Documentos de Académico

Documentos de Profesional

Documentos de Cultura

067

Cargado por

saurabh1116Descripción original:

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

067

Cargado por

saurabh1116Copyright:

Formatos disponibles

Energy 26 (2001) 705722 www.elsevier.

com/locate/energy

Comparative second-law analysis of internal combustion engine operation for methane, methanol, and dodecane fuels

C.D. Rakopoulos, D.C. Kyritsis

*

Internal Combustion Engines Laboratory, Dept. of Mechanical Engineering, National Technical University of Athens, 9 Heroon Polytechniou Str., Zografou 15780, Athens, Greece

Abstract A method for both combustion irreversibility and working medium availability computations in a highspeed, naturally-aspirated, four-stroke, internal combustion engine cylinder is presented. The results of the second-law analysis of engine operation with n-dodecane (n-C12H26) fuel are compared with the results of a similar analysis for cases where a light, gaseous (CH4) and an oxygenated (CH3OH) fuel is used. The rate of entropy production during combustion is analytically calculated as a function of the fuel reaction rate with the combined use of rst- and second-law arguments and a chemical equilibrium hypothesis. It is shown theoretically that the decomposition of lighter molecules leads to less entropy generation compared to heavier fuels. This is veried computationally for the particular fuels and the corresponding decrease in combustion irreversibility is calculated. Special reference is made to the effect of the lower mixing entropy of the exhaust gas of an oxygenated fuel (CH3OH) as a contribution to the discussion of the advantages and disadvantages of the use of such fuels. 2001 Elsevier Science Ltd. All rights reserved.

1. Introduction The limitations imposed by the second law of thermodynamics on the operation of thermal engines are among the most fundamental conclusions of classical thermodynamics. However, quantitative second-law analysis is much less frequently used to study these devices than its rstlaw counterpart. Recent studies [1,2] show that almost 1/3 of the energy of a fossil fuel is destroyed during the combustion process in power generation. This has caused a renewed interest in exergy analyses, since effective management and optimization of thermal systems is emerging as a major modern technical problem [3]. The equations for the second law analysis of thermodyn* Corresponding author. Present address: Yale University, Dept. of Mechanical Engineering, 9 Hillhouse Ave, Room 117, New Haven, CT 06520, USA. Fax: +1-203-432-7654. E-mail address: dimitrios.kyritsis@yale.edu (D.C. Kyritsis).

0360-5442/01/$ - see front matter 2001 Elsevier Science Ltd. All rights reserved. PII: S 0 3 6 0 - 5 4 4 2 ( 0 1 ) 0 0 0 2 7 - 5

706

C.D. Rakopoulos, D.C. Kyritsis / Energy 26 (2001) 705722

Nomenclature afv cv, cp G g H h I N0 NO2 P Q R S s T U u V Injected fuel molar availability (J/kmol) Molar heat capacity (J/kmol K) under constant volume (or pressure) Gibbs free energy (J) Molar Gibbs free energy (J/kmol K) Enthalpy (J) Molar enthalpy (J/kmol) Irreversibility (J) Molar quantity (kmoles) in the dead state Molar quantity (kmoles) of oxygen Pressure (Pa) Heat (J) Universal gas constant (8314 J/kmol K) Entropy (J/K) Molar entropy (J/kmol K) Temperature (K) Internal energy (J) Molar internal energy (J/kmol) Volume (m3)

Greek Symbols a b g Number Number Number working of atoms of carbon in the fuel molecule of atoms of hydrogen in the fuel molecule of atoms of oxygen in the fuel molecule medium availability (J)

Subscripts 0 fv i pr re Dead state Fuel liquid Fuel vapor Species in the working medium Prepared fuel Reacted fuel

Superscript 0 Dead state

C.D. Rakopoulos, D.C. Kyritsis / Energy 26 (2001) 705722

707

Abbreviations ATDC After top dead center BTDC Before top dead center CA Crank angle (degrees)

amic systems are presented and discussed thoroughly in Ref. [2] and are used to analyze the operation of power plants in Refs. [4] and [5]. For internal combustion engines, early work [6,7] on the evaluation of the global engine operation using of second-law techniques was followed by detailed availability and irreversibility calculations during the engine cycle [810]. Second-law arguments have been used to evaluate novel engine concepts [6], to investigate the effect of operating parameters on efciency [9], and more recently, to reveal interesting aspects of the transient engine operation [11]. The overall energy and availability balance during an engine cycle are studied analytically in Refs. [12] and [13]. In this article, we present a generalization of the method developed in Ref. [9] for the secondlaw analysis of the operation with dodecane fuel and use it to analyze the operation with alternative fuels. Specically, the cases of a light gaseous fuel (CH4) and an oxygenated (CH3OH) fuel were studied. Using the extensive experimental data available for the case of n-dodecane (n-C12H26) injection, which typically represents the diesel fuel in the study of automotive or smaller size diesel engines [14,15], the fuel reaction (combustion) rate is determined [16]. Combustion irreversibility is analytically calculated as a function of the fuel reaction rate with the use of second-law analysis and a chemical equilibrium hypothesis. The differential variation of working medium availability is computed throughout the engine cycle. Both quantities can be integrated during the cycle to yield a total combustion loss and the exhaust gas availability. The combustion loss is a measure of the entropy created during combustion, which can not be revealed by rst-law analysis. The exhaust gas availability contains more information than its enthalpy counterpart as far as the possible operation of exhaust gas heat recovery devices is concerned. Such devices include exhaust gas turbines and Rankine bottoming cycles, and are restricted in their operation by second-law arguments, in a manner that can not be evaluated by rst-law analysis. 2. Experimental facility modeling approach The engine used to study the operation with dodecane fuel was a Lister LV1, direct-injection diesel engine. This was a four-stroke, naturally-aspirated, air-cooled engine with a bowl-inpiston combustion chamber having a bore of 85.73 mm, a stroke of 82.55 mm and a rod length to crank radius ratio of 3.6. The compression ratio was 18 and the nominal speed range was between 1000 and 3000 rpm. A three-hole injector nozzle (hole diameter of 250 m) was used for dodecane injection. It was located near the combustion chamber center with an opening pressure of 190 bar. The full load conditions correspond to equivalence ratio of j=0.625, injec-

