stainless

Steel

Products

DE =

Weight of Weld Metal

Weight of Electrode Used.

Solid Wire

& Rod

Products

For instance, if it takes 4 lbs. of electrode to deposit

3 lbs. (1.4 kg) of weld metal, E = 3/4 = .75 or 75%.

F. Gas Flow Rate (Cubic Feet/Hour)

ESAB

TIG & MIG

Wires

For GMAW with solid wires use a shielding gas flow rate of 25 to 30 cubic feet per hour. For small

diameter flux cored electrodes (1/16 or 1.6 mm diameter and under) use 35 cubic feet per hour. For

large diameter flux cored electrodes (5/64 and over) use 40-45 cubic feet per hour.

G. Gas Cost Per Cubic Foot

Cored

Wire

Products

Gas cost per cubic foot will vary depending on the type of shielding gas being used and your location.

3. Complete the calculations in the Proposed Method and Present Method columns and record the

calculated costs in the blanks on the far right, (5) & (6) of each column.

Submerged

Arc

Products

Hardsurfacing

Products

4. Add the calculated cost and record the sums at the bottom, (7) & (8) of each column.

5. Subtract Present Method cost (6) from Proposed Method cost (5) for each of the sections titled Labor

& Overhead, Electrode, and Gas. Enter the differences in the blanks indicated at right (5 minus 6).

Negative numbers should be enclosed in parenthesis ( ).

Filler Metal

Consumption

StubLoss

Correction

Calculations

Electrode/Wire

Consumption

Filler Metals

ASTM

Steels

Conversion

Tables

Weld Metal Cost

Worksheet

Weight/Foot

Weld Metal

Weight/Meter

Weld Metal

6. In the Total Variable Cost/lb section, subtract Present Method cost (8) from Proposed Method cost

(7). Enter the difference in the blank indicated as Total. Negative numbers should be enclosed in

parenthesis ( ).

A (negative) number in Total represents the cost reduction you will realize as a

dollar saving per pound of weld metal deposited.

7. The bottom section of the form will be useful if you must buy new equipment to use the proposed

product. That part of the form is self-explanatory with the exception of the DEPOSITION FACTOR. The

deposition factor is simply the deposition rate multiplied by the operating factor and is already a part of

the calculation as shown at (9) in the labor and overhead formula for the proposed method.

7

4/12/2012 2:21 PM

Handbook - Calculations

1 of 1

http://www.esabna.com/EUWeb/FM_handbook/577fm8_8.htm

Covered

Electrodes

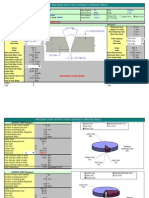

ESAB Weld Metal Cost Worksheet

Prepared For:

Stainless

Steel

Products

Customer Name

(1) Proposed Method Cost Calculation

Formulas for Calculating

(3)

Rate

Cored

Wire

Products

Gas

=

=

$9.80

2.05

Cost Increase

(4)

(6)

$45.00

= $45.00

5.4 X 0.3 =

1.62

$27.78

1.33

(5-6)

($17.98)

Factor

(9)

(4)

Electrode Cost/lb

Deposition Efficiency

(3)

Gas Flow Rate (Cu ft/hr)

=

X Gas Cost/Cu ft.

1.78

0.87

Sum of the Above

(5)

(4)

40

(4)

0.02

0.8

10.2

Total Variable Cost/lb

Deposited Weld Metal

0.08

$11.93

(7)

(6)

0.85

0.64

2" (50mm) stub

(4)

(5)

Deposition Rate (lbs/hr)

Submerged

Arc

Products

$45.00

4.59

Result

(Cost Reduction)

@250 Amps

(5)

$45.00

10.2 X 0.45

(3)

Electrode

E7018 3/16" (4.8 mm)

1/16" (1.6 mm) @ 300 Amps

(4)

Labor & Overhead

Labor & =

Cost/Hr

Overhead Deposition XOperating

ESAB

TIG & MIG

Wires

(2) Present Method Cost Calculation

Dual Shield 7100 Ultra (E71T-1)

Cost per Pound Deposited Weld Metal

Solid Wire

& Rod

Products

Hardsurfacing

Products

Date:

0

5.4

Total Variable Cost/lb

Deposited Weld Metal

(5-6)

0.72

(6)

=

(5-6)

0.08

(8)

=

(7-8)

$29.11

($17.18)

Total

Pounds of Weld Metal and Welder Man Hours Required to Amortize Equipment Cost

Equipment Cost

Power Supply

Wire Feeder

Gun & Accessories

Filler Metal

Consumption

Total

Equipment Cost in Dollars

Savings/lb

$2,900

$2,900

$17.18

Pounds of Weld Metal Deposition Factor =

Required to

Amortize Cost

(9)

