Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Henery 2-025-001 Rev.N

Cargado por

rlynch33Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Henery 2-025-001 Rev.N

Cargado por

rlynch33Copyright:

Formatos disponibles

CHATHAM, IL U.S.A.

62629

OIL LEVEL CONTROL BOOKLET

INSTALLATION AND SERVICE INSTRUCTIONS SECTION TITLE I INTRODUCTION II TYPES OF SYSTEMS III OIL SEPARATORS IV OIL RESERVOIRS V MECHANICAL OIL REGULATORS VI ELECTRO-MECHANICAL REGULATORS VII ADAPTER KITS VIII SERVICE/TROUBLESHOOTING IX REPLACEMENT PARTS PAGES 1 2 3 4 5-7 8-9 10 11-12 13

2-025-001 REV. N

HENRY TECHNOLOGIES OIL CONTROL INSTRUCTION BOOKLET

SECTION I - INTRODUCTION

This oil control booklet covers oil control systems for reciprocating, rotary, or scroll compressors using halocarbon refrigerants only. Do not use this guide or the products contained within for screw or rotary-vane compressors or for ammonia systems. A proper oil control system is essential to insure compressor lubrication and energy efficient cooling. An oil control system can be a very cost effective alternative to replacing expensive compressors due to loss of oil. If installed correctly, an oil control system can give years of trouble-free operation and protect compressors from lack of oil and varying oil levels with little or no maintenance. Oil traveling through the system tends to build up in the evaporator, condenser, and vessels of an air-conditioning or refrigeration system. This causes a lack of oil return to the compressor until finally, in most cases, a large amount returns as a slug of oil. A slug of oil down the suction line can be just as damaging to the compressor as a slug of liquid refrigerant. This delay in oil return requires an additional amount of oil to be added to the system, depending on the size of the system, the piping, the temperatures, the miscibility of the refrigerant/oil mix, and the refrigerant velocity. In many systems, this extra oil can amount to 15 gallons or more. By removing oil from the discharge gas of compressors, not only is the oil level for each compressor more accurately controlled, the efficiency of the system is increased. Oil does not change phase from liquid to gas in an air-conditioning or refrigeration system and therefore makes a very poor refrigerant. Due to this, it will not pick up and reject heat nearly as well as refrigerant and a system will actually have to cool the oil as it tries to cool the evaporator, reducing the amount of heat the refrigerant can pick up. Oil also takes up volume through the system that otherwise could be filled with refrigerant, causing higher mass flow rates through the system. Additionally, oil tends to film the condenser tubing walls lowering heat transfer and as oil and refrigerant exits the expansion valve, the oil will foam, insulating the evaporator walls and again lowering heat transfer. In this manner, oil traveling through the system can affect efficiency very dramatically in a variety of ways. Note, however, that an oil control system does not replace the need for proper system design. An oil control system will drastically reduce the amount of oil going through the system, however, suction traps, correct piping, and proper sizing of valves, controls, and components must still be implemented to insure the system will work properly.

GENERAL INFORMATION

In all oil control systems, a means to feed oil to the compressors without bypassing hot gas to the crankcases is needed. In single compressor or low-pressure systems, an internal float in the oil separator accomplishes this. These floats will open to feed a few ounces of oil and close once the oil level has dropped. The float cycles as needed to return as much oil as the separator separates from the discharge. It is required that all oil systems have a discharge check valve installed between the oil separator and the condenser. This prevents refrigerant migration and back feeding to the oil separator during compressor off cycles. If this check valve is not installed, the separator can feed excessive liquid refrigerant to the compressor once the compressor starts, causing dilution of the oil, excessive foaming, erratic oil pressures, and possible compressor damage. Due to the reduced amount of oil going through the system, a means to remove debris from the oil is required in the oil control system, since the oil will not travel through the suction and liquid line filters. An oil strainer can be used to pick up debris in most systems and one should be placed in each oil line to every compressor. For systems using POE oil, a filter or filter-drier must be used to prevent clogging of valves. Polyolester (POE) oil is a very good solvent and will scavenge the system of debris that mineral oil will not. This debris can lead to clogging of components in the oil control system as well as the refrigeration system as a whole. Insure that the filters throughout the whole system are changed three times in the first three months to avoid problems. Never remove or loosen components in the system when the system is under pressure or contains refrigerant. Loss of refrigerant or personal injury may result. All components are labeled with a maximum working pressure that must not be exceeded. All components are built with a factor of safety before rupturing, however, permanent damage to the component may occur if the maximum working pressure for any component is exceeded. When installing or servicing a component, always leak test and then evacuate (pull into vacuum) the system prior to adding refrigerant to insure all joints are sealed and will prevent loss of refrigerant.

Page 1

5/7//98

HENRY TECHNOLOGIES OIL CONTROL INSTRUCTION BOOKLET

SECTION II - TYPES OF SYSTEMS

SINGLE COMPRESSOR SYSTEM

A single compressor oil system is the most basic system. The compressor discharge is piped to the inlet of an oil separator and the outlet of the oil separator is piped to the condenser. An oil return line is brought from the oil separator through an oil filter or strainer back to the compressor crankcase oil fill port or the suction line. A float in the oil separator opens and feeds a small amount of oil, bypassing the rest of the cooling system. The oil is returned under head pressure to the crankcase or suction line on compressors without crankcase connections. This float prevents hot gas from bypassing to the crankcase by closing when the oil level falls.

LOW PRESSURE OIL SYSTEM

This system is normally used for parallel compressors and uses three basic components: Oil Separator, Oil Reservoir, and Oil Level Regulators. Again, the common discharge is piped to the inlet of the oil separator and the outlet of the oil separator is piped to the condenser. An oil return line is brought from the oil separator to the top valve of the oil reservoir. A vent line is installed to the suction line with a pressure valve in line to lower the pressure in the reservoir, making a low pressure oil system. This valve will keep the reservoir pressure a set pressure above suction depending on the value of the valve, either 5 or 20 psig. This allows a constant differential pressure, which is the reservoir oil pressure minus crankcase pressure, of either 5 or 20 psig to the oil level regulator. Mechanical oil level regulators are rated for pressures ranging from 5 to 90 psig differential. The bottom valve of the oil reservoir is piped to oil level regulators mounted on the compressor crankcases. These regulators open to feed oil as the oil level drops and closes as the oil level raises to the set level. In this manner, the oil level in the compressor is kept at a constant level. Either one oil strainer per regulator or one oil filter per separator must be used to remove debris from the oil. On satellite systems, insure that all regulators see a positive oil differential pressure that falls within the range for each regulator.

