Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Assignment Automation and Control

Cargado por

Somsay Thongked0 calificaciones0% encontró este documento útil (0 votos)

94 vistas4 páginasOptical encoder generates n s = 100 pulses / rev Rotation speed n = 800 rew / min 1 2. X 1u mm = 4 mm!pitch a) Find control resolution of system CR 1 from equation. B) Find travel speed of the table at maximum motor speed n m.

Descripción original:

Derechos de autor

© Attribution Non-Commercial (BY-NC)

Formatos disponibles

PDF, TXT o lea en línea desde Scribd

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoOptical encoder generates n s = 100 pulses / rev Rotation speed n = 800 rew / min 1 2. X 1u mm = 4 mm!pitch a) Find control resolution of system CR 1 from equation. B) Find travel speed of the table at maximum motor speed n m.

Copyright:

Attribution Non-Commercial (BY-NC)

Formatos disponibles

Descargue como PDF, TXT o lea en línea desde Scribd

0 calificaciones0% encontró este documento útil (0 votos)

94 vistas4 páginasAssignment Automation and Control

Cargado por

Somsay ThongkedOptical encoder generates n s = 100 pulses / rev Rotation speed n = 800 rew / min 1 2. X 1u mm = 4 mm!pitch a) Find control resolution of system CR 1 from equation. B) Find travel speed of the table at maximum motor speed n m.

Copyright:

Attribution Non-Commercial (BY-NC)

Formatos disponibles

Descargue como PDF, TXT o lea en línea desde Scribd

Está en la página 1de 4

Somsay THONKED (KGC 100018)

1

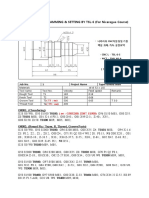

Question 6.34

From the question have:

Gear ratio r

g

= 1

Leadscrew pitch P = 2.5 theads/cm = 4 mm/pitch

Optical encoder generates n

s

= 100 pulses/rev

Rotation speed N = 800 rew/min

1

2.5

1u mm = 4 mmpitc

a) Control resolution of system CR

1

?

b) Frequency of pulse train emitted f

P

?

c) Travel speed of the table at maximum motor speed N

m

?

Answer

a) Find control resolution of system CR

1

from equation.

CR

1

=

P

n

s

r

g

CR

1

=

4

1uu 1

= u,u4

min

pulsc rcw

b) Fine frequency of pulse train emitted f

P

P

=

n

s

6uP

when

= I

t

= NP

= 8uu 4 = S2uu mmmin

So

p

=

3200100

604

= 1,SSS.SSS pulscsscc

c) Find travel speed of the table at maximum motor speed N

m

N

m

= r

g

N

N

m

= 1 8uu rc:min

Pitch

10 mm

Somsay THONKED (KGC 100018)

2

HOMEWORK

Part process programing of milling and drilling machine

Write a part of program to :

a.) Milling the outer profile (end mill 10 mm)

b.) Drilling the points (drill 5 mm)

Answer :

a.) Milling the outer profile (end mill 10 mm)

We are some assumptions to make the program completely:

- The part is 10 mm thick, so the bottom tip of the cutter will be

positioned 25 mm below the part top surface, which correspondens to

z=-25 mm,

- Cutter diameter data has been manually entered into offset register 05.

- At the beginning of the job, the cutter will be positioned so that its

center tip is at a target point located at x=0, y= -50.0, and z= +10.0

- Spindle speed = 1000rev/min

- Feed rate = 40 mm/min

Somsay THONKED (KGC 100018)

3

NC Part Program Code Comments

N001 G21 G90 G92 X0 Y-050.0 Z010.0; Define origin of axes

N002 G00 Z-025.0 S1000 M03; Rapid move to cutter depth, turn spindle on.

N003 G01 G94 G42 Y0 D05 F40; Engage part, start cutter offset

N004 G01 X200.0; Mill lower part edge

N005 G01 Y050.0; Mill right straight edge

N006 G01 X150.0; Mill upper straight edge

N007 G17 G02 X125.0 Y075.0 R025.0; Circular interpolation, clockwise

N008 G01 Y100.0; Mill upper part after circular shape

N009 G01 X025.0; Mill most upper straight part

N010 G01 X0 Y050.0; Mill left part edge

N011 G01 Y0; Mill left part straight

N012 G40 G00 X-40.0 M05; Rapid exit from part, cancel offset

N013 G00 X0 Y-050.0; Rapid move to target point

N014 M30; End of program, stop machine

b.) Drilling the points (drill 5 mm)

Assumptions :