708

C.D. Rakopoulos, D.C. Kyritsis / Energy 26 (2001) 705722

tion timing of 22CA BTDC and injection duration of 24CA. Measurements were taken for equivalence ratios 0.600 and 0.470 and injection timings of 19, 22 and 25CA BTDC. A detailed description of the experimental setup and the data acquisition interface has been presented in Refs. [8,9,14,16]. A single-zone model was used to simulate the engine operation. The most important assumptions were the following: 1) The working medium was considered, in general, to be a mixture of 10 species (O2, N2, CO2, H2O, H2, OH, NO, CO, O, H) and fuel vapor; 2) All 10 species were considered as ideal gases; 3) Blowby was ignored; 4) The residual gas fraction was taken equal to 10% independent of conditions of operation, which was a reasonable assumption for the operating parameters described above [9,16]. Experimental data were available only for dodecane injection. Computationally, the cases of methane (CH4) and methanol (CH3OH) injection were also investigated. Proper processing of the experimentally acquired indicator diagrams can yield the preparation and reaction rates of the fuel, as described in detail in Refs. [16] and [18]. The preparation stage involved vaporization of the fuel, its superheating to the temperature of cylinder gases and mixing with the oxidizer so that a ammable mixture forms in certain regions of the combustion chamber. The intuitive assumption that preparation times for gaseous (CH4) injection must be much shorter than the ones for liquid injection is not correct [19]. Summarizing the data processing algorithm here for the purpose of completeness, we can state that it correlates the differential change in mixture composition to the differential of the natural logarithm of pressure in the combustion chamber. Similar but signicantly simpler approaches to the calculation of an effective burning law from pressure data are presented in Refs. [14] and [20]. The reacted and prepared fuel quantities computed are used as input to the equilibrium code described below. The tting of a Wibbe function [20] to the reacted fuel distribution makes this analysis much simpler. As Fig. 1 shows, the Wibbe function offers a exible and accurate approximation to the reacted fuel quantity. The four coefcients of the function are calculated using a least squares t. It should be mentioned that the crank angle at the start of combustion must be located for such a formulation to work. This poses a difculty in modeling diesel combustion since ignition is not forced (e.g. by a spark plug). The onset of combustion could, in principle, be calculated. However, this complicates the model signicantly without adding any value to the present study. The angle of onset of combustion is treated as a parameter of the Wibbe function determined by the least square algorithm. Once the molar quantities Npr and Nre of prepared and reacted fuel, respectively, are known, determination of the thermodynamic condition of the working medium requires calculation of pressure P, temperature T and the molar quantities Ni of the aforementioned ten species. This calculation was achieved through the solution of 12 equations consisting of: The ideal gas equation of state for the mixture:

11

PV RT

i 1

Ni

(1)

C.D. Rakopoulos, D.C. Kyritsis / Energy 26 (2001) 705722

709

Fig. 1. Approximation of the reacted fuel quantity by a Wibbe function.

The energy balance for a closed system of variable volume:

11 11

dQ dNpr(hfl hfv) pdV

i 1

uidNi dT

i 1

Nicvi dNprhfv

(2)

The rst two terms on the left-hand side are the heat inux. The third term is the work output of the system. The rst two terms on the right hand side are the change in internal energy of the working medium due to the change of its composition and temperature respectively. The third term is the enthalpy inux to the working medium due to fuel vaporization. The volume is calculated analytically as a function of the crank angle. The thermodynamic properties are computed as a function of T by polynomial ttings to the data of JANAF Thermochemical Tables [21]. Heat transfer through the system boundary is calculated as a function of T, the thermodynamic properties of the working medium and the wall temperature using Annands formula, as described in Ref. [9]. The molar quantities Ni are calculated using a chemical equilibrium assumption. Specically, we assume that the following six reactions among the above 10 species were in equilibrium: H22H

710

C.D. Rakopoulos, D.C. Kyritsis / Energy 26 (2001) 705722

O22O

H2 O22OH

N2 O22NO

2H2 O22H2O

2CO O22CO2 At each crank angle, equilibrium equations for these six reactions as well as atom number conservation equations for the atoms of C, H, O and N, constitute a 1010 system of equations which can be solved for Ni. This is a generalization of the procedure described in Refs. [9] and [15] for dodecane, where the validity of the chemical equilibrium assumption is discussed. In general, the chemical equilibrium assumption is not valid for the formation of pollutants, especially NO at the late stage of the expansion stroke when the chemical kinetics freezes yielding quantities of NO at the exhaust much higher than the equilibrium values [17,20]. Given the fact that the quantities of pollutants are in any case small, the main conclusions of this work are not affected.

