Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Connection

Cargado por

asad_naqviDerechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Connection

Cargado por

asad_naqviCopyright:

Formatos disponibles

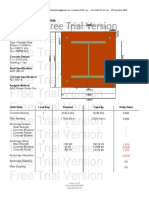

BASE PLATE BEARING ON CONCRETE

PROJECT TITLE

MUA

BYCO OIL PAKISTAN (FLUE GAS DUCT SUPPORT)

Doc. No. P1121-CAL-C501 P PROJECT No. 1121 REV. 0 Date Page August12,2011 1 of 1

BASE PLATE DESIGN FOR SP-01 APPROVED BY: AT AU

PREPARED BY: REVIEWED BY:

DATA INPUT DEAD LOAD (Nominal) LIVE LOAD (Nominal) CONCRETE PEDESTAL SIZE BASE PLATE SIZE

PDL PLL SPED. SBASE

115 Kips 345 Kips 24 22 x x 24 22 inch inch

( 511.52 KN ) ( 1534.56 KN ) ( 600 mm x 600 mm ) ( 550 mm x 550 mm ) ( 20.7 Mpa ) ( 20.7 Mpa ) ( 248.4 Mpa ) ( 400.2 Mpa ) ( 248.4 Mpa ) ( 400.2 Mpa )

SECTION PROPERTIES (approx.)

'c (CONC.) MATERIAL YIELDING STRENGTH (CONC.) 'c (GROUT) MATERIAL YIELDING STRENGTH (GROUT) MATERIAL YIELDING STRENGTH (PLATE) y (PLATE) Fu (PLATE) MATERIAL ULTIMATE STRENGTH (COLUMN) MATERIAL YIELDING STRENGTH (COLUMN) y (COL) Fu (COL) MATERIAL ULTIMATE STRENGTH (COLUMN) DESIGN METHODOLOGY SECTION PROPERTIES OF COLUMN HEIGHT OF SECTION WIDTH OF FLANGE THICKNESS OF WEB THICKNESS OF FLANGES (BOTH)

GIRDER -

3 Ksi 3 Ksi 36 Ksi 58 Ksi 36 Ksi 58 Ksi LRFD

12.7x12.2x0.55x0.9

Ix Iy Sx Sy Zx Zy rx ry A ( 3069.12 KN ) J D (d) F (bf) Tw (tw) Tf (tf) 317.5 mm 305 mm 13.75 mm 22.5 mm

825.27 in4 272.53 in4 129.96 in 44.68 in 152.35 in 3 77.58 in 5.43 in 3.12 in 27.96 in2 6.58 in4 9481.45 in6 10.60 Ksi 16.12052 (Ksi)-2

( 290954.51 mm2 )

3

CALCULATE THE REQD. STRENGHT ULTIMATE LOAD AREA (PEDESTAL) AREA (PLATE) CALCULATE THE BASE PLATE AREA REQUIRED AREA (PLATE)

PU A (PED.) A (PLATE)

690 Kips ( 371612.16 mm2 ) Cw 576 in2 ( 312257.44 mm2 ) X1 484 in2 X2 450.98 in2 < 484 in a

A1(req)

1 (a)- Check Base Plate Dimensions:

Verifying d + 2(3 in) and B bf + 2(3 in) N VERIFYING HEIGHT OF PLATE VERIFYING WIDTH OF PLATE AREA OF PEDESTAL N B A2(req) 18.7 in 18.2 in 576 in2 < < in 22 in 22

.. (Table 14-2) a a

> 450.980392156863 in a

VERIFY THE CONCRETE BEARING STRENGTH CONCRETE BEARING STRENGTH CHECK

DEFLECTION CHECK MAXIMUM DEFLECTION (CALCULATED) 0.6 in calc SPAN LENGTH L 23 ft FLOOR BEAM BEAM TYPE MAX. LIVE+DEAD LOAD => L / 240 DEFLECTION LIMIT max 1.15 in

