Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Final 1

Cargado por

Shobisan SenthilnathanDescripción original:

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Final 1

Cargado por

Shobisan SenthilnathanCopyright:

Formatos disponibles

Industrial Training Report

CHAPTER 01

1. INTRODUCTION TO THE TRAINING ESTABLISHMENT

1.1 Organization overview

Central engineering consultancy bureau (CECB) is one of the major construction and consulting organization that is involved in civil engineering and building construction today. It has been a leader in engineering since 1973. This corporation was implemented as a semi government organization under the Ministry of irrigation and water resources management. This organization plays a major role in the government sector construction industry in Sri Lanka. Mission of the company is to be the internationally recognized leading Srilankan engineering organization making use of resources to acquire excellence in civil, electrical and mechanical engineering architecture, project management of developments, power and energy, software technology. During the past 35 years CECB has provided engineering consultancy services in a wide range of fields for a larger number of major hydropower and building projects, and has emerged as the premier engineering consultancy organization in the country. In addition, CECB has undertaken several projects in the recent past and completed successfully. 1.2 General Profile of Central Engineering Consultancy Bureau : Central Engineering Consultancy Bureau : No.415, Baudhaloka mawatha, Columbo 07 : 011 2668800, 011 2687369, 011 2815317 : cecb@slt.lk : Buildings and civil engineering contracts : M1 : National construction contractors association in 1996 for Timely completion, workmanship and quality finish for period of construction house. water resources, infrastructure

engineering and utilizing state of the art

Name of company Address Contact no Web address Nature of business ICTAD Grading Awards

B.Koby

Page 1

Industrial Training Report

1.3

Main functions Provision of consultancy services in hydropower, building, roads and bridges, port and coastal engineering, irrigation engineering, environmental engineering, electrical and mechanical engineering etc. Undertaking of design & build construction including buildings, roads and bridges

1.4

Organization structure

The administration of the CECB is by a Chairman and a Board of directors. General Manager directly reports to board of directors. The two main divisions of the CECB are engineering consultancy and construction unit and a General Manager and an Additional General Manager is responsible for each respectively. They have many deputy general managers for several sections, project managers, and Specialist engineers, engineers, drawing officer, architect and technical assistant. The human resource base of the CECB consist around 700 personnel of whom 60% represent professional and technical grades. These include specialist staff in various disciplines such as architectural, structural, electrical, mechanical, irrigation, land surveying, etc.

Add GM: Additional General Manager EPC DGM SD E&M HP F C TS : Engineer Procure Construct : Deputy General Manager : Structural Design : Electro &Mechanical : Hydro Power : Finance : Contracts : Technical Services

HR: Human Resources WS: Water supply & Sewerage SE: Specialist Engineer PM: Project Manager Mr: Manager AC: Accountant EN: Engineer DO: Drawing officer AD: Administration

B.Koby

Page 2

Industrial Training Report

1.5

Organizational chart

Chairman &board of directors General Manager

Addl GM consult

Addl GM EPC

DGM SD

DGM MSP

DGM E&M

DGM HP

DGM F

DGM C

DGM TS

DGM HR

DGM EPC1

DGM EPC2

SE SD

SE WS

PM

PM

PM

SE C

Mr AD

PM

PM

EN

EN

EN

EN

EN

AC

CD O

AO

AC C

EN

DO

DO

DO

DO

DO

DO

Figure 1.1 organization chart

B.Koby

Page 3

Industrial Training Report

1.6

Projects of central engineering consultancy bureau

There are many projects are going on in Srilanka and also completed several massive projects. These projects indicate their performance in this field. Central engineering consultancy bureau has projects in overseas. Government projects are undertaken by this firm in present. Some completed projects of this firm Administrative complex Sethsiripaya Office Building for Ministry of Religious Affairs (Dahampaya) at Colombo International Buddhist Conference Hall at Kelaniya Head office Premises for National Savings Bank at Colombo Building for the Department of Government Analysis at Battaramulla Building for the Department of Land Commissioner at Battaramulla Dawson Grand Residencies Project at Colombo

Some ongoing projects of this firm Proposed wards &Doctors quarters at chavakacheri Building for the Department of Land Commissioner International Buddhist Conference Hal Vet Hospital University of Peradeniya Nawalapitiya Police Station Uma Oya Survey Works Naula Bus Stand Kaluganga guruwela road E-Courts Building at Galle Oncology complex Batticaloa teaching hospital

B.Koby

Page 4

Industrial Training Report

1.7

Strengths and weaknesses

CECB has extensive in house computer facilities, an excellent technical library, a good stock of survey and drawing instruments, geological and soil investigation equipment, testing laboratories and a large fleet of vehicle and thus is in a position to provide consultancy services and contracting services to major engineering projects island wide at a short notice. There are several regional offices established district wise such as Colombo, Galle, Kandy (Digana), Badulla, Gampaha, Rathnapura, Anurathapura, and Kilinochi. It is easy to manage organization. Since valuable professionals often leave for foreign countries so as to work or follow their higher degrees CECB happened to face loss of effective management team.

1.8

Usefulness to srilankan society

The Bureau is prepared to undertake development challenges in accordance with the changes of social, economical and political situation in the country. CECB has grown and expanded to become the largest Engineering establishment among the public sector organizations of Sri Lanka by way of applying flexible strategies to suit the countrys requirements. They also fulfil their part in educating the civil Engineering students up to a satisfactory level by providing a good training. Therefore in my view, they are doing a great service to our motherland despite the small size of the company. As CECB carries out many building and infrastructure projects in foreign countries it possesses a good name everywhere as a Srilankan company.

B.Koby

Page 5

Industrial Training Report

CHAPTER 02

2. TRAINING EXERIENCE

2.1 INTRODUCTION

I went to CECB head office and joined as a trainee from 01 st of March. As I entered a contract with CECB as a trainee they were doing the Consultancy part of Rehabilitation of Irrigation and Salt water Exclusion Schemes under CARE (Conflict Affected Region Emergency) Project in Northern Province. This project included 17 irrigation schemes and 7 salt water exclusion scheme. I was committed to do Survey of the 4 irrigation schemes out of 17 irrigation schemes. I was in Vavunikulam,Visvamadu,Madawalasingam and Thannimurippu in Mullaitivu district until 24th of April.Since 25th April till 8th of May mainly, I was assigned to the site Construction of wards and Doctors Quarters in Chavakachcheri Base hospital where CECB did the design and build part.From 9th of May till 26th June, I was assigned to the site of construction of court complex and judgers residence at Mallakam. Then I went and involved to the project of rehabilitation of Vavunikkulam scheme head works in Mullaitivu. As far as my training is concerned these are my training places and I am to describe in a wide range about my training experiences in the following chapters.

B.Koby

Page 6

Industrial Training Report

2.2

INTRODUCTION OF THE IRRIGATION PROJECT : Rehabilitation of irrigation and salt exclusion schemes : Northern provincial council : Central engineering consultancy bureau

Project Client Consultant

Our project is rehabilitation of 17 irrigation schemes and 07 salt exclusion schemes in the Northern Province under CARE project. CECB is doing the consulting service in this project. When we joined the training, project was at the initial stage. We did the detail surveying for design purpose. Following stages of the works are in the consulting service. Carry out Participatory Rural Appraisal Walk through Survey Surveying & Leveling Conduct Environmental Assessment Farming up development proposals, design & preparation of drawings Preparation of working drawings and Draft cost estimates Ratification meeting Final cost estimation Environmental Management plan and Social safeguard measures Prepare bidding document

We did the surveying on following tanks

Name of scheme District Beneficiary Area In acres 1 2 3 4 Madawalasingam tank Thannimurippu tank Vavunikulam Visuvamadu tank Mullaitivu Mullaitivu Mullaitivu Mullaitivu 398 2364 6897 808 45.00 235.00 585.00 85.00 Anticipated requirement(Rs.Mn.)