3. Second-law analysis 3.1. Concepts and denitions Availability of a system is dened as the maximum work that can be produced from the system through interaction with its surroundings during a reversible transition to a state of thermal, mechanical, and chemical equilibrium with its environment, and while heat is exchanged during the transition only with this environment. This state of equilibrium is dened as the dead state of the system and it depends on the pressure P0, the temperature T0 and the composition of the environment. In the present study, the environment is dry atmospheric air with P0=1 bar and T0=298 K. Thermal equilibrium is achieved when there is no heat exchange between the system and the environment, i.e. when the system is at temperature T0. Similarly, mechanical equilibrium is achieved when there is no work exchange between the system and its environment. Chemical equilib-

C.D. Rakopoulos, D.C. Kyritsis / Energy 26 (2001) 705722

711

Fig. 2. The closed system under consideration and the related availability streams.

rium is achieved when no system component can react with the environment. For the present case, this means that in the dead state all the 11 species of the working medium have been either oxidized or reduced to N2, O2, CO2, and H2O. It is shown in Refs. [2224] that the availability of a closed system is equal to U P0V T0S G0 (3)

A direct consequence of the above denition is that when a differential amount of reversible work dW=(P P0)dV is extracted from a system, its availability is reduced by exactly that amount. Similarly, when a differential amount of heat dQ is supplied to the system at temperature T, the system availability is increased by an amount dQ(1 T0/T). The system under consideration is shown in Fig. 2. It is a closed system, since only the part of the cycle from inlet valve closing to exhaust valve opening is considered. The only mass inux to the system is the prepared fuel, which takes place after injection. The differential availability uxes can also be seen in Fig. 2. On the basis of the availability balance, the differential variation of the working medium availability is given by d (P P0)dV [dQ dNpr(hfl hfv)](1 T0/T) dNprafv dI (4)

On the right hand side, the rst term is availability outux from the system in the form of work. The second term is availability input through heat ux and the third term is availability added to the system by the fuel vapor. The term dI makes Eq. (4) different from a conservation equation. During combustion working medium availability is destroyed and a differential amount dI of

712

C.D. Rakopoulos, D.C. Kyritsis / Energy 26 (2001) 705722

combustion irreversibility is produced. Similarly, during fuel preparation, there is availability destruction due to mixing, which is included in the calculation of afv, as shown later. From Eqs. (3) and (4), it can be seen that in order to calculate the combustion irreversibility, one has to determine the dead state and calculate afv. 3.2. Determination of the dead state For the system to reach the dead state at P0=1 bar and T0=298 K, all of the working medium constituents have to be either oxidized or reduced to N2, O2, CO2 and H2O. Knowledge of the precise mechanism with which this happens is not necessary for determination of the molar quantity of each of the four species in the dead state. Instead, one can write atom conservation relations of the type: NO1/2 N2 1/2 O2 This schematic representation has no meaning as a chemical reaction; it simply shows the relation of molar quantities between the working medium species and the molar quantities of N2 and O2 in the dead state. A similar relation for the complete oxidation of an oxygenated fuel vapor gives: CaHbOg (a b/4 g/2)O2aCO2 b/2H2O Finally, similar considerations for all species, yield the following relations for the composition of the dead state: N0 2=NN2+NNO/2 N N0 2=NCO2+aNfv+NCO CO N0 2=NO2(a+b/4g/2)Nfv+(NO+NNONH2NCO)/2+(NOHNH)/4 O N0 2O=NH2O+(b/2)Nfv+NH2+(NH+NOH)/2 H The differential variation of the G0 term is then given by:

4

(5)

dG0

i 1

dN0 gi(T0,P0) RT0ln i

N0 i N0 i

(6)

The second term of this sum corresponds to the entropy of mixing in the dead state. 3.3. Availability introduced to the system with the fuel vapor The fuel vapor availability consists of two parts. The rst part, usually termed thermal or thermo-mechanical part, is equal to:

C.D. Rakopoulos, D.C. Kyritsis / Energy 26 (2001) 705722

713

afv, thermomechanical hfv T0sfv g0 fv

(7)

This is the amount of availability introduced by the injected gas. A second part, usually termed thermo-chemical availability, is due to the ability of fuel to react and produce reactants of lower availability. For the calculation of the thermochemical availability, we consider the reaction of complete oxidation of the fuel in atmospheric air: CaHbOg ((a b/4 g/2)/0.21)(0.21O2 0.79N2)aCO2 b/2H2O [0.79(a b/4 g/2)/0.21]N2 It is shown [23], that the thermochemical availability is equal to the difference in Gibbs free energy between reactants and products at temperature T0 and pressure P0. It follows that: afv, thermochemical g0 ag0 2 (b/2)g0 2O (a b/4 g/2)g0 2 fv CO H O RT0ln aa(b/2)b/2ee a+b/4g/2)a+b/4g/2zz (8)

where the last term of the sum accounts for the difference in entropy of mixing between products and reactants, and e and z are dened as follows: e (a b/4 g/2)/0.21

z 0.79e a b/2 Adding Eqs. (7) and (8) we get for the total fuel availability: afv hfv T0sfv ag0 2 (b/2)g0 2O (a b/4 g/2)g0 2 RT0ln CO H O aa(b/2)b/2ee a+b/4g/2)a+b/4g/2zz