=

168.8

4.59

=

Welder Man Hours

Required to

Amortize Cost

37 Hours

StubLoss

Correction

Calculations

Electrode/Wire

Consumption

Filler Metals

ASTM

Steels

Conversion

Tables

Weld Metal Cost

Worksheet

Weight/Foot

Weld Metal

Weight/Meter

Weld Metal

4/12/2012 2:20 PM

Handbook - Calculations

1 of 1

http://www.esabna.com/EUWeb/FM_handbook/577fm8_8.htm

Covered

Electrodes

ESAB Weld Metal Cost Worksheet

Prepared For:

Stainless

Steel

Products

Customer Name

(1) Proposed Method Cost Calculation

Formulas for Calculating

(3)

Rate

Cored

Wire

Products

Gas

=

=

$9.80

2.05

Cost Increase

(4)

(6)

$45.00

= $45.00

5.4 X 0.3 =

1.62

$27.78

1.33

(5-6)

($17.98)

Factor

(9)

(4)

Electrode Cost/lb

Deposition Efficiency

(3)

Gas Flow Rate (Cu ft/hr)

=

X Gas Cost/Cu ft.

1.78

0.87

Sum of the Above

(5)

(4)

40

(4)

0.02

0.8

10.2

Total Variable Cost/lb

Deposited Weld Metal

0.08

$11.93

(7)

(6)

0.85

0.64

2" (50mm) stub

(4)

(5)

Deposition Rate (lbs/hr)

Submerged

Arc

Products

$45.00

4.59

Result

(Cost Reduction)

@250 Amps

(5)

$45.00

10.2 X 0.45

(3)

Electrode

E7018 3/16" (4.8 mm)

1/16" (1.6 mm) @ 300 Amps

(4)

Labor & Overhead

Labor & =

Cost/Hr

Overhead Deposition XOperating

ESAB

TIG & MIG

Wires

(2) Present Method Cost Calculation

Dual Shield 7100 Ultra (E71T-1)

Cost per Pound Deposited Weld Metal

Solid Wire

& Rod

Products

Hardsurfacing

Products

Date:

0

5.4

Total Variable Cost/lb

Deposited Weld Metal

(5-6)

0.72

(6)

=

(5-6)

0.08

(8)

=

(7-8)

$29.11

($17.18)

Total

Pounds of Weld Metal and Welder Man Hours Required to Amortize Equipment Cost

Equipment Cost

Power Supply

Wire Feeder

Gun & Accessories

Filler Metal

Consumption

Total

Equipment Cost in Dollars

Savings/lb

$2,900

$2,900

$17.18

Pounds of Weld Metal Deposition Factor =

Required to

Amortize Cost

(9)

=

168.8

4.59

=

Welder Man Hours

Required to

Amortize Cost

37 Hours

StubLoss

Correction

Calculations

Electrode/Wire

Consumption

Filler Metals

ASTM

Steels

Conversion

Tables

Weld Metal Cost

Worksheet

Weight/Foot

Weld Metal

Weight/Meter

Weld Metal

4/12/2012 2:20 PM

Handbook - Calculations

1 of 1

http://www.esabna.com/EUWeb/FM_handbook/577fm8_9.htm

Covered

Electrodes

Weight Per Foot of Weld Metal for Fillet Welds and

Elements of Common Butt Joints (lb/ft) Steel

Instructions

Stainless

Steel

Products

1. Make a drawing of the cross-section of the joint to exact scale.

2. Divide the cross-section into right triangles, rectangles and

sketch in the desired reinforcement.

3. Measure the thickness, angles angle leg lengths, root opening

and the length and height of the reinforcement.

4. Total the weight per foot of each of the elements from the chart

for the weight per foot of the weld.

Solid Wire

& Rod

Products

ESAB

TIG & MIG

Wires

Cored

Wire

Products

Submerged

Arc

Products

Hardsurfacing

Products

Filler Metal

Consumption

StubLoss

Correction

Electrode/Wire

Consumption

Conversion

Tables

1/8

3/16

1/4

.027

.040

.053

.053

.080

.106

.080

.119

.159

.106

.159

.212

.159

.239

.318

.212

.318

.425

.002

.005

.009

.005

.011

.019

.007

.016

.028

.011

.025

.044

.015

.035

.061

.027

.060

.106

.027

.035

5/16

3/8

7/16

1/2

.066

.080

.091

.106

.133

.159

.186

.212

.199

.239

.279

.318

.265

.318

.371

.425

.390

.478

.557

.637

.531

.637

.743

.849

.015

.021

.028

.037

.029

.042

.057

.075

.044

.064

.087

.114

.069

.099

.129

.176

.096

.138

.188

.245

.166

.239

.325

.425

.044

.053

.062

.071

Weld Metal Cost

Worksheet

Weight/Foot

Weld Metal

Weight/Meter

Weld Metal

lbs./ft. of Rectangle A

G

1/8" 3/16" 1/4"