Table 2.1 Details of Surveyed tanks

B.Koby

Page 7

Industrial Training Report

2.2.1 Participatory Rural Appraisal meeting Discuss with water users about the problem encountered by existing condition of tank and structure. And also get the idea about requirement of water users.

2.2.2 Walk through survey The purpose of walk through survey Draw the rough sketch of tank bund, canal. Mark the location of the structures along the bund or canal. Identify the present condition of the structure.

Issue tree was drawn from collection of walk through survey data. Issue tree indicate the existing location of the structures along the canal or bund.

Figure 2.1 A Typical Issue tree

B.Koby

Page 8

Industrial Training Report

2.2.3 Detailed surveying Surveying is a general term that covers any survey work carried out in connection with the construction of an engineering project. Surveying is the technique, profession and science of accurately determining the terrestrial or three-dimensional position of points and the distances and angles between them. We did the detailed surveying for design purpose. We used the Total station for the detailed surveying.

2.2.3.1 Detailed survey on tank bund Detailed survey on tank bund was carried out taking longitudinal sections at approximately every 25m intervals and cross sections at those locations, approximately extending 25m to the upstream side and 20m to the downstream side.

2.2.3.2 Detailed survey on canal Detailed survey on canal was carried out taking longitudinal sections at 25m intervals and cross sections at those locations. Also we took the cross sections at specific locations such as canal bend and specific variation place.

2.2.3.3 Surveying instruments Following instruments were used during the detailed surveying Total station Optical prisms Tripod GPS Measuring tapes Wooden pegs Mallet Pole

B.Koby

Page 9

Industrial Training Report

2.2.3.3.1 Total station A total station is an electronic instrument used in modern surveying. The total station is an electronic theodolite integrated with an electronic distance meter to read slope distances from the instrument to a particular point. Total station is a very advance instrument for survey works now a day. It gives the accurate measurements of coordinates and elevation of a surveyed point with respect to the station orientation.

Figure 2.2 Front view of Total station

B.Koby

Page 10

Industrial Training Report

Figure 2.3 Rear view of Total station 2.2.3.3.2 Prism Prism sits on the pole or tripod and is the target for the eye piece cross hairs in the total station.

Figure 2.4 Prism B.Koby Page 11

Industrial Training Report

2.2.3.3.3 Global positioning system Global positioning system is a worldwide radio-navigation system formed from the constellation of 24 satellites and their ground stations. It is a system mainly used to locate the user's position at a time. Although GPS was originally intended for military applications, but now it is mainly used in marine, location-based services and terrestrial navigation. GPS can work for 24 hours in any type of weather condition, irrespective of sun and rain. The GPS satellite circles the earth twice a day in a precise orbit and transmits signal information to earth. GPS receivers take into this information and use 'triangulation method' to calculate the user's exact location. The meaning of 'triangulation' is receiving radio signals from a distance. Along with knowing the distance, you also need to know exactly the position of the satellites in space. This is done with the help of high orbits and carefully monitoring the instruments for locating the satellites. Finally you also need to correct any type of delays that the signal can experience as it has to travel for a long distance through the atmosphere.

GPS is important as it helps you to figure out where you are and where you are going when you are traveling from one place to another. Navigation and positioning are important but cumbersome activities, which GPS makes it easier. Once GPS locates your position, and then it starts tracing other factors like speed, bearing, tracks, trip distance, distance to destination and several other details.

We did the GPS survey for indentify the location of the tank and also marked the location of structures. It is useful for large area surveying because of positions accurate to 3metres.

B.Koby

Page 12

Industrial Training Report

2.2.3.4 Commencement of survey 2.2.3.4.1 Tripod setup Begin setting up the tripod by spreading the legs and extending/contracting the legs so that the height of the tripod will be suitable for observation when the total station is placed on top of the tripod. Position the tripod directly over the top of a control point, spreading the legs far enough to insure stability. Make sure, by sighting downward through the center screw on the tripod, that the tripod is centered over the control point. Position the tripod shoes firmly on the ground, keeping in mind the need to remain over the top of the control point and that the tripod should remain relatively level.

2.2.3.4.2 Mounting the total station With the tripod in place, carefully remove the total station from its carrying case and place it on the tripod head. Attach the total station to the tripod head loosely by turning the mounting screw clockwise. With the total station still loosely attached to the tripod head; look through the eye piece on the black optical plummet two-in-one knob located on the front side of the total station. Rotate the optical plummet eye piece knob (the smaller of the two-in-one knobs) until the cross hair center mark can be seen clearly. Rotate the focusing knob (the larger of the two-in-one optical plummet eye piece knobs) until the control point on the ground is in focus. Now, slide the total station around on top of the tripod while viewing the control point through the eye piece of the optical plummet. Once the total station is centered over the control point, tighten the tripod mounting screw so that the total station is firmly attached to the tripod.

Note: If you are unable to see the control point through the eye piece, repeat the tripod set up procedure again.

B.Koby

Page 13

Industrial Training Report

2.2.3.4.3 Leveling the total station With the tripod and total station now centered over the top of the control point, adjust the tripod legs by extending/contracting them, to position the bubble of the circular vial located on the tribrach of the total station to the center. DO NOT try to push down on the tripod shoe with your foot to make these adjustments-this may disturb the tripod location. With the tripod now level, release the clamp screw by turning it counter-clockwise until the total station rotates freely. Now check the plate level. Adjust the leveling screws until the bubble is centered. You should always adjust the two leveling screws the spirit level is between at the same time, and always with either both thumbs turning inwards or both thumbs turning outwards. Then turn the level a quarter turn and use the remaining leveling screw to adjust the bubble again. Repeat between these two positions making finer corrections until the level remains centered when the total station is rotated. Check a couple of other directions to be sure the unit is leveled. Check the optical plummet again and if necessary, slide the unit again to center it over the control point. Upon completion of leveling, the "bubble" of the circular vial should still remain in the center. If not, return to step of leveling Total station and check the level again

2.2.3.5 Method of surveying by total station Point B

Point A Point A is our initial point of surveying The total station was set & leveled at point A. Then Point A acted as station point. The station coordinate was entered for station point A Example: N 10000.000 E 10000.000 Z 100.000 B.Koby

Point C

Page 14

Industrial Training Report

Instrument height was measured and entered. The compass was fixed on Total station. Then the station orientation was set by rotating the Total station towards north and horizontal angle set to zero. Prism pole was moved in needed points such as longitudinal sectional points and cross sectional points and readings were taken. When we took reading, prism pole height should be entered in Total station.

Before remove the instrument, the next control point B reading was taken. Example: Coordinate of point B N 9972.564 E 9989.125 Z 99.184

The total station was set and leveled at point B. Then Point B acted as station point and station coordinate was entered for point B. N 9972.564 E 9989.125 Z 99.184

Instrument height was measured and entered. Then point A is entered as Back sight coordinate. N 10000.000 E 10000.000 Z 100.000

Then the prism was set and levelled on tripod at point A and the prism height was measured. Prism at point A was focused and station orientation was set. Then reading A was taken & checked with previous coordinate A. It was done for cross-check. Here variation of 5 mm was allowed. Readings of longitudinal sectional points and cross sectional points were taken. Likewise, we did the detailed surveying by using Total station. When we finished the surveying at a day, we placed the temporary bench mark (TBM). And next day we started continuing from that TBM.

B.Koby

Page 15

Industrial Training Report

2.2.3.6 Temporary bench mark Temporary Bench Marks are often established around the survey site. TBMs are required to be stable. The main site reference is often a steel pin set in a block of concrete but wooden pegs set in concrete with a nail head providing the reference level are often used. During my surveying wooden pegs set in concrete with a nail head was used. It is good practice to establish a number of TBMs around the perimeter of a canal system.