- The part is 10 mm thick, for drilling the deep will be 15 mm which

correspondens to z=-15 mm

- Feed rate 0.05 mm/rev

- Diameter of drilling = 5 mm

- Spindle speed = 1000 rev/min

- At the beginning of the job, the drill will be positioned so that its center

tip is at a target point located at x=0, y= -50.0, and z= +10.0

NC Part Program Code Comments

N001 G21 G90 G92 X0 Y-050.0 Z010.0; Define origin of axes

N002 G00 X025.0 Y025.0; Rapid move to first hole location

N003 G01 G95 Z-15.0 F0.05 S1000

M03;

Drill first hole

N004 G01 Z010.0; Retract drill from hole

N005 G00 X050.0; Rapid move to second hole

Somsay THONKED (KGC 100018)

4

N006 G01 G95 Z-15.0 F0.05; Drill second hole

N007 G01 Z010.0; Retract drill from hole

N008 G00 Y075.0; Rapid move to third hole

N009 G01 G95 Z-15.0 F0.05; Drill third hole

N010 G01 Z010.0; Retract drill from hole

N011 G00 X075.0 Y050.0; Rapid move to 4th hole

N012 G01 G95 Z-15.0 F0.05; Drill the 4th hole

N013 G01 Z010.0; Retract drill from hole

N014 G00 X100.0 Y075.0; Rapid move to 5th hole

N015 G01 G95 Z-15.0 F0.05; Drill the 5th hole

N016 G01 Z010.0; Retract drill from hole

N017 G00 X175.0 Y025.0; Rapid move to 6th hole

N018 G01 G95 Z-15.0 F0.05; Drill the 6th hole

N019 G01 Z010.0; Retract drill from hole

N020 G00 X0 Y-050.0 M05; Rapid move to target point

N021 M30; End of program, stop machine

También podría gustarte

- Lec # 12.3 Problem Solving CNC Part Programing (Week#12)Documento9 páginasLec # 12.3 Problem Solving CNC Part Programing (Week#12)SAIF KHANAún no hay calificaciones

- Homework Solution# 3 I&ME 471 Due 3/31: Hint: You Will Need To Calculate The NDocumento4 páginasHomework Solution# 3 I&ME 471 Due 3/31: Hint: You Will Need To Calculate The NBizuayehu TadesseAún no hay calificaciones

- CNC ProgrammingDocumento62 páginasCNC ProgrammingSanjog Maiti100% (1)

- 6 Semester: Student ProfileDocumento19 páginas6 Semester: Student Profilealokkumar707977Aún no hay calificaciones

- 3 G Codes Part 1 CNC PDFDocumento23 páginas3 G Codes Part 1 CNC PDFMichael CampbellAún no hay calificaciones

- CNC Shop ManualDocumento15 páginasCNC Shop Manualmsuhani011Aún no hay calificaciones

- Debre Tabor University: Faculty of Technology Department of Electromechanical EngineeringDocumento25 páginasDebre Tabor University: Faculty of Technology Department of Electromechanical EngineeringBIRSHAún no hay calificaciones

- CNC-Lab Mechanical ManualDocumento21 páginasCNC-Lab Mechanical ManualHaresh RaisinghaniAún no hay calificaciones

- Computer Aided Engineering: Assignment On CNC ProgrammingDocumento13 páginasComputer Aided Engineering: Assignment On CNC ProgrammingShaswata BoseAún no hay calificaciones

- Lucrarea 6Documento16 páginasLucrarea 6Dorin BarcanAún no hay calificaciones

- CAM ASSIGNMENT RutuDocumento10 páginasCAM ASSIGNMENT RutuksdrAún no hay calificaciones

- CNC ProgramDocumento37 páginasCNC ProgramBas RamuAún no hay calificaciones

- CCA Report 2 PDFDocumento8 páginasCCA Report 2 PDF39SEAShashi KhatriAún no hay calificaciones

- CNCDocumento43 páginasCNCVenky VenkateshAún no hay calificaciones

- CNC Lab 2 Turning CNCDocumento29 páginasCNC Lab 2 Turning CNCMuhammad UmerAún no hay calificaciones

- CNC ProgrammingDocumento60 páginasCNC ProgrammingRohan Dutta100% (2)

- M & G Code Sample FileDocumento9 páginasM & G Code Sample Fileandhab1Aún no hay calificaciones

- CNC Programming (Manual Part Programming) Preparatory FunctionsDocumento8 páginasCNC Programming (Manual Part Programming) Preparatory Functionskirthi83Aún no hay calificaciones

- CNC Programming "Milling": Module ObjectivesDocumento37 páginasCNC Programming "Milling": Module Objectiveshasan alsarrafAún no hay calificaciones

- CNC Lathe S& T P, G & Setting.1Documento4 páginasCNC Lathe S& T P, G & Setting.1marciano1980Aún no hay calificaciones

- CNC PROGRAMMING TITLEDocumento104 páginasCNC PROGRAMMING TITLEAnvit TiwariAún no hay calificaciones