3.4. Calculation of combustion irreversibility If we substitute Eqs. (3) and (6) in Eq. (4) and subtract Eq. (2) multiplied by T0/T, we get: dI dNprafv [dQ dNpr(hfl T0 N c dT T i 1 i pi

11 4

T0 Ni T0 t dN (s Rln VdP hfv)] ) dNprhfv T 0i 1 i i T Ni

11

(9)

dN0g0i i

i 1

714

C.D. Rakopoulos, D.C. Kyritsis / Energy 26 (2001) 705722

The energy balance for the system can be reformulated in enthalpy terms as:

10 10

dQ dNpr(hfl hfv) VdP

i 1

hidNi hfv (

i 1

Nicpi Nfvcpfv)dT dNprhfv

(10)

Eq. (10) is the expression of the same energy balance as Eq. (2) reformulated in terms of enthalpy. If Eq. (10) is multiplied by T0/T and subtracted from Eq. (9), keeping in mind that the expression for gI is gi hi Tsi RTln(Ni/ it is shown that: dI T0 dN g Ti 1 i i

11 4

Ni)

dN0g0i dNpr[afv hfv(1 i

i 1

T0 )] T

(11)

This proves that the differential availability destruction is only a function of the differential change in mixture composition. It is interesting to note that one of the main mechanisms of irreversibility production, namely heat transfer, affects the nal result only indirectly since dI is not an explicit function of dQ. Irreversibility production due to uid viscosity, as discussed in Ref. [1], can not be calculated within the framework of the current single-zone analysis.

4. Results and discussion The availability balance during the engine cycle is presented for the dodecane injection case in Fig. 3. Only the closed part of the engine cycle is presented, i.e. the part from the closing of the intake valve to the opening of the exhaust valve. This is a balance between ve terms: working medium availability, availability transfer through work, availability transfer through heat, input of availability with the injected fuel, and destruction of availability (production of irreversibility). All ve terms are calculated independently as described earlier. The decit in the balance caused by the employed numerical scheme is of the order of 1% of the availability of the injected fuel. Since the availability input with the injected fuel starts and ends abruptly with the start and end of injection, respectively, it is expected that discontinuities in the derivative of the corresponding curve should appear. During fuel injection and preparation, there is a gradual fuel availability inux. It can be noted that there is a signicant loss of working medium availability during the fuel preparation. This is due to working medium cooling because of fuel vaporization. The production of irreversibility due to irreversible heat transfer during compression is negligible compared to the combustion irreversibility. In fact, signicant production of irreversibility takes place only after ignition. This may be due to insufcient modeling of heat transfer within the framework of a single-zone model and should be investigated further with the use of multi-zone models like the ones presented in Refs. [16,17]. It is reminded, however, that Eq. (11) shows that heat transfer affects combustion irreversibility only indirectly.

C.D. Rakopoulos, D.C. Kyritsis / Energy 26 (2001) 705722

715

Fig. 3.

Availability balance for operation with dodecane fuel.

No experiments were conducted with either methanol (CH3OH) or methane (CH4) injection, since this would involve re-design of the employed hardware well beyond the scope of this work. However, some characteristics of the availability balance can be used to extract useful information by substituting dodecane with alternative fuels in the employed code. Fig. 4 shows the effect of fuel reaction rate on combustion irreversibility. The fuel is dodecane, the equivalence ratio is kept constant and equal to 0.600, and the reaction rate is computationally modied in the code (increased and decreased by a factor of 3). As a result of this modication, only the detailed time evolution of the combustion irreversibility is drastically affected, whereas the total irreversibility production only varies by approximately 2%. Similar results hold for numerical modications of the preparation rate, and for the other terms of the availability balance described above. In the case of the alternative fuels examined here no experimental data are available for the calculation of the precise time history of the availability balance. The above analysis, though, shows that the total value of each of the terms of this balance at the end of the closed cycle is mainly a function of the total quantity of the injected fuel and not of the detailed preparation and reaction rates. The comparison of these total values for the three fuels is meaningful if it reveals differences much higher than 25% of the total combustion irreversibility. If we substitute CH3OH and CH4 in the employed code as injected fuels and keep the equivalence ratio equal to 0.600 as in the dodecane case, we can compute availability balances like the ones shown in Figs. 5 and 6. The mass ow rate of air is also kept the same for all three fuels. This is one simple baseline that can be used for the comparison. However the methodology to be presented here can be used for more complicated reference criteria, e.g. same load (i.e. indicated mean effective pressure), equivalent pollutant emissions etc. Same equivalence ratio and air quantity means approximately same load since the stoichiometric air/fuel ratios and the lower

716

C.D. Rakopoulos, D.C. Kyritsis / Energy 26 (2001) 705722

Fig. 4. Effect of numerical increase and numerical decrease of the reaction rate by a factor of 3 on combustion irreversibility.

Fig. 5. Availability balance for operation with methane fuel.