2.2.4 Problem encountered solutions granted As surveying irrigation area was tremendous we didnt close the traverse. But crosscheck was made even after every station point is set. We were in Mullaitivu. Since it is a dangerous place which consists of mines we were afraid of performing our job without annoyance & disturbance. While we found mines on our way of working we informed mines clearance organization & got their help to overcome these issues and then carried out our work.

2.3

IRRIGATION SYSTEMS

When we did the surveying, we got the idea about irrigation systems. An irrigation system is implemented to maximize the usage of water in agricultural development to achieve increased the flood production.

2.3.1 Abbreviations used in irrigation MSL FSL HFL FB BTL FSD Mean See Level Full Supply Level High Flood Level Free Board Bund Top Level Full Supply Depth

2.3.1.1 Mean See Level The altitude of all the points in the land is given with reference to the MSL

B.Koby

Page 16

Industrial Training Report

2.3.1.2 Full Supply Level Generally this is the level at which the storage starts to spill and corresponds to the maximum capacity for the storage. Sometimes the FSL may be set lower than the maximum capacity for dam safety reasons.

2.3.1.3 High Flood Level The maximum water level is higher than full supply level in the water spread area of the tank for storing the water. When the inflow is higher than outflow of water in spillway that time the water could reach the maximum water level. It restricted to store the water up to this maximum water level during rainy days.

2.3.1.4 Free Board The free board is the difference in height between the top of the bund and the maximum water level. If we store water up to free board level, the bund will definitely be damaged because during the rainy season, the soil of the bund might erode.

2.3.1.5 Bund Top Level The Tank bund level is the level of the top of the bund. The Tank bund level is equal to the free board level and is higher than the maximum water level. The height of the tank bund level depends upon the type of the soil, topography or slope of the area, and the depth of the tank.

2.3.1.6 Full Supply Depth The full supply depth is the depth of water in a channel, and it flows at maximum capacity in the channel.

B.Koby

Page 17

Industrial Training Report

2.3.2 Structures in irrigation system

2.3.2.1 Bund Bund is built across the flow and water is served for later usage when it is needed. Unless the foundation of a water retaining structure is carried down to an impervious layer, a steady seepage flow is set up under the deference in head across the structure. Function of each component is as follows

Figure 2.5 Typical section of tank bund 2.3.2.1.1 Rip-Rap Rip-Rap is the production to the embankment material against wave action, velocity of flow, rain wash and wind action.

2.3.2.1.2 Free Board Free Board is the extra precautionary height of the bund above high flood level.

2.3.2.1.3 Clay core wall Clay core wall is provided to arrest seepage below the main bund.

2.3.2.1.4 Turfing Turfing has to be done both slope upstream and downstream. This prevents erosion of slopes of the bund due to heavy rain.

B.Koby

Page 18

Industrial Training Report

2.3.2.1.5 Toe filter Toe filter is provided to prevent moving out of soil particles with seeping water.

2.3.2.1.6 Toe Drain The toe drain provides the path for the seepage water.

2.3.2.2 Sluice A tank sluice consists a pipe running under the bund to convey water from the tank to the main canal with suitable regulating arrangements at the upstream end and stilling arrangements at the downstream end. The size of the pipe is determined by the maximum quantity of water required to convey. It is desirable to use bigger pipes than the theoretically necessary so that the replacement of the sluice will not become necessary when additional command area are taken under the tank.

2.3.2.3 Spillway Spillway is provided in all reservoirs to displace the surplus floodwater from the reservoir after they have been filled to Maximum capacity. Spillway acts as the safety valve. In addition to providing sufficient capacity, the spillway must be hydraulically and structurally adequate and must be located so that spillway discharges will not erode or damage the downstream of the bund. The spillways bounding surfaces must be erosion resistant to withstand the scouring velocities created by the drop from the reservoir surface to the tail water, and usually some device will be required for dissipation of energy of the bottom of drop. The following types of spillways are used in tanks. Natural spill Clear over fall spill Morning glory spill Chute spillway Radial gated spill way

B.Koby

Page 19

Industrial Training Report

2.3.2.4 Drop structures and chutes Drop structures or chutes are required to reduce the bottom slope of canals lying on steeply sloping land in order to avoid high velocity of the flow and risk of erosion. These structures permit the canal to be constructed as a series of relatively flat sections, each at a different elevation. Drop structures take the water abruptly from a higher section of the canal to a lower one. In a chute, the water does not drop freely but is carried through a steep, lined canal section. Chutes are used where there are big differences in the elevation of the canal.

2.3.2.5 Distribution control structures Distribution control structures are required for easy and accurate water distribution within the irrigation system and on the farm.

Division boxes

Division boxes are used to divide or direct the flow of water between two or more canals or ditches. Water enters the box through an opening on one side and flows out through openings on the other sides. These openings are equipped with gates

Turnouts

Turnouts are constructed in the bank of a canal. They divert part of the water from the canal to a smaller one. Turnouts can be concrete structures or pipe structures.

2.3.2.6 Culvert It is often necessary to carry irrigation water across roads. Culverts are used to carry the water across roads. The structure consists of masonry or concrete headwalls at the inlet and outlet connected by a buried pipeline

B.Koby

Page 20

Industrial Training Report

2.3.3 Irrigation canal system The network of waterways, which supplies water from tank to the farms, is known as the irrigation canal system. The canal system contains different types of canals and various methods of control systems. Water is made to flow by gravity only. So proper leveling along the proposed canal is important before construction of irrigation system.

Canal bund width F B FSD Bed Figure 2.6 Typical cross section of canal width 2.3.3.1 Main Canal Main canal commences from the downstream stilling basin of the sluice to carry the irrigation water to the irrigable area.

2.3.3.2 Distributory Canals Distributory canals are introduced in an irrigation system to serve different tracts in the same direction of the main canal. And it takes off from the main canal.

2.3.3.3 Field Canal This the last link in an irrigation canal system and this may take off from main or distributor canal. Water is directly delivered to the farm from field canal.

2.3.3.4 Drainage Canal Drainage canals are provided at the tail end of each field to drain out the excess water from the field.

B.Koby

Page 21

Industrial Training Report

2.4

BUILDING CONSTRUCTION

2.4.1 Project brief Project Funded by Client Executive agency Consultant Contractor Total contract sum Duration : Construction of courts complex & judges residence at Mallakam : Asian Development Bank : Ministry Of Justice : Ministry Of Economic Development : Central Engineering Consultancy Bureau : Daya Construction (Pvt) Ltd : Rs. 175,365,789.49 : 18 months

2.4.2 Setting out of building The first step in building setting out is to identify a base line according to the site layout plan. We established the base line considering the permanent structures and the relevant distances to structural parts from them as given in the drawings. Setting out was done based on the principle of Whole to part. According to this principle the largest possible rectangle of the building was found and set up first. Then it was further divided into small parts completing the major setting out for the building. It is very important that setting out process is done in a horizontal plane. Main instruments involved in this process were Theodolite, Steel and Linen Tapes, Arrows, Wooden pegs, Wire nails and Nylon threads. After establishing the base line, the main rectangle was set up using the pegs and theodolite. Arrows were used as temporary pegs and wooden pegs were driven for permanent pegs .90 angle was taken by the theodolite and Pythagoras rule was also commonly used for the process. When using the Pythagoras rule proper care must be paid to obtain the largest possible combination of triangles for higher accuracy. Steel tape must be used to measure long distances and it must be tightly stretched when taking the readings.

B.Koby

Page 22

Industrial Training Report

Wooden pegs atop by a wire nail were driven to establish the grid lines of the building. These pegs were driven at places such that they wont be disturbed by field work etc. Usually they were driven with a distance of 1.5 meter from the grid line.

