Documentos de Académico

Documentos de Profesional

Documentos de Cultura

S 1 FM

Cargado por

Milan BanicDescripción original:

Título original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

S 1 FM

Cargado por

Milan BanicCopyright:

Formatos disponibles

Quality System ISO9001 Certied Environmental Management System ISO14001 Certied

Metallic Design Level 1 Ball Valve CE

U.S. Patent #5,996,627 & 6,241,487 Other U.S. Patents Applied for

S1F

Air-Operated Double Diaphragm Pump

ENGINEERING, PERFORMANCE & CONSTRUCTION DATA

I M2 c T5 II 2GD T5

INTAKE/DISCHARGE PIPE SIZE

1 NPT (internal) 1 BSP Tapered (internal)

CAPACITY

0 to 45 gallons per minute (0 to 170 liters per minute)

AIR VALVE

No-lube, no-stall design

SOLIDS-HANDLING

Up to .25 in. (6mm)

HEADS UP TO

125 psi or 289 ft. of water (8.6 Kg/cm2 or 86 meters)

DISPLACEMENT/STROKE

.11 Gallon / .42 liter

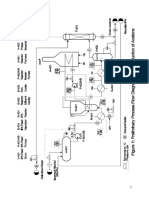

MODEL S1F Metallic Performance Curve

BAR PSI

Performance based on the following: elastomer fitted pump, flooded suction, water at ambient conditions. The use of other materials and varying hydraulic conditions may result in deviations in excess of 5%.

5(00)

100

7 6

100

80 5

25(00)

80 P SI (5 .44 B ar)

30(51) 35(00)

HEAD

8 Bar

3 2

40

40 PS I

(2.72

Bar)

20 1 0 0

20 PSI (1.3

6 Bar) Air In

let Pressur

30 25 20 15 10 5

9.1 7.6 6 4.5 3 1.5

0 0

5 20

10 40

15 60

20 80

25 100

30 120

35 140

40 160

45 180

50

U.S. Gallons per minute Liters per minute

CAPACITY

SANDPIPER pumps are designed to be powered only by compressed air.

s1fmdl1ds-REV0508

Model S1F Metallic Page 1

METERS

60

60 PS

I (4.0

40(68)

FEET

NPSHR

10(17) PSI 15(00) (6.8 Bar 20(34) )

Explanation of Pump Nomenclature, S1F Metallic Design Level 1 Ball Valve

MODEL S1FB1ABWANS000. S1FB1AIWANS000. S1FB1AGTANS000. S1FB1ANWANS000. S1FB1A1WANS000. S1FB1ACTANS000. S1FB1IBWANS000. S1FB1IIWANS000. S1FB1IGTANS000. S1FB1INWANS000. S1FB1I1WANS000. S1FB1ICTANS000. S1FB1IIWANS000. S1FB1SBWANS000. S1FB1SGTANS000. S1FB1SNWANS000. S1FB1S1WANS000. S1FB1SCTANS000. Pump Pump Brand Size S S S S S S S S S S S S S S S S S S 1F 1F 1F 1F 1F 1F 1F 1F 1F 1F 1F 1F 1F 1F 1F 1F 1F 1F Check Valve Type B B B B B B B B B B B B B B B B B B Design Level 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 Wetted Material A A A A A A I I I I I I I S S S S S Diaphragm/ Check Valve Materials B I G N 1 C B I G N 1 C I B G N 1 C Check Valve Seat W W T W W T W W T W W T W W T W W T Non-Wetted Material Porting Options Options A A A A A A A A A A A A A A A A A A N N N N N N N N N N N N N N N N N N Pump Pump Kit Style Options Options S S S S S S S S S S S S S S S S S S 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 00. 00. 00. 00. 00. 00. 00. 00. 00. 00. 00. 00. 00. 00. 00. 00. 00. 00. Shipping Weight lbs. (kg) 28 (13) 28 (13) 28 (13) 28 (13) 28 (13) 28 (13) 46 (21) 46 (21) 46 (21) 46 (21) 46 (21) 46 (21) 46 (21) 43 (20) 43 (20) 43 (20) 43 (20) 43 (20)

Pump Brand S= SANDPIPER Pump Size 1F=1" Check Valve Type B= Ball Design Level 1= Design Level Wetted Material A= Aluminum I = Cast Iron S= Stainless Steel H= Alloy C Diaphragm Check Valve Materials 1= Santoprene/Santoprene B= Nitrile/Nitrile C= FKM/PTFE I = EPDM/Santoprene G= PTFE-Neoprene/PTFE N= Neoprene/Neoprene Z= One-Piece Bonded/PTFE