3/8"

lbs./ft. of Rectangle A

G

1/8" 3/16" 1/4"

3/8"

1/2"

45

lbs./ft. Reinforcement C

H

1/16" 1/8" 3/16" 1/4"

.884

.106

.124

.141

.212

1/2"

lbs./ft. of Triangle B

S

10

15 22 1/2 30

9/16

5/8

11/16

3/4

.119

.133

.146

.159

.239

.265

.292

.318

.358

.398

.438

.478

.478

.531

.584

.637

.716

.796

.876

.995

.955

1.061

1.167

1.274

.047

.058

.070

.084

.095

.117

.142

.169

.144

.178

.215

.256

.223

.275

.332

.396

.383

.464

.552

.451

.664

.804

.956

.080

.088

.097

.106

.159

.177

.195

.212

.239

.265

.292

.318

.354

.389

.424

13/16

7/8

15/16

1

.172

.186

.199

.212

.345

.371

.398

.425

.517

.557

.597

.637

.690

.743

.796

.849

1.035

1.114

1.194

1.274

1.380

1.486

1.592

1.698

.098

.114

.131

.149

.198

.230

.263

.300

.301

.349

.400

.456

.464

.538

.618

.703

.648

.751

.863

.981

1.121

1.300

1.493

1.698

.115

.124

.133

.141

.230

.248

.266

.283

.345

.371

.398

.424

.460

.495

.530

.566

1 1/8

1 1/4

1 3/8

1 1/2

1 5/8

1 3/4

1 7/8

2

2 1/4

2 1/2

2 3/4

3

.239

.265

.292

.318

.478

.531

.584

.637

.716

.796

.876

.955

.955

1.061

1.167

1.274

1.433

1.592

1.751

1.910

1.910

2.123

2.335

2.547

.188

.232

.281

.334

.379

.468

.567

.674

.577

.712

.861

1.023

.890

1.099

1.330

1.582

1.241

1.532

1.853

2.206

2.149

2.653

3.210

3.821

.159

.177

.195

.212

.318

.354

.389

.424

.477

.531

.584

.637

.637

.707

.777

.849

.345

.371

.390

.425

.690

.743

.796

.649

1.035

1.114

1.194

1.274

1.380

1.486

1.592

1.698

2.069

2.229

2.388

2.547

2.759

2.972

3.184

3.396

.393

.455

.523

.594

.792

.918

1.053

1.197

1.201

1.393

1.599

1.820

1.857

2.154

2.473

2.813

2.589

3.002

3.447

3.921

4.484

5.200

5.970

6.792

.230

.248

.266

.283

.460

.495

.531

.566

.690

.743

.796

.849

.920

.990

1.061

1.132

.478

.530

.584

.636

.955

1.061

1.167

1.274

1.433

1.592

1.751

1.910

1.910

2.123

2.335

2.547

2.865

3.184

3.502

3.821

3.821

4.245

4.669

5.094

.752

.928

1.123

1.337

1.516

1.871

2.264

2.695

2.303

2.844

3.441

4.095

3.561

4.396

5.319

6.330

4.963

6.127

7.414

8.823

8.596

10.613

12.841

15.282

.318

.354

.389

.424

.637

.707

.778

.849

.955

1.061

1.167

1.273

1.273

1.415

1.556

1.698

T

Inches 1/16"

Calculations

Filler Metals

ASTM

Steels

lbs./ft. of Triangle B

S

10

15 22 1/2 30

T

Inches 1/16"

.311

45

lbs./ft. Reinforcement C

H

1/16" 1/8" 3/16" 1/4"

4/12/2012 2:20 PM

Handbook - Calculations

1 of 1

http://www.esabna.com/EUWeb/FM_handbook/577fm8_10.htm

Covered

Electrodes

Weight Per Meter of Weld Metal for Fillet Welds

and Elements of Common Butt Joints (Kg/m) Steel

Instructions

Stainless

Steel

Products

1. Make a drawing of the cross-section of the joint to exact scale.

2. Divide the cross-section into right triangles, rectangles and

sketch in the desired reinforcement.

3. Dimension the thickness, angles angle leg lengths, root opening

and the length and height of the reinforcement.

4. Total the weight per meter of each of the elements from the

chart for the weight per meter of the weld.