- ME 473 Unit 5Documento21 páginasME 473 Unit 5Ama Serwaa YeboahAún no hay calificaciones

- CNC PPTDocumento28 páginasCNC PPTpallivenu289Aún no hay calificaciones

- EA C412 FMS Turning and Threading FundamentalsDocumento21 páginasEA C412 FMS Turning and Threading Fundamentalstayalpunit196524Aún no hay calificaciones

- HAAS - Mill Programming Workbook AnswersDocumento9 páginasHAAS - Mill Programming Workbook Answersenamicul50Aún no hay calificaciones

- Cam Manul Me Ii SemDocumento17 páginasCam Manul Me Ii SemVignesh VaranAún no hay calificaciones

- Tugas Rutin Iv CNC - JulyadyDocumento11 páginasTugas Rutin Iv CNC - JulyadyNovita P SilalahiAún no hay calificaciones

- Description For M Codes3Documento19 páginasDescription For M Codes3balabooksAún no hay calificaciones

- Document From RDocumento26 páginasDocument From RRahul SehgalAún no hay calificaciones

- Lesson Eighteen TextDocumento4 páginasLesson Eighteen TextVignesh WaranAún no hay calificaciones

- Aplicaţie: Elaborarea Itinerarului Tehnologic Si A Programului CNC Pentru Strunjirea Completa A Piesei de Proba PPR54Documento3 páginasAplicaţie: Elaborarea Itinerarului Tehnologic Si A Programului CNC Pentru Strunjirea Completa A Piesei de Proba PPR54Andreea MariaAún no hay calificaciones

- 3 G Codes Part 1 CNCDocumento23 páginas3 G Codes Part 1 CNCKnyenk CahbrutalAún no hay calificaciones

- U W CNC Lathe CNC Program ExamplesDocumento30 páginasU W CNC Lathe CNC Program ExamplesTrần Xuân Thanh100% (1)

- Programming Fanuc OtDocumento13 páginasProgramming Fanuc OtsaminziAún no hay calificaciones

- 8 Fixed Canned Cycles (CNC Course CD) PDFDocumento24 páginas8 Fixed Canned Cycles (CNC Course CD) PDFVeerasamy SureshbabuAún no hay calificaciones

- Cadcam Lab (Ime 751)Documento25 páginasCadcam Lab (Ime 751)Nawaz KhanAún no hay calificaciones

- Assigment Computer Numerical ControlDocumento5 páginasAssigment Computer Numerical Controlfazo fmakaAún no hay calificaciones

- Final WordDocumento27 páginasFinal WordShaswata BoseAún no hay calificaciones

- CNC Milling ReportDocumento10 páginasCNC Milling ReportDheeraj audichyaAún no hay calificaciones

- Milling Example 2010-PolarDocumento18 páginasMilling Example 2010-PolarShamsir Ibni ShukriAún no hay calificaciones

- CNC Milling ReportDocumento10 páginasCNC Milling ReportMohammad AL-MasriAún no hay calificaciones

- Trevisan DS600Documento16 páginasTrevisan DS600IrudhayarajAnthonySamyAún no hay calificaciones

- ENGR480 Manufacturing Systems: Spring 2010Documento33 páginasENGR480 Manufacturing Systems: Spring 2010Tanvon MalikAún no hay calificaciones

- NC Part ProgrammingDocumento36 páginasNC Part Programmingabyzen0% (1)

- Tugas CNC Miling Gerak Melingkar Adib NHDocumento3 páginasTugas CNC Miling Gerak Melingkar Adib NHMirza ArAún no hay calificaciones

- CNC English Code Controller SystemDocumento17 páginasCNC English Code Controller Systemmarciano1980Aún no hay calificaciones

- EXP: 2 Date: Manual Part Program For Radial Grooving, Threading and Axial Drilling Operation Using Canned CycleDocumento9 páginasEXP: 2 Date: Manual Part Program For Radial Grooving, Threading and Axial Drilling Operation Using Canned CyclegowthamakAún no hay calificaciones

- Circular Interpolation Programming Example 123456Documento14 páginasCircular Interpolation Programming Example 123456Kennaa GadaaAún no hay calificaciones

- Module 2 Part 1Documento147 páginasModule 2 Part 1FRANCIS THOMASAún no hay calificaciones

- VMC ProgrammingDocumento22 páginasVMC ProgrammingDynamic bhagwanAún no hay calificaciones

- G-Code InstructionsDocumento55 páginasG-Code InstructionsSantiago LopezAún no hay calificaciones

- MSC Lecture 6Documento28 páginasMSC Lecture 6Chán Chênh VênhAún no hay calificaciones

- 5 - G-CodeDocumento55 páginas5 - G-CodefamilyumaAún no hay calificaciones

- Engineers Precision Data Pocket ReferenceDe EverandEngineers Precision Data Pocket ReferenceCalificación: 3 de 5 estrellas3/5 (1)

