Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Frozen Lamb Issues and Solutions

Cargado por

Syamsul RadzieDescripción original:

Título original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Frozen Lamb Issues and Solutions

Cargado por

Syamsul RadzieCopyright:

Formatos disponibles

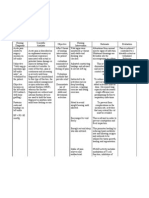

PROBLEMS WITH FROZEN LAMB AND RECOMMENDATIONS ON COUNTERMEASURING IT.

Prepared for Mr Lim Siew Siew Branch Manager TESCI HYPERMARKET Wangsa Maju, Kuala Lumpur By Rohana bt Ali Store Manager TESCI HYPERMARKET Wangsa Maju, Kuala Lumpur

EXECUTIVE SUMMARY. This report is prepared for the Branch Manager, TESCI Hypermarket Wangsa Maju Kuala Lumpur. This report is in conjunction with problems faced by the storage department previously regarding the frozen lamb quality. Recently our department has received comments from the customers regarding the frozen lamb supplied by Alaf Frozen Sdn Bhd which has peculiar taste. Therefore, this report will serve also as a proposal paper on what should be done to countermeasure the problems. This report is divided into two sections, the first is on the problems identified and the second section is on the suggestions on actions to be taken.

1.0

BACKGROUND. Cold storage is an integral part of this hypermarket, without which the hypermarket will

incur bigger losses as there are a huge number of food products that spoil quickly. The storage plan of this hypermarket aims at providing the capacity required for buffer and operational stock of food grains to maintain the customer satisfaction and general warehousing. The broad approach is to provide scientific storage capacity and reduce dependence on the capacity under cover and plinth. The management has also been making efforts to improve the traditional storage practices in vogue at the farm level. As a Store Manager of this department I was always being consulted by the customers regarding the frozen food distributed by this hypermarket. For recent weeks, I have received many complaints concerning the peculiar tastes of the frozen lamb supplied by Alfa Frozen Sdn Bhd. These complaints if not taken into considerations will give negative effects to our hypermarket. Twenty samples of frozen meat were taken from independent butchers and a supermarket to determine whether they had given peculiar taste. Nineteen out of twenty samples were found decay and rotten after being defrost and when cooked given peculiar tastes. An urgent meeting was then held with the Quality Department to identify the source of the problems and ways to overcome them. Therefore in this report I would like to address our

company regarding the complaints and steps that should be taken to countermeasure the problems.

2.0

COMPLAINTS ON THE PECULIAR LAMB TASTES. After thorough investigations by the store, I found that the peculiar tastes was due to :

1.

Meat preservation - Meat preservation (including livestock, game poultry), includes a set treatment processes for preserving nutritious properties, taste, texture and color of raw, partially cooked or cooked meats while keeping them edible and safe to consume. The meat preservation that is concerned with preventing development of undesirable micro

organisms, especially harmful bacteria causing spoilage or decomposition and decay. In the case of the peculiar tastes of the lamb provided by Alfa Frozen Sdn Bhd it has been found out that the lamb was not preserved properly by the supplier. 2. The second problem detected by us in the meeting is that the problems may be highly influenced by meat perishability. In many cases,most of the edible tissues of healthy pigs, beef, veal, and lambs are sterile, or contain very low microorganism population levels. The slaughtering process, by severing the vascular system, introduces the first major contamination. These may have been neglected by our supplier and our company should take notice of this and inform our supplier. 3. Other than that our customers also complaint that the lamb supplied did not fresh during purchase. Freshness and quality at the time of freezing affect the condition of frozen foods. If frozen at peak quality, thawed foods emerge tasting better than foods frozen near the end of their useful life. 4. Customers also complaint that the frozen lamb provided have strong smell. It is regular that frozen meat should have a very slight, unpleasant odor. Nevertheless, in our case customers complaints that the odour had extremely ruins the taste of the lamb. Even freshly painted areas may be rejected due to the odor of paint. Meats from different species of animals should not be stored together, as their characteristic odors may cause odor tainting.

3.0

SUGGESTIONS TO COUNTER MEASURE THE PROBLEMS. In order to counter measure the problems I had conducted a meeting with my staff and

came out with some suggestions. 3.1 ON THE BEHALF OF THE SUPPLIER

Firstly, the quality of fresh meat is influenced by a number of factors, which include firmness, marbling, connective tissue condition, and texture. It is suggested that Alfa Frozen Sdn Bhd should take few steps to prevent the lamb from decay.

1.

High quality muscle has a rigid structure. Soft muscle results from the same factors

contributing to low juice retention and is therefore even more objectionable than it would be on the basis of its lack of firmness alone. For processing, fabricating, slicing, and displaying, the meat firmness is an important attribute of quality, and any tendency toward softness reduces desirability. Firmness is also influenced by the nature and firmness of the fat itself, as well as by the variation in the muscle's fat content. 2. The qualities of the fresh meat have an influence on its response during freezing and

during storage in the frozen state. It is suggested that Alfa Frozen Sdn Bhd should freeze the meat as rapidly as possible and stored at a temperature well below 0 F (-18 C). Freezing, nevertheless, cannot improve quality. Low quality meat, frozen or cured under the best conditions possible, will still be low quality when consumed. High quality meat, however, can deteriorate if not frozen, stored, or cured under proper conditions. That was what happened to the meat supplied by Alfa Frozen Sdn Bhd and result to the peculiar tastes as complained by the customer. 3. Alfa Frozen Sdn Bhd also has to take into consideration on the carcass maturity. It is a

significant factor influencing beef- and lamb-carcass grades. Advances in maturity are reflected by calcification of cartilaginous tips on the spinous processes and by calcification of cartilage in the sacral region. In lamb, the calcification of the break joint makes it impossible to remove the foot at this joint. A widening of the costal bones (ribs) also occurs with advancing maturity.

4.

Another factors that will help to counter measure our problems on the peculiar taste of the lambs is the colour stability of the lamb. Colour stability varies widely among different products and storage temperatures. The only significant change at 0 to -20 F (18 C to -29 C) is a slightly lighter appearance, and there is no significant change in any product at 32 F (0 C). Temperatures of 47 F (8 C) result in significant changes, particularly in