Solid Wire

& Rod

Products

ESAB

TIG & MIG

Wires

Cored

Wire

Products

Submerged

Arc

Products

Hardsurfacing

Products

Filler Metal

Consumption

StubLoss

Correction

Calculations

Electrode/Wire

Consumption

Filler Metals

ASTM

Steels

Conversion

Tables

1.588

Kg/m of Rectangle A

G

3.175 4.783 6.350 9.525 12.700

3.18

4.76

6.35

0.040

0.060

0.079

0.079

0.119

0.158

7.94

9.53

11.11

12.70

0.098

0.119

0.135

0.158

T

mm

14.29

15.88

17.46

19.05

T

mm

Weld Metal Cost

Worksheet

Weight/Foot

Weld Metal

Weight/Meter

Weld Metal

Kg/m of Triangle B

S

15 22 1/2

30

10

0.003

0.007

0.013

0.007

0.016

0.028

0.010

0.024

0.042

0.016

0.037

0.065

0.022

0.052

0.091

0.040

0.089 0.040

0.158 0.052

0.022

0.031

0.042

0.055

0.043

0.062

0.085

0.112

0.065

0.095

0.129

0.170

Kg/m of

0.247

0.356

0.484

0.632

10

15

0.102

0.147

0.192

0.262

Triangle

S

22 1/2

0.143

0.205

0.280

0.365

B

1.588

0.198 0.296 0.394 0.580 0.790

0.237 0.356 0.473 0.711 0.948

0.277 0.415 0.552 0.829 1.106

0.315 0.473 0.632 0.948 1.263

Kg/m of Rectangle A

G

3.175 4.783 6.350 9.525 12.700

30

45

0.065 1.315

0.079 0.158

0.092 0.185

0.106 0.210 0.315

Kg/m Reinforcement C

H

1.59

3.18

4.76

6.35

0.177

0.198

0.217

0.237

0.356

0.394

0.434

0.473

0.533

0.592

0.652

0.711

0.711

0.790

0.869

0.948

1.065

1.184

1.303

1.481

1.421

1.579

1.736

1.896

0.070

0.086

0.104

0.125

0.141

0.174

0.211

0.251

0.214

0.265

0.320

0.381

0.332

0.409

0.494

0.589

0.463

0.570

0.690

0.821

0.671

0.988

1.196

1.423

0.119

0.131

0.144

0.158

0.237

0.263

0.290

0.315

0.356

0.394

0.434

0.473

0.527

0.579

0.631

20.64

22.23

23.81

25.40

0.256

0.277

0.296

0.315

0.513

0.552

0.592

0.632

0.769

0.829

0.888

0.948

1.027

1.106

1.184

1.263

1.540

1.658

1.777

1.896

2.053

2.211

2.369

2.527

0.146

0.170

0.195

0.222

0.295

0.342

0.391

0.446

0.448

0.519

0.595

0.679

0.690

0.800

0.919

1.056

0.964

1.117

1.284

1.460

1.668

1.934

2.222

2.527

0.171

0.185

0.198

0.210

0.342

0.369

0.396

0.421

0.513

0.552

0.592

0.631

0.684

0.737

0.789

0.842

28.58

31.75

34.93

38.10

0.356

0.394

0.434

0.473

0.711

0.790

0.869

0.948

1.065

1.184

1.303

1.421

1.421

1.579

1.738

1.896

2.132

2.369

2.605

2.842

2.842

3.159

3.474

3.790

0.280

0.345

0.418

0.497

0.564

0.696

0.844

1.003

0.859

1.059

1.281

1.522

1.324

1.635

1.979

2.354

1.847

2.280

2.757

3.283

3.198

3.948

4.776

5.686

0.237

0.263

0.290

0.315

0.473

0.527

0.579

0.631

0.710

0.790

0.869

0.948

0.948

1.052

1.156

1.263

41.28

44.45

47.63

50.80

0.513

0.552

0.580

0.632

1.027

1.106

1.184

1.263

1.540

1.658

1.777

1.896

2.053

2.211

2.369

2.527

3.079

3.317

3.553

3.790

4.105

4.422

4.738

5.053

0.585

0.677

0.778

0.884

1.178

1.366

1.567

1.781

1.787

2.073

2.379

2.708

2.763

3.205

3.679

4.186

3.852

4.467

5.129

5.834

6.672

7.738

8.883

10.106

0.342

0.369

0.396

0.421

0.684

0.737

0.790

0.842

1.027

1.106

1.184

1.263

1.369

1.473

1.579

1.684

57.15

63.50

69.85

76.20

0.711

0.789

0.869

0.946

1.421

1.579

1.736

1.898

2.132

2.369

2.605

2.842

2.842

3.159

3.474

3.790

4.263

4.723

5.211

5.686

5.686

6.317

6.947

7.580

1.119

1.381

1.671

1.989

2.256

2.784

3.369

4.010

3.427

4.232

5.120

6.093

5.298

6.542

7.916

9.420

7.385

9.117

11.032

13.129

12.791 0.473 0.948 1.421

15.792 0.527 1.052 1.579

19.107 0.579 1.158 1.736

22.740 0.631 1.263 1.894