SAFE IN DEFLECTION

>

calc 0.6 in

REVIEWED BY

APPROVED BY

LRFD

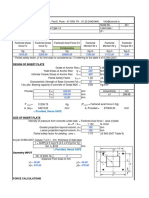

1- UPLIFT LOA T = Wind Load (Nominal) Dead Load (Nominal) Design Methodology WL DL LRFD 60 Kips 5 Kips (Tension) => => 266.89 KN 22.24 KN

1- NO. OF BOL n = n = T/rod = Rn =

1-

REQD. STRENGTH DUE TO UPLIFT ON COLUMN T = 91.5 Kips

Uplift (Tension) 2NUMBER OF ANCHOR RODS

Rn =

Bolt Diameter Anchor Rod Grade Anchor Rod Pull-out Strength Number of Bolts Number of Bolts (Provided) Tensile Strength of Anchor Rod Force per Rod Design Strength of Rod

b = Np =

n = np = Fu = T/rod =

1 in

=> => => No's No's => => =>

24 mm 240 Mpa 112.10 KN

Gr. 36 25.2 Kips 4 4

Rn =

58 Ksi 22.88 Kips 25.61 Kips

{ = 0.75}

724 Mpa 101.75 KN 113.92 KN

Design Strength is OK

LRFD

ASD = (60) - (0.6 x5 ) 57 Kips = (60) / (25.2 ) 3.0 No's = 4 = 14.25 Kips

1- UPLIFT LOAD (1.6 x60) - (0.9 x5 ) T 91.5 Kips 1- NO. OF BOLTS (60) / (25.2 ) n 4.0 No's 4 n 22.88 Kips T/rod (0.75)x(58) x(0.785 ) 34.15 Kips (0.75)x(34.1475) 25.61 Kips

Table: 3.2: Anchor Rod Concrete Pull-out Strength (Kips) Rod Rod Dia Concrete Pull-out Area Bearing b Area Np (Kips) An 2 2 (in) Gr. 36 Gr. 55 Gr. 105 (in ) (in ) 1 5/4 0.31 0.69 11.6 15.4 19.3 16 2 3/4 0.44 0.91 15.2 20.3 25.4 20 3 7/8 0.6 1.22 20.5 27.3 34.1 22 4 1 0.79 1.5 25.2 33.6 42 24 5 1 1/8 0.99 1.81 30.4 40.5 50.7 28 6 1 1/4 1.23 2.24 37.7 50.2 62.8 32 7 1 1/2 1.77 3.13 52.6 70.1 87.7 37 8 1 3/4 2.41 4.17 70 93.4 117 45 9 2 3.14 5.35 90 120 150 51 10 11 12 13 14 15 16 17 2 1/4 2 1/2 2 3/4 3 3 1/4 3 1/2 3 3/4 4 3.98 4.91 5.94 7.07 8.3 9.62 11 12.6 6.69 8.17 9.8 11.4 13.3 15.3 17.5 19.9 112 137 165 191 223 257 294 334 150 183 220 254 297 343 393 445 187 229 274 318 372 429 491 557 58 64 70 77 83 89 96 102

Rn = (34.1475) / (2)

17.07 Kips

0.79

###

25.2

SHEAR CONNECTION CHECKS

PROJECT TITLE

PREPARED BY: MUA ASCO - PIPE TRESTLE (WATER SYSTEM) SHEAR BOLT DESIGN OF PIPE TRESTLES REVIEWED BY: AT APPROVED BY: AT REV. 0 Doc. No. PROJECT # Date Page P1124-CAL-C501 P1124 October1,2011 1 of 1

DATA INPUT AXIAL LOAD (Nominal) (i) - BOLT DATA BOLT MATERIAL TYPE OF BOLT TENSILE STRENGTH (BOLT) SHEAR STRENGTH (BOLT) DIAMETER OF BOLT NUMBER OF BOLTS