C.D. Rakopoulos, D.C. Kyritsis / Energy 26 (2001) 705722

717

Fig. 6. Availability balance for operation with methanol fuel.

heating values of the examined fuels do not differ signicantly. In Ref. [9] the effect of load on the availability balance during operation with dodecane is studied. In order to be conclusive about the potential advantages of alternative fuels from the second-law-analysis point of view, these fuels will have to be implemented experimentally so that the conditions of optimal operation are determined. Then the operating cycles at the optimal conditions for each particular fuel will have to be compared with each other according to the procedure described here. The detailed time evolution of each of the terms of the presented balances of Figs. 5 and 6 is a function of the precise preparation and reaction rates of CH3OH and CH4, which can only be determined from experimental data. However, the exhaust gas availability (available for heat recovery devices) and the total combustion irreversibility can be approximated without the knowledge of this data, provided that reaction has been completed reasonably early relative to the exhaust valve opening timing. Figs. 79 show the comparison between injected fuel availability, exhaust gas availability and combustion irreversibility for the three fuels, for injection with the same equivalence ratio. It can be seen that the injected fuel availability is signicantly higher for the methanol case. Because of the oxygen content of the fuel, higher molar quantity of fuel is necessary for combustion with the same equivalence ratio. Comparing the results for methane and n-dodecane, we observe a signicant decrease of combustion irreversibility for methane combustion. This is in agreement with the theoretical expectation that the decomposition of the larger n-dodecane molecule during chemical reaction should create higher entropy increase than the decomposition of a lighter methane molecule. To illustrate this point, we consider the combustion of parafns in oxygen, although similar arguments hold for any fuel and oxidizer. In general, a parafn would burn according to the scheme: CnH2n+2 (1.5n 0.5)O2nCO2 (n 1)H2O

718

C.D. Rakopoulos, D.C. Kyritsis / Energy 26 (2001) 705722

Fig. 7. Injected fuel availability for three alternative fuels.

Fig. 8.

Exhaust gas availability for three alternative fuels.

C.D. Rakopoulos, D.C. Kyritsis / Energy 26 (2001) 705722

719

Fig. 9. Combustion irreversibility for three alternative fuels.

The entropy of mixing of reactants and products respectively are: Sreactants=R(1ln( 1 1.5n+0.5 )+1.5n+0.5)ln( )) 1.5n+1.5 1.5n+1.5

n n+1 +(n+1)ln( )) Sproducts=R(nln( 2n+1 2n+1

(12)

If, again without loss of generality, we assume that n is sufciently large so that n+1 n, 1.5n+1.5 1.5n+0.5 1.5n and 2n+1 2n we can derive: Sproducts Sreactants R(2nln2 ln(1.5n)) (13) which is obviously an ascending function of n. The decrease of combustion irreversibility is even higher for the case of oxygenated fuel. This can be explained as follows: The entropy of mixing is calculated as Smixing=R Niln(Ni/ Ni) and is maximum when the mixture fractions of all the components of a mixture are equal. Small entropy of mixing means high availability of reactants and signicant availability loss during the transition to products. In the case of hydrocarbons, the mixture of reactants consists almost totally of air and has a small entropy of mixing. In the methanol case, the fuelair molar ratio in the reactants is higher because of the oxygen content of methanol. This means higher entropy of

720

C.D. Rakopoulos, D.C. Kyritsis / Energy 26 (2001) 705722

mixing of the reactants and less entropy production during the transition to products. It can be also observed that, in the methanol case, the availability of exhaust gas is increased in absolute terms. This is due on one hand to the smaller production of entropy during combustion and on the other to the fact that, for the same equivalence ratio, the injected fuel availability is higher for methanol injection. As a fraction of the injected fuel availability, the exhaust gas availability is also increased in the methanol case as it can be seen from Figs. 7 and 8. A second-law efciency can be dened as the ratio of extracted work over injected fuel availability. It should be stressed that this ratio is only calculated here for the closed part of the cycle and is not the second-law efciency of the full cycle. Comparison of the efciency for the three cases is presented in Fig. 10. It seems that the use of alternative fuels leads to better secondlaw efciency. However, especially as far as the comparison between methane and methanol is concerned, the difference is small so that conclusions should be drawn with caution given the assumptions of the current analysis. Methanol vapor, for instance, was assumed to be an ideal gas but this is only a coarse approximation, given the fact that the critical point of methanol is 513 K and 8.1 bar. More accurate modeling of the thermodynamic properties of methanol may alter the injected fuel availability. Moreover, for the accurate calculation of the irreversibility created during combustion, an accurate computation of methanol combustion kinetics is necessary. It would also be interesting to investigate the effect of the fact that this is a single-zone analysis by incorporating the current arguments in multi-zone codes, following e.g. Ref. [11]. Revisiting the above assumptions may yield more accurate information about the advantages Figs. 69 imply for oxygenated fuels. However, the

Fig. 10. Second-law efciency for three alternative fuels.

C.D. Rakopoulos, D.C. Kyritsis / Energy 26 (2001) 705722

721

main point remains that entropy increase during combustion is smaller for such fuels because of the lower mixing entropy of the mixture of reactants. 5. Conclusions A method for the analytic calculation of irreversibility and exhaust gas availability is generalized and used to evaluate alternative fuels in a high-speed, direct-injection, naturally-aspirated, four-stroke diesel engine. Combustion irreversibility is shown to be the main source of irreversibility during the engine operation and its differential variation is calculated as an analytic function of the differentials of the molar quantities of the constituents of the working medium. Decrease in combustion irreversibility is achieved with the use of a lighter (methane) and, even more, of an oxygenated (methanol) fuel for the same equivalence ratio of operation. This is due to the combustion characteristics of these fuels which involve lower entropy of mixing in the combustion products. So far, the driving force for the study of alternative fuels has been to decrease pollutant emissions. Given the increasing interest in conservation, the use of such fuels may be seen in a different perspective since there are indications that it involves a more effective use of the chemical energy of the fuel. References