1.894

2.106

2.315

2.527

0.119

0.177

0.237

0.158 0.237

0.237 0.356

0.315 0.473

0.315

0.473

0.632

45

Kg/m Reinforcement C

H

1.59

3.18

4.76

6.35

10

4/12/2012 2:18 PM

También podría gustarte

- Commercial Steel Estimating: A Comprehensive Guide to Mastering the BasicsDe EverandCommercial Steel Estimating: A Comprehensive Guide to Mastering the BasicsAún no hay calificaciones

- Productivity and EcononyDocumento69 páginasProductivity and EcononyVijayan MunuswamyAún no hay calificaciones

- Structural Steel LessonsDocumento7 páginasStructural Steel LessonsIngeniero EstructuralAún no hay calificaciones

- Enter Data:: MM M Weld Size (Leg) Unit Weld LengthDocumento6 páginasEnter Data:: MM M Weld Size (Leg) Unit Weld Lengtharifin rizal100% (1)

- Cost Estimate: Description Qty Price UM Draw Me TotalDocumento17 páginasCost Estimate: Description Qty Price UM Draw Me TotalVinod Kumar ChettiarAún no hay calificaciones

- Fabrication NormsDocumento8 páginasFabrication NormsRenny DevassyAún no hay calificaciones

- ESAB Calculating Filler Metal Consumption PDFDocumento10 páginasESAB Calculating Filler Metal Consumption PDFRuben Cruz S0% (2)

- Kerala Bhooparishkarana Niyamam Marxistukar Thozhilali Vargathe Vanchicha CharithramDocumento162 páginasKerala Bhooparishkarana Niyamam Marxistukar Thozhilali Vargathe Vanchicha Charithrampaimpilly100% (1)

- Determining The Cost of WeldingDocumento22 páginasDetermining The Cost of WeldingSanjay J NAún no hay calificaciones

- Welding Cost Estimating: Lecture No 3 DR Arwa HusseinDocumento42 páginasWelding Cost Estimating: Lecture No 3 DR Arwa HusseinArwa HusseinAún no hay calificaciones

- Welding Cost Managment Layout ModifiedDocumento13 páginasWelding Cost Managment Layout ModifiedmrAún no hay calificaciones

- Determining The Cost of Welding Part 1 by Duane K. Miller 2004 7pDocumento7 páginasDetermining The Cost of Welding Part 1 by Duane K. Miller 2004 7pjosea_pena100% (1)

- Pipe WeldingDocumento6 páginasPipe Weldingyohanes_pamungkas_2Aún no hay calificaciones

- ENG Structural SteelsDocumento2 páginasENG Structural SteelsOlalla CuiñaAún no hay calificaciones

- Flux Cored Welding Calculator for Steel MaterialDocumento2 páginasFlux Cored Welding Calculator for Steel MaterialKhamdi AfandiAún no hay calificaciones

- Demo Weld Cost Calc XL-UnprotectedDocumento10 páginasDemo Weld Cost Calc XL-UnprotectedA R0% (1)

- Cost Calculation Program For Productivity in WeldingDocumento20 páginasCost Calculation Program For Productivity in WeldingiyigunAún no hay calificaciones

- A Guide To Estimating The Consumption of Welding Consumables-NADocumento1 páginaA Guide To Estimating The Consumption of Welding Consumables-NAManuel Antonio Santos VargasAún no hay calificaciones

- Introduction To Cost EstimatingDocumento22 páginasIntroduction To Cost EstimatingArwa HusseinAún no hay calificaciones

- Determining The Cost of WeldingDocumento7 páginasDetermining The Cost of WeldingGilbertoUGO0% (1)

- Arc Welding Specific SteelsDocumento169 páginasArc Welding Specific Steelsmario fisgaAún no hay calificaciones

- Miller RMDDocumento4 páginasMiller RMDRony Lesbt100% (1)

- Weld Cost Calc XL1.3.2mmDocumento3 páginasWeld Cost Calc XL1.3.2mmVipin JoseAún no hay calificaciones

- Demo Weld Cost Calc XL (Recovered)Documento9 páginasDemo Weld Cost Calc XL (Recovered)Bhagyesh B. MaskeAún no hay calificaciones

- Determinacion de Los Costos de Soldadura para Union de FileteDocumento26 páginasDeterminacion de Los Costos de Soldadura para Union de FiletejavierAún no hay calificaciones