Page 2

5/7//98

HENRY TECHNOLOGIES OIL CONTROL INSTRUCTION BOOKLET

SECTION III - OIL SEPARATORS

OIL SEPARATOR INSTALLATION (used on Single Compressor or Low Pressure Systems only)

1. S-1900, S-5200, S-5700 series oil separators - Remove the plastic shipping plug from the bottom flange of the oil separator and replace with a steel pipe plug. Use Loctite #12929 sealant or equivalent and torque to 13-15 ft-lbs. 2. A valve may be added if desired to the female 1/8 NPTF oil drain fitting on the bottom of S-1900, S-5700, S-5100, and S-5200 series oil separators. This fitting opens into the tank and will drain oil completely from the separator. This feature is useful for frequent oil change-outs 3. Precharge the oil separator with the same oil used in the system. This oil may be poured through the inlet or outlet fitting on all catalog separators. This oil precharge is the amount that is needed to just float the needle valve float. This amount of oil will stay in the oil separator when in operation and will seal the needle and prevent damage to the float mechanism. There have been instances that the float has been damaged by the turbulent hot gas bouncing the float if the separator was not precharged, which has caused the float mechanism to leak.

HELICAL MODEL NO. S-5180, S-5181 S-5182, 85, 87, 88 S-5190, 92, 94 S-5200/S-5410 series

OIL PRECHARGE 4 oz. / 11 cl 14 oz. / 40 cl 40 oz. / 114 cl 25 oz. / 71 cl

CONVENTIONAL NO. S-5500 series S-5800 series S-5600 series S-1900/S-5700 series

OIL PRECHARGE 12 oz. / 34 cl 12 oz. / 34 cl 30 oz. / 86 cl 25 oz. / 71 cl

4. Install oil separator vertically between compressor and condenser, reasonably close to the compressor to insure that the discharge gas in the separator remains super-heated. Make sure that proper piping practices are used to prevent excessive vibration in the discharge line. If used, vibration eliminators and mufflers should be piped before the oil separator. If the oil separator has a bottom stud, the stud must be in an opening large enough to receive the stud and its weld fillet. Use as much of the bottom for bearing as possible: this tends to arrest vibration. Tighten nut to 15 ft-lbs. torque. If the separator has mounting legs, insure that the legs are properly attached to the mounting surface by bolts or welds. DO NOT SUPPORT THE OIL SEPARATOR BY THE DISCHARGE LINE ALONE! This will cause abnormal stress and fatigue on the line and fittings and may cause failure of the joints. 5. Attach compressor discharge line to INLET of the oil separator and the OUTLET of the separator to a discharge check valve and then to the condenser. The check valve will prevent liquid refrigerant migrating and back feeding from the condenser. 6. The oil return fitting is normally a 3/8 S.A.E. male flare fitting or a 3/8 ODS fitting on X versions. A 3/8 line should be installed from this fitting to either the compressor fill port or suction line on a single compressor system or the top valve on the oil reservoir in a low pressure oil system. A sight glass in the oil return line is a useful way to view oil feeding from the oil separator for trouble-shooting. A 3/8 liquid line sight glass may be used for this. If installing an oil separator in an existing single compressor system with either no oil separator or an inefficient separator, it is suggested to run the oil return line to the suction line of the compressor and install a oil drain valve either in the compressor crankcase (preferred) or in the 1/8 NPTF oil drain (if available) of the separator. This will allow you to see when excess oil is flooding the separator and compressor and to drain this oil from the system. A hand valve may also be installed in the oil return line to service the separator. 7. Silver braze the connections with a standard alloy used to join copper tubing to steel for refrigeration applications. Tin-Lead solders are NOT acceptable. Clean flux from connections after soldering/brazing. On oil separators with ODS connections located on the flange plate, care must be taken to prevent the gasket from temperatures over 300 degrees F. Place a wet rag on the header plate to keep it cool while soldering or brazing. 8. Insulate the oil separator and add a heat band when the oil separator is mounted in a potentially cold ambient area or if the oil separator is in the air stream of the condenser fans. This will prevent refrigerant from condensing in the separator while the system is running. 4 heat bands may be added to the sump of replaceable float separators.

Page 3

5/7//98

HENRY TECHNOLOGIES OIL CONTROL INSTRUCTION BOOKLET

Heat Band # S-9101 S-9111 S-9112

Diam. 4 4 6

Voltage 110 220 220

Watts 25 25 50

Used on S-5200, S-5410, S-1900, S-5500, S-5700, S-5800 Series, S-5182, 85, 87, 88 S-5200, S-5410, S-1900, S-5500, S-5700, S-5800 Series, S-5182, 85, 87, 88 S-5600 Series, S-5190, S-5192, S-5194

* S-5410 Series for Europe only

SECTION IV - OIL RESERVOIRS

OIL RESERVOIR INSTALLATION (used on Low Pressure Systems only)

1. Mount the oil reservoir to a sturdy frame using the brackets supplied. It is not necessary for the oil reservoir to be mounted higher than the compressors so long as a reservoir pressure valve is installed and positive oil pressure differential is maintained. Gravity feed systems (no reservoir pressure valve) are not generally used or suggested, however, in these systems, insure that the reservoir is mounted at least 6 feet above the compressor crankcase level. 2. Oil the rotalock gaskets and install the rotalock valves. Front seat the bottom valve to prevent oil draining while filling. 3. Precharge the oil reservoir with the same oil used in the system. This oil may be fed through the inlet valve. The oil precharge will vary depending on the nature of the installation: fill to the top sight glass on new systems and to the bottom sight glass when installing into a system that has either had no oil separator or had an inefficient oil separator. A new system will lose a small amount of oil to the system and to the lines in the oil control system until it balances out. Adding a separator to an existing system will remove excess oil from the system and a means for oil to be collected and drained from the system must be used. The 1/4 flare access fitting on the bottom rotalock valve may be used for this. 4. Install the 3/8 line from the oil separator to the top (inlet) valve of the reservoir. 5. Install the 3/8 line from the bottom (outlet) valve to an oil header. The oil header should be sized to provide adequate oil feed to each oil regulator without pressure drop. 6. Install the reservoir pressure valve and vent line to the suction line on the 3/8 male flare on top of the reservoir. 7. Insure that both valves are back seated prior to running the system to allow oil flow. 8. Check the oil level frequently after the system is started. The oil level should be monitored for a few hours after start-up and should be checked again several times in the first two weeks of operation. For existing systems, remove oil if the level is above the bottom sight glass when the system is checked. It may take some time to get excess oil from the system depending on how much is present, how the system is piped and how much of full capacity the system is running. Check the system periodically until the oil remains at a fairly consistent level. For new systems, if the level is low on the next service call, oil should be added until the upper sight glass shows oil. After this, the system should balance out and oil should not be added until the level drops below the bottom sight glass. Insure that the oil level is checked during each service call and the level maintained just below the top sight glass.

RESERVOIR PRESSURE VALVE INSTALLATION (used on Low Pressure Systems only)

1. Install pressure valve on 3/8 male flare connection on top of the oil reservoir. 2. Pipe 3/8 line to the suction line for vent.