[1] Dunbar WR, Lior N. Sources of combustion irreversibility. Combust Sci Technol 1994;103:4161. [2] Dunbar WR, Lior N, Gaggioli RA. The component equations of energy and exergy. Trans ASME, J Energy Res Technol 1992;114:7583. [3] Bejan A, Tsatsaronis G, Moran M. Thermal design and optimization. New York: John Wiley and Sons Inc, 1996. [4] Dunbar WR, Lior N, Gaggioli RA. Combining fuel cells with fuel-red plants for improved exergy efciency. Energy 1991;16:125974. [5] Gaggioli RA, Yoon JJ, Patulski SA, Latus AJ, Obert EF. Pinpointing the real inefciencies in power plants and energy systems. In: Gaggioli RA, editor. Washington DC: Proc. American Power Conference 1975:671679. [6] Flynn PF, Hoag KL, Kamel MM, Primus RJ. A new perspective on diesel engine evaluation based on second law analysis. SAE Paper No. 840032. Warrendale, PA: Society of Automotive Engineers Inc., 1984. [7] Primus RJ, Hoag KL, Flynn PF, Brandts MC. An appraisal of advanced engine concepts using second law techniques. SAE Paper No. 841287. Warrendale, PA: Society of Automotive Engineers Inc., 1984. [8] Rakopoulos CD, Andritsakis, EC. DI and IDI diesel engine combustion irreversibility analysis. Proc. ASMEWAM, AES Vol. 30 and HTD Vol. 266, New Orleans, LA, November 1993:1732. [9] Rakopoulos CD, Andritsakis EC, Kyritsis DC. Availability accumulation and destruction in a DI diesel engine with special reference to the limited cooled case. Heat Recov Syst CHP 1993;13:26175. [10] Rakopoulos CD. Evaluation of a spark ignition engine cycle using rst and second law analysis techniques. Energy Convers Mgmt 1993;34:1299314. [11] Rakopoulos CD, Giakoumis EG. Simulation and exergy analysis of transient diesel engine operation. Energy 1997;22:87585. [12] Beretta GP, Keck JC. Energy and entropy balances in a combustion chamber. Combust Sci Technol 1983;30:1929. [13] Bedran EC, Beretta GP. General Thermodynamic analysis for engine combustion modeling. SAE Paper No. 850205. Warrendale, PA: Society of Automotive Engineers Inc., 1985. [14] Kouremenos DA, Rakopoulos CD, Hountalas DT. Multi-zone modeling for the prediction of pollutants emissions and performance of DI diesel engines. Trans SAE J Engines 1997;106:94057.

722

C.D. Rakopoulos, D.C. Kyritsis / Energy 26 (2001) 705722

[15] Rakopoulos CD, Hountalas DT, Tzanos EI, Taklis GN. A fast algorithm for calculating the composition of diesel combustion products using 11 species chemical equilibrium scheme. Adv Engng Software 1997;19:10919. [16] Kouremenos DA, Rakopoulos CD, Andritsakis EC. A non-linear differential equations methodology for the determination of gas properties in diesel engine cylinders. In: Proc. Int. Conf. ECOS92-ASME, Zaragosa, Spain, 653664. [17] Rakopoulos CD, Hountalas DT. Development and validation of a 3-D multizone combustion model for the prediction of DI diesel engines performance and pollutants emissions. Trans SAE J Engines 1998;107:141329. [18] Rakopoulos CD, Hountalas DT, Mavropoulos GC, Giakoumis EG. An integrated transient analysis simulation model applied in thermal loading calculations of an air-cooled diesel engine under variable speed and load conditions. Trans SAE J Engines 1997;106:92339. [19] Abraham J, Magi V, MacInnes J, Bracco FV. Gas vs. spray injection: Which mixes faster? SAE Paper No.940895. Warrendale, PA: Society of Automotive Engineers, Inc., 1994. [20] Heywood JB. Internal combustion engine fundamentals. New York: McGraw-Hill, 1988. [21] JANAF (Joint Army Navy and Air Force) Thermochemical Tables, National Bureau of Standards Publication NSRDSNBS 37, 1971. [22] Moran MJ. Availability analysis: a guide to efcient energy use. New Jersey: Prentice Hall, 1982. [23] Bejan A. Advanced engineering thermodynamics. New York: John Wiley and Sons Inc, 1988. [24] Gyftopoulos EP, Beretta GP. Thermodynamics: fundamentals and applications. New York: McMillan, 1991.

También podría gustarte

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceCalificación: 4 de 5 estrellas4/5 (895)

- Cam Lab: ND ST THDocumento2 páginasCam Lab: ND ST THsaurabh1116Aún no hay calificaciones

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeCalificación: 4 de 5 estrellas4/5 (5794)

- Cad LabDocumento5 páginasCad Labsaurabh1116Aún no hay calificaciones

- Shoe Dog: A Memoir by the Creator of NikeDe EverandShoe Dog: A Memoir by the Creator of NikeCalificación: 4.5 de 5 estrellas4.5/5 (537)

- M.Tech Power System SchemeDocumento4 páginasM.Tech Power System Schemesaurabh1116Aún no hay calificaciones

- Grit: The Power of Passion and PerseveranceDe EverandGrit: The Power of Passion and PerseveranceCalificación: 4 de 5 estrellas4/5 (588)