- Weld Cost Calc XLDocumento63 páginasWeld Cost Calc XLRobert WhitakerAún no hay calificaciones

- Gmaw Thumb RuleDocumento68 páginasGmaw Thumb Rule0502raviAún no hay calificaciones

- Welding Costs: Job KnowledgeDocumento3 páginasWelding Costs: Job KnowledgeMuhammed Sulfeek100% (1)

- Weld Cost CalculationDocumento15 páginasWeld Cost CalculationMustafa KaramürselAún no hay calificaciones

- Welding Prcesses Estimation RecordDocumento5 páginasWelding Prcesses Estimation RecorddineshshankarAún no hay calificaciones

- Roofing Materials Guide for Ridge Caps, Fascia and FlashingDocumento38 páginasRoofing Materials Guide for Ridge Caps, Fascia and Flashingsan htet aung0% (1)

- Welding Cost Estimation For 12 Joints in 8 NPS SCH 80 PDFDocumento1 páginaWelding Cost Estimation For 12 Joints in 8 NPS SCH 80 PDFAnonymous VRspXsmAún no hay calificaciones

- Submerged Arc Welding: Training & EducationDocumento17 páginasSubmerged Arc Welding: Training & Educationtanveer ahmedAún no hay calificaciones

- Weld WeightDocumento10 páginasWeld WeightDivyesh PatelAún no hay calificaciones

- Welding Cost Optimization with GMAWDocumento6 páginasWelding Cost Optimization with GMAWratneshkumar2004Aún no hay calificaciones

- Determining The Cost of WeldingDocumento7 páginasDetermining The Cost of WeldingSriram VjAún no hay calificaciones

- Manufacturing Processes Lab WeldingDocumento8 páginasManufacturing Processes Lab WeldingKhalid EwigAún no hay calificaciones

- Calculate Weld VolumeDocumento4 páginasCalculate Weld VolumeTAUFIKAún no hay calificaciones

- Welding Cost Estimation For 12 Joints in 8 NPS Sch. 80Documento1 páginaWelding Cost Estimation For 12 Joints in 8 NPS Sch. 80WeldPulse100% (2)

- How To Weld "T-1" Constructional Alloy Steels: ForewordDocumento12 páginasHow To Weld "T-1" Constructional Alloy Steels: ForewordjoseritoAún no hay calificaciones

- Arc Studwelding SystemsDocumento24 páginasArc Studwelding SystemsTan Chee DingAún no hay calificaciones

- Maryland Metrics Technical Data Chart TolerancesDocumento1 páginaMaryland Metrics Technical Data Chart TolerancesMerimAún no hay calificaciones

- PreheatDocumento2 páginasPreheatScott TrainorAún no hay calificaciones

- Fit-Up Inspection Report: Location: Weld Type Equipment Description: Date: Report No.: SystemDocumento1 páginaFit-Up Inspection Report: Location: Weld Type Equipment Description: Date: Report No.: SystemAnonymous 0rt9KWmNAún no hay calificaciones

- ME 2257 CAM Drawing LaboratoryDocumento54 páginasME 2257 CAM Drawing LaboratoryM.ThirunavukkarasuAún no hay calificaciones

- Weld CostsDocumento2 páginasWeld CostsJina Chandran100% (1)

- Welding and Fabrication NoteDocumento54 páginasWelding and Fabrication NoteluminiousAún no hay calificaciones

- Mayank Financial ModelingDocumento105 páginasMayank Financial Modelingmayankmongia100Aún no hay calificaciones

- Steel Weight Chart: Comprehensive Guide to Metal Sizes and WeightsDocumento6 páginasSteel Weight Chart: Comprehensive Guide to Metal Sizes and WeightsNitin LendeAún no hay calificaciones

- Calculate Weld Metal VolumeDocumento7 páginasCalculate Weld Metal VolumeChris De La Torre0% (1)

- The Ultimate GD&T Pocket Guide: 2nd EditionDocumento2 páginasThe Ultimate GD&T Pocket Guide: 2nd EditionsrinivignaAún no hay calificaciones

- Estimating Steel Building Installation PDFDocumento2 páginasEstimating Steel Building Installation PDFJurie_sk3608Aún no hay calificaciones

- Material TableDocumento1 páginaMaterial TablepratikkapseAún no hay calificaciones

- AWSPipeWeld - American Welding SocietyDocumento2 páginasAWSPipeWeld - American Welding Societybarukomkss100% (1)

- Conversion of MT To Inch DiaDocumento4 páginasConversion of MT To Inch DianikunjAún no hay calificaciones

- 101.lean - Welds Cost Calculator Customer Welding Position: HorizontalDocumento4 páginas101.lean - Welds Cost Calculator Customer Welding Position: HorizontalSamAún no hay calificaciones