Check Valve Seat A= Aluminum C= Carbon Steel S= Stainless Steel T= PTFE W= UHMW Non-Wetted Material Options A= Painted Aluminum I = Cast Iron Y= Painted Aluminum with Stainless Steel Hardware Z= Cast Iron with Stainless Steel Hardware Porting Options N= NPT Threads B= BSP (Tapered) Threads R= Raised Face 150# Threaded ANSI Flange Pump Style S= Standard Pump Options 0= None 1= Sound Dampening Mufer 2= Mesh Mufer 3= High temperature Air Valve w/Integral Mufer 4= High temperature Air Valve w/Sound Dampening Mufer 5= High temperature Air Valve w/Mesh Mufer 6= Metal Mufer 7= Metal Mufer with Grounding Cable

Kit Options 00.= None P0.= 10-30VDC Pulse Output Kit P1.= Intrinsically-Safe 5-30VDC,110/120VAC, 220/240VAC Pulse Output Kit P2.= 110/120 or 220/240VAC Pulse Output Kit E0.= Solenoid Kit with 24VDC Coil E1.= Solenoid Kit with 24VDC Explosion-Proof Coil E2.= Solenoid Kit with 24VAC/12VDC Coil E3.= Solenoid Kit with 12VDC Explosion-Proof Coil E4.= Solenoid Kit with 110VAC Coil E5.= Solenoid Kit with 110VAC, 60 Hz Explosion-Proof Coil E6.= Solenoid Kit with 220VAC Coil E7.= Solenoid Kit with 220VAC, 60 Hz Explosion-Proof Coil E8.= Solenoid Kit with 110VAC, 50 Hz Explosion-Proof Coil E9.= Solenoid Kit with 230VAC, 50 Hz Explosion-Proof Coil SP.= Stroke Indicator Pins

Note: Pumps are only ATEX compliant when ordered with pump options 6 or 7, and kit options 00, P1, E1, E3, E5, E7, E8 or E9.

s1fmdl1ds-REV0508

Model S1F Metallic Page 2

CAUTION! Operating temperature limitations are as follows:

Operating Temperatures

Materials

Nitrile: General purpose, oil-resistant. Shows good solvent, oil, water and hydraulic fluid resistance. Should not be used with highly polar solvents like acetone and MEK, ozone, chlorinated hydrocarbons and nitro hydrocarbons. EPDM: Shows very good water and chemical resistance. Has poor resistance to oil and solvents, but is fair in ketones and alcohols. Neoprene: All purpose. Resistant to vegetable oil. Generally not affected by moderate chemicals, fats, greases and many oils and solvents. Generally attacked by strong oxidizing acids, ketones, esters, nitro hydrocarbons and chlorinated aromatic hydrocarbons. Santoprene: Injection molded thermoplastic elastomer with no fabric layer. Long mechanical flex life. Excellent abrasion resistance. Virgin PTFE: Chemically inert, virtually impervious. Very few chemicals are known to react chemically with PTFE: molten alkali metals, turbulent liquid or gaseous fluorine and a few fluoro-chemicals such as chlorine trifluoride or oxygen difluoride which readily liberate free fluorine at elevated temperatures. FKM (Fluorocarbon): Shows good resistance to a wide range of oils and solvents; especially all aliphatic, aromatic and halogenated hydrocarbons, acids, animal and vegetable oils. Hot water or hot aqueous solutions (over 70F) will attack FKM. Polypropylene: UHMW:

Maximum 190F 88C 280F 138C 200F 93C

Minimum -10F -23C -40F -40C -10F -23C

275F 135C

-40F -40C

220F 104C

-35F -37C

350F 177C

-40F -40C

180F 82C 180F 82C

32F 0C -35F -37C

For specic applications, always consult The Warren Rupp Chemical Resistance Chart

s1fmdl1ds-REV0508

Model S1F Metallic Page 3

Dimensions: S1F Metallic

Dimensions in Inches Dimensional Tolerance:1/8"

Discharge Port 1" NPT

Suction Port 1" NPT

Pump Shown With 530-028-550 Integral Muffler Both Suction And Discharge Ports Are Available With 1" BSP Tapered Connection

Dimension

A 10 3/8 10 3/8

Integral Muffler 1" NPT Exhaust Port For Optional Muffler Styles Or Piping Exhaust Air In Submerged Applications.