PAXIAL A325 THREADED Fu (BOLT) Fv (BOLT) b nb

30 Kips Ksi 90 Ksi 48 Ksi 3/4 in 3

=> Ab

0.442 in2

(ii) - MEMBER DATA MATERIAL YIELDING STRENGTH (MEMBER) 'y (MEMBER) MATERIAL ULTIMATE STRENGTH (MEMBER) Fu (MEMBER) THICKNESS OF WEB (WHERE BOLTS ARE PROVIDED) th. (WEB) (iii) - GUSSET DATA th. (GUSSET) PLATE THICKNESS MATERIAL YIELDING STRENGTH (GUSSET PLATE) y (GUSSET) Fu (GUSSET) MATERIAL ULTIMATE STRENGTH (GUSSET PLATE) (iv) - GEOMETRY NO. OF COLUMNS

36 Ksi 58 3/5 in

1/2 in 36 Ksi 58

NO. OF ROWS

FILL THE FOLLOWING TABLE AS SHOWN IN THE FIGURE:

TABLE FOR Lc

(for Bolts and Member)

1 1.18

FOR HORIZONTAL BOLT SPACING (in)

2 2.36

3 2.36

TABLE FOR Lc

(for Bolts and Gusset)

HORIZONTAL SPACE (in)

1.18

CONNECTION CHECKS (i) - SHEAR FAILURE OF BOLTS SHEAR FORCE REQD. FOR FAILURE OF BOLTS Rn (ii) - BEARING FAILURE OF MEMBER BEARING STRENGTH FOR 1st COLUMN BEARING STRENGTH FOR 2nd COLUMN BEARING STRENGTH FOR 3rd COLUMN

47.72 Kips

Rn 1 Rn 2 Rn 3

23.26 Kips 46.51 Kips 46.51 Kips

FOR 1 BOLTS 23.26 Kips FOR 1 BOLTS 46.51 Kips FOR 1 BOLTS 46.51 Kips

P(TOTAL) BEARING FAILURE OF MEMBER REQUIRES TOTAL LOAD OF: 116.28 Kips UPPER LIMIT CONTROLLING HOLE ELONGATIONRe (iii) - BEARING FAILURE OF GUSSET BEARING FAILURE (GUSSET PLATE) Rn UPPER LIMIT CONTROLLING HOLE ELONGATIONRe (iv) - SLIP CRITICAL FAILURE NO. OF SLIP PLANES TYPE OF HOLES TYPE OF SURFACE 46.98 Kips FOR 3 BOLTS 140.94 Kips

19.38 Kips 39.15 Kips

Ns

2

NORMAL HOLES

CLASS A: UNPAINTED CLEAN MILL SURFACE

= =

1.0 0.33

SLIP RESISTANCE OF CONNECTIONS

str

35.24 Kips

FOR 3 BOLTS 105.72 Kips

MAXIMUM LOAD THAT A BOLT CAN CARRY P(MAX)

15.91 Kips

a

CONNECTIONS ARE SAFE FOR ALL TYPES OF FAILURE

CHECKED BY

También podría gustarte

- Design of RCC Footing As Per ACI 318 95 EdDocumento2 páginasDesign of RCC Footing As Per ACI 318 95 EdMaad Ahmed Al-MaroofAún no hay calificaciones

- W12x30 Beam To BeamDocumento6 páginasW12x30 Beam To BeamWin ThanAún no hay calificaciones

- Base Plate1Documento6 páginasBase Plate1jobees7850Aún no hay calificaciones

- Base PlateDocumento15 páginasBase PlatemaheshbandhamAún no hay calificaciones

- 6-Bracing Connection - TDocumento2 páginas6-Bracing Connection - TMUTHUKKUMARAMAún no hay calificaciones

- 1 - Wind Load CalculationsDocumento54 páginas1 - Wind Load CalculationsMASOOD MIYANAún no hay calificaciones

- MM Met D19084 RP 012Documento96 páginasMM Met D19084 RP 012Dass DassAún no hay calificaciones