- Industrial Engineer: Passbooks Study GuideDe EverandIndustrial Engineer: Passbooks Study GuideAún no hay calificaciones

- Materials Engineering: Proceedings of the First International Symposium, University of the Witwatersrand, Johannesburg, South Africa, November 1985De EverandMaterials Engineering: Proceedings of the First International Symposium, University of the Witwatersrand, Johannesburg, South Africa, November 1985J. V. BeeAún no hay calificaciones

- Weight Per Meter of WeldDocumento1 páginaWeight Per Meter of Weldreza329329Aún no hay calificaciones

- Welder's Handbook (Air Products Co.)Documento48 páginasWelder's Handbook (Air Products Co.)Patrick DominguezAún no hay calificaciones

- Engineering Welding Handbook99 PDF TigDocumento48 páginasEngineering Welding Handbook99 PDF TigSorin Stanescu100% (1)

- Millets Recipes-A Healthy ChoiceDocumento75 páginasMillets Recipes-A Healthy ChoicePrakash J PeramabalurAún no hay calificaciones

- The Fracture Behaviour of Girth Welds in High Strength High Yield To Tensile Ratio Linepipe Steels 1Documento194 páginasThe Fracture Behaviour of Girth Welds in High Strength High Yield To Tensile Ratio Linepipe Steels 1paimpillyAún no hay calificaciones

- Minuet 2 Instruction For UseDocumento64 páginasMinuet 2 Instruction For UsepaimpillyAún no hay calificaciones

- As 1365-Tolerance HandbookDocumento17 páginasAs 1365-Tolerance Handbooktruongphuong12Aún no hay calificaciones

- Development and Processing of Low Carbon Bainite SteelDocumento486 páginasDevelopment and Processing of Low Carbon Bainite Steelpaimpilly100% (1)

- CSR - A Panoramic View - DR Bhasker ChatterjiDocumento39 páginasCSR - A Panoramic View - DR Bhasker ChatterjicodemakitAún no hay calificaciones

- Limits To Growth Digital Scan VersionDocumento211 páginasLimits To Growth Digital Scan VersionAdriansyah Rendra Kusuma100% (1)

- Palmgren - Miner's RuleDocumento2 páginasPalmgren - Miner's Rulematealoredana8015Aún no hay calificaciones

- Transient Flow in Gas PipelineDocumento107 páginasTransient Flow in Gas PipelinepaimpillyAún no hay calificaciones

- Shackelford HDD CrossingDocumento0 páginasShackelford HDD CrossingpaimpillyAún no hay calificaciones

- A High Performance, Damage Tolerant Fusion Bonded Epoxy CoatingDocumento15 páginasA High Performance, Damage Tolerant Fusion Bonded Epoxy CoatingpaimpillyAún no hay calificaciones

- HPCL Material Preservation GuidelinesDocumento7 páginasHPCL Material Preservation GuidelinespaimpillyAún no hay calificaciones

- Transient Flow in Gas PipelineDocumento107 páginasTransient Flow in Gas PipelinepaimpillyAún no hay calificaciones

- Indian Raiilway - BS-105 With A&c 2Documento17 páginasIndian Raiilway - BS-105 With A&c 2paimpillyAún no hay calificaciones

- Advantages of Polypropylene Based CoatingsDocumento13 páginasAdvantages of Polypropylene Based CoatingspaimpillyAún no hay calificaciones

- Area Classifications ATEX - NEMADocumento20 páginasArea Classifications ATEX - NEMApaimpillyAún no hay calificaciones

- Digital RadiographyDocumento3 páginasDigital RadiographypaimpillyAún no hay calificaciones

- Wall Loss Measurement - Computed-RadiographyDocumento69 páginasWall Loss Measurement - Computed-RadiographyJeganeswaranAún no hay calificaciones

- Induction Bends For High Strength Line PipeDocumento88 páginasInduction Bends For High Strength Line PipepaimpillyAún no hay calificaciones

- NDT - Auto RT 5Documento12 páginasNDT - Auto RT 5paimpillyAún no hay calificaciones

- PNGRB RulesDocumento34 páginasPNGRB RulesVenkata Rama KrishnaAún no hay calificaciones

- Guidance For Use of The BSH Standard Design of Offshore Wind Turbines"Documento13 páginasGuidance For Use of The BSH Standard Design of Offshore Wind Turbines"paimpillyAún no hay calificaciones

- F45 CDD 01Documento54 páginasF45 CDD 01paimpillyAún no hay calificaciones

- Roller CatalogueDocumento37 páginasRoller CatalogueAldi ZuldiansyahAún no hay calificaciones