Integral Mufer Pulse Output Kit Aluminum Stainless Steel Mesh Mufer Sound Dampening Mufer

11 27/32 11 31/32 13

1 3/32 1 7/32

5/16 7/16

6 7/32 6 11/32

12 23/32 12 27/32

13

Air Inlet 1/2" NPT

Metal Mufer

12 1/2

Metric Dimensions: S1F Metallic

Dimensions in Millimeters Dimensional Tolerance: 3mm

Discharge Port 1" NPT

Suction Port 1" NPT

Pump Shown With 530-028-550 Integral Muffler Both Suction And Discharge Ports Are Available With 1" BSP Tapered Connection

Dimension Integral Mufer Pulse Output Kit Aluminum Stainless Steel Mesh Mufer Sound Dampening Mufer Metal Mufer 330 A 264 264 301 304 28 31 8 11 158 161 323 326 B C D E F

Integral Muffler 1" NPT Exhaust Port For Optional Muffler Styles Or Piping Exhaust Air In Submerged Applications

Air Inlet 1/2" NPT

330

319

s1fmdl1ds-REV0508

Model S1F Metallic Page 4

También podría gustarte

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeCalificación: 4 de 5 estrellas4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe EverandThe Little Book of Hygge: Danish Secrets to Happy LivingCalificación: 3.5 de 5 estrellas3.5/5 (399)

- Catalogue of CRIO Recommended - v4Documento14 páginasCatalogue of CRIO Recommended - v4Milan BanicAún no hay calificaciones

- Table of Total Emissivity: MetalsDocumento0 páginasTable of Total Emissivity: MetalsbwiessnethAún no hay calificaciones

- Displacement Transducer Data Sheet and SpecificationsDocumento6 páginasDisplacement Transducer Data Sheet and SpecificationsMilan BanicAún no hay calificaciones

- 2012 Industrial Products PDFDocumento9 páginas2012 Industrial Products PDFMilan BanicAún no hay calificaciones

- Heat Generation Prediction in The Railway Draw Gear Rubber-Metal SpringDocumento10 páginasHeat Generation Prediction in The Railway Draw Gear Rubber-Metal SpringMilan BanicAún no hay calificaciones

- Modeling Material Damping Properties in AnsysDocumento16 páginasModeling Material Damping Properties in AnsysNono_geotec100% (1)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryCalificación: 3.5 de 5 estrellas3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceCalificación: 4 de 5 estrellas4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)De EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Calificación: 4 de 5 estrellas4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeDe EverandShoe Dog: A Memoir by the Creator of NikeCalificación: 4.5 de 5 estrellas4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureCalificación: 4.5 de 5 estrellas4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe EverandNever Split the Difference: Negotiating As If Your Life Depended On ItCalificación: 4.5 de 5 estrellas4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDe EverandGrit: The Power of Passion and PerseveranceCalificación: 4 de 5 estrellas4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaCalificación: 4.5 de 5 estrellas4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerDe EverandThe Emperor of All Maladies: A Biography of CancerCalificación: 4.5 de 5 estrellas4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDe EverandOn Fire: The (Burning) Case for a Green New DealCalificación: 4 de 5 estrellas4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersCalificación: 4.5 de 5 estrellas4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDe EverandTeam of Rivals: The Political Genius of Abraham LincolnCalificación: 4.5 de 5 estrellas4.5/5 (234)

- Rise of ISIS: A Threat We Can't IgnoreDe EverandRise of ISIS: A Threat We Can't IgnoreCalificación: 3.5 de 5 estrellas3.5/5 (137)

- The Unwinding: An Inner History of the New AmericaDe EverandThe Unwinding: An Inner History of the New AmericaCalificación: 4 de 5 estrellas4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyCalificación: 3.5 de 5 estrellas3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreCalificación: 4 de 5 estrellas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Calificación: 4.5 de 5 estrellas4.5/5 (119)

- The Perks of Being a WallflowerDe EverandThe Perks of Being a WallflowerCalificación: 4.5 de 5 estrellas4.5/5 (2099)

- Her Body and Other Parties: StoriesDe EverandHer Body and Other Parties: StoriesCalificación: 4 de 5 estrellas4/5 (821)

- Biochemistry A Short Course 3rd Edition Ebook PDF VersionDocumento61 páginasBiochemistry A Short Course 3rd Edition Ebook PDF Versionramona.evans546100% (44)

- Gacan Qabad Chemistry Book With AnswersDocumento32 páginasGacan Qabad Chemistry Book With Answerscazmi Andirahman100% (1)