Page 4

5/7//98

HENRY TECHNOLOGIES OIL CONTROL INSTRUCTION BOOKLET

SECTION V - MECHANICAL OIL LEVEL REGULATORS

(used on Low Pressure Systems only)

REGULATOR MODEL NO. S-9010 S-9010A S-9015 S-9090 S-9090A S-9110 S-9120 S-9130 S-9190

CONNECTION SIZE 3 BOLT 1 7/8 B.C. 4 BOLT 50mm B.C. NPTF FEMALE 3 BOLT 1 7/8 B.C. 4 BOLT 50 mm B.C. 3 BOLT 1 7/8 B.C. 3 BOLT 1 7/8 B.C. 3 BOLT 1 7/8 B.C. 3 BOLT 1 7/8 B.C.

OPER. PRESSURE DIFFERENTIAL, psig 5-30 5-30 5-30 5-90 5-90 5-30 5-30 5-90 30-90

OIL LEVEL, SIGHT GLASS ADJUSTABLE * + ADJUSTABLE * + + ADJUSTABLE * + ADJUSTABLE * +

* These adjustable oil regulators are designed to feed oil between 1/4 and 5/8 glass levels at the various specified pressure differentials. The regulator may adjust beyond this range due to the actual oil pressure. Maintain all adjustable regulator levels according to compressor manufacturers specifications. + Do not operate ANY regulator at 1/4 sight glass when using an adapter with inside diameter smaller than the regulator flange port. Note: S-9010A and S-9090A 4 bolt 50mm B.C. for European use only (Bitzer Compressors)

Page 5

5/7//98

HENRY TECHNOLOGIES OIL CONTROL INSTRUCTION BOOKLET

GENERAL INFORMATION

All regulators have a operating pressure differential range that should not be confused with its working pressure. The operating differential is the difference of pressure between the oil feeding into the regulator and the component where the regulator is controlling oil level. Specifically, the reservoir pressure minus the crankcase pressure. If the differential pressure is too low for that regulator, insufficient oil flow to the compressor may result. If the differential pressure is too high, the regulator will over-fill. Adjustable regulators include an adjustment mechanism to raise or lower the oil set point. Our exclusive design eliminates the need to shut the system down and disconnect the oil feed lines in order to adjust the oil level regulator. The oil level may be adjusted while the system is under pressure and running. Adjust the oil level by removing the seal cap, the locking disk (S-9130 & S-9190 series only), and rotating the adjustment clockwise to lower, counter clockwise to raise the oil level. Replace cap and locking disk when done. Each full turn of the adjustment mechanism moves the oil level approximately 1/16. Oil levels on these regulators are typically factory set just below 1/2 sight glass.

ASSEMBLY OF OIL LEVEL REGULATORS ON COMPRESSORS WITH 3 BOLT 1 7/8B.C.

1. Remove compressor sight glass. 2. Lightly oil and insert one of the o-rings supplied in the groove of the regulator flange to be connected to the compressor. Assemble supplied bolts and nuts to the flange and evenly and alternately torque bolts to approximately 5 ft-lbs. 3. Lightly oil and insert another supplied o-ring in the compressor sight glass groove. Lightly oil and insert the supplied quad-ring in the regulator flange groove. The o-ring and quad-ring nestle within each other and together will seal the two grooves. Assemble the 3 bolt compressor sight glass to the oil regulator and install supplied bolts and nuts. Evenly and alternately torque bolts to approximately 5 ft-lbs. 4. Install oil supply line from oil reservoir to 3/8 male flare inlet on top of the regulator. 5. If an equalization connection is supplied, install oil equalization line between regulators if desired, otherwise, leave this connection sealed. 6. Insure that the regulator is level. Failure to level the regulator may cause false visual oil levels in the sight glass and can cause insufficient oil levels. If the regulator is not level, check and level the compressor as necessary. 7. Allow oil to feed and insure that the oil level matches the compressor manufacturers suggestions. Some suggested oil levels are included below in the adapter kit table. DO NOT LEAVE SYSTEM UNATTENDED UNTIL YOU KNOW THAT THE REGULATOR IS INSTALLED AND LEVEL CHECKED CORRECTLY.

Page 6

5/7//98

HENRY TECHNOLOGIES OIL CONTROL INSTRUCTION BOOKLET ASSEMBLY OF OIL LEVEL REGULATORS WITH THREADED OR FLANGED ADAPTER KITS

1. Remove compressor sight glass and replace with adapter kit. Use gaskets or o-rings from the compressor sight glass to install the adapter kit. Oil all gaskets and o-rings with a light coat of the same oil used in the system. Thread sealant may be used on threaded adapters. Flanged adapter bolts to the compressor should be evenly and alternately torqued to approximately 9 ft-lbs. Universal adapter kit 3-033-217 can be either welded or brazed to a blank sight glass housing or gland from the compressor sight glass. If the hole is too small to accept the 1 1/4 tube, the hole must be bored out to 1.25 diam. and 1/8 minimum depth. If the hole is too large, bush down the hole with a piece of tubing or reducing coupling. Insert the 1 1/4od tube in the hole and insure that it is level and braze or weld all joints. 2. Lightly oil and insert one of the o-rings supplied in the groove of the regulator flange to be connected to the adapter kit. On the adapter kit, rotate the swivel flange so that when installed, the regulator is level. Assemble supplied bolts and nuts to the flange and evenly and alternately torque bolts to approximately 5 ft-lbs. 3. Lightly oil and insert another supplied o-ring in the other regulator flange groove. Assemble the 3 bolt sight glass supplied with the adapter kit to the oil regulator and install supplied bolts and nuts. Evenly and alternately torque bolts to approximately 5 ft-lbs. 4. Install oil supply line from oil reservoir to 3/8 male flare inlet on top of the regulator. 5. If an equalization connection is supplied, install oil equalization line between regulators if desired, otherwise, leave this connection sealed. 6. Level the regulator. Failure to level the regulator may cause false visual oil levels in the sight glass and can cause insufficient oil levels. 7. Allow oil to feed and insure that the oil level matches the compressor manufacturers suggestions. Some suggested oil levels are included below in the adapter kit table. DO NOT LEAVE SYSTEM UNATTENDED UNTIL YOU KNOW THAT THE REGULATOR IS INSTALLED AND LEVEL CHECKED CORRECTLY.

Page 7

5/7//98

HENRY TECHNOLOGIES OIL CONTROL INSTRUCTION BOOKLET

SECTION VI - ELECTRO-MECHANICAL OIL LEVEL REGULATORS

.7 .8 1.1

3/8 1/2 3/4

.8 1.0

1/2 3/4

These sight glass levels are when using POE oil. Levels may vary with other oil types or densities.