The diagonals of the main rectangle were checked to determine its accuracy. Accurately set up main rectangle was then subdivided to obtain the consisting gridlines. These were obtained by the using structural drawings, Theodolite and steel tape. Nylon threads are stretched between the pegs to obtain the gridlines when necessary.

2.4.2.1 Problem encountered and solution granted Since baseline peg was nearer to the footing excavation, setting out was too difficult by using theodolite. Then that peg was changed to a suitable place by using the theodolite. 2.4.3 Excavation After finishing the initial setting out, excavation was carried out both manually as well as mechanically. Excavation was done 6 inches more than the actual size of the foundation each side to provide working space. The excavated soil was transported away from there by frontend loader. The soil was stored at the site for backfilling work. The foundations shall be placed at a minimum depth of 900mm below existing ground level according to the design requirements Time consuming for excavation is lesser than manual excavation. If you understand how to operate the machine better you will increase the safety of using the machine and you will be more efficient at your job. This machine removes all sorts of things like unwanted tree stumps and roots.

2.4.3.1 Problem encountered and solution granted In Mallakam court complex site, while excavating pits we found skeletons in a pit. Then we stopped working and contacted with ministry of justice. We didnt work further at the pit until the investigation over in connection with the affair.

B.Koby

Page 23

Industrial Training Report

2.4.4 Screed concrete The purpose of screed concrete is to maintain the proper cover for the foundation. After the process of excavation, pit bottom was leveled and covered with polythene. This polythene prevents the water in concrete infiltrate in to the ground. Then the concrete was poured and leveled to 2 inches thickness with the help of 2*2 timber. The grade 15 (cement: fine aggregate: coarse aggregate=1:3:6) concrete was used for screed. No compaction was done for screed concreting.

2.4.5 Reinforcement Concrete is high compressive strength and low resistance to tension. Its tensile strength is approximately one-tenth of its compressive strength. Consequently, tensile reinforcement has to be provided to supplement the tensile strength of the reinforced concrete section. Steel and concrete can be used in combination because: Concrete and reinforcement can work together because there is a sufficiently strong bond between the two materials. There are no relative movements of the bars and the surrounding concrete before cracking. Concrete and steel expand and contract at the same rate under temperature changes.

2.4.5.1 Reinforcement details Reinforcement is very important in the field of the construction. So it should be exactly as specified in the given structural drawings. Each bar of reinforcement has a definite force to resist and it can only fulfill its function if it is in its correct position. It is important to be aware of the different types of reinforcing steel, how to identify them and where to use them.

2.4.5.1.1 Type of steel

2.4.5.1.1.1 Tor steel

T or Y denotes steel, which has a ribbed appearance and may be twisted. This is used to be known as high tensile steel, which is called as tor steel or yield steel. In our site we used 10mm, 12mm, 16mm, 20mm and 25mm diameter bars. For all reinforcement work tor steel was used and its strength is 460N/mm2.

B.Koby

Page 24

Industrial Training Report

2.4.5.1.1.2 Mild steel

In schedules, R for round is mild steel in the form of plain smooth bars. This can be easily cut and bend. In addition, its strength is 250N/mm2. Therefore, it is mostly used for column stirrups and beam stirrups. In our site the 6 and 10 mm diameters bars were used.

2.4.5.1.2 Bar notation Reinforcement on details drawings is described by a coding system to simplify preparation and reading of the details. For example: - 9T10-08-15B1 9 T 10 08 150 B1 - No of bars - Type of steel (T-tor steel & R-Mild steel) - Bar diameter in mm - Bar mark - Spacing - Bottom (position)

Abbreviations used B1 B2 T1 T2 - Bottom reinforcement - Distribution bars in bottom net - Top reinforcement - Distribution bars in top net

2.4.5.1.3 Weight of steel bar 1m tor steel weight is calculated approximately below the equation. Weight = diameter / 162.162 Where, Diameter is in mm Weight is in kg/m

B.Koby

Page 25

Industrial Training Report

Diameter(mm) Weight (kg/m) 6 10 12 16 20 25 0.222 0.616 0.888 1.579 2.467 3.854

Table 2.2 Steel bar weights per meter 2.4.5.1.4 Bar bending schedule The bar bending schedule is used to economics the steel usage and to reduce the wastage according to the drawings the site engineer calculate the number of bar needed. Then tabulate value is given to the bar bender then they can bend the required amount of reinforcement.

2.4.5.1.5 Bending the bar In my site manual bending is done by fixing nails to a stationary frame at required spacing bars are bent by applying power to the bar. This is used to bent bars smaller than 16mm diameter. The bending of R6 is done with this. The accuracy of the angles bent is low. Column main bars and footings bars were bended by machine according to the bar schedule.

2.4.5.1.6 Fabrication of reinforcement work Reinforcement must be securely fined in the formwork so that the bars tire not displaced by workers walking on them or by the placement of concrete. It is essential for the safety of a structure to ensure that the correct size, shape and grade of reinforcement is used, and that the reinforcement is fixed accurately and securely in the position specified.

B.Koby

Page 26

Industrial Training Report

Important checks, during the reinforcement work are: Number of bars Diameter of bars Lap length Crank length Spacing between the stirrups Check whether spaces of each reinforcement bar were in correct or not. Binding should be tightened properly. Covering should be maintained. In the case of double net, stools are used between the two nets to get required space between them.

2.4.5.1.6.1 Lapping of two bars

According to the design, lap length is 45* for tension 36* for compression

But in our site we used 50 * for both tension and compression lap length. where is bar diameter. Example:T12 Lap Lap length T12 Figure 2.7 Lapping of bars

(1)

Lapping length = 50 * = 50* 12 = 600 mm

B.Koby

Page 27

Industrial Training Report

(2) T20 Lap Lap length T1 6 Lapping length =50 * = 50* 16 (small bar diameter) = 800 mm

2.4.5.1.6.2 Crank of bar

Figure 2.8 Lapping of bars

Y X Figure 2.9 Crank of bar X: Y =10:1 In column bar schedule, crank is important. The slope of the inclined portion of a cranked bar should be 1 in 10. Crank the upper bars to extend the lowest bars. Example: - column bar diameter 16 mm

crank Figure 2.10Crank of bar

crank length=10*16=160 mm

2.4.5.1.6.3 Stirrups In our site we used mild steel and tor steel for the stirrups. Stirrups are used to bear the shear force and holding the reinforcement bars in same position. All bars in compression should be tied by a link passing around the bar in such away that it tends to move the bar towards the centre of the column.

B.Koby

Page 28

Industrial Training Report

Main Binder Main bar bar Binde r Column with 4 main bars Column with 6 main bars

Column with 8 main bars Figure 2.11 Stirrups for columns

2.4.5.1.6.4 Stools Stool is necessary in slab reinforcement work. Stools are used to separate the top reinforcement mesh and bottom reinforcement mesh. Those should strength enough to bear the load without changing the gap of two layers. 12 mm or 16 mm bars are used to make the stools.

Stool height

Figure 2.12 Stool

Stool height = slab thickness - (top (main bar diameter +distribution bar diameter) + bottom (main bar diameter + distribution bar diameter) + (bottom cover + top cover)) B.Koby Page 29

Industrial Training Report

2.4.5.1.7 Footing reinforcement arrangement The footing is the most important of the structures which is used to transmit and distribute the load from the structure to the ground. This must be accomplished without exceeding the bearing capacity of the soil beneath the foundation and the settlement and particularly settlement must be kept within reasonable limit. There are different sizes of individual pad footings in my site. Many of pad footings are square. Pad foundation which is intended for sustaining concentrated loads from a single point load such as structural columns. The size and shape of a footing depend upon the design of the structure. .

