Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Basic Vacuum Theory

Cargado por

petar petarDescripción original:

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Basic Vacuum Theory

Cargado por

petar petarCopyright:

Formatos disponibles

www.jets.

no

JETS VACUUM AS. P.O. Box 14, N-6069 Hareid, Norway. Tel. + 47 70 03 91 00. Fax + 47 70 03 91 01. E-mail: post@jets.no

www.jets.no

ISSUE H - January 2007 -

Jets Vacuum Product Catalogue

Vacuum theory & background

www.jets.no

JETS VACUUM AS. P.O. Box 14, N-6069 Hareid, Norway. Tel. + 47 70 03 91 00. Fax + 47 70 03 91 01. E-mail: post@jets.no

www.jets.no

ISSUE H - January 2007 - 2

Jets Vacuum Product Catalogue

Vacuum theory & background

Contents:

Company presentation........................................................................................................................................................................3

Terminology...........................................................................................................................................................................................4

Basic vacuum theory............................................................................................................................................................................5

The vauum toilet system.....................................................................................................................................................................9

Vacuum toilet system - Advantages.................................................................................................................................................10

Vacuum systems - History..................................................................................................................................................................11

The vacuum tank system....................................................................................................................................................................12

The ejector system...............................................................................................................................................................................13

The vacuumarator system..................................................................................................................................................................14

The Jets system.....................................................................................................................................................................................15

The Jets system - Advantages............................................................................................................................................................16

Mode of operation Jets Vacuumarator.............................................................................................................................................17

Contents

www.jets.no

JETS VACUUM AS. P.O. Box 14, N-6069 Hareid, Norway. Tel. + 47 70 03 91 00. Fax + 47 70 03 91 01. E-mail: post@jets.no

www.jets.no

ISSUE H - January 2007 -

Jets Vacuum Product Catalogue

Vacuum theory & background

SANITARY SYSTEMS MADE TO PLEASE.

With its unique design fexibility, Jets Sanitary systems are suit-

able for any marine installation.

Simple-in line installation, no need for tanks, small footprint and

scope for tailor made confgurations make Jets the preferred

solution for vessels from fshing boats to cruise ships.

PROVEN TECHNOLOGY - THOUSANDS OF INSTALLATIONS

WORLD WIDE

The number of Jets installations is accelerating. Every second

new built ship with a vacuum toilets system is ftted with Jets.

GLOBAL SUPPORT

We have a close network of enthusiastic, highly qualifed

representatives with professional experience.

The know-how in marine sanitation, developed over the years

since the start of Jets in 986 is one of Jets most important

assets.

Every response from customers gives us an opportunity to

improve performance and reduce cost.

Combining this feedback with our practical expertise gives us a

strong basis for fulflling your needs and providing sanitary

systems made to please.

Jets Vacuum AS

www.jets.no

JETS VACUUM AS. P.O. Box 14, N-6069 Hareid, Norway. Tel. + 47 70 03 91 00. Fax + 47 70 03 91 01. E-mail: post@jets.no

www.jets.no

ISSUE H - January 2007 -

Jets Vacuum Product Catalogue

Vacuum theory & background

Atmospheric pressure:

Air pressure at sea level

Vacuum:

Any air pressure below atmospheric pressure

Grey water:

Water from showers, wash basins and laundry

Black water:

Water and effuents from toilets

Vacuum generator:

Equipment which generates and maintain

vacuum

Vacuumarator:

A vacuum generator developed by Jets which

generates vacuum, macerates sewage and

transfers sewage in one and the same opera-

tion. The pump of the vacuumarator is a spe-

cially developed Helivac pump.

Vacuum unit:

A unit consisting of one or more vacuum gen-

erators or Vacuumarators with control equip-

ment.

Vacuum system:

A complete system consisting of vacuum unit,

vacuum toilets and in some cases also inter-

face units for grey water and urinals.

EFD valve:

Electronic fushing and discharge valve. The

mechanism operating the fushing and dis-

charge of toilets.

ED valve:

Electronic discharge valve. The mechanism

operating the discharge of the content in a

grey water interface unit or a urinal tank.

FD valve:

Flush and discharge valve. Used together with

the VPC controller for operation of toilets.

VPC controller:

Vacuum powered cam controller. Mechanism

for pneumatic operation of the FD valve.

VPC-V controller:

Vacuum powered cam controller. Mechanism

for vacuum operation of the FD valve.

Sealing liquid ring:

Liquid ring created by the rotor when a vacu-

umarator is in operation.

Sealing liquid:

Liquid needed for safe operation, normally

re-supplied black water from the pipes on the

pressure side.

Grey water interface unit:

Tank (normally 8 or 16 ltr) ftted with an ED

valve and a level sensor for activating the ED

valve and discharge of the tank. Unit to be

used to interface grey water by gravity with the

Vacuum system.

Collecting tank:

Tank for colleting of black and in some cases

also grey water from a Vacuum system.

Holding tank:

Tank for holding ( storage) of black and in

some cases also grey water.

Vacuum breaker:

Device to prevent back fow (siphon effect)

with contaminated water going from a toilet

and into the fresh water supply system.

Sewage Treatment plant:

Plant for treatment of black water and in some

cases also grey water before overboard dis-

charge.