REGULATOR MODEL # S-9030 S-9040 CONNECTION SIZE 3 BOLT 1 7/8 B.C. NPTF FEMALE VOLTAGE 24 V AC 50/60 hz 24 V AC 50/60 hz OPERATING DIFFERENTIAL 5-300 psig 5-90 psig OIL LEVEL, SIGHT GLASS ADJUSTABLE ADJUSTABLE

GENERAL INFORMATION

Electro-mechanical regulators are used to regulate oil levels at both low and high pressures. These units incorporate a float switch and solenoid valve combination and feature a circuit for compressor protection from loss of oil. This alarm circuit is especially important on hermetic or scroll compressors where no external oil pressure safety switch is possible. On S-9030 and S-9040 regulators, the float switch actually contains two switches, the top one to open and close the solenoid valve, and another 1/8 lower that can be used as an alarm output rated at 24 volt AC, 20 VA pilot duty. This output may be used to work a relay to open the compressor safety circuit, but a time delay should be installed. The regulator oil level may be adjusted by loosening the compression nut and raising or lowering the float switch, thus raising or lowering the feed and alarm set points accordingly. The compression nut should be tightened 1/4 turn past hand tight. DO NOT OVER TIGHTEN.

INSTALLATION

1. 2. 3. Follow the installation instructions for Mechanical Oil Level Regulators in Section VI to mount the regulator to the compressor. Wiring to power and alarm relay should be as shown and installed by qualified personnel in accordance with federal and local codes. S-9030 & S-9040 - If the alarm relay is used with a relay to shut off compressor power, it is advised to include a time delay in the circuit.

Page 8

5/7//98

HENRY TECHNOLOGIES OIL CONTROL INSTRUCTION BOOKLET

Page 9

5/7//98

HENRY TECHNOLOGIES OIL CONTROL INSTRUCTION BOOKLET

SECTION VII - OIL REGULATOR ADAPTER KITS REGULATOR ADAPTER KITS BY COMPRESSOR

Compressor Manufacturer

Bitzer Bock Bristol Carrier Carlyle Carrier Carlyle Copeland Copeland Copeland Copeland Copeland Copeland Dunham-Bush Dunham-Bush Frascold Grasso Thermtrol Maneurop Prestcold Prestcold Schnacke-Grasso Schnacke-Grasso Tecumseh Trane Trane Trane Vilter Vilter York York Any Any Pattern Not Listed

Model Number

AM,F 10 hp & under: DA,DR,5F,5H,06D,06CC 15 hp & over: EA,ER,06E,06CC under 5 tons: Copelametic HA,KA,EA,3A,LA,ER,3R Discus, 2D, 3D, 4D, 6D, 9D, 4R, 6R, 9D, 9R, MD, MR, NR older model 8R, 8D 8DP3 Scroll Big 4 D All Models All Models K C, E, R, L, & LG P, R,S,PA,RA,SA,CK,CM,CH,CG M,R K GC,GS,JS 1/4" Flare Equalization Extension (3.22" long) 3/8" Flare Equalization Extension (3.23" long) Universal Adapter Kit

Recommended Oil Level

1/2 glass 1/2 glass 1/2 glass 1/4 glass 1/4 glass 1/2 glass 1/4 glass 1/4 glass 1/4 glass 1/4 glass 1/2 glass 1/2 glass 1/2 glass 1/2 glass 1/2 glass 1/2 glass 1/2 glass 1/2 glass 1/2 glass 1/2 glass 1/2 glass 1/2 glass 1/2 glass 1/2 glass 1/2 glass 1/2 glass 1/2 glass 1/2 glass 1/2 glass 1/2 glass Any

Sight Glass Configuration

4 bolt 50mm B.C. 4 bolt 1 31/32" B.C. 15/16"-20 Thread 1 1/2"-18 Thread 3 bolt 1 7/8" B.C. 1 1/8"-12 Thread 3 bolt 1 7/8" B.C. 4 bolt 2 1/8" B.C. 3 bolt 1 7/8" B.C. 3 bolt 1 7/8" B.C. 3/4" NPT 3 bolt 1 7/8" B.C. 4 bolt 2 1/8" B.C. 3 bolt 1 7/8" B.C. 1" NPT 1 1/8"-18 Thread 1 1/8"-12 Thread 42mm Thread 2" x 16 Thread 1 1/4" NPT 1 1/8"-12 Thread 3 bolt 1 7/8" B.C. 5 bolt 2 1/2" B.C. 3/4" NPT 1 1/2" NPT 2" NPT 3 bolt 1 7/8" B.C. 1" NPT 3 bolt 1 7/8" B.C. 3 bolt 1 7/8" B.C. 1 1/4" OD Steel Tube

Henry Technologies Kit No.

3-033-253 3-033-244 3-033-242 3-033-204 3-033-201* 3-033-202 3-033-201* 3-033-207 3-033-212 3-033-254 3-033-218 3-033-201* 3-033-203 3-033-201* 3-033-228 3-033-246 3-033-202 3-033-216 3-033-205 3-033-219 3-033-202 3-033-201* 3-033-206 3-033-218 3-033-208 3-033-209 3-033-201* 3-033-228 3-033-221 3-033-227 3-033-217

* 3-033-201 included with all oil level regulators from Henry Technologies. Kit consists of two O-rings, one Quad ring, bolts and nuts. Note: All adapters with sight glass pattern different from 3 bolt 1 7/8 B.C. include one 3 bolt 1 7/8" B.C. sight glass. Where an extra length is needed to clear obstructions, use either 3-033-212 (2.59" long) or 3-033-254 (3.25" long)

+ Do not operate ANY regulator at 1/4 sight glass when using an adapter with inside diameter smaller than the regulator flange port.