Type F1 F2 F3 F4 F5 F6 F7 Size (mm) 900*900 1200*1200 1400*1400 1600*1600 1700*1700 1800*1800 2100*2100 Height (mm) 200 225 250 275 300 325 375 Reinforcement T10@125 T10@150 T12@175 T12@175 T12@150 T12@150 T16@225

Table 2.3 Footing sizes and reinforcement details

Section view

Plan view Figure 2.13 Typical pad footing

B.Koby

Page 30

Industrial Training Report

2.4.5.1.8 Column reinforcement arrangement A column is a slender, vertical member that carries a superimposed load. Concrete columns, especially those subjected to bending stresses, must always be reinforced with steel. Column is the most critical element of a structure since it bares all the loads and it transfers to the foundation. If a column fails in its service or as an element, there is a threat that the whole structure may be in a situation to collapse. Therefore it is important to fix the column reinforcements in the correct position to minimize any eccentricity of loads or any defect. The starter bars of the columns were fixed during the footing reinforcement work. The position of the column was marked by setting out. The bars were fixed by referring the structural drawings. The shear links were fixed at correct spacing. The 50mm cover block was used up to first floor and 25mm cover block was used thereafter. A minimum main bar diameter is 12 mm. square and rectangular shaped columns are used in my site.

Figure 2.14 Typical column

B.Koby

Page 31

Industrial Training Report

2.4.5.1.9 Floating reinforcement arrangement A column is supposed to be a vertical member starting from foundation level and transferring the load to the ground. The term floating column is also a vertical element which ends at its lower level rests on a beam which is a horizontal member.

2.4.5.1.10 Slab reinforcement arrangement When rebar arrange for slab, main bars and distribution bar should be considered. Normally smallest span bars are main bars and longest span bars are distribution bars, it depends on the load transfer. In bottom, main bars should be below the distribution bars. In top, main bars should be above the distribution bar. TOP Main bar distribution bar

Main bar

distribution

BOTTOM Figure 2.15 Bar arrangement in slab

2.4.6 Form work Formwork must be strong enough to bear the force during placing and compaction of the concreting. The formwork must be without deformation. Therefore supports must be provided at proper interval. Further for vertical structures verticality must be maintained. For horizontal structure level must be maintained. In my site timber was used as formwork for footing. It must be accurately set out. Concrete being a fluid when placed, it will take up the shape of the form work which must therefore be of the correct shape, size and in the right position.

B.Koby

Page 32

Industrial Training Report

2.4.7 Cover block Purpose of cover block To maintain the space between shuttering and outer reinforcement because of prevent the reinforcement from corrosion and increase the fire resistance. The size of Cover depend on Weather condition Fire resistance Grade of concrete Cover block strength Cover block strength should be more than or same grade of concrete. Cover block casting Mixing ratio (cement: sand: chips) = 1: 1.5:3 A part of binding wire was placed inside the cover block when casting. Cover block can be used after 28 days from casting day.

Item Water retaining structures Roof slab top Columns up to DPC Figure 2.16 Cover block Beams, columns above DPC

Cover

50 mm

cover

50mm 50 mm 25 mm

Table 2.4 Required cover for structures

B.Koby

Page 33

Industrial Training Report

2.4.8 Concrete Concrete is widely used in domestic, commercial, recreational, rural and educational construction. It is a durable material provided it is designed, specified and constructed properly. Concrete is a mixture of cement, sand, aggregates and water. The proportions of those materials and admixtures decide the strength and quality. In my site ordinary Portland cement, river sand and 20mm coarse aggregate were used to prepare the concrete. Some time admixtures are added to the concrete. Use of admixtures offers certain beneficial effects to concrete, including improved quality, acceleration or retardation of setting time, control of strength development and improved workability. There are three factors that should be taken into consideration when preparing and using the concrete, as follows. Quality

Quality of concrete is measured by its strength and durability. The principal factors affecting the strength of concrete are w/c (water: cement) ratio, using good quality aggregates. It is better to use the concrete quickly as soon as possible after mixing. The using time should not exceed the setting time of the concrete. Durability of concrete is the ability of the concrete to resist disintegration due to the freezing, thawing and chemical attacks. Workability

Workability means how easy it is to place, handle, compact and finish a concrete mix. Concrete that is stiff or dry may be difficult to Handle, Place, Compact, and Finish and, if not constructed properly, will not be as strong or durable when finally hardened. A slump test can be used to measure the workability of concrete. Economy

Economical of concrete depend on effective use of materials, effective operation and ease of handling. The cost of producing good quality concrete is an important consideration in the overall cost of the project. Therefore good concrete should have high quality, required workability and be economical.

B.Koby

Page 34

Industrial Training Report

2.4.8.1 Grade of concrete The grade of concrete is very important for strength and durability of reinforced concrete structures. Although strength and durability of concrete are inter-related, it is not always true that high strength concrete has high durability. This is because, the durability depends on the porosity of concrete rather than strength. As far as the reinforced concrete water retaining structures are concerned, the durability requirements are more demanding because concrete is subjected to more severe environmental conditions in those structures. Because of this reason, higher grade of concrete is normally specified for reinforced concrete water retaining structures. Grade 15, Grade 20 and Grade25 are used in our site.

Grade of concrete

Mixing ratio of (cement : sand : aggregate)

Application

Grade 15 Grade 20 Grade 25

1: 3 : 6 1 : 2 :4 1 : 1.5 :3

screed concrete, floor concrete lintels, sills column, beam, footing

Table 2.5 Grade of concrete

2.4.8.2 Mixing concrete The mixing could be done manually or by machine. The proportioning of the mix may be done by either volume or weight. But in my site mixing of concrete was done according the volume.

2.4.8.2.1 Hand mixing Hand mixing concrete would not be as uniform as when mixed by machine. For easiness of

mixing, it may be necessary to add a little bit more water than that which has been recommended. The mixing is done on a clean floor, which is nonporous or on a mixing board. First, the fine aggregate was spread on board and then cement was added on top of it. They were then mixed thoroughly by using shovel. The coarse aggregate was then spread over and whole in-gradients mixed thoroughly. The heap of material could be constantly turned over by a shovel while the water was being added.

B.Koby

Page 35

Industrial Training Report

2.4.8.2.2 Machine mixing Machine mixing is uniform if the mixing is done properly. For this machine mixing is faster and better than hand mixing. Cement and the aggregates were fed in to the mixture simultaneously. At the mean time water was added to the mixture. Mixing was continued until the concrete is uniform consistency and colour.

2.4.8.3 Compaction of concrete Compaction is removing the air from concrete. Proper compaction results in concrete with an increased density which is stronger and more durable.A vibration to the concrete will remove the voids. For small scale concrete tampering is enough. But for large scale concrete, using a vibrator is essential. Normally a poker vibrator is used to vibrate the concrete and compact it. Voids reduce the contact between the concrete and the reinforcement and other embedded metals. The required bond will not be achieved then and the reinforced member will not be as strong as it should be. Voids also increase the permeability which in turn reduces the durability and strength. A poor compaction will produce honey combs on the surface of the concrete element, which directly opens the reinforcement to the air and water which accelerates the corrosion process. Therefore concrete should be thoroughly compacted using the poker when the concrete is laid. Especially highly reinforced areas and corners should be thoroughly compacted using the poker, in order to make free from voids. Compaction must be done as concrete is placed, while it is still plastic. Never let concrete dry out and stiffen because it will be too hard to compact.

2.4.8.4 Poker vibrator In my site poker vibrator was used to compact the concrete. When the concrete was vibrated using the poker continuously, air bubbles rise up to the surface of the concrete and freed.