- Solutions For H2 Chemistry PaperDocumento18 páginasSolutions For H2 Chemistry PaperChong560% (1)

- New Process For Production of Trah Ydro UranDocumento9 páginasNew Process For Production of Trah Ydro UranGreten TreutelAún no hay calificaciones

- Nitroanilne TLCDocumento23 páginasNitroanilne TLCzatty kim100% (1)

- GMW16717 - Decorative Interior Laminates and FilmsDocumento16 páginasGMW16717 - Decorative Interior Laminates and Films廖健翔Aún no hay calificaciones

- Topic 6 - Fertiliser and Plant NutritionDocumento56 páginasTopic 6 - Fertiliser and Plant Nutritionsuhana safieeAún no hay calificaciones

- Single Organic Test PDFDocumento15 páginasSingle Organic Test PDFgreatAún no hay calificaciones

- Introduction to Enzymes: Biological CatalystsDocumento23 páginasIntroduction to Enzymes: Biological Catalystsahmad aliAún no hay calificaciones

- HPLCDocumento170 páginasHPLCAdimas Gilang RamadhaniAún no hay calificaciones

- InMet I Well-Fed State Spring 23Documento32 páginasInMet I Well-Fed State Spring 23Erin HillAún no hay calificaciones

- E9 5711 PDFDocumento285 páginasE9 5711 PDFDiegoAún no hay calificaciones

- AgarDocumento22 páginasAgarmeerameringeoge100% (1)

- Outstanding Chemical Resistance Apply by Brush, - Roller or Spray Unlimited Shelf Life - 100% Solids - Simple To Use - DurableDocumento2 páginasOutstanding Chemical Resistance Apply by Brush, - Roller or Spray Unlimited Shelf Life - 100% Solids - Simple To Use - DurableAlfred GomoeliaAún no hay calificaciones

- Mass Per Unit Area of Pile Yarn Floor Coverings: Standard Test Method ForDocumento10 páginasMass Per Unit Area of Pile Yarn Floor Coverings: Standard Test Method ForJuanAún no hay calificaciones

- PS 3 ContDocumento3 páginasPS 3 ContDenisse Leonoras-PatersonAún no hay calificaciones

- Vitamin E - Food Chemistry, Composition and Analysis 2004 - Eitenmiller & LeeDocumento526 páginasVitamin E - Food Chemistry, Composition and Analysis 2004 - Eitenmiller & LeeCecilia Grunauer100% (2)

- Lecture:10 Oxalic Acid Dr. N. K. PatelDocumento7 páginasLecture:10 Oxalic Acid Dr. N. K. PatelUMAIR Ali100% (1)

- Online IIT JEE Study Material For Physics, Chemistry and Maths - JEE 2016Documento13 páginasOnline IIT JEE Study Material For Physics, Chemistry and Maths - JEE 2016Kushal BislaAún no hay calificaciones

- Malaysia's Leading Palm Oil Exporter & ManufacturerDocumento7 páginasMalaysia's Leading Palm Oil Exporter & Manufacturerverlencia khosasihAún no hay calificaciones

- II. Cot AnalysisDocumento32 páginasII. Cot AnalysisSuraj BhattaraiAún no hay calificaciones

- AcetoneDocumento7 páginasAcetoneGeorgiana AndreeaAún no hay calificaciones

- I. Fungsi Propylene Recovery UnitDocumento25 páginasI. Fungsi Propylene Recovery Unitars danuAún no hay calificaciones

- Media Biochemical TestsDocumento36 páginasMedia Biochemical TestsIsmail Bazly ZarirAún no hay calificaciones

- View Online: Photochemistry of Drugs Overview and Practical ProblemsDocumento73 páginasView Online: Photochemistry of Drugs Overview and Practical ProblemsmariaantoanetaAún no hay calificaciones

- Ascorbyl PalmitateDocumento2 páginasAscorbyl PalmitatealmutazimAún no hay calificaciones

- United States Patent Office: Patented June 16, 1964Documento3 páginasUnited States Patent Office: Patented June 16, 1964Vansala GanesanAún no hay calificaciones

- Identification of PolymersDocumento4 páginasIdentification of PolymersJennifer JenkinsAún no hay calificaciones

- APG Synthesis EP0619318A1Documento11 páginasAPG Synthesis EP0619318A1menoddin.shaikhAún no hay calificaciones

- Selective Oxidation of Secondary AlcoholsDocumento24 páginasSelective Oxidation of Secondary AlcoholsFernando Silva BetimAún no hay calificaciones