- 2 0 Insert Plate Calculations Type 14 PDFDocumento4 páginas2 0 Insert Plate Calculations Type 14 PDFALPHYL BALASABASAún no hay calificaciones

- EMBEDDED PLATE CONNECTION DESIGNDocumento78 páginasEMBEDDED PLATE CONNECTION DESIGNAkhil VNAún no hay calificaciones

- Monorail 0.5 TonDocumento9 páginasMonorail 0.5 TonAndreas HendiAún no hay calificaciones

- Rectangular BasePlate DesignDocumento13 páginasRectangular BasePlate DesignMuhammad HasanAún no hay calificaciones

- Diagram Drawing Design Forces and DetailsDocumento6 páginasDiagram Drawing Design Forces and Detailswaweng22Aún no hay calificaciones

- BEAM Moment Connection - UB 254x146x37Documento7 páginasBEAM Moment Connection - UB 254x146x37Shriniwas NaikAún no hay calificaciones

- Actual Base Plate Design-V1.2-42-210Documento6 páginasActual Base Plate Design-V1.2-42-210Livian TeddyAún no hay calificaciones

- 4 stiffened-WH500X400X12X25-WH500X400X12X25Documento7 páginas4 stiffened-WH500X400X12X25-WH500X400X12X25phanikrishnabAún no hay calificaciones

- Gusset Plate Connection DesignDocumento3 páginasGusset Plate Connection DesignMin Khant KyawAún no hay calificaciones

- Combined FootingDocumento34 páginasCombined FootingchakrapanithotaAún no hay calificaciones

- Deep Beam CheckDocumento10 páginasDeep Beam CheckNikhil AgrawalAún no hay calificaciones

- Final Design of Angle Members For 4leged Single Angle TowersDocumento65 páginasFinal Design of Angle Members For 4leged Single Angle Towersks_raghuveerAún no hay calificaciones

- Composite Steel-Concrete Construction DesignDocumento16 páginasComposite Steel-Concrete Construction Designpresentasi mankonAún no hay calificaciones

- Bolted Moment Connection 2x2Documento22 páginasBolted Moment Connection 2x2Немања КараклајићAún no hay calificaciones

- Torsional beam design with USD methodDocumento2 páginasTorsional beam design with USD methodShane BondAún no hay calificaciones

- Design of Raft SlabDocumento6 páginasDesign of Raft SlabVenkatesha HebbarAún no hay calificaciones

- Design of column splice plates and weldsDocumento4 páginasDesign of column splice plates and weldsNiraj Shinde100% (1)

- Bsep SMFDocumento6 páginasBsep SMFamirgholami1100% (1)

- Example Foundation Calculation by AfesDocumento25 páginasExample Foundation Calculation by AfesPanithi Brahmasâkhâ100% (1)

- Design of bracing for 1000 KL OHTDocumento4 páginasDesign of bracing for 1000 KL OHTankkeshmundra1Aún no hay calificaciones

- Structure Column DesignDocumento6 páginasStructure Column DesignGeorge GeorgianAún no hay calificaciones

- CSE 362 Design of Steel Structures Section Properties and CapacitiesDocumento19 páginasCSE 362 Design of Steel Structures Section Properties and CapacitiesRufus ChengAún no hay calificaciones

- Column Base PlateDocumento3 páginasColumn Base PlatePurnima ArkalgudAún no hay calificaciones

- Brace TR W6X25Documento6 páginasBrace TR W6X25mihai_serban13Aún no hay calificaciones

- Design Calculation Sheet For Purlins: WL (P) WL (S)Documento1 páginaDesign Calculation Sheet For Purlins: WL (P) WL (S)Ahsan SattarAún no hay calificaciones

- 1.wind Load BNBC Aisc Open Code 60mDocumento9 páginas1.wind Load BNBC Aisc Open Code 60mAnonymous ep7LE5ZdP5Aún no hay calificaciones