Terminology

www.jets.no

JETS VACUUM AS. P.O. Box 14, N-6069 Hareid, Norway. Tel. + 47 70 03 91 00. Fax + 47 70 03 91 01. E-mail: post@jets.no

www.jets.no

ISSUE H - January 2007 -

Jets Vacuum Product Catalogue

Vacuum theory & background

We consider the air to be homogeneous

Talking about atmospheric air, we actually talk about a mixture of several gases

and steam. In the following we consider air to be a homogeneous mass. We

assume that air consists of particles equal in size, weight and behaviour. We

ignore the fact that air normally contains steam.

Particles in movement

At sea level 1m air has the weight of approximately 1,2 kg. This air consists of

a great amount of particles that are in constant movement. To illustrate this one

can imagine a great amount of small balls buzzing around in a limited space,

resulting many collisions between the particles and the environment. The envi-

ronment may be the walls in a tank, a piping system or a liquid surface. This is

of great importance for the pump technique.

Atmospheric pressure

All these collisions acts as a constant pressure on the environment. This pres-

sure we call the

Atmospheric pressure

It acts in all directions and is equal to the weight of the air mass in a given area.

Absolute pressure

The pressure decreases proportionally with the altitude as the air gets thinner.

In the empty space some hundred kilometres above sea level the pressure has

decreased to zero. The amount of particles and the collisions are then so rare,

that a pressure cannot be measured.

We have to emphasize that a completely empty space does not exist, and it

can also not be practically created. The pressure existing in the imagined emp-

ty space is at the absolute zero point. Going down through the atmosphere a

rising pressure can be measured. These levels of pressure are called abso-

lute pressures.

Measuring units

The pressure measured at sea level is called one atmosphere; atm. Several

measuring units have been used to defne this pressure.

atm equals:

kp/cm = the weight of a 760 mm quicksilver pillar = 760 Torr = the weight of

a 10,33 m water pillar

The normal atmospheric pressure is internationally fxed at 1013 mbar. Pres-

sure is to be measured in mbar or N/m. N/m is seldom used as a measuring

unit today. For simplicity pressures in a vacuum sanitary system are normally

measured in % vacuum.

Vacuum area

The pressure area from the absolute zero point to the atmospheric pressure is

called the vacuum area or the underpressure area. We have to emphasize that

there is no such thing as a negative pressure. Underpressure or vacuum is

therefore pressure level, which are beneath the atmospheric pressure.

More...

Basic Vacuum

Theory

www.jets.no

JETS VACUUM AS. P.O. Box 14, N-6069 Hareid, Norway. Tel. + 47 70 03 91 00. Fax + 47 70 03 91 01. E-mail: post@jets.no

www.jets.no

ISSUE H - January 2007 - 6

Jets Vacuum Product Catalogue

Vacuum theory & background

Boyle-Mariottes law gives us the following equation:

P x V = K

P = pressure, V = volume, K = constant value

More...

Basic Vacuum

Theory

Boyle-Mariottes law

If the temperature is kept constant for a defned amount of gas, the

pressure and the volume will be inversely proportional.

This can be illustrated in the following way:

Cylinder A contains m air at atmosphere pressure (0 mbar).

The air pressure is called: P = 0 mbar

The volume is called: V = m

In cylinder B the piston has been pushed so far down that the volume in

the cylinder has become 0,5m.

This means that the air particles have been compressed, so that the

particle density is twice as big as in fg. A. We assume that the tempera-

ture has not been changed from A to B.

P

A

= 1013 mbar

V

A

= 1 m

3

P

B

= 2026 mbar

V

B

= 0,5 m

3

P

C

= 506,5 mbar

V

C

= 2 m

3

A B

The fgures represent cylinders with a piston.

C

The air pressure in B will be: P = 2026 mbar

The volume will be: V = 0,5 m

In cylinder C, we have pulled the piston further out, so that the volume

in the cylinder now is 2 m. Because we have the same amount of air in

the cylinder, this means that the particle density is only 50% compared

to fg. A. Therefore also the pressure is halved. We still assume that the

temperature has not been changed.

The air pressure in C will be: P = 506,5 mbar

The volume will be: V = 2 m

When we multiply pressure and volume in these three cases, we will

get the following:

P

A

x V

A

= 1013 x 1 = 1013

P

B

x V

B

= 2026 x 0,5 = 1013

P

C

x V

C

= 506,5 x 2 = 1013

We can see that pressure multiplied with volume is equal in all three

cases. This means that if you change the condition of a closed mass of

air, the multiplication of pressure and air will be kept constant.

This is called Boyle-Mariottes law.

In fg. C, when we pulled the piston, we created an empty space (a

low pressure area) between the piston and the air beneath it. Because

of the internal pressure in the air mass, this space was immediately

flled with air particles. After a short time, the dispersion became uniform

in the whole cylinder. The pressure became equal in the whole cylinder.

www.jets.no

JETS VACUUM AS. P.O. Box 14, N-6069 Hareid, Norway. Tel. + 47 70 03 91 00. Fax + 47 70 03 91 01. E-mail: post@jets.no

www.jets.no

ISSUE H - January 2007 - 7

Jets Vacuum Product Catalogue

Vacuum theory & background

It is the pressure within the mass of air that pushes the air particles into

the empty space beneath the piston.