- Machine Shop Trade Secrets: Second EditionDe EverandMachine Shop Trade Secrets: Second EditionCalificación: 4 de 5 estrellas4/5 (7)

- Leader in Water Purification Systems RougingDocumento16 páginasLeader in Water Purification Systems RougingtomcanAún no hay calificaciones

- CIA Interview GuideDocumento14 páginasCIA Interview GuideCody ToebbickeAún no hay calificaciones

- الصراع التنظيمي وأثره...Documento25 páginasالصراع التنظيمي وأثره...mohmod moohAún no hay calificaciones

- Manual LubDocumento25 páginasManual LubMota Guine InformaçõesAún no hay calificaciones

- MasterCard Approves PAX Card ReaderDocumento2 páginasMasterCard Approves PAX Card ReaderThinakaran RajamoorthiAún no hay calificaciones

- 1 s2.0 S1350630720317192 MainDocumento16 páginas1 s2.0 S1350630720317192 MainmaximAún no hay calificaciones

- City Profil Addis AbabaDocumento33 páginasCity Profil Addis AbabaEyuale TAún no hay calificaciones

- Docu31515 VNXe3100 VNXe3150 Replacing A Solid State Disk (SSD)Documento6 páginasDocu31515 VNXe3100 VNXe3150 Replacing A Solid State Disk (SSD)john malloyAún no hay calificaciones

- Infrared Spectroscopy of FAME in Biodiesel Following DIN 14078 PDFDocumento2 páginasInfrared Spectroscopy of FAME in Biodiesel Following DIN 14078 PDFPedro AluaAún no hay calificaciones

- Chemical ProcessDocumento43 páginasChemical ProcesstavolenAún no hay calificaciones

- Oracle Payslip PDFDocumento2 páginasOracle Payslip PDFVaishnavi DappureAún no hay calificaciones

- ATTDocumento3 páginasATTforu_kkkAún no hay calificaciones

- Tybms Sem 5 CCPRDocumento45 páginasTybms Sem 5 CCPROswin DsouzaAún no hay calificaciones

- Check List: For Processing of RA Bills @Documento9 páginasCheck List: For Processing of RA Bills @pvnAún no hay calificaciones

- Parliamentary Procedure in The Conduct of Business MeetingDocumento14 páginasParliamentary Procedure in The Conduct of Business MeetingEstephanie SalvadorAún no hay calificaciones

- MohammedTauhiduzzaman Resume LinkedInDocumento3 páginasMohammedTauhiduzzaman Resume LinkedIntauhid_zaman6776Aún no hay calificaciones

- Unified HSE Passport Standard LRDocumento60 páginasUnified HSE Passport Standard LRSHRISH SHUKLAAún no hay calificaciones

- Wagga Wagga Health and Knowledge Precinct Final ReportDocumento102 páginasWagga Wagga Health and Knowledge Precinct Final ReportDaisy HuntlyAún no hay calificaciones

- Google Inc 2014Documento19 páginasGoogle Inc 2014Archit PateriaAún no hay calificaciones

- Huawei Switch Configuration CommandDocumento10 páginasHuawei Switch Configuration CommandMohamed Khalil RouissiAún no hay calificaciones

- Python GUI Examples (Tkinter Tutorial)Documento18 páginasPython GUI Examples (Tkinter Tutorial)LeonAún no hay calificaciones

- What Digital Camera - May 2016Documento100 páginasWhat Digital Camera - May 2016Alberto ChazarretaAún no hay calificaciones

- Flyrock Prediction FormulaeDocumento5 páginasFlyrock Prediction FormulaeAmy LatawanAún no hay calificaciones

- Difference Between Offer and Invitation To TreatDocumento5 páginasDifference Between Offer and Invitation To TreatBrian Okuku Owinoh100% (2)

- Inbound 6094510472110192055Documento2 páginasInbound 6094510472110192055MarielleAún no hay calificaciones

- Defences of Illegality in England, Canada and the USDocumento11 páginasDefences of Illegality in England, Canada and the USBetteDavisEyes00Aún no hay calificaciones

- OBURE Understanding How Reits Market WorksDocumento3 páginasOBURE Understanding How Reits Market WorksJohn evansAún no hay calificaciones

- Concrete Construction Article PDF Strategic Planning For ContractorsDocumento4 páginasConcrete Construction Article PDF Strategic Planning For ContractorsMohammed NizamAún no hay calificaciones

- Internship Contract AppendixDocumento3 páginasInternship Contract AppendixSheAún no hay calificaciones

- Best Practices in Non-Revenue Water en FinalDocumento96 páginasBest Practices in Non-Revenue Water en FinalEddiemtonga100% (1)