- Code Ref. Calculations Output: Column Size: 254 X 146 X 44.64kg/m UBDocumento9 páginasCode Ref. Calculations Output: Column Size: 254 X 146 X 44.64kg/m UBkhewzyAún no hay calificaciones

- Crane Stub Weld DesignDocumento1 páginaCrane Stub Weld DesignkalpanaadhiAún no hay calificaciones

- Bolt Design (Blodget)Documento4 páginasBolt Design (Blodget)Mayuresh KudveAún no hay calificaciones

- Bracing Connection RefDocumento5 páginasBracing Connection Refsukarma acharyaAún no hay calificaciones

- 4.T&Angle-Brace Connection (M Project) - 0618Documento49 páginas4.T&Angle-Brace Connection (M Project) - 0618Omprakash KhodkeAún no hay calificaciones

- Design of rigid connection detail 85Documento215 páginasDesign of rigid connection detail 85Umer AziqAún no hay calificaciones

- Splice Design - LRFDDocumento22 páginasSplice Design - LRFDkalpanaadhiAún no hay calificaciones

- Prestressed WorksheetDocumento11 páginasPrestressed WorksheetBhaumik MerchantAún no hay calificaciones

- Design Data: Design For Base Plate (Fixed)Documento4 páginasDesign Data: Design For Base Plate (Fixed)Wibawa WorksAún no hay calificaciones

- AISC Connection 2nd Edition (4+2) Bolts Knee No UseDocumento6 páginasAISC Connection 2nd Edition (4+2) Bolts Knee No UseTuấnThanhAún no hay calificaciones

- Fin Plate-Beam To Beam Inside (AISC-LRFD)Documento184 páginasFin Plate-Beam To Beam Inside (AISC-LRFD)AshishAún no hay calificaciones

- 2.column Base Plate (Fixed Type)Documento15 páginas2.column Base Plate (Fixed Type)ZevanyaRolandTualakaAún no hay calificaciones

- ASD-Insert Plate CheckDocumento12 páginasASD-Insert Plate CheckJvv GudboyAún no hay calificaciones

- Project by Location: Girting Design ADocumento10 páginasProject by Location: Girting Design AJurie_sk3608Aún no hay calificaciones

- Isolated Footing DesignDocumento14 páginasIsolated Footing DesignDhandapany ArunAún no hay calificaciones

- Combined FootingDocumento2 páginasCombined Footingsantosh-a-biraj-3307Aún no hay calificaciones

- Shear Capacity of Pier Cap Corbel DesignDocumento5 páginasShear Capacity of Pier Cap Corbel DesignBharathi ThadigotlaAún no hay calificaciones

- Bolted Connection Angle Brace TensionDocumento2 páginasBolted Connection Angle Brace TensionRajib MaharjanAún no hay calificaciones

- RAFTER-COLUMN CONNECTION DESIGNDocumento6 páginasRAFTER-COLUMN CONNECTION DESIGNpriantomoAún no hay calificaciones

- Shear Connection For Ismb 300 TO ISMB350 COL: Bolt CalculationDocumento4 páginasShear Connection For Ismb 300 TO ISMB350 COL: Bolt CalculationNitin SakpalAún no hay calificaciones

- Column-Beam Connection Design Calculation SheetDocumento13 páginasColumn-Beam Connection Design Calculation SheetShamik Ghosh0% (1)

- Column Design Name of WorkDocumento43 páginasColumn Design Name of WorkPalani KumarAún no hay calificaciones

- Danh Gia Lien Ket Ban de Chan Cot ThepDocumento2 páginasDanh Gia Lien Ket Ban de Chan Cot ThepNguyen Duc CuongAún no hay calificaciones

- IicDocumento58 páginasIicAUNGPSAún no hay calificaciones

- Composite Floor BeamDocumento6 páginasComposite Floor BeamAhmed Ben Hmida50% (2)

- Moment Splice - BackupDocumento74 páginasMoment Splice - BackupKiran AcharyaAún no hay calificaciones