When the air was fully compacted, the rising of the air bubbles stopped and this could be used as an indicator of full compaction. The area of concrete being compacted by poker vibrator at once is called radius of action. For concrete of average workability (i.e. slump of

B.Koby

Page 36

Industrial Training Report

80 mm) with a poker size between 2575 mm, concrete should usually be vibrated for between 5 and 15 seconds. Some Precautions for using poker vibrator Poker must be applied vertically Make sure there are enough workers so some can compact while others continue to place. Always compact in a definite pattern so the radius of action overlaps and covers the whole area of the concrete The poker should be long enough to reach and enter into the layers of concrete under the one being compacted Taking the poker out too quickly will leave a hole in the concrete. To close the hole, vibrate near the hole and take the poker out very slowly Never touch the form face with the poker as it can damage the formwork and the concrete Never touch the reinforcement with the poker Never spread or move concrete sideways with the poker, always use a shovel

2.4.8.5 Curing When water is added to cement chemical reaction takes place (Hydration of cement), which results setting and hardening of cement. Mixing water is usually sufficient for the initial hydration of cement. If however, there is insufficient water in the concrete during its setting period, concrete cant develop its full strength. When concrete is laid, its water content is rapidly loss, if insufficient precautions are not taken. This is due to evaporation occurs in the action of sun, wind and heat generated during setting of cement. The prevention of such process is known as CURING. But in sites normally curing will be done for 10 14 days. This is sufficient for concrete to reach the required strength. If proper curing is not taken place, there will be shrinkage initially and it will lead to cracks. There are two methods of curing is available. One is supplying moisture to concrete and the other is preventing moisture from concrete. But in our site we normally used the first method and also used sacks for prevent the moisture from concrete. The curing was done for 7 days. B.Koby Page 37

Industrial Training Report

2.4.8.6 Slump test This test was done to make sure the concrete mix is workable. When the slump is less, the workability is less and when the slump is more workability is more. Even though workability depends on grade and size of aggregates it also depends on the ratio of coarse aggregates to fine aggregates quantity of water efficiency of mixing quantity of concrete

The slump was checked for each truck of concrete in my site. The sample was taken from the truck and brought to the place where test was done by wheel borrow. The following tools were used for the slump test, Standard slump cone (100 mm top diameter x 200 mm bottom diameter x 300 mm high) Small scoop Rod (600 mm long x 16 mm diameter) Ruler Slump plate (500 mm x 500 mm)

Procedure for the slump test The cone and the base plate were cleaned and cone was wetted with water The cone was kept on the base plate and hold under the legs by standing on foot pieces 1/3 volume of the cone was filled with the concrete sample and compacted 25 times using rod and then Next 1/3 volume also filled and compacted as above The final 1/3 volume was filled just above the top and compacted 25 times using rod The surface was levelled by rolling the rod at the top of cone and concrete was removed in the base plate. The legs were taken off from the foot pieces and cone was lifted vertically upward by holding handles The cone was turned upside down and the rod was placed across the up turned cone The average height between rod and top of the concrete was measured using rule Page 38

B.Koby

Industrial Training Report

Figure 2.17 Slump test According to how the concrete locates after slump test, there are three types of slumps,

Figure 2.18 Types of slump 2.4.8.7 Cube test Cube test is essential for take the decision about strength of the concrete. Standard cube size is 150 x 150 x150 mm. The following tools were used for the cube test, 150 x150 x 150 mm size steel cube moulds and base plates standard steel bar mould oil scraper

Procedure for the cube test First the cube moulds were cleaned and oil was applied to inner surface of mould. The cube moulds were filled by randomly selected sample of fresh concrete. When filling the mould initial 1/3 of mould (1st layer) was filled and 35 blows were applied by the standard rod. Likewise balance two layers were filled the blows applied evenly. Then the top mould was smoothed by trowel and excess concrete was removed by using scrapper. Then the cubes were kept in safety place for drying without disturbance. After 24 hours the moulds were removed carefully and then cubes were soaked into water for curing. After 7 and 28 days cubes were tested using compression testing. Page 39

B.Koby

Industrial Training Report

2.4.9 Problems encountered and solutions granted The voids and gaps were not closed during the inspection. This will cause grout leakage. We closed the voids by using sponge. In some places cover between formwork and link was not enough. We kept the cover block there. The cover blocks were not enough in the roof slab due to this the net sagged. We kept enough cover blocks to prevent that problem.

2.5

RENOVATION OF IRRIGATION QUARTERS

Renovation of irrigation quarters is also under project of rehabilitation of Vavunikkulam scheme head works in Mullaitivu. Brick masonry, floor concrete and roof frame works were done in irrigation quarters.

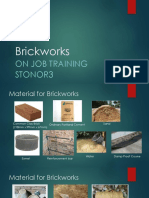

2.5.1 Brick masonry Brick masonry was done in renovation of irrigation quarters. Normal size of brick 21510265mm is called work size. The usual size of a brick is such that with one mortar joint to each face the combination shall be 22511275mm. Before it is used for construction it should be put into the water at least one hour. If they are not put into water the bricks would absorb water from cement mixture and this would reduce in hydration reaction in cement and reduce the strength of walls. The strength of a brick masonry structure depends on the type and uniformity of the individual bricks selected, as well as the style of masonry used. In my site English bond was used for one brick thickness wall. This consists of alternate courses of headers and stretchers. . The existing wall top was chipped and washed before laying bricks.

Figure 2.19 English bond B.Koby Page 40

Industrial Training Report

2.5.1.1 Mortar for brick masonry Mortar is a combination of cement, sand and water. Mortar was generally mixed on volume basis with the help of a gauge box. In my site mixing was done by manually and using a tilting drum. Mortar ratio is 1:5 (cement: sand) for brick works.

2.5.2 Floor concrete After packing of rubble, bottom level was measured after that top level was marked in wall by using level instrument. Before the concreting, water was spread over the pacing rubble. Floor concrete was poured to thickness 75 mm. Grade 15 (1:3:6)/40 mm aggregate size concrete was used for floor concrete.

2.5.3 Roof frame work Roof frame work was carried out for Calicut tile roof. All the members of roof frame were timber. Our roof pitch was 30 o. Calicut tile roof rafter spacing is 450mm and reaper spacing is 300mm.

Item Ridge plate Timber purlin Wall plate Rafter Reaper Size 175mm 50mm 200mm 100mm 100mm 75mm 100mm 50mm 50mm 25mm

Table 2.6 Roof member sizes

B.Koby

Page 41

Industrial Training Report

2.6

REHABILITATION OF HEAD WORKS : Rehabilitation of Vavunikulam scheme head works in Mullaitivu : Irrigation department : Central engineering consultancy bureau : M/S Sun construction : Rs.240 000 000.00

Project Client Consultant Contractor Total contract sum

2.6.1 Bund construction As I joined the project it was at the initial stage of process. We made site clearance of jungle and marked toe line. We took joint level off before stripping Join level is taken by the both the contracting and consulting parties in order to calculate actual quantity of filling materials. Approval was taken for the purpose of removing trees. Removing top soil of 75mm thickness by dozer All debris and stumps were removed out site and burned to ashes Filling material (soil) was brought to the site from approved borrow area Borrow area its an area where appropriate material is taken out, where it won't be missed, and used as what is called "fill" to build up a new area. Borrowed area should have good moisture content and shouldnt have roots of trees. Soil was compacted after every filling of the thickness of 300 mm.

B.Koby

Page 42

Industrial Training Report

2.6.1.1 Compaction of soil Soil compaction is defined as the method of mechanically increasing the density of soil. If performed improperly, settlement of the soil could occur and result in unnecessary maintenance costs or structure failure. There are some reasons to compact soil Increases load bearing capacity Prevents soil settlement Provides stability Reduces the water seepage, swelling and contraction

2.6.1.2 Trail compaction test The purpose of trail compaction test is to get number of roller passes required. We used core cutter method to find field density of the soil. Join level was taken after stripping Setting out was done for mark the toe line, and 50m direction parallel to the dam axis. Existing surface was compacted by sheep foot roller. Selected borrow soil was transported to place of trail compaction. Roots and stumps were removed. Then soil was spread and levelled to 300mm thickness with the help of driven pegs. After spreading the soil sheep foot roller was driven in direction parallel to the dam axis. Core cutter test was carried out after 7 passes, 8 passes and 9 passes of roller.