This capability of pushing is the basis for all pump technique.

The capability applies to air- and liquid pumps. All the time there must be

a certain pressure on the inlet or the suction side of a pump.

Within a locked up mass of

air, the pressure is equal.

V = 00 ltr

P = 000 mbar

Tank: Pump:

Piston displacement = 0ltr

Pos 2

Pos

To the

atmosphere

Non return valves

The principle of a vacuum pump

The fgure indicates a closed tank that contains 100 litres of air at

000 mbar pressure.

A thin pipeline connects the tank with the inlet side of a hand pump. The

pressure side of the hand pump opens to the atmosphere. Non-return valves

are placed in the pipeline on each side of the pump. The pump has a 0 litres

piston displacement. We now ignore the volume in the pipeline.

When the piston is in position 1, the total volume is:

V

= 00ltr.

When the piston is in position 2, the total volume is:

V

2

= V

+0ltr. = 0ltr.

The starting point for the pump operation is:

P x V = 1000 x 100 = 100000

When the piston has been pulled to position 2, the pressure in the tank will

push air particles over to the pump, until the pressure is the same in both

tank and pump. The new pressure level, after the frst piston stroke, is called

P.

This means that when the piston is pulled to the top (position 2), the total vol-

ume in the system is 0 ltr.

According to Boyle Mariottes law P x V = constant

This gives us the following:

P

x 110 = 100000

By solving the equation, we fnd that

P

= 909 mbar.

Thereafter, when the piston is pushed to the bottom (position 1), we will get

the following result:

Volume in the system = V = 00 ltr.

Pressure, P

= 909 mbar

More...

Basic Vacuum

Theory

www.jets.no

JETS VACUUM AS. P.O. Box 14, N-6069 Hareid, Norway. Tel. + 47 70 03 91 00. Fax + 47 70 03 91 01. E-mail: post@jets.no

www.jets.no

ISSUE H - January 2007 - 8

Jets Vacuum Product Catalogue

Vacuum theory & background

Comparison table between new and old

vacuum measurement units:

By the next piston stroke we will get:

909 x 100 = P

2

x 110

By solving the equation, we fnd that

P

2

= 826 mbar.

Continuing this process, we will fnd the following:

P

3

= 750 MBAR P

4

= 681 MBAR P

5

= 619 MBAR

P

6

= 562 MBAR P

7

= 513 MBAR P

8

= 464 MBAR

P

9

= 424 MBAR P

10

= 385 MBAR

Concluding that the pressure drop per piston stroke is getting less and

less.

The pressure will never reach zero.

To illustrate the function, the fgure showed a simple piston pump. With

some exceptions, the principle is the same for all pump types:

The working element in the pump (e.g piston or rotor) creates an

empty space which will be flled because of the pressure in the suc-

tion pipeline.

Thereafter, the connection between the suction pipeline and the rotor/pis-

ton will be closed, and the air is pushed out through the pumps discharge

pipe.

If the pumps working element only consists of mechanical parts, the ca-

pacity per stroke or rotation will be the same all over the pressure area in

which it operates.

mbar N/m

2

atm % Vacuum mH

2

O

1013 101300 1,0 0 10,33

1000 100000 0,98 1,3 10,20

900 90000 0,88 11,1 9,17

600 60000 0,59 40,8 6,11

300 30000 0,29 70,4 3,05

100 10000 0,10 90 1,02

0 0 0 100 0

Basic Vacuum

Theory

www.jets.no

JETS VACUUM AS. P.O. Box 14, N-6069 Hareid, Norway. Tel. + 47 70 03 91 00. Fax + 47 70 03 91 01. E-mail: post@jets.no

www.jets.no

ISSUE H - January 2007 - 9

Jets Vacuum Product Catalogue

Vacuum theory & background

What is a vacuum toilet

system?

The basic principle behind a vacuum toilet system is to use differences

in air pressure to transport sewage from toilets and urinals and even-

tually also grey water from sinks and showers. In a modern vacuum

system the vacuum is generated directly on the piping, keeping the total

system at a constant vacuum, normally between 35 and 50 % vacuum.

When a toilet is fushed approximately 60 litres of air is sucked into the

piping together with approximately 1 litre of water. The water and sew-

age create a slug and the transport proceeds in such slugs as a re-

sult of the difference in air pressure in front of and behind the slug.

%

vacuum

Slug

From

toilet

etc.

To vacuum

generator

0%

vacuum

During the transport in the piping system the slug is effected by gravity

and will after a time fatten out. Because of this it is necessary to have

low point in the piping in order to re- form slugs and thus re-establish

the pressure difference needed for further transport.

The Vacuum toilet

system

www.jets.no

JETS VACUUM AS. P.O. Box 14, N-6069 Hareid, Norway. Tel. + 47 70 03 91 00. Fax + 47 70 03 91 01. E-mail: post@jets.no

www.jets.no

ISSUE H - January 2007 - 0

Jets Vacuum Product Catalogue

Vacuum theory & background

Vacuum toilet system

Advantages

During the last 0 years vacuum toilet systems have become

common on all types of ships.

Designers and builders of passenger ships and special ves-

sels have for many years used vacuum systems as a standard.