- An 775 An 776 An 777 An 778 An 840 An 842 An 838 An 844Documento1 páginaAn 775 An 776 An 777 An 778 An 840 An 842 An 838 An 844blackhawkAún no hay calificaciones

- Practical Guidelines Inspect Repair HDG Coatings 2008Documento24 páginasPractical Guidelines Inspect Repair HDG Coatings 2008forbeskaAún no hay calificaciones

- Industrial TrainingDocumento15 páginasIndustrial TrainingPranav0% (1)

- ZINCALUME G250 G250S Datasheet PDFDocumento0 páginasZINCALUME G250 G250S Datasheet PDFadityavicky1Aún no hay calificaciones

- Technical Specification FOR 220Kv Isolators: Gujarat State Electricity Corporation LTDDocumento22 páginasTechnical Specification FOR 220Kv Isolators: Gujarat State Electricity Corporation LTDVelu SamyAún no hay calificaciones

- GEO L26 Steel and Cement IndustriesDocumento33 páginasGEO L26 Steel and Cement IndustriesChinmay JenaAún no hay calificaciones

- Monel K500 PDFDocumento6 páginasMonel K500 PDFOZAIRTRADELINKAún no hay calificaciones

- Join Metal Parts with Gas Welding, Brazing & SolderingDocumento105 páginasJoin Metal Parts with Gas Welding, Brazing & SolderingAnuj Verma100% (1)

- Pubs 91518021Documento16 páginasPubs 91518021Yogi173Aún no hay calificaciones

- Steel Sheet, Zinc-Aluminum-Magnesium Alloy-Coated by The Hot-Dip ProcessDocumento3 páginasSteel Sheet, Zinc-Aluminum-Magnesium Alloy-Coated by The Hot-Dip ProcessMohammed KhalidAún no hay calificaciones

- Painting Specification PDFDocumento17 páginasPainting Specification PDFGaurav TripathiAún no hay calificaciones

- Erdemir Product Catalog 2014 PDFDocumento166 páginasErdemir Product Catalog 2014 PDFGantulga NerguiAún no hay calificaciones

- Aryl Halide and Vinyl HalideDocumento67 páginasAryl Halide and Vinyl HalideAhmadBadruzzamanShuib100% (1)

- Phase Diagrams ExplainedDocumento131 páginasPhase Diagrams Explainedkshitiz kumarAún no hay calificaciones

- Schm312 NotesDocumento97 páginasSchm312 NotesSandile SynthaxError Mabika100% (1)

- Stainless Steel For Bridge ApplicationDocumento57 páginasStainless Steel For Bridge ApplicationDtscAún no hay calificaciones

- Structural Steel Design by Jay Ryan SantosDocumento19 páginasStructural Steel Design by Jay Ryan SantosjayryansantosAún no hay calificaciones

- 3 Eng Stainless Steel Tube AnnealingDocumento16 páginas3 Eng Stainless Steel Tube AnnealingVictor HugoAún no hay calificaciones

- ISRO Mechanical Engineering Paper ExplanationDocumento22 páginasISRO Mechanical Engineering Paper ExplanationShivangi MishraAún no hay calificaciones

- BT JOE Quiz 3 MetalDocumento2 páginasBT JOE Quiz 3 MetalJess AndanAún no hay calificaciones

- CLEANING JET ENGINESDocumento3 páginasCLEANING JET ENGINESAbraham GamerosAún no hay calificaciones

- Grizzly g0463 MDocumento40 páginasGrizzly g0463 MCarlos RamirezAún no hay calificaciones

- AWS Specifications For Filler MaterialDocumento9 páginasAWS Specifications For Filler MaterialExsan OthmanAún no hay calificaciones

- Design of Power ScrewsDocumento19 páginasDesign of Power ScrewsSOURAV JADHAVAún no hay calificaciones

- Everything You Need to Know About Iron-Carbon Phase DiagramsDocumento13 páginasEverything You Need to Know About Iron-Carbon Phase DiagramsAbhishek SakatAún no hay calificaciones

- English For Engineer 2Documento8 páginasEnglish For Engineer 2Raka Setiawan0% (1)

- Useful Information For The Valve IndustryDocumento9 páginasUseful Information For The Valve Industryhummingbird4uAún no hay calificaciones

- OCE Mechanical Engineering Foundry Technology Lesson PlanDocumento3 páginasOCE Mechanical Engineering Foundry Technology Lesson PlanManjunatha EikilaAún no hay calificaciones

- Protection Against Corrosion: International Packaging Solutions ... Always One Step AheadDocumento8 páginasProtection Against Corrosion: International Packaging Solutions ... Always One Step AheadMohammed Al-OdatAún no hay calificaciones