Page 10

5/7//98

HENRY TECHNOLOGIES OIL CONTROL INSTRUCTION BOOKLET

SECTION VIII SERVICE/TROUBLESHOOTING

Very little service needs to be performed on oil control systems. Most or all service necessary will stem from debris in the oil, especially in systems using polyolester (POE) oil. Filters in POE oil systems should be changed at least three times in the first three months of operation and at least once a year after start-up. Many of the oil separators have cleanable/replaceable floats. Drain the oil from the separator through the 1/8 NPTF fitting on the bottom of the float assembly plate on S-1900, S-5700, and S-5200 series separators. If the float is clogged shut, there will be excessive amounts of oil in the separator, be prepared to catch a few gallons of oil on larger separators. When cleaning a float, insure that all debris is removed from the area around the float, including the magnet that picks up steel filings. Back feed oil through the 3/8 flare oil return fitting with a hand oil pump to push any debris from inside the float seat. Newer S-5200 series Helical Oil Separators include a screen tube in the sump area, which catches some debris before it enters the float sump. This screen tube should be removed and cleaned and reinserted when replacing the float assembly. Always replace the header plate gasket every time the float is removed. Re-torque all bolts evenly to 35 foot pounds. The separator must be precharged with oil after replacing the float. Oil may be back-fed into the separator through the 3/8 flare oil return fitting with a hand pump. This will take about 120 psig of pressure, but a hand pump should be able to push the float open. Once the oil is in, the float valve will keep the oil in the separator. Troubleshooting oil systems involves physically checking a few key components in the system: the oil return line from the separator, the oil reservoir level, the oil regulator levels, the oil line sight glass, and the amount of oil that can be drained from the oil separator. The first thing to check is the oil return line. Feeling the oil return line and seeing how often it gets hot is the main way to tell if the separator is working properly. It is easier if an oil line sight glass is installed, mainly because if the oil line is hot you dont really know if it is oil or hot gas causing it to be hot. If the oil line cycles between hot and cold at least a few times per hour, the separator is most likely working properly. The float tends to open and feed a few ounces of oil at a time and shut until the oil builds back up. If the oil return is cycling, there is no need to drain the separator, look at the other oil components. Always check the oil reservoir level during a service call. Oil levels in the reservoir will normally vary during periods of varying loads: compressors shut-down, hot-gas defrost, etc. This is normal, however if the level is consistently low or high, the oil system should be checked thoroughly. Compressor oil levels can be deceiving. It is some times hard to tell if the regulator is feeding oil or if oil is coming down the suction line. If the reservoir has too much pressure, often times this pressure will force oil out of the regulator and show a low level, even though there is excessive oil in the compressor. Many times the best way to check the oil in the compressor is to shut off the oil feeding to the regulator and wait a few minutes. If oil is pushed out of the regulator or trapped in the motor cavity on semi-hermetics, the compressor will over-fill. The oil line sight glass is a good way to see how the separator is working. Look for movement in the glass. If the separator is not feeding on single or low-pressure systems, the sight glass will have little or no movement and normally will appear empty, depending on how it is piped. If the separator is feeding, the sight glass will show a rush of oil and foam past the glass. To check the oil level in the separator if the separator has a drain, shut off the oil return line to prevent further feeding, pump down the system, shut off the system, evacuate the separator, and drain the oil from the bottom. The separator should hold precharge amount plus or minus a few ounces during operation. By looking at the amount above or below the precharge, any problem with the separator or float can be determined by this amount The Helical Oil Separators (S-5100 and S-5200 series) are not likely to fail due to debris as other types of oil separators, however, the float valve can be clogged or damaged. When a Helical Oil Separator is installed, the system load is not changed, and the separator worked fine for a while, if oil return from the separator becomes a problem, the float or other component is most likely the cause. Note that there is no way to clean or repair an all welded oil separator. If it is determined that the float is clogged or otherwise malfunctioning, the entire oil separator must be replaced. When the refrigerant and/or oil types are changed in a system, there is the potential for leaks around o-ring seals. Most elastomers absorb oil and refrigerant and may swell or shrink when exposed to a new oil or refrigerant. In these cases, replace the o-rings and seals in the system as needed.

Page 11

5/7//98

HENRY TECHNOLOGIES OIL CONTROL INSTRUCTION BOOKLET

SYSTEMS S-SINGLE L-LOW PRESSURE S, L S, L SEPARATOR OIL RETURN LINE OIL RESERVOIR LEVEL COMPRESSOR OIL LEVELS OIL LINE SIGHT GLASS AMOUNT OF OIL DRAINED FROM SEPARATOR PRECHARGE AMOUNT PRECHARGE AMOUNT PRECHARGE AMOUNT PROBABLE CAUSES CORRECTIVE ACTION

CYCLES CYCLES

STEADY ALWAYS LOW

STEADY STEADY OR LOW

CYCLES CYCLES

CYCLES

ALWAYS LOW

HIGH

CYCLES

CYCLES

ALWAYS LOW

HIGH

CYCLES

PRECHARGE AMOUNT PRECHARGE AMOUNT PRECHARGE AMOUNT PRECHARGE AMOUNT

S, L

CYCLES

ALWAYS HIGH

STEADY OR HIGH

CYCLES

CYCLES

ALWAYS HIGH

LOW

CYCLES

CYCLES

ALWAYS HIGH

LOW

CYCLES

SYSTEM WORKING PROPERLY SYSTEM WORKING PROPERLY, NOT ENOUGH OIL OIL LEVEL SET TOO HIGH ON REGULATORS, POSSIBLE REGULATOR LEAKING EXCESSIVE RESERVOIR PRESSURE SYSTEM WORKING PROPERLY, TOO MUCH OIL OIL LEVEL SET TOO LOW ON REGULATORS INSUFFICIENT RESERVOIR PRESSURE

NONE ADD OIL TO SYSTEM

LOWER REGULATOR LEVELS, REPLACE REGULATOR IF NECESSARY

CHECK RESERVOIR PRESSURE VS. SUCTION REMOVE OIL FROM SYSTEM RAISE REGULATOR LEVELS CHECK RESERVOIR PRESSURE VS. SUCTION, REPLACE RESERVOIR PRESSURE VALVE REPLACE STRAINERS OR REGULATORS REMOVE EXCESS OIL FROM SYSTEM

CYCLES

ALWAYS HIGH

LOW

CYCLES

PRECHARGE AMOUNT EXCESSIVE OIL

S, L

ALWAYS HOT OR VERY FREQUENTLY HOT

ANY

ANY

STREAM OF OIL

S, L

ALWAYS HOT OR VERY FREQUENTLY HOT

ANY

ANY

HOT GAS OR FOAM

EMPTY

OIL STRAINERS OR REGULATORS CLOGGED SYSTEM OIL LOGGED, SEPARATOR FEEDING MORE OIL THAN COMPRESSORS NORMALLY SHOULD EMIT SEPARATOR FLOAT STUCK OPEN OR LEAKING

S, L

ALWAYS HOT OR VERY FREQUENTLY HOT

ANY

ANY

HOT GAS OR FOAM

EMPTY

S, L

ALWAYS ROOM TEMP ALWAYS ROOM TEMP ALWAYS ROOM TEMP COLD, SWEATING OR FROSTING AT START UP

EMPTY

EMPTY

EMPTY

EXCESSIVE OIL

SEPARATOR TOO SMALL EXCESSIVE VELOCITY CAUSING FLOAT TO BOUNCE SEPARATOR FLOAT CLOGGED OIL FILTER CLOGGED SEPARATOR TOO LARGE, INEFFICIENT SEPARATION LIQUID REFRIGERANT BACK FEEDING OR MIGRATING TO SEPARATOR DURING COMPRESSOR OFF CYCLE LIQUID REFRIGERANT CONDENSING IN SEPARATOR FROM LOSS OF SUPERHEAT, COLD AMBIENT, POSSIBLE SEPARATOR TOO LARGE