4m area was selected in

Figure 2.20 Trial compaction B.Koby Page 43

Industrial Training Report

2.6.1.2.1 Field density test by core cutter method After the compaction of each layer the density achieved in the field should be determined. In the site core cutter method can be done to determine the density of the compacted fill material. The apparatus needed for this test is a. Cylindrical core cutter b. Steel dolly c. Steel rammer d. Balance, with an accuracy of 1g e. Straightedge f. Square metal tray 300mm x 300mm x 40mm g. Trowel

2.6.1.2.1.1 Procedure for core cutter method After the compaction a small area, approximately 30cm square of the soil layer was leveled for test. The steel dolly was placed on top of the cutter and the latter was rammed down vertically into the soil layer until only about 15mm of the dolly just above the surface. Then the cutter was dug out of the surrounding soil, care being taken to allow some soil to project from the lower end of the cutter. The end of the soil core was trimmed flat in level with the ends of the cutter by means of the straightedge. The cutter containing the soil core was weighed. The soil core was removed from the cutter and a representative sample was placed in an air-tight container and its water content (w)

B.Koby

Page 44

Industrial Training Report

2.6.1.2.1.2 Calculations Weight of container Weight of container +wet soil Weight of container + dry soil Weight of wet soil Weight of dry soil Weight of water Moisture content = m1 = m2 = m3 = m2 - m1 = m3 - m1 = m2 - m3 = (m2-m3)/ (m3-m1) =w Weight of core cutter Volume of cutter Weight of core cutter + soil Weight of soil Bulk density of soil ( ) Moisture content Dry density of the soil (d ) = W1 =V = W2 = W2 W1 = (W2 W1)/V =w =

B.Koby

Page 45

Industrial Training Report

Dry density

Max density

Optimum moisture content

Moisture content

Figure 2.21 Dry density VS Moisture content graph From this degree of compaction can be calculated Degree of Compaction = Dry Density of the Excavated soil *100 Maximum Dry Density 2.6.2 Spillway construction Spill construction has to finish as soon as possible before starting the rainy season. After bund construction spillway height can be raised from existing level of spill. Vavunikulam tank spill length is 200m. Setting out was done for excavation. Excavation was carried out by excavator. Screed concrete was placed thickness 50mm. Reinforcement cover was kept 50mm because it is water retaining structure. Extension of spill with single reinforcement net because of the spill connects with existing spill.

Figure 2.22 Construction of spill B.Koby Page 46

Industrial Training Report

2.7

SAFETY ASPECTS AT THE SITE

Construction is a relatively hazardous undertaking. There are significantly more injuries and lost workdays due to injuries or illnesses in construction than in virtually any other industry. These work related injuries and illnesses are exceedingly costly. Therefore We should have some considerations on safety aspects.

2.7.1 Managing site access to protect the public There is a need to define boundaries physically, where necessary, by suitable fencing. The type of fencing should reflect the nature of the site and its surroundings. All construction sites require : Measures to manage access through defined boundaries; and Steps to exclude unauthorized people.

2.7.2 Site welfare The nature and scale of facilities required will depend on the size, location and type of project. Facilities include: Toilets Washing facilities Drinking water Changing rooms and lockers Facilities for rest

Everyone who works on any site must have: access to adequate toilet and washing facilities; a place for preparing and consuming refreshments; and Somewhere for storing and drying clothing and personal protective equipment.

These facilities can be provided at a central location accessible within a reasonable distance or time.

B.Koby

Page 47

Industrial Training Report

2.7.3 Noise and vibration Regular, frequent exposure to loud noise can permanently damage a persons hearing. Noise can also create a safety risk if it makes it difficult for workers to communicate effectively or stops them hearing warning signals. Vibrating hand tools used in compaction can cause handarm vibration syndrome (HAVS).Workers exposure to vibration need to be assessed and managed. 2.7.4 Falls from height During demolition and dismantling, workers can be injured falling from edges, through openings, fragile surfaces and partially demolished floors. Duty holders have a responsibility to assess, eliminate and control the risks of falls from height. Find out more about falls from height.

2.7.5 Injury from falling materials Workers and passers-by can be injured by the premature and uncontrolled collapse of structures, and by flying debris. A safe system of work is one that keeps people as far as possible from the risks. This may include: establishing exclusion zones and hard-hat areas, clearly marked and with barriers or hoardings if necessary covered walkways using high-reach machines reinforcing machine cabs so that drivers are not injured training and supervising site workers

2.7.6 Safety aspects in my site In my site there were safety measures for workers, their health and for the site. Following were some of such measures for workers in my site. Safety helmets were worn in working premises. Different colours were used to identify the people. yellow was used by labours, white was used by Engineers and technical officers . Safety boots were worn during concreting Page 48

B.Koby

Industrial Training Report

Appropriate gloves for workers those who worked in reinforcement, concrete and cleaning

Above measures were for the individual safety of the each worker. For the safety as whole, following steps were taken. Barrier tapes were tied surrounding areas with higher degree of accidents Safety net was provided around the building to prevent dust and debris to neighbour houses and safe the people from fallen things Safe electricity supply with main switch boards and trip switches Lights were provided when working in less light Signboards displaying safety hints

2.8

MACHINERY USED AT THE SITE

Some machinery used in our site, were Excavator, front end loader, dozer, Concrete truck mixer, Soil compactor, Poker Vibrator and Below I have attached some details of some of the machineries that were used in our site.

2.8.1 Excavator Excavators are heavy construction equipment consisting of a boom, stick, bucket and cab on a rotating platform. The house sits atop an undercarriage with tracks or wheels. A cableoperated excavator uses winches and steel ropes to accomplish the movements. Fuel consumption is 16-18 litres per hour. Excavators are used in many ways: Digging of trenches, holes, foundations Material handling Brush cutting with hydraulic attachments Forestry work Demolition General grading/landscaping Heavy lift, e.g. lifting and placing of pipes Mining, especially, but not only open-pit mining River dredging Page 49

B.Koby

Industrial Training Report

2.8.2 Dozer A bulldozer is a equipped with a substantial metal plate used to push large quantities of soil, sand, rubble, etc., during construction work and typically equipped at the rear with a clawlike device to loosen densely-compacted materials. Bulldozers can be found on a wide range of sites, mines and quarries, military bases, heavy industry factories, engineering projects and in farming. The bulldozer blade is a heavy metal plate on the front of the tractor, used to push objects, and shoving sand, soil and debris. Dozer blades usually come in three varieties: A straight blade ("S blade") which is short and has no lateral curve and no side wings and can be used for fine grading. A universal blade ("U blade") which is tall and very curved, and has large side wings to carry more material.

2.8.3 Sheep foot roller Rollers are also used in landfill compaction. Such compactors typically have knobbed ("sheeps-foot") wheels, and do not achieve a smooth surface. The knobs aid in compression due to the smaller area contacting the ground.

2.8.4 Tipper A tipper is a truck used for transporting loose material such as sand, gravel, or dirt for construction. A typical dump truck is equipped with a hydraulically operated open-box bed hinged at the rear, the front of which can be lifted up to allow the contents to be deposited on the ground behind the truck at the site of delivery.