- Beam SpliceDocumento7 páginasBeam SpliceJuan BradleyAún no hay calificaciones

- Ramazan 2014 - Al-Khobar KSA (Jafari)Documento1 páginaRamazan 2014 - Al-Khobar KSA (Jafari)asad_naqviAún no hay calificaciones

- Service Canal Precast Cover SketchDocumento1 páginaService Canal Precast Cover Sketchasad_naqviAún no hay calificaciones

- Hydraulic Design of Cut-Off Drain Km0+700 To Km1+120Documento7 páginasHydraulic Design of Cut-Off Drain Km0+700 To Km1+120asad_naqviAún no hay calificaciones

- Column LRFDshear (SI)Documento8 páginasColumn LRFDshear (SI)asad_naqviAún no hay calificaciones

- Pump Clinic 33Documento8 páginasPump Clinic 33fnahas_bhAún no hay calificaciones

- HandrailDocumento1 páginaHandrailasad_naqviAún no hay calificaciones

- Flat Slab ExcelDocumento6 páginasFlat Slab Excelasad_naqvi67% (3)

- ANSI TIA EIA 222 G Wind Load CalculationsDocumento2 páginasANSI TIA EIA 222 G Wind Load Calculationsasad_naqvi100% (5)

- Maccaferri Soft Soil Stabilization Design SpreadsheetDocumento13 páginasMaccaferri Soft Soil Stabilization Design SpreadsheetAlbaro Andres TorricoAún no hay calificaciones

- 5001-11!16!12-SP-101-D1 (Corrosion Inhibition System For Flowline)Documento8 páginas5001-11!16!12-SP-101-D1 (Corrosion Inhibition System For Flowline)asad_naqviAún no hay calificaciones

- In-line crusher solves kaolin clay lump problemsDocumento2 páginasIn-line crusher solves kaolin clay lump problemsasad_naqviAún no hay calificaciones

- In-line crusher solves kaolin clay lump problemsDocumento2 páginasIn-line crusher solves kaolin clay lump problemsasad_naqviAún no hay calificaciones

- Single Footing Design - Telecomm, Transmission & Guyed Tower & Pole - TIA 222F & ACIDocumento12 páginasSingle Footing Design - Telecomm, Transmission & Guyed Tower & Pole - TIA 222F & ACIasad_naqvi100% (2)

- HYSYS Print69565Documento1 páginaHYSYS Print69565asad_naqviAún no hay calificaciones

- Excel - Gyan New (For 2003)Documento207 páginasExcel - Gyan New (For 2003)asad_naqviAún no hay calificaciones

- Presentation On Lighting Design by Tooba ImlakDocumento23 páginasPresentation On Lighting Design by Tooba Imlakasad_naqviAún no hay calificaciones

- Quran DictionaryDocumento1664 páginasQuran Dictionaryasad_naqviAún no hay calificaciones

- In-line crusher solves kaolin clay lump problemsDocumento2 páginasIn-line crusher solves kaolin clay lump problemsasad_naqviAún no hay calificaciones

- UntitledDocumento2 páginasUntitledasad_naqviAún no hay calificaciones

- Cold-Formed Beam Web Penetration Design GuideDocumento22 páginasCold-Formed Beam Web Penetration Design Guideasad_naqviAún no hay calificaciones

- Bimetallic Steam TrapsDocumento2 páginasBimetallic Steam Trapsasad_naqviAún no hay calificaciones

- Education Summary Form: 1. Personal DetailsDocumento2 páginasEducation Summary Form: 1. Personal Detailsasad_naqviAún no hay calificaciones

- Safety Shoes for Work WearDocumento1 páginaSafety Shoes for Work Wearasad_naqviAún no hay calificaciones

- DNV 2-7-1Documento60 páginasDNV 2-7-1Apostolie Iulian100% (1)

- AM Army Type Trolley HoistDocumento2 páginasAM Army Type Trolley Hoistasad_naqviAún no hay calificaciones