OLD SYSTEMREMOVE FLOAT AND CLEAN/REPLACE NEW SYSTEMINSURE OIL SEPARATOR WAS PRECHARGED REVIEW SEPARATOR SIZING

S, L S, L

EMPTY EMPTY

EMPTY EMPTY

EMPTY EMPTY

EXCESSIVE OIL PRECHARGE OR EMPTY DO NOT DRAIN SEPARATOR

REMOVE AND CLEAN/REPLACE FLOAT REPLACE FILTER DOUBLE-CHECK SIZING INSTALL DISCHARGE CHECK VALVE BETWEEN SEPARATOR & CONDENSER

S, L

ANY

ANY

LIQUID REFRIGERANT & OIL

S, L

COLD, SWEATING OR FROSTING WHILE SYSTEM RUNNING

ANY

ANY

LIQUID REFRIGERANT & OIL

DO NOT DRAIN SEPARATOR

INSULATE SEPARATOR, ADD HEAT BAND REVIEW SEPARATOR SIZING

Page 12

5/7//98

HENRY TECHNOLOGIES OIL CONTROL INSTRUCTION BOOKLET

SECTION IX REPLACEMENT PARTS

Oil Separators

Model Number S-5500 series S-5800 series S-5600 series S-5700 series S-1900 series S-5100 series S-5200 series SN-5200 series (Europe only) S-5400 series (Europe only) Description 4 O.D. Conventional All-Welded 4 O.D. Conventional Cleanable 6 O.D. Conventional All-Welded 6 O.D. Conventional Cleanable 8, 10, or 12 Conventional Cleanable 4 or 6 O.D. Helical All-Welded 6, 8, 10, or 12 Helical Cleanable 6, 8, 10, or 12 Helical Cleanable, Suitable for R-717 8, 10, or 12 Helical Cleanable, Suitable for R-717 Gasket Float Screen All-welded unit, no service possible A-5000-30 Not Replaceable Sump Screen

2-023-001

None

All-welded unit, no service possible 2-023-001 2-023-001 A-5700-30 A-1900-30 3-010-301 Not Replaceable None None

All-welded unit, no service possible 2-023-001 2-023-001 2-023-001 A-1900-30 A-2900-30 A-2900-30 None None None 2-010-048 None None

Oil Reservoirs

Model Number S-9109 S-9108U (Europe only) S-9108 Capacity 2 gal (9.1 L) 3 gal (13.6 L) 4 gal (18.2 L) Rotalock Valve 2-030-122 2-030-122 2-030-122 Rotalock Gasket 2-023-018 2-023-018 2-023-018 Sight Glass 3-020-053 3-020-053 3-020-053 Qty. 2 2 3

Mechanical Oil Level Regulators

Model Number S-9010A, S-9090A All Others Seal Kit 3-033-201 Sight Glass 3-020-011 2-020-006 Gasket 2-023-005 O-ring 2-023-002 Qty. 2 Quad Ring 2-023-003 Qty. 1

Electro-Mechanical Oil Level Regulators

Model Number S-9030 S-9040 Voltage 24 V AC 24 V AC Float Switch Kit 3-044-016 3-044-016 Solenoid Valve Kit 3-044-017 3-044-017 Time Delay Module 3-044-018

Page 13

5/7//98

También podría gustarte

- Copelametic Tandem CompressorsDocumento4 páginasCopelametic Tandem CompressorsjosecevmspAún no hay calificaciones

- Oil SystemDocumento22 páginasOil Systemlopesmr100% (1)

- Boiler Module VDocumento23 páginasBoiler Module VdeepanckAún no hay calificaciones

- LEDEEN ActuatorsDocumento24 páginasLEDEEN ActuatorssalmonsilalahiAún no hay calificaciones

- CA-Valves and Solenoid Valves ENG 2019 LowResDocumento326 páginasCA-Valves and Solenoid Valves ENG 2019 LowResjurandyr LamegoAún no hay calificaciones

- Olaer EhvDocumento12 páginasOlaer EhvandinoAún no hay calificaciones

- 3 Way Spirax Sarco s22 - 06Documento8 páginas3 Way Spirax Sarco s22 - 06Zoran DanilovAún no hay calificaciones

- API-ALL PanDocumento23 páginasAPI-ALL PanBajajAún no hay calificaciones

- Atmospheric Relief Valve ManualDocumento12 páginasAtmospheric Relief Valve ManualTarun ChandraAún no hay calificaciones

- Process Control Elements in The LoopDocumento1 páginaProcess Control Elements in The LoopMark Tristan VallesterosAún no hay calificaciones

- Bladder Accumulator Olaer EHV EHVF 1425384043 PDFDocumento16 páginasBladder Accumulator Olaer EHV EHVF 1425384043 PDFJas SumAún no hay calificaciones

- Reciprocating Compressor Cooloing ConsoleDocumento22 páginasReciprocating Compressor Cooloing ConsolerutujaAún no hay calificaciones

- PMC 02 Process Control Fundamentals Control Loop PDFDocumento29 páginasPMC 02 Process Control Fundamentals Control Loop PDFPrince PrashanthAún no hay calificaciones

- Handbook Oil Control 01-Co-EngDocumento26 páginasHandbook Oil Control 01-Co-EngfebriAún no hay calificaciones

- Furnaces (: Also Called Fired Heaters)Documento28 páginasFurnaces (: Also Called Fired Heaters)deua2004Aún no hay calificaciones

- Model Answers of FractionationDocumento16 páginasModel Answers of FractionationAhmed Mohamed KhalilAún no hay calificaciones

- Boiler Water TreatmentDocumento57 páginasBoiler Water TreatmentUmar AsimAún no hay calificaciones

- Lesson Plan CPE420-Sept 13-Jan 14Documento6 páginasLesson Plan CPE420-Sept 13-Jan 14lancaugilaAún no hay calificaciones

- New Microsoft Office Word DocumentDocumento15 páginasNew Microsoft Office Word DocumentSwapnil RaulAún no hay calificaciones

- 23.bladder AccumlatorDocumento12 páginas23.bladder AccumlatorM S GokulAún no hay calificaciones

- Reciprocating Compressor I. What Is A Reciprocating Compressor?Documento13 páginasReciprocating Compressor I. What Is A Reciprocating Compressor?Bá TrườngAún no hay calificaciones

- Pressure Relief ValveDocumento1 páginaPressure Relief ValveCham Kok SoonAún no hay calificaciones

- Compressir Lubrication Theory DanfossDocumento7 páginasCompressir Lubrication Theory DanfossSlavikNZAún no hay calificaciones

- F 0077 e 55Documento6 páginasF 0077 e 55Bùi Cảnh TrungAún no hay calificaciones