In recent years however, the trend goes in direction of vacuum

systems on all types and sizes of ships. The majority of South

Korean Shipyards are now using vacuum toilet systems as a

standard. The main reason for this is of course the fact that

the vacuum system is the most cost effective solution.

Due to:

- High level of installation fexibility

- Total independence of gravity

- Small pipe diameter

- Simple installation

- Low water consumption

Vacuum toilet

system

- Advantages

www.jets.no

JETS VACUUM AS. P.O. Box 14, N-6069 Hareid, Norway. Tel. + 47 70 03 91 00. Fax + 47 70 03 91 01. E-mail: post@jets.no

www.jets.no

ISSUE H - January 2007 -

Jets Vacuum Product Catalogue

Vacuum theory & background

First generation

Vacuum tank - Vacuum pump

The Swede Joel Liljendahl developed the frst Vacuum toilet sys-

tem in the 90s. The idea of Liljendahl was to use vacuum toi-

lets in buildings to reduce water consumption in order to be able

to utilize waste products for soil improvement.

Vacuum is created on a vacuum tank by conventional vacuum

pumps

Vacuum tank system has good vacuum generating capacities,

but also some drawbacks.

Liljendahl sold his concept to Electrolux, who saw a great poten-

tial in the ship market. Gradually the Electrolux system became

quite common on passenger ships and larger ferries.

Second generation

Atmospheric tank og Ejector

In 97 a Finnish company introduced a new technology for op-

erating a vacuum toilet system. The new solution was to make

use of an atmospheric collecting tank and to pump black water

through an ejector to create vacuum. This system was simpler

and more economical than Electrolux vacuum tank/vacuum

pump system. In 1985 the Finnish company acquired Electrolux

vacuum toilet system and established a monopoly in the market.

Vacuum systems

- History

Third generation

Jets Vacuumarator

Jets was established in 986 and introduced in 987 radical

new technology for marine vacuum toilet systems. Combining

the Helivac technology invented by the Dane Willy Johst with

a highly effcient macerator - Jets frst Vacuum generators

brought down the monopoly and offered customers new, highly

competitive solutions.

In 989 Jets introduced the now famous Vacuumarator a

helical screw pump with a built-on macerator. This refnement

of the technology introduced by Jets in 987 gave the market a

unique inline vacuum generator suitable for installation in any

type of ships.

The frst generation of Jets Vacuum generators from 1987 is

patented. Jets Vacuumarator technology is also patented.

Continuously developing the Vacuumarator technology a se-

cond version was introduced in 1993, a third in 2000, and the

latest and currently most effcient was introduced in 2006.

www.jets.no

JETS VACUUM AS. P.O. Box 14, N-6069 Hareid, Norway. Tel. + 47 70 03 91 00. Fax + 47 70 03 91 01. E-mail: post@jets.no

www.jets.no

ISSUE H - January 2007 - 2

Jets Vacuum Product Catalogue

Vacuum theory & background

The vacuum tank

system

The vacuum tank system is a well-known principle and

has for more than 00 years been used in a long range

of industrial applications. This solution was introduced

for use in Vacuum sewage applications early in the

60s.

A tank is put under vacuum by use of a vacuum pump.

Effuents are collected in this tank, which is constantly

kept under vacuum.

The system has a great effciency, but it has also some

drawbacks:

a. A vacuum tank is needed.

b. For large systems the tank will be large and bulky

due to the special shape that is needed.

c. The system is diffcult to install in ships, a lot of free

space is required.

d. The system is expensive and complicated.

www.jets.no

JETS VACUUM AS. P.O. Box 14, N-6069 Hareid, Norway. Tel. + 47 70 03 91 00. Fax + 47 70 03 91 01. E-mail: post@jets.no

www.jets.no

ISSUE H - January 2007 -

Jets Vacuum Product Catalogue

Vacuum theory & background

The ejector system

Use of an ejector to create vacuum is an old and well known prin-

ciple.

An ejector is a nozzle and vacuum is created by pumping liquid

via this nozzle. The speed of the liquid creates a vacuum. In order

to operate the ejector, a centrifugal pump and a pipe between the

pump and the ejector, are needed. A considerable volume of liquid

is at all times needed in the tank just in order to generate vacuum.

Vacuum is created in the pipeline by pumping liquid from the tank

- via the ejector and back into the tank. There is no vacuum cre-

ated in the tank. Therefore the pressure in the tank will be atmos-

pheric.

Ejector systems have in general low power to effciency rate and

they also have some other drawbacks.

a. Large circulation of liquid, especially at low liquid level in the

tank may result in foaming. A cure against foaming is use of anti

foaming agents, which can be quite expensive.

b. The collecting tank may overheat due to large circulation of the

liquid. c. A considerable volume of liquid is at all times need-

ed in the tank just in order to generate vacuum.

d. Ejectors can only handle very small amounts of grey water.

www.jets.no

JETS VACUUM AS. P.O. Box 14, N-6069 Hareid, Norway. Tel. + 47 70 03 91 00. Fax + 47 70 03 91 01. E-mail: post@jets.no

www.jets.no

ISSUE H - January 2007 -

Jets Vacuum Product Catalogue

Vacuum theory & background

The vacuumarator

system

The Vacuumarator system is based upon a technical principle invented

by Jets Vacuum A/S.

A Vacuumarator is a screw pump with a built-on macerator . This device

will generate Vacuum, macerate sewage and pump the effuent to either

a treatment plant or to a collecting tank.

The Vacuumarator principle allows for an in line installation of a toilet

systems Vacuum generator . It greatly simplifes the total installation and

eliminates the requirement for a tank in order to generate vacuum.

Vacuumarator systems has a high power to effciency rate and have also

a long range of other advantages:

a) In line installation.

b) No tank needed to generate Vacuum

c) Direct interface with sewage treatment plants.

d) Minimum of space requirement.

www.jets.no

JETS VACUUM AS. P.O. Box 14, N-6069 Hareid, Norway. Tel. + 47 70 03 91 00. Fax + 47 70 03 91 01. E-mail: post@jets.no

www.jets.no

ISSUE H - January 2007 -

Jets Vacuum Product Catalogue

Vacuum theory & background

The Jets system

Jets Vacuumarators are available in different sizes and capacities.

A Vacuum unit will consist of one

or more Jets Vacuumarators which

keep the mains under vacuum. Start

and stop of the Vacuumarator are

controlled by a pressure switch nor-

mally set for operation between

- 0 % Vacuum.

Toilets are connected to the pipes via

special valves. Jets toilets are avail-

able in a range of different models

and mechanisms.

The connection to piping is only

open during the fushing and dis-

charge cycle.

When a toilet is operated, sewage

waste water and air are sucked into

the vacuum mains and transported to the Vacuumarator. The built-on

macerator fnely pulps the sewage while pumping it to a Sewage Treat-

ment Plant or a collecting tank.

In a Jets system transport is provided by differential air pressure (Vacuum)

and thus the requirement for gravity is totally elimi-

nated. The advantages of the Jets system

compared with conventional systems

are as follows:

- PPNG NDEPENDENT UPON GRAVTY

- VERTCAL LFT CAPABLTY

- WATER CONSUMPTON OF

1,2 LTR. PR. FLUSH

- SMALL DAMETER PPNG

- HGH DEGREE OF NSTALLATON

FLEXBLTY.

The heart of a Jets system is the pat-

ented Jets Vacuumarator.

A Jets Vacuumarator is a helical

screw pump with a built-on macera-

tor.

It can pump any combination of black

- grey water and air.

A Vacuumarator can pump the sew-

age directly to a sewage treatment

plant, a collecting tank of any type or,

in some cases, directly overboard.

www.jets.no

JETS VACUUM AS. P.O. Box 14, N-6069 Hareid, Norway. Tel. + 47 70 03 91 00. Fax + 47 70 03 91 01. E-mail: post@jets.no

www.jets.no

ISSUE H - January 2007 - 6

Jets Vacuum Product Catalogue

Vacuum theory & background

The Jets system

- Advantages

Jets Vacuum AS has a totally new approach to Vacuum toilet

system offering the latest, easiest to install and most reliable

technology available.

SOME ADVANTAGES OF THE VACUUMARATOR SYSTEM :

IN - LINE INSTALLATION - NO REQUIREMENT FOR TANK

A Vacuumarator generates Vacuum directly on the pipeline, macerates

thesewage and pumps it to either a sewage treatment plant or a collect-

ing tank. all in the same operation. The fow of liquid and air is via

the Vacuumarator .

HIGLY FLEXIBLE SOLUTIONS WITH EASY INSTALLATION

A Jets Vacuum unit is totally independent upon location of the sewage

treatment plant or a collecting tank ( if this is used) . It can be located

almost any where in the ship.

Connecting to the piping is as easy as it can get - pipe in and pipe

out.

EXTREMELY COMPACT AND LOW WEIGHT VACUUM UNITS

Jets has the smallest and most compact vacuum generating unit avail-

able.

DIRECT INTERFACE WITH ALL TYPES OF SEWAGE TREAT-

MENT PLANTS

IF A COLLECTING TANK IS USED -MORE THAN 95 %

UTILIZATION OF COLLECTING TANK CAPACITY

SAFE AND HIGHLY EFFICIENT VACUUM GENERATORS

Compared to an ejector a Vacuumarator is approx 40 % more effcient.

This allows for a large safety margin and a better operation of the sys-

tem.

All Jets equipment is designed with focus on the highest reliability with

low life cycle costs.

BUILT-ON MACERATOR IMPROVEMENT OF THE TREAT-

MENT PROCESS

A built-on macerator with one rotating and one stationary knife fnely

pulps the sewage while pumping it to the treatment plant.

NO FOAMING

There is no circulation of liquid in a Jets system and accordingly there is

no risk of foaming

www.jets.no

JETS VACUUM AS. P.O. Box 14, N-6069 Hareid, Norway. Tel. + 47 70 03 91 00. Fax + 47 70 03 91 01. E-mail: post@jets.no

www.jets.no

ISSUE H - January 2007 - 7

Jets Vacuum Product Catalogue

Vacuum theory & background

Mode of operation

Jets Vacuumarator

Liquid ring Rotor

Macerator

Jets Vacuumarator

CREATES VACUUM

MACERATES SEWAGE

PUMPS SEWAGE

A Jets Vacuumarator is a helical screw pump with a built-on

macerator.

It will create vacuum, macerate black water and pump it downstream

in same operation. A Jets Vacuumarator can pump any combination of

black / grey water and air.

The built-on macerator consists of a rotating part bolted to the shaft

and a stationary part bolted to the suction chamber. All black water will

be macerated before arriving at the suction chamber. Metal objects will

not enter the macerator. Such items will be defected and remain in the

suction housing without creating damage or blockage.

In operation black water creates a seal between the helical rotor and

the housing.

The thickness of this seal will depend upon the volume of black or

grey water arriving from the toilets showers or wash basins.

In peak vacuum generating ( air pumping) mode the black water seal

will touch the rotor hub on one side and the tip of the rotor on the

other .

This principle creates a series of progressive crescent shaped cavi-

ties travelling from suction to pressure side of the rotor. Air, black and

grey water is pulled into those cavities and transported through the

vacuumarator.

Suction Discharge

También podría gustarte

- Basic Vacuum Theory PDFDocumento17 páginasBasic Vacuum Theory PDFada guevarraAún no hay calificaciones

- Hazen WilliamsDocumento2 páginasHazen WilliamssushilkumarAún no hay calificaciones

- Learn Vacuum Sewer Design Fundamentals at Upcoming SeminarDocumento75 páginasLearn Vacuum Sewer Design Fundamentals at Upcoming SeminarPumpdesignAún no hay calificaciones

- Steps of CalculationDocumento16 páginasSteps of Calculationsarno sarnoAún no hay calificaciones

- AnMBR Wastewater Treatment: Anaerobic Membrane BioreactorsDocumento20 páginasAnMBR Wastewater Treatment: Anaerobic Membrane BioreactorsNimitosh GuptaAún no hay calificaciones

- WLTSR (Lvl-04) Tower C - (25.07.2015)Documento1 páginaWLTSR (Lvl-04) Tower C - (25.07.2015)Syed Shahbaz100% (1)

- Energy Consumption of Tanks & VatsDocumento12 páginasEnergy Consumption of Tanks & Vatsamechmar5935Aún no hay calificaciones

- AL GURM Vacuum Sewer SystemDocumento22 páginasAL GURM Vacuum Sewer SystemRamesh Kumar VadlamaniAún no hay calificaciones

- Weil Pump Flow and Basin Sizing Calculator (EDocFind - Com)Documento15 páginasWeil Pump Flow and Basin Sizing Calculator (EDocFind - Com)mohdnazirAún no hay calificaciones

- Calculating Pressure Loss - Equivalent Pipe Length MethodDocumento1 páginaCalculating Pressure Loss - Equivalent Pipe Length MethodRamachandran VenkateshAún no hay calificaciones

- KOBELCO Welding Handbook 2009Documento202 páginasKOBELCO Welding Handbook 2009shamsabbasAún no hay calificaciones

- Pipe SizingDocumento16 páginasPipe SizingnagarajhebbarAún no hay calificaciones

- ROEDIGER 2007 RoeVac Vacuum Sewer SystemDocumento12 páginasROEDIGER 2007 RoeVac Vacuum Sewer SystemcarloscartasineAún no hay calificaciones

- Sprinkler Systems Design DataDocumento51 páginasSprinkler Systems Design Datahasanadel88Aún no hay calificaciones

- SBD 6479 WaterCalcWorksheet 01 12Documento4 páginasSBD 6479 WaterCalcWorksheet 01 12NghiaAún no hay calificaciones

- How To Calculate Septic Tank Size - CivilologyDocumento5 páginasHow To Calculate Septic Tank Size - CivilologyHang ChethaAún no hay calificaciones

- WCDocumento6 páginasWCSheraz TariqAún no hay calificaciones

- Pump Power Calculator PDFDocumento6 páginasPump Power Calculator PDFDjalel la Parole100% (1)

- Hydraulic CalculationsDocumento79 páginasHydraulic CalculationsKhaled SamirAún no hay calificaciones

- Static Pressure Calculations For SPF 1 Building 1 (As Per Ifc)Documento2 páginasStatic Pressure Calculations For SPF 1 Building 1 (As Per Ifc)Karthy GanesanAún no hay calificaciones

- Thin Walled VesselsDocumento9 páginasThin Walled VesselsBibek ShresthaAún no hay calificaciones

- Design & Control Smart Automatic Water Monitoring SystemDocumento3 páginasDesign & Control Smart Automatic Water Monitoring SystemRahul SharmaAún no hay calificaciones

- Level Measurement SystemDocumento8 páginasLevel Measurement SystemVarun Kumar100% (1)

- Perfect Chloro Systems - Gas ..Documento6 páginasPerfect Chloro Systems - Gas ..nazar750Aún no hay calificaciones

- Measure Flow with Orifice PlatesDocumento18 páginasMeasure Flow with Orifice PlatesJhon AlfonsoAún no hay calificaciones

- Water Supply CalculationDocumento2 páginasWater Supply Calculationpraktika82Aún no hay calificaciones

- Biomass Plant Lightning Protection Systems SpecificationDocumento4 páginasBiomass Plant Lightning Protection Systems SpecificationsriramAún no hay calificaciones

- 10 Analysis of Pipe Flows: The Moody ChartDocumento8 páginas10 Analysis of Pipe Flows: The Moody ChartMiguel Angel Alvarez BoreaAún no hay calificaciones

- Hydraulic Services Design GuideDocumento216 páginasHydraulic Services Design GuideSenthil SeliyanAún no hay calificaciones

- Instructional Manual For Cooling Tower (Heat Transfer)Documento7 páginasInstructional Manual For Cooling Tower (Heat Transfer)ramniwas123Aún no hay calificaciones

- Expansion Tank CalcDocumento1 páginaExpansion Tank Calc1985PolytechAún no hay calificaciones

- Hazen Williams EquationDocumento1 páginaHazen Williams EquationNur IzzaidahAún no hay calificaciones

- ROEDIGER 2007 RoeVac Vacuum Sewer System PDF PresentationDocumento69 páginasROEDIGER 2007 RoeVac Vacuum Sewer System PDF PresentationClaudio Della RoccaAún no hay calificaciones

- Pipe Class & Thickness Guide for ShipbuildingDocumento19 páginasPipe Class & Thickness Guide for ShipbuildingfarhanAún no hay calificaciones

- Measurement of Insulation Resistance IR Part 1Documento5 páginasMeasurement of Insulation Resistance IR Part 1hafizg100% (1)

- 3 Sewage and Sewer DesignDocumento25 páginas3 Sewage and Sewer DesignMuhammad AmirAún no hay calificaciones

- Flow MeterDocumento12 páginasFlow MeterDaniel MilosevskiAún no hay calificaciones

- Desaireador GKMOSS - Tray - Deaerator - Brochure PDFDocumento6 páginasDesaireador GKMOSS - Tray - Deaerator - Brochure PDFCdMoraSAún no hay calificaciones

- Wastewater DesignDocumento37 páginasWastewater Designscarmathor90Aún no hay calificaciones

- Manage pool plant performance with this interactive toolDocumento4 páginasManage pool plant performance with this interactive tooljarabos8609Aún no hay calificaciones

- Water Distribution ManualDocumento20 páginasWater Distribution ManualOxfamAún no hay calificaciones

- Pump MathsDocumento10 páginasPump MathsSakib RafeeAún no hay calificaciones

- Flow in Pipe ManifoldsDocumento4 páginasFlow in Pipe Manifoldskasandra01100% (1)

- RedValve - Mixing in Storage TanksDocumento49 páginasRedValve - Mixing in Storage TanksRWBalmeloAún no hay calificaciones

- Finding The Difficult' Leaks: Mfarley@alvescot - Demon.co - UkDocumento4 páginasFinding The Difficult' Leaks: Mfarley@alvescot - Demon.co - UkYoussefAún no hay calificaciones

- WHA Water Hammer ArrestorsDocumento5 páginasWHA Water Hammer ArrestorsvitgahiAún no hay calificaciones

- PDF Steam Condensate Return LinesDocumento5 páginasPDF Steam Condensate Return Linesjesus_manrique2753Aún no hay calificaciones

- Hanshin 2519-3241VHDocumento7 páginasHanshin 2519-3241VHnotaden1849Aún no hay calificaciones

- Static Pressure Concept 1Documento8 páginasStatic Pressure Concept 1bharath477Aún no hay calificaciones

- Introduction:-: UnitsDocumento8 páginasIntroduction:-: UnitsSANJAYAún no hay calificaciones

- Level Measurement Methods Using Hydrostatic PressureDocumento22 páginasLevel Measurement Methods Using Hydrostatic PressureJunaid JohnsonAún no hay calificaciones

- Understanding Process Vacuum Condensers: Issue 3Documento4 páginasUnderstanding Process Vacuum Condensers: Issue 3pothanAún no hay calificaciones

- Mechanical Sensors 25augustDocumento74 páginasMechanical Sensors 25augustSasikumar SukumaranAún no hay calificaciones

- Instrument QuestionsDocumento71 páginasInstrument QuestionsFA AyAún no hay calificaciones

- Build Hookah 2Documento12 páginasBuild Hookah 2dannyjan5080Aún no hay calificaciones

- Vacuum Science and TechnologyDocumento7 páginasVacuum Science and TechnologywestewrAún no hay calificaciones

- CatalogDocumento482 páginasCatalogAnonymous 6EW2MsFbkAún no hay calificaciones

- Basic principles of vacuum technology overviewDocumento54 páginasBasic principles of vacuum technology overviewFederico Leon100% (1)

- A Dictionary For The Petroleum Industry (2nd Edition)Documento242 páginasA Dictionary For The Petroleum Industry (2nd Edition)AliLamamra100% (3)

- Pressure Measurement Part1Documento7 páginasPressure Measurement Part1salemAún no hay calificaciones

- Rapid System Aeroprofile fitting instructions in multiple languagesDocumento2 páginasRapid System Aeroprofile fitting instructions in multiple languagespetar petarAún no hay calificaciones

- Formule MFII Vjezbe 01Documento3 páginasFormule MFII Vjezbe 01petar petarAún no hay calificaciones

- Formule MFII Vjezbe 01Documento3 páginasFormule MFII Vjezbe 01petar petarAún no hay calificaciones

- Formule MFII Vjezbe 07Documento5 páginasFormule MFII Vjezbe 07petar petarAún no hay calificaciones

- Ensuring Efficient Reliability For Marine Thermal Systems: Industry OverviewDocumento24 páginasEnsuring Efficient Reliability For Marine Thermal Systems: Industry Overviewpetar petar100% (1)

- NbarDocumento27 páginasNbarpetar petarAún no hay calificaciones

- Micro Station Tips & TricksDocumento20 páginasMicro Station Tips & TricksgraymondrAún no hay calificaciones

- Model For Calculating The Refractive Index of DiffDocumento5 páginasModel For Calculating The Refractive Index of DiffNANAún no hay calificaciones

- Ray OpticsDocumento41 páginasRay OpticsHannah VsAún no hay calificaciones

- Power Generation Engine Performance DataDocumento4 páginasPower Generation Engine Performance Dataacere18100% (1)

- A Stated-Preference Study of The Willingness-To-Pay To Reduce Traffic Risk in Urban vs. Rural RoadsDocumento13 páginasA Stated-Preference Study of The Willingness-To-Pay To Reduce Traffic Risk in Urban vs. Rural RoadsSantanu KumarAún no hay calificaciones

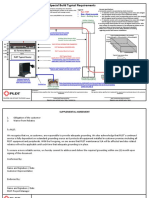

- Special Build Typical Requirements (Rev1) PDFDocumento2 páginasSpecial Build Typical Requirements (Rev1) PDFToper CdjAún no hay calificaciones

- Periodic TableDocumento1 páginaPeriodic TableChemist MookaAún no hay calificaciones

- Add Nordic Semiconductor DFU To SDK Example: Bluetooth Low EnergyDocumento32 páginasAdd Nordic Semiconductor DFU To SDK Example: Bluetooth Low EnergyDaniel Ernesto EspitiaAún no hay calificaciones

- Two Sigma - LeetCodeDocumento2 páginasTwo Sigma - LeetCodePeeyushAún no hay calificaciones

- Measure Runoff and Soil Loss at Erosion Plots in TanzaniaDocumento19 páginasMeasure Runoff and Soil Loss at Erosion Plots in TanzaniaMohd Sofiyan Bin SulaimanAún no hay calificaciones

- Dell Emc Data Domain Dd3300 Faq: Frequently Asked QuestionsDocumento14 páginasDell Emc Data Domain Dd3300 Faq: Frequently Asked QuestionseriquewAún no hay calificaciones

- May June 2019 P02Documento40 páginasMay June 2019 P02Rongrui ZhouAún no hay calificaciones

- Quantitative Method Problem SetDocumento10 páginasQuantitative Method Problem SetConstanceAún no hay calificaciones

- Record results of toy soldier experiment times with different massesDocumento42 páginasRecord results of toy soldier experiment times with different massesTeoh Han Jie100% (1)

- Eb 20 11Documento408 páginasEb 20 11henryAún no hay calificaciones

- 5437 1Documento190 páginas5437 1Khateeb RehmanAún no hay calificaciones

- HE Drilling JarsDocumento32 páginasHE Drilling Jarsmr_heeraAún no hay calificaciones

- Midterm - ICT1 ExamDocumento4 páginasMidterm - ICT1 ExamHelen PerlasAún no hay calificaciones

- Liquefaction AnalysisDocumento16 páginasLiquefaction AnalysisKristi Engineering Services Pvt. Ltd.Aún no hay calificaciones

- CH1 The Foundations - Logic and ProofsDocumento106 páginasCH1 The Foundations - Logic and ProofsMOHAMED BACHARAún no hay calificaciones

- Definition, Scope and Nature of EconomicsDocumento29 páginasDefinition, Scope and Nature of EconomicsShyam Sunder BudhwarAún no hay calificaciones

- Adverb Clause of Time (Adverbial Cause of Time)Documento9 páginasAdverb Clause of Time (Adverbial Cause of Time)Toh Choon HongAún no hay calificaciones

- Battery ModelingDocumento6 páginasBattery ModelingmusabnajeebAún no hay calificaciones

- Vesda Arrange Fire Alarm SystemDocumento1 páginaVesda Arrange Fire Alarm SystemGaurav Kumar SharmaAún no hay calificaciones

- Indicate The Answer Choice That Best Completes The Statement or Answers The QuestionDocumento10 páginasIndicate The Answer Choice That Best Completes The Statement or Answers The QuestionHasan EserAún no hay calificaciones

- Transformer X - R CalculationDocumento2 páginasTransformer X - R CalculationTharindu WimalasekaraAún no hay calificaciones

- Aimo 2019 Trial g6Documento6 páginasAimo 2019 Trial g6Jomar EjedioAún no hay calificaciones

- Surveying - Traverse Surveying - TraverseDocumento13 páginasSurveying - Traverse Surveying - Traversebills100% (1)

- V Single Vane Pumps: 1 - "F3" 2 - Pump TypeDocumento14 páginasV Single Vane Pumps: 1 - "F3" 2 - Pump TypeJose Leandro Neves FerreiraAún no hay calificaciones

- VT2009B Eng 02 953680Documento2 páginasVT2009B Eng 02 953680gabrieltracto100% (1)