- Ee - Ii - 1Documento33 páginasEe - Ii - 1saurabh1116Aún no hay calificaciones

- The Yellow House: A Memoir (2019 National Book Award Winner)De EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Calificación: 4 de 5 estrellas4/5 (98)

- 05.09.2020 Internal MechanicalDocumento1 página05.09.2020 Internal Mechanicalsaurabh1116Aún no hay calificaciones

- M. Tech. Semester - I: Concrete Construction Technology (MCEBT 105/IBMCEBT 905)Documento40 páginasM. Tech. Semester - I: Concrete Construction Technology (MCEBT 105/IBMCEBT 905)saurabh1116Aún no hay calificaciones

- M. Tech. Semester - I: Advanced Power System Protection (MEEPE 104)Documento44 páginasM. Tech. Semester - I: Advanced Power System Protection (MEEPE 104)saurabh1116Aún no hay calificaciones

- The Little Book of Hygge: Danish Secrets to Happy LivingDe EverandThe Little Book of Hygge: Danish Secrets to Happy LivingCalificación: 3.5 de 5 estrellas3.5/5 (400)

- M. Tech. Semester - I: Distributed Computing (MCSCS 101/1MCS1)Documento20 páginasM. Tech. Semester - I: Distributed Computing (MCSCS 101/1MCS1)saurabh1116Aún no hay calificaciones

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe EverandNever Split the Difference: Negotiating As If Your Life Depended On ItCalificación: 4.5 de 5 estrellas4.5/5 (838)

- Ce - Ii - 1Documento50 páginasCe - Ii - 1saurabh1116Aún no hay calificaciones

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureCalificación: 4.5 de 5 estrellas4.5/5 (474)

- M. Tech. Semester - I: Data Mining and Data Warehousing (MCSSE 104)Documento10 páginasM. Tech. Semester - I: Data Mining and Data Warehousing (MCSSE 104)saurabh1116Aún no hay calificaciones

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryCalificación: 3.5 de 5 estrellas3.5/5 (231)

- M. Tech. Semester - IX: Highway Materials (IBMCETE 903)Documento20 páginasM. Tech. Semester - IX: Highway Materials (IBMCETE 903)saurabh1116Aún no hay calificaciones

- Rise of ISIS: A Threat We Can't IgnoreDe EverandRise of ISIS: A Threat We Can't IgnoreCalificación: 3.5 de 5 estrellas3.5/5 (137)

- M. Tech. Semester - II: Transportation Planning (IBMCETE806)Documento14 páginasM. Tech. Semester - II: Transportation Planning (IBMCETE806)saurabh1116Aún no hay calificaciones

- The Emperor of All Maladies: A Biography of CancerDe EverandThe Emperor of All Maladies: A Biography of CancerCalificación: 4.5 de 5 estrellas4.5/5 (271)

- Annual Exam Invigilation Duty-2020Documento3 páginasAnnual Exam Invigilation Duty-2020saurabh1116Aún no hay calificaciones

- M. Tech. Semester - I: Advanced Water Treatment Technology (MCEEV 103/1MEV3)Documento44 páginasM. Tech. Semester - I: Advanced Water Treatment Technology (MCEEV 103/1MEV3)saurabh1116Aún no hay calificaciones

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaCalificación: 4.5 de 5 estrellas4.5/5 (266)

- M. Tech. Semester - IX: Highway Materials (IBMCETE 903)Documento20 páginasM. Tech. Semester - IX: Highway Materials (IBMCETE 903)saurabh1116Aún no hay calificaciones

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersCalificación: 4.5 de 5 estrellas4.5/5 (345)

- Ce - IiiDocumento18 páginasCe - Iiisaurabh1116Aún no hay calificaciones

- On Fire: The (Burning) Case for a Green New DealDe EverandOn Fire: The (Burning) Case for a Green New DealCalificación: 4 de 5 estrellas4/5 (74)

- Ce - IiDocumento51 páginasCe - Iisaurabh1116Aún no hay calificaciones

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyCalificación: 3.5 de 5 estrellas3.5/5 (2259)

- Maximum Marks: 100 Min. Passing Marks: 33 Attempt Any Five Questions. Marks of Questions Are Indicated Against Each QuestionDocumento1 páginaMaximum Marks: 100 Min. Passing Marks: 33 Attempt Any Five Questions. Marks of Questions Are Indicated Against Each Questionsaurabh1116Aún no hay calificaciones

- Team of Rivals: The Political Genius of Abraham LincolnDe EverandTeam of Rivals: The Political Genius of Abraham LincolnCalificación: 4.5 de 5 estrellas4.5/5 (234)

- Vivekananda Institute of Technology - East, Jaipur Mechanical Engineering HT Lab Group: 1Documento2 páginasVivekananda Institute of Technology - East, Jaipur Mechanical Engineering HT Lab Group: 1saurabh1116Aún no hay calificaciones

- The Unwinding: An Inner History of the New AmericaDe EverandThe Unwinding: An Inner History of the New AmericaCalificación: 4 de 5 estrellas4/5 (45)

- B.lib Examination DutiesDocumento1 páginaB.lib Examination Dutiessaurabh1116Aún no hay calificaciones

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreCalificación: 4 de 5 estrellas4/5 (1090)

- Service Manual Outline: Section 1 - Important InformationDocumento11 páginasService Manual Outline: Section 1 - Important InformationajcapetillogAún no hay calificaciones