2.8.5 Concrete Truck Mixer These are used to transport the mixed concrete from the batching plant to the site and the final mixing is done using the mixer. Concrete is contained in a barrel/drum at the back of the vehicle and rotates at a speed of 1- 2rpm while transporting. While the concrete is discharged, this is accelerated and the drum rotates at a higher speed of about 10 15 rpm. The drum is cleaned after the unloading of concrete. Truck mixer used at our site had a capacity of 2 m3. The discharge of concrete could be easily controlled by the operator and B.Koby Page 50

Industrial Training Report

this makes it very easy to lay the concrete in the formwork in required quantities at the required time. 2.8.6 Poker Vibrator Petrol driven porker was used in our site. The pokers were in the diameter of 75mm and 50mm. The purpose of the Poker vibrator is to compact the concrete. 2.8.7 Concrete mixer A concrete mixer is a device that uniformly combines cement, aggregate such as sand, and water to form concrete. A typical concrete mixer uses a revolving drum to mix the components. For smaller volume works portable concrete mixers are often used so that the concrete can be made at the construction site, giving the workers full time to use the concrete before it hardens.

B.Koby

Page 51

Industrial Training Report

CHAPTER 03

3. CONCLUSION

Training is a process in order to change a human being's attitude, knowledge, skills and behaviour. The training opportunity given to us in construction establishment was very much significant, appreciable and helpful to understand the actual performance, practice and procedures of an industrial civil engineer. It provided me a unique opportunity to visualize and understand the organization structure, responsibilities of each management and other professional, who are specialist in their particular field. Experience gathered & problems encountered enabled me to answer to several questions arisen in academic knowledge without which a professional carrier would be incomplete. Actually, there is a slight difference between the actual performance & procedure that a civil engineer in the industry follow and carry out and the learning from our academic lecture. This is actually because of situation and the practical involvements differ from the industry. As I gathered some experience in this training, better way of solving any practical problems goes away with the experience, the civil engineer should develop their own art to contribute their maximum, and the Department of civil engineering has a crucial task to perform which is to produce tactical civil engineer to the Industry. With construction industry becoming more competitive it is necessary to improve in a structured way in order to manage & handle other people in the industry. The valuable chance provided to them should be utilized to the maximum by showing their punctuality, involvement, dedication, exactness & concentration in whatever the work given to them & to get adapted to their organizational culture, where their attitude should be on learning rather than expecting everything from their superiors. Even though the work given lacked value or diversity, steps should be taken on their own initiative to obtain better results. This would create a good impression about him & the educational centre where he was educated. Also depending on the potential of the student there are high possibilities to recruit them to their organization once he got pass out from the university. Also as they return back to the

B.Koby

Page 52

Industrial Training Report

university they are considered as matured under graduates having good personality skills & positive attitudes. A special fact that I should mention is that I found the workshop really encouraging and useful. It did put the base foundation to my training session. So my suggestion is the workshops should not be limited to only one day in the future, at least it should be provided for a week. Another suggestion I would like to make is that if possible the department should take measures to evaluate each students training monthly. Therefore, the training evaluation should be done during the training session and not after the training session since no lecturer would be able to give what the student missed during the training session. This training process is a rectangular one, which has four corners. That is the student, University, training firm and NAITA. Though each and every student has a similar base in training, the experience he gets is depended is upon his personal commitment towards the job. During the training sessions, I also learnt how to more with people so that they get a favourable image on you. So I think these collaboration and interaction skills will greatly help me when I pass out and practice as a professional civil engineer.

I personally think that a person should get a favorable first impression on whatever job he does. Otherwise, he will be frustrated easily. Therefore, this training experience has moved my objectives to great heights. In addition, I sincerely pray that I will be able to serve mother Lanka as a professional Finally to conclude my report, I would like to say that the Industrial training had a great influence towards our academic knowledge not only to get the practical and technical knowledge but we had a chance of being familiar with the construction industry before going to the Industry as professionally qualified civil engineer.

B.Koby

Page 53

Industrial Training Report

CONTENTS

CHAPTER 01 ....................................................................................................................... 1 1. INTRODUCTION TO THE TRAINING ESTABLISHMENT ...................................... 1 1.1 1.2 1.3 1.4 1.5 1.6 1.7 1.8 Organization overview ........................................................................................... 1 General Profile of Central Engineering Consultancy Bureau .................................. 1 Main functions ....................................................................................................... 2 Organization structure............................................................................................ 2 Organizational chart ............................................................................................... 3 Projects of central engineering consultancy bureau ................................................ 4 Strengths and weaknesses ...................................................................................... 5 Usefulness to srilankan society .............................................................................. 5

CHAPTER 02 ....................................................................................................................... 6 2. TRAINING EXERIENCE ............................................................................................. 6 2.1 2.2 INTRODUCTION ................................................................................................. 6 INTRODUCTION OF THE IRRIGATION PROJECT .......................................... 7

2.2.1 Participatory Rural Appraisal meeting ................................................................ 8 2.2.2 Walk through survey .......................................................................................... 8 2.2.3 Detailed surveying ............................................................................................. 9 2.2.3.1 2.2.3.2 2.2.3.3 Detailed survey on tank bund .................................................................... 9 Detailed survey on canal ........................................................................... 9 Surveying instruments............................................................................... 9

2.2.3.3.1 Total station ........................................................................................ 10 2.2.3.3.2 Prism .................................................................................................. 11 2.2.3.3.3 Global positioning system ................................................................... 12 B.Koby Page 54

Industrial Training Report

2.2.3.4

Commencement of survey ....................................................................... 13

2.2.3.4.1 Tripod setup........................................................................................ 13 2.2.3.4.2 Mounting the total station ................................................................... 13 2.2.3.4.3 Leveling the total station ..................................................................... 14 2.2.3.5 2.2.3.6 Method of surveying by total station ....................................................... 14 Temporary bench mark ........................................................................... 16

2.2.4 Problem encountered solutions granted ............................................................ 16 2.3 IRRIGATION SYSTEMS ................................................................................... 16

2.3.1 Abbreviations used in irrigation ....................................................................... 16 2.3.1.1 2.3.1.2 2.3.1.3 2.3.1.4 2.3.1.5 2.3.1.6 Mean See Level ...................................................................................... 16 Full Supply Level ................................................................................... 17 High Flood Level .................................................................................... 17 Free Board .............................................................................................. 17 Bund Top Level ...................................................................................... 17 Full Supply Depth ................................................................................... 17

2.3.2 Structures in irrigation system .......................................................................... 18 2.3.2.1 Bund ....................................................................................................... 18

2.3.2.1.1 Rip-Rap .............................................................................................. 18 2.3.2.1.2 Free Board .......................................................................................... 18 2.3.2.1.3 Clay core wall ..................................................................................... 18 2.3.2.1.4 Turfing ............................................................................................... 18 2.3.2.1.5 Toe filter ............................................................................................. 19 2.3.2.1.6 Toe Drain ........................................................................................... 19 2.3.2.2 2.3.2.3 2.3.2.4 B.Koby Sluice ...................................................................................................... 19 Spillway.................................................................................................. 19 Drop structures and chutes ...................................................................... 20 Page 55

Industrial Training Report

2.3.2.5 2.3.2.6

Distribution control structures ................................................................. 20 Culvert .................................................................................................... 20

2.3.3 Irrigation canal system ..................................................................................... 21 2.3.3.1 2.3.3.2 2.3.3.3 2.3.3.4 2.4 Main Canal ............................................................................................. 21 Distributory Canals ................................................................................. 21 Field Canal ............................................................................................. 21 Drainage Canal ....................................................................................... 21

BUILDING CONSTRUCTION ........................................................................... 22

2.4.1 Project brief ..................................................................................................... 22 2.4.2 Setting out of building...................................................................................... 22 2.4.2.1 Problem encountered and solution granted .............................................. 23

2.4.3 Excavation ....................................................................................................... 23 2.4.3.1 Problem encountered and solution granted .............................................. 23