- Baelz-Electrodyn - 2 and 3 Way Control Valves For Hot Oil - BPE57Documento0 páginasBaelz-Electrodyn - 2 and 3 Way Control Valves For Hot Oil - BPE57Josito HNAún no hay calificaciones

- Basic Parts of A BoilerDocumento9 páginasBasic Parts of A Boilermessi107Aún no hay calificaciones

- Ammonia Plant Maint.Documento11 páginasAmmonia Plant Maint.mahmadwasiAún no hay calificaciones

- No Oil Pump - No Pre Lubrification - Low Oil Quantity: Ep - 68.1 Psig Ep - 470 KpaDocumento1 páginaNo Oil Pump - No Pre Lubrification - Low Oil Quantity: Ep - 68.1 Psig Ep - 470 KpaKashif VeeraAún no hay calificaciones

- 23 09 13.33 - Control ValvesDocumento25 páginas23 09 13.33 - Control Valvesforevertay2000Aún no hay calificaciones

- Crude Oil TreatmentDocumento85 páginasCrude Oil Treatmentamiegy440Aún no hay calificaciones

- Liquid Recirculation System-2Documento7 páginasLiquid Recirculation System-2Behnam AshouriAún no hay calificaciones

- 08b PDFDocumento38 páginas08b PDFProcess EngineerAún no hay calificaciones

- Refrigeration Screw Compressors and Chilling Units PDFDocumento8 páginasRefrigeration Screw Compressors and Chilling Units PDFAmandeep singhAún no hay calificaciones

- Twin Screw Compressor PLC Operation Manual (PDFDrive)Documento158 páginasTwin Screw Compressor PLC Operation Manual (PDFDrive)sola sidoAún no hay calificaciones

- Buffer and Barrier Fluids PDFDocumento4 páginasBuffer and Barrier Fluids PDFrgbhattacharyaAún no hay calificaciones

- AERCO Boiler Benchmark 3.0Documento129 páginasAERCO Boiler Benchmark 3.0hfdadl100% (1)

- CP PetDocumento4 páginasCP PetjayeshAún no hay calificaciones

- Installation, Operation, and Maintenance Manual Magnitude Magnetic Bearing Centrifugal Chillers IOM 1210-7Documento70 páginasInstallation, Operation, and Maintenance Manual Magnitude Magnetic Bearing Centrifugal Chillers IOM 1210-7MAún no hay calificaciones

- Comparison Carrier vs. McQuayDocumento2 páginasComparison Carrier vs. McQuayPradeep SukumaranAún no hay calificaciones

- Trays in RefineryDocumento22 páginasTrays in RefineryHammad HashmiAún no hay calificaciones

- 11 Compressor Terms Acronyms Units of MeasureDocumento8 páginas11 Compressor Terms Acronyms Units of MeasureLe Anh DangAún no hay calificaciones

- Centrifugal Compressor 1588467358 PDFDocumento59 páginasCentrifugal Compressor 1588467358 PDFEngr TheyjiAún no hay calificaciones

- HX HN Compressors Brochure 2015 0318 LRDocumento20 páginasHX HN Compressors Brochure 2015 0318 LRAlbert Paco GoytiaAún no hay calificaciones

- Refrigeration (VCRS &VARS)Documento19 páginasRefrigeration (VCRS &VARS)Vinesh TalpankarAún no hay calificaciones

- KSB Mechanical Seals - Failure Analysis PDFDocumento34 páginasKSB Mechanical Seals - Failure Analysis PDFWaqas WakeelAún no hay calificaciones

- Electrostatic Coalescer (Laminar Flow)Documento3 páginasElectrostatic Coalescer (Laminar Flow)Yusof SundangAún no hay calificaciones

- Zeks Compressed Air SolutionsDocumento39 páginasZeks Compressed Air SolutionsChristian MabayaAún no hay calificaciones

- Piping Lube OilOilconsole - enDocumento8 páginasPiping Lube OilOilconsole - engopojiAún no hay calificaciones

- Systems Description Lubricating Oil System For LM2000Documento3 páginasSystems Description Lubricating Oil System For LM2000KALPUSHAún no hay calificaciones

- Chapter 6 Screw CompressorsDocumento26 páginasChapter 6 Screw CompressorsHoàngViệtAnhAún no hay calificaciones

- Helical Oil SeparatorsDocumento6 páginasHelical Oil SeparatorsGauravAún no hay calificaciones

- Best Practices For Steam Control Valve InstallationDocumento4 páginasBest Practices For Steam Control Valve InstallationBen MusimaneAún no hay calificaciones

- 19xr CLT 13ssDocumento116 páginas19xr CLT 13ssRicardoAún no hay calificaciones

- Troubleshooting Boiler OperationDocumento5 páginasTroubleshooting Boiler OperationRahul ChandrawarAún no hay calificaciones

- HVAC ChillerDocumento39 páginasHVAC ChillerRaja VigneshAún no hay calificaciones

- Compressor Exams SolutionsDocumento18 páginasCompressor Exams SolutionsMohamed BalbaaAún no hay calificaciones

- Unit 3 Fractionation & Distillation EquipmentDocumento15 páginasUnit 3 Fractionation & Distillation EquipmentKha Mn100% (1)

- Understanding Oil Return in Refrigeration SystemsDocumento6 páginasUnderstanding Oil Return in Refrigeration SystemsSvetoslav VlashkiAún no hay calificaciones

- Parker Oil Cross ReferenceDocumento3 páginasParker Oil Cross ReferenceWarwick HolthamAún no hay calificaciones

- Oil SepratorsDocumento4 páginasOil SepratorsMohammad Amer0% (1)

- CombustionDocumento35 páginasCombustionBernard Tan100% (1)

- Defrost Catalog by ICMDocumento14 páginasDefrost Catalog by ICMrlynch33Aún no hay calificaciones

- Rinnai Service ManualDocumento112 páginasRinnai Service Manualrlynch33100% (1)

- UNT 1100 Controller User GuideDocumento87 páginasUNT 1100 Controller User Guiderlynch33Aún no hay calificaciones

- Fenwall Series35-72Documento8 páginasFenwall Series35-72rlynch33Aún no hay calificaciones

- McdonmillserviceDocumento40 páginasMcdonmillservicerlynch33Aún no hay calificaciones

- Fireye E340 Boiler Room ControlDocumento44 páginasFireye E340 Boiler Room Controlrlynch33Aún no hay calificaciones

- Carlyle Compressor O6D/EDocumento72 páginasCarlyle Compressor O6D/Erlynch33100% (6)

- Oil Controls ManualDocumento84 páginasOil Controls Manualrlynch33100% (2)

- Steam Traps - Engineering Data ManualDocumento50 páginasSteam Traps - Engineering Data ManualThitikorn Wassanarpheernphong100% (1)

- Boiler Control System EngineeringDocumento79 páginasBoiler Control System EngineeringAdelChAún no hay calificaciones

- Manual de Instalação - DanfossDocumento36 páginasManual de Instalação - DanfossdocitohAún no hay calificaciones

- Danfoss PF000G102Documento212 páginasDanfoss PF000G102abby_nipaAún no hay calificaciones

- Sprolan 3-Wat Heat Reclaim Valves Service ManualDocumento12 páginasSprolan 3-Wat Heat Reclaim Valves Service Manualrlynch33Aún no hay calificaciones

- Maintenance and Operation Small Heating SystemsDocumento159 páginasMaintenance and Operation Small Heating Systemsrlynch33Aún no hay calificaciones

- Copeland Scroll ZRK5 CompressorDocumento16 páginasCopeland Scroll ZRK5 Compressorrlynch33Aún no hay calificaciones

- Central Boiler PlantsDocumento351 páginasCentral Boiler Plants설동하Aún no hay calificaciones

- Heatcraft - Engineering Manual (2008)Documento44 páginasHeatcraft - Engineering Manual (2008)sauro83% (12)

- Fireye E340 Boiler Room ControlDocumento44 páginasFireye E340 Boiler Room Controlrlynch33Aún no hay calificaciones

- Oil Pressure Problems in Refrigeration SystemsDocumento6 páginasOil Pressure Problems in Refrigeration Systemsrlynch33100% (1)

- Formulas For The HVAC TradesmanDocumento14 páginasFormulas For The HVAC Tradesmanrlynch33Aún no hay calificaciones

- Microprocessor - Based DDC FundamentalsDocumento20 páginasMicroprocessor - Based DDC FundamentalsthenshanAún no hay calificaciones

- Danfoss Refrigeration BasicsDocumento24 páginasDanfoss Refrigeration Basicsrlynch33100% (1)

- Carlyle Service ManualDocumento124 páginasCarlyle Service Manualrlynch3394% (16)

- Sacmi Vol 2 Inglese - II EdizioneDocumento416 páginasSacmi Vol 2 Inglese - II Edizionecuibaprau100% (21)

- XI STD Economics Vol-1 EM Combined 12.10.18 PDFDocumento288 páginasXI STD Economics Vol-1 EM Combined 12.10.18 PDFFebin Kurian Francis0% (1)

- 9.admin Rosal Vs ComelecDocumento4 páginas9.admin Rosal Vs Comelecmichelle zatarainAún no hay calificaciones

- Estimation and Detection Theory by Don H. JohnsonDocumento214 páginasEstimation and Detection Theory by Don H. JohnsonPraveen Chandran C RAún no hay calificaciones

- Defeating An Old Adversary Cement Kiln BallsDocumento5 páginasDefeating An Old Adversary Cement Kiln BallsManish KumarAún no hay calificaciones

- FBW Manual-Jan 2012-Revised and Corrected CS2Documento68 páginasFBW Manual-Jan 2012-Revised and Corrected CS2Dinesh CandassamyAún no hay calificaciones

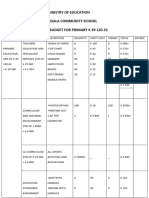

- Ministry of Education Musala SCHDocumento5 páginasMinistry of Education Musala SCHlaonimosesAún no hay calificaciones

- Chapter 3 Searching and PlanningDocumento104 páginasChapter 3 Searching and PlanningTemesgenAún no hay calificaciones

- Time-Dependent Deformation of Shaly Rocks in Southern Ontario 1978Documento11 páginasTime-Dependent Deformation of Shaly Rocks in Southern Ontario 1978myplaxisAún no hay calificaciones

- Descriptive Statistics - SPSS Annotated OutputDocumento13 páginasDescriptive Statistics - SPSS Annotated OutputLAM NGUYEN VO PHIAún no hay calificaciones

- Numerical Transformer Differential RelayDocumento2 páginasNumerical Transformer Differential RelayTariq Mohammed OmarAún no hay calificaciones

- Nisha Rough DraftDocumento50 páginasNisha Rough DraftbharthanAún no hay calificaciones

- EC2 406006 001 EFE 0121 - Controgen Generator Excitation System Description - Rev - ADocumento29 páginasEC2 406006 001 EFE 0121 - Controgen Generator Excitation System Description - Rev - AAnonymous bSpP1m8j0n50% (2)

- MSA Chair's Report 2012Documento56 páginasMSA Chair's Report 2012Imaad IsaacsAún no hay calificaciones

- Jetweigh BrochureDocumento7 páginasJetweigh BrochureYudi ErwantaAún no hay calificaciones

- PartitionDocumento5 páginasPartitionKotagiri AravindAún no hay calificaciones

- TP1743 - Kertas 1 Dan 2 Peperiksaan Percubaan SPM Sains 2023-20243Documento12 páginasTP1743 - Kertas 1 Dan 2 Peperiksaan Percubaan SPM Sains 2023-20243Felix ChewAún no hay calificaciones

- Random Variable N N Mean or Expected Value: Number of Ducks Type of Duck AmountDocumento2 páginasRandom Variable N N Mean or Expected Value: Number of Ducks Type of Duck AmountAngie PastorAún no hay calificaciones

- Lecture 1Documento11 páginasLecture 1Taniah Mahmuda Tinni100% (1)

- Labor CasesDocumento47 páginasLabor CasesAnna Marie DayanghirangAún no hay calificaciones

- Switch CondenserDocumento14 páginasSwitch CondenserKader GüngörAún no hay calificaciones

- Aman 5Documento1 páginaAman 5HamidAún no hay calificaciones

- Customer Satisfaction-ICICI Bank-Priyanka DhamijaDocumento85 páginasCustomer Satisfaction-ICICI Bank-Priyanka DhamijaVarun GuptaAún no hay calificaciones

- BSBOPS601 Develop Implement Business Plans - SDocumento91 páginasBSBOPS601 Develop Implement Business Plans - SSudha BarahiAún no hay calificaciones

- Bill Swad's Wealth Building Strategies - SwadDocumento87 páginasBill Swad's Wealth Building Strategies - Swadjovetzky50% (2)

- Go Ask Alice EssayDocumento6 páginasGo Ask Alice Essayafhbexrci100% (2)

- Possession: I. A. Definition and Concept Civil Code Art. 523-530 CasesDocumento7 páginasPossession: I. A. Definition and Concept Civil Code Art. 523-530 CasesPierrePrincipeAún no hay calificaciones

- Exercise 23 - Sulfur OintmentDocumento4 páginasExercise 23 - Sulfur OintmentmaimaiAún no hay calificaciones

- Practitioners Guide For Business Development Planning in FPOsDocumento70 páginasPractitioners Guide For Business Development Planning in FPOsMythreyi ChichulaAún no hay calificaciones

- QCM Part 145 en Rev17 310818 PDFDocumento164 páginasQCM Part 145 en Rev17 310818 PDFsotiris100% (1)