- Cat C7 .Documento4 páginasCat C7 .dionymackAún no hay calificaciones

- Ford 1982 3.8L V6Documento22 páginasFord 1982 3.8L V6sc100% (1)

- Catalogo Motor 638 SEM Cummins 6BT5.9Documento64 páginasCatalogo Motor 638 SEM Cummins 6BT5.9Diego Alejandro QuinteroAún no hay calificaciones

- Waukesha Gas Engines: Control SystemsDocumento15 páginasWaukesha Gas Engines: Control SystemsKilienAún no hay calificaciones

- 6090HF485-224 KW - 2200 - 8 - 46 Stage IIIADocumento2 páginas6090HF485-224 KW - 2200 - 8 - 46 Stage IIIAKeivinMCAún no hay calificaciones

- Free Technical Paper DownloadDocumento11 páginasFree Technical Paper Downloadhayat umar bhatAún no hay calificaciones

- BMW 740i 7-Series (E38) (1996 - 2001)Documento12 páginasBMW 740i 7-Series (E38) (1996 - 2001)IgorIlnickijAún no hay calificaciones

- Manual Partes Motor CAT 3516BDocumento928 páginasManual Partes Motor CAT 3516Barturo cusihuaman quispe100% (4)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Calificación: 4.5 de 5 estrellas4.5/5 (121)

- Yamaha TDM 900 PartsDocumento79 páginasYamaha TDM 900 Partsalexandrumos100% (1)

- Master Catalog September 2017Documento587 páginasMaster Catalog September 2017v100% (1)

- Governing, Ignition System, Fire OrderDocumento33 páginasGoverning, Ignition System, Fire OrderProf. Jignesh Sohaliya100% (1)

- Denso Ecd-VDocumento118 páginasDenso Ecd-VIongornistu100% (5)

- Air Car AbstractDocumento1 páginaAir Car AbstractPradeep Kadamat33% (3)

- Sebp4550 06 00 All PDFDocumento723 páginasSebp4550 06 00 All PDFJosé ProençaAún no hay calificaciones

- The Perks of Being a WallflowerDe EverandThe Perks of Being a WallflowerCalificación: 4.5 de 5 estrellas4.5/5 (2104)

- Diesel Engines 12V/16V 4000 M90: For Vessels With Low Load Factors (1DS)Documento2 páginasDiesel Engines 12V/16V 4000 M90: For Vessels With Low Load Factors (1DS)Alberto100% (1)

- FuelTech - Cat2019.0 - USADocumento19 páginasFuelTech - Cat2019.0 - USAJose Miguel del RioAún no hay calificaciones

- Detroit Diesel Miami SERIES 60 Parts CatalogDocumento16 páginasDetroit Diesel Miami SERIES 60 Parts CatalogÖnder Büyükişcan100% (3)

- Engines For Planing BoatsDocumento16 páginasEngines For Planing BoatsAlex MarcusAún no hay calificaciones

- Her Body and Other Parties: StoriesDe EverandHer Body and Other Parties: StoriesCalificación: 4 de 5 estrellas4/5 (821)

- HTTPS::WWW - Lsengineers.co - Uk:media:advice centre:GX160:GX160 Adjustment InformationDocumento1 páginaHTTPS::WWW - Lsengineers.co - Uk:media:advice centre:GX160:GX160 Adjustment InformationSady KanettiAún no hay calificaciones

- Problem Statement - Chem e CarDocumento9 páginasProblem Statement - Chem e Carhimanshucool21Aún no hay calificaciones

- Technical Data Liebherr R9200Documento46 páginasTechnical Data Liebherr R9200Yudi AriantoAún no hay calificaciones

- Especificaciones Nissan ZD30 TD DIDocumento2 páginasEspecificaciones Nissan ZD30 TD DIGuilherme Tyska56% (9)

- Honda: Group Engine Year No. Displace No. Model Cyl. Ment G A18A G A20ADocumento7 páginasHonda: Group Engine Year No. Displace No. Model Cyl. Ment G A18A G A20AЕвгений Дынник100% (1)

- Engine MisfireDocumento6 páginasEngine MisfireAkhileshAún no hay calificaciones

- Renault Kerax Engine Service ManualDocumento257 páginasRenault Kerax Engine Service Manualkamel hatt100% (10)

- Catalogo de Partes NXTDocumento67 páginasCatalogo de Partes NXTlainer chauxAún no hay calificaciones

- 100C PM #70696879Documento354 páginas100C PM #70696879Roberto MarianoAún no hay calificaciones

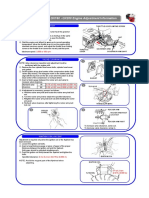

- 03 - Valve Clearance - AdjustmentDocumento10 páginas03 - Valve Clearance - AdjustmentJeffrey Mac FarlaneAún no hay calificaciones

- CK Geely 00001Documento115 páginasCK Geely 00001Miguel Angel PanequeAún no hay calificaciones

- Fire on the Horizon: The Untold Story of the Gulf Oil DisasterDe EverandFire on the Horizon: The Untold Story of the Gulf Oil DisasterAún no hay calificaciones

- Electric Motors and Drives: Fundamentals, Types and ApplicationsDe EverandElectric Motors and Drives: Fundamentals, Types and ApplicationsCalificación: 4.5 de 5 estrellas4.5/5 (12)