Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Fender Hot Rod Deluxe Master Volume Modification

Cargado por

ColdwaterdropinDerechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Fender Hot Rod Deluxe Master Volume Modification

Cargado por

ColdwaterdropinCopyright:

Formatos disponibles

LEAD MASTER REPLACEMENT

Since the owners manual came with a schematic, I studied it to see if there was anything I could do about these issues. I found the problem with the lead mode volume control was pretty straightforward: these turkeys had put a LINEAR taper pot in there where an AUDIO taper pot belonged. All volume controls should be audio taper. Thats why theyre called audio taper. The ear hears sound levels exponentially, on a logarithmic scale. A sound with ten times the power of another sound we perceive as TWICE as loud, not ten times as loud. If we use a linear taper potentiometer in a standard volume control circuit, we will hear 10 as only twice as loud as 1. If we use an audio taper pot, 10 will sound ten times as loud as 1, which is what we expect. Since 10=10 no matter what, an audio taper pot will have a much lower level 1 than a linear taper pot. Fenders engineers know this. Therefore, Fender has been using this trick for some time on their solid-state amps, which are primarily targeted to the lower end of the market where the less experienced players buy. A player walks into the music store, plugs in and turns up to 2. The amp wails like a banshee, and he/she immediately turns the volume down to about 1/2 so as not to be expelled from the store. The player thinks, wow, if this thing is this loud at 2, it must have just gobs of volume in reserve. If I buy this amp, my drummer will never be able to drown me out again! Cha-ching, another amp sold.

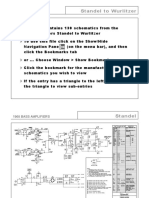

Since I use this amp more often for practice than performance, I need to be able to easily dial in a lower volume, so I just replaced the lead mode volume control (labeled MASTER on the chassis) with an audio taper pot. Heres how: 1. First, bleed off any residual voltage from the power supply. An easy way is to turn the amp on, let it warm up for a few minutes, and then LEAVING THE STANDBY SWITCH ON, turn the POWER switch to OFF. Unplug the amp from the wall. This allows the warmed-up tubes to drain the power supply for you. Remove the back panel (6 screws), all control knobs, and nuts on the controls and jacks. Check one of the filter caps with a voltmeter to be sure there are no lethal voltages left. Any remaining voltage can be discharged with an alligator lead. Remove the 6 screws holding the main circuit board to the chassis, and then remove the 1 screw holding the ground wire that goes from the board to the chassis over by the input jacks. 2. Carefully pull the circuit board down and away from the chassis. It is very easy to damage the controls against the upper lip of the chassis, so be extremely careful here. Now you have access to the solder side of the circuit board. 3. Unsolder and remove the MASTER control (R26, 100kB). Now, the only drop-in replacement that Im aware of which will accomplish our goal is the same control that is being used for the clean VOLUME control (R6, 250kA). I havent actually tried one of these, but I have used 250kA pots, and I couldnt hear any difference at all. If you have this pot on hand, great. Solder it in, reverse steps 1 and 2, and youre finished. If not, any good quality 100kA to 250kA pot that will fit can be used. In fact, I dont see any reason why a 500kA wouldnt work. After all, vintage amps routinely used 1meg pots as volume controls. Carvin makes an excellent small body 500kA pot, which they use for the tone controls on their guitars. I used a similar sized unit from a scrap circuit board I had lying around. DO NOT TRY A RADIO SHACK CONTROL. I tried their 100kA pot on a friends unit, and it doesnt even turn on until after 3. This was not due to a defective pot. I opened it and found that this was the way it was designed. What crap! If your replacement cant be soldered directly to the circuit board, you will have to run short jumpers from the pots terminals to the points on the PC that the old pot was soldered to. No big deal. When putting the circuit board back into the chassis, pay attention to the Bright switch, the Drive and More Drive switches, and particularly the LED. They sometimes dont want to line up properly and it wouldnt take much force to break them. Also, the plastic threads on the jacks of this unit are ridiculously easy to strip if you cross-thread them or over-tighten them. Be as careful as you can.

Justin's comments: Here's a pic of my very sloppy version of this mod. Professional huh? It was the first mod I ever did to this amp. I used an old 250K mini-pot that was in my Japanese '62 Reissue Strat basically because it was the exact size of the old pot and was logarithmic. Regular sized pots didn't want to fit in the HRDx's chassis. I had trouble unsoldering the pots 3 lugs and 4-point grounding "wings". I ended up cutting those grounding wing things off. The holes the wings left were so big I couldn't fill it with a wire, so I just left them in there and soldered a wire from the pot's casing to the wings. Not too pretty, but did I mention it works great? If you're good with your hands you may want to check out this excellent tutorial on replacing the Master and making it look professional! Note: The electric tape you see was done to try to fix a shorting problem I had a while ago. It was NOT the pot, I just put it there to see if it solved the problem. It did not fix it. You do NOT need electrical tape around it on the chassis. The problem was later solved, which was something completely different.

Since the first draft of this document, Ive discovered something about this modification that I didnt like. The good news is that Ive also discovered a very easy remedy. I was sitting in with a friends band at a party. We were playing pretty loudly, and I noticed that I had to set my lead master control to about 8 or 9 to equal the clean channel at 4 or 5. This bugged me because it didnt seem like there was much more volume available (there actually was; the difference between 9 and 10 was HUGE), so I went back to the schematic later to see what I could do. I found that Fender had built in some attenuation into the lead master circuit to balance their linear taper pot with the clean channels audio taper pot. The remedy is to remove this attenuation. I did this by merely soldering a jumper wire across R45 (47K), which you find near the lead master control. This just about doubles the volume of the lead signal. So now, with the new control and the overall volume boosted, you have an amp with more available lead volume than a stock unit, but which is also easier to control at low volumes. The best of both worlds!

También podría gustarte

- The Jazz Compositions of Edo Castro - For Small EnsembleDe EverandThe Jazz Compositions of Edo Castro - For Small EnsembleAún no hay calificaciones

- The Jazz Guitarist's Handbook: An In-Depth Guide to Chord Symbols Book 2: The Jazz Guitarist's Handbook, #2De EverandThe Jazz Guitarist's Handbook: An In-Depth Guide to Chord Symbols Book 2: The Jazz Guitarist's Handbook, #2Aún no hay calificaciones

- DIY: The Lopez Tube AmpDocumento6 páginasDIY: The Lopez Tube AmpToMAún no hay calificaciones

- Ultimatum Fuzz: The Ultimate Experience in Vintage-Style Octave-Up FuzzDocumento9 páginasUltimatum Fuzz: The Ultimate Experience in Vintage-Style Octave-Up FuzzRicardo UrioAún no hay calificaciones

- Dunlop Wah True-BypassDocumento8 páginasDunlop Wah True-Bypassasdfasdfsa3459Aún no hay calificaciones

- Champ 5F1 ManualDocumento28 páginasChamp 5F1 Manualmed vetAún no hay calificaciones

- Baxandall NegativeFeedbackToneDocumento7 páginasBaxandall NegativeFeedbackTonemichaelbrendenAún no hay calificaciones

- Power ScalingDocumento1 páginaPower ScalingGuitar RoomAún no hay calificaciones

- DIY SynthDocumento8 páginasDIY SynthFernando Palomera HualamánAún no hay calificaciones

- SRPP DesignDocumento5 páginasSRPP Designandree wAún no hay calificaciones

- PCB 5e3Documento6 páginasPCB 5e3josemfcAún no hay calificaciones

- Inside The Fender VibratoneDocumento18 páginasInside The Fender Vibratonewhorne24Aún no hay calificaciones

- Zonk Machine AnalysisDocumento5 páginasZonk Machine AnalysisRobWileyAún no hay calificaciones

- SMX Range: Operating InstructionsDocumento28 páginasSMX Range: Operating InstructionsFerran Ros SendraAún no hay calificaciones

- Valveking 212 DiagramDocumento12 páginasValveking 212 DiagramDan Radu TalpalariuAún no hay calificaciones

- ST To WuDocumento131 páginasST To WuGio GioAún no hay calificaciones

- Pre Amp Fender Pedals.Documento7 páginasPre Amp Fender Pedals.João Victor SallesAún no hay calificaciones

- 12x8 .15" Pitch Stripboard: Input OutputDocumento1 página12x8 .15" Pitch Stripboard: Input OutputRobWileyAún no hay calificaciones

- 5 Way Rotary Tone SelectorDocumento1 página5 Way Rotary Tone SelectorChris Efstathiou100% (1)

- Laney Lv300 H Twin SCHDocumento8 páginasLaney Lv300 H Twin SCHrataboloAún no hay calificaciones

- Behind The Bucket BrigadeDocumento23 páginasBehind The Bucket Brigadefusgtr100% (3)

- Stompbox Clone ListDocumento6 páginasStompbox Clone Listjaydub911Aún no hay calificaciones

- Dummy Coils For PickupsDocumento2 páginasDummy Coils For PickupsRoland CziliAún no hay calificaciones

- Diy Synth Voice Manual PDFDocumento25 páginasDiy Synth Voice Manual PDFἈρσένιος ΦιλοθέουAún no hay calificaciones

- 0415 Guitar Synth 2Documento8 páginas0415 Guitar Synth 2Daniel RoblesAún no hay calificaciones

- Tube Phono Preamp - NotesDocumento15 páginasTube Phono Preamp - NotesStelios PanarasAún no hay calificaciones

- Review: Ming Da MC-2A3 Tube Preamp - Audiogon Discussion ForumDocumento13 páginasReview: Ming Da MC-2A3 Tube Preamp - Audiogon Discussion Forumandree wAún no hay calificaciones

- The Technology of The Tube ScreamerDocumento12 páginasThe Technology of The Tube ScreamereduoricoAún no hay calificaciones

- The Fender Bassman 5F6-A Family of Preamplifier Circuits-A Wave Digital Filter Case StudyDocumento8 páginasThe Fender Bassman 5F6-A Family of Preamplifier Circuits-A Wave Digital Filter Case StudyEduardoAún no hay calificaciones

- The Fender TBX Tone Control Mod, Part 2Documento2 páginasThe Fender TBX Tone Control Mod, Part 2ScrbertoAún no hay calificaciones

- Amp-Cradle - 1.1Documento15 páginasAmp-Cradle - 1.1Miguel ClementeAún no hay calificaciones

- Circuit Guide Vemuram Jan RayDocumento1 páginaCircuit Guide Vemuram Jan Raybenoi31Aún no hay calificaciones

- DIY Club Project 1 Part 2 of 4 v03Documento21 páginasDIY Club Project 1 Part 2 of 4 v03M HAún no hay calificaciones

- Steel String Singer - COLGANDocumento1 páginaSteel String Singer - COLGANdisse_detiAún no hay calificaciones

- Dumb Le NotesDocumento7 páginasDumb Le NotesFrank Puchi100% (1)

- BaxandallDocumento15 páginasBaxandallJuan Jose Perez HernandezAún no hay calificaciones

- The Most Important Tube in Your Amp? The Phase Inverter!Documento3 páginasThe Most Important Tube in Your Amp? The Phase Inverter!Rica TheSickAún no hay calificaciones

- Hammond SongsDocumento10 páginasHammond SongsPablo PluutAún no hay calificaciones

- Dod 280Documento1 páginaDod 280Augusto Figueira100% (1)

- Stairville LED Bar 252 ManualDocumento12 páginasStairville LED Bar 252 ManualBlaize110Aún no hay calificaciones

- VVR2Documento15 páginasVVR2Guitar RoomAún no hay calificaciones

- Fuzz Face AnalysisDocumento26 páginasFuzz Face AnalysisgianmarcoAún no hay calificaciones

- Adding True Bypass To A Vintage Big MuffDocumento8 páginasAdding True Bypass To A Vintage Big MuffOliver SuttonAún no hay calificaciones

- Amp ScrapbookDocumento10 páginasAmp Scrapbookarturxox1zAún no hay calificaciones

- Our Philosophy On Amp ModificationsDocumento25 páginasOur Philosophy On Amp ModificationshonkAún no hay calificaciones

- Keeley bd-2 Phat Mod ManualDocumento1 páginaKeeley bd-2 Phat Mod ManualNAún no hay calificaciones

- MUFF GUTS - The Big Muff Circuit, Wiring Diagrams, Schematics, Replacement PartsDocumento7 páginasMUFF GUTS - The Big Muff Circuit, Wiring Diagrams, Schematics, Replacement PartsgianmarcoAún no hay calificaciones

- IMPORTANT - Andy Sneap SuggestionsDocumento7 páginasIMPORTANT - Andy Sneap SuggestionsSimone Lanzoni100% (1)

- CS3 Mods PDFDocumento6 páginasCS3 Mods PDFAnonymous LgJH9UE2jAún no hay calificaciones

- Transistor Audio Amplifier CircuitDocumento2 páginasTransistor Audio Amplifier CircuitMidhun U KAún no hay calificaciones

- Okko Diablo ManualDocumento2 páginasOkko Diablo ManualcaesparzaAún no hay calificaciones

- Theremin FuzzDocumento8 páginasTheremin FuzzAdrianoEngelAún no hay calificaciones

- King Slayer Effect PedalDocumento10 páginasKing Slayer Effect PedalPablo RagoAún no hay calificaciones

- Altec 1628 Mixer ModsDocumento2 páginasAltec 1628 Mixer ModsbjoihawkAún no hay calificaciones

- Sovtek 5881 Wxt/6L6 WGC Tube GuideDocumento8 páginasSovtek 5881 Wxt/6L6 WGC Tube GuideKon GekasAún no hay calificaciones

- 59 Bassman ManualDocumento10 páginas59 Bassman ManualtiganiadaAún no hay calificaciones

- Aura Lee (Alto Saxophone)Documento1 páginaAura Lee (Alto Saxophone)ColdwaterdropinAún no hay calificaciones

- Rock Star GravesitesDocumento7 páginasRock Star GravesitesColdwaterdropinAún no hay calificaciones

- Cool Riffs 2 - Woodwinds (Concert Pitch)Documento1 páginaCool Riffs 2 - Woodwinds (Concert Pitch)ColdwaterdropinAún no hay calificaciones

- Cool Riffs 1 - Woodwinds (Concert Pitch)Documento1 páginaCool Riffs 1 - Woodwinds (Concert Pitch)ColdwaterdropinAún no hay calificaciones

- Bruno Mars - Uptown Funk (Alto Saxophone)Documento1 páginaBruno Mars - Uptown Funk (Alto Saxophone)ColdwaterdropinAún no hay calificaciones

- Jason Derulo - Talk Dirty (Alto Saxophone)Documento1 páginaJason Derulo - Talk Dirty (Alto Saxophone)ColdwaterdropinAún no hay calificaciones

- Joe Satriani - Top Gun Theme (Concert Pitch)Documento1 páginaJoe Satriani - Top Gun Theme (Concert Pitch)ColdwaterdropinAún no hay calificaciones

- The 100 Worst Guitar Riffs Licks and Solos of All TimeDocumento14 páginasThe 100 Worst Guitar Riffs Licks and Solos of All TimeColdwaterdropinAún no hay calificaciones

- Jean Knight - Mr. Big Stuff (Alto Saxophone)Documento1 páginaJean Knight - Mr. Big Stuff (Alto Saxophone)ColdwaterdropinAún no hay calificaciones

- Bob Marley - Simmer Down (Alto Saxophone)Documento1 páginaBob Marley - Simmer Down (Alto Saxophone)ColdwaterdropinAún no hay calificaciones

- George Michael (Wham) - Careless Whisper (Concert Pitch)Documento1 páginaGeorge Michael (Wham) - Careless Whisper (Concert Pitch)ColdwaterdropinAún no hay calificaciones

- Various Synth Riffs For Woodwinds - Vol. 2 (Concert Pitch)Documento1 páginaVarious Synth Riffs For Woodwinds - Vol. 2 (Concert Pitch)ColdwaterdropinAún no hay calificaciones

- Various Synth Riffs For Woodwinds - Vol. 1 (Concert Pitch)Documento1 páginaVarious Synth Riffs For Woodwinds - Vol. 1 (Concert Pitch)ColdwaterdropinAún no hay calificaciones

- Champs - Tequila (Alto Saxophone)Documento1 páginaChamps - Tequila (Alto Saxophone)ColdwaterdropinAún no hay calificaciones

- Doctor JokesDocumento53 páginasDoctor JokesColdwaterdropin100% (1)

- Daphne Sheldrick Interview 2012Documento1 páginaDaphne Sheldrick Interview 2012ColdwaterdropinAún no hay calificaciones

- Dog PoopDocumento4 páginasDog PoopColdwaterdropinAún no hay calificaciones

- Barkays - Soulfinger (Alto Saxophone)Documento1 páginaBarkays - Soulfinger (Alto Saxophone)ColdwaterdropinAún no hay calificaciones

- Recorded Amplifiers Vs SimulatorsDocumento6 páginasRecorded Amplifiers Vs SimulatorsColdwaterdropinAún no hay calificaciones

- How To Bias A Guitar Tube AmplifierDocumento28 páginasHow To Bias A Guitar Tube AmplifierColdwaterdropin90% (10)

- Boston Skateboarding 1985Documento7 páginasBoston Skateboarding 1985ColdwaterdropinAún no hay calificaciones

- 85346Documento6 páginas85346Tomuta StefanAún no hay calificaciones

- Im 2Documento294 páginasIm 2Mohammad RaheelAún no hay calificaciones

- Output Feedback Nonlinear Control of Three-Phase Grid-Connected PV GeneratorDocumento14 páginasOutput Feedback Nonlinear Control of Three-Phase Grid-Connected PV GeneratorAchrafSaadaouiAún no hay calificaciones

- Model:: AE4425Y-GS1ADocumento8 páginasModel:: AE4425Y-GS1AEvandro Jva compressoresAún no hay calificaciones

- Qubino - Flush On Off Thermostat PLUS - User Manual - V1.3-S2Documento2 páginasQubino - Flush On Off Thermostat PLUS - User Manual - V1.3-S2juancar2006Aún no hay calificaciones

- Annex 2 - Delivery Format - Task 2Documento10 páginasAnnex 2 - Delivery Format - Task 2Diego Alejandro Cardona GiraldoAún no hay calificaciones

- (Temp) Checklist For Inspection & Functional Acceptance Tests in Factory and Pre-Commissioning Test On Site (Green V 3.0)Documento12 páginas(Temp) Checklist For Inspection & Functional Acceptance Tests in Factory and Pre-Commissioning Test On Site (Green V 3.0)pdrichAún no hay calificaciones

- Basic Electrical and Instrumentation Engineering - Lecture Notes, Study Material and Important Questions, AnswersDocumento25 páginasBasic Electrical and Instrumentation Engineering - Lecture Notes, Study Material and Important Questions, AnswersM.V. TVAún no hay calificaciones

- SPPG 66kv Ed.7.2 Feb 2012Documento155 páginasSPPG 66kv Ed.7.2 Feb 2012landtransport100% (5)

- BVD 2121 GBDocumento4 páginasBVD 2121 GBanon_487899699Aún no hay calificaciones

- Trainwreck Pacific Transformer DocumentsDocumento22 páginasTrainwreck Pacific Transformer DocumentsrythmaccountAún no hay calificaciones

- Wind Turbine Modelling Approaches For Dynamic Power System SimulationsDocumento7 páginasWind Turbine Modelling Approaches For Dynamic Power System SimulationsYounes AdnaniAún no hay calificaciones

- HP-PN71400-1 - Lightwave Signal Analyzers Measure Relative Intensity NoiseDocumento24 páginasHP-PN71400-1 - Lightwave Signal Analyzers Measure Relative Intensity Noisesirjole7584100% (1)

- 4.1 Wireless Devices For McomDocumento22 páginas4.1 Wireless Devices For McomPOOJA GAún no hay calificaciones

- 20KW Wind TurbineDocumento11 páginas20KW Wind TurbineIvonei Ferreira da Silva S.Aún no hay calificaciones

- S1S2122 KE37503 Chapter 4Documento100 páginasS1S2122 KE37503 Chapter 4PenziiAún no hay calificaciones

- Apxvf18s C A20Documento2 páginasApxvf18s C A20Francisco RevecoAún no hay calificaciones

- WPH02 01 Que 20160609Documento24 páginasWPH02 01 Que 20160609adAún no hay calificaciones

- Conveyor Auxiliaries - WPDocumento47 páginasConveyor Auxiliaries - WPPaulAún no hay calificaciones

- Expt No 3Documento3 páginasExpt No 3puja maneAún no hay calificaciones

- ATS400Documento1 páginaATS400Noel RamosAún no hay calificaciones

- Epas G9 M Q3 W7-W8Documento4 páginasEpas G9 M Q3 W7-W8ALLYSSA MAE PELONIAAún no hay calificaciones

- LUXEON Versat 3030 HP CW 150: Industry-Leading Solutions For Exterior Automotive LightingDocumento17 páginasLUXEON Versat 3030 HP CW 150: Industry-Leading Solutions For Exterior Automotive LightingMhmd GhanimAún no hay calificaciones

- UC3848Documento9 páginasUC3848Sergio Daniel BarretoAún no hay calificaciones

- PCS100 UPS-I BrochureDocumento4 páginasPCS100 UPS-I BrochureJosephine Wong Sian CheeAún no hay calificaciones

- SDN-C Compact DIN Rail Series: Power SuppliesDocumento5 páginasSDN-C Compact DIN Rail Series: Power SuppliesVickocorp SlpAún no hay calificaciones

- Syllabus - EMT1255 - Spring 2021Documento4 páginasSyllabus - EMT1255 - Spring 2021joeysaladsiscoolAún no hay calificaciones

- SM G530H Tshoo 7 PDFDocumento27 páginasSM G530H Tshoo 7 PDFarjuna nisaAún no hay calificaciones

- Inversor Abb 3 8kwDocumento2 páginasInversor Abb 3 8kwapi-290643326Aún no hay calificaciones

- Price List 2014Documento18 páginasPrice List 2014João Carlos OliveiraAún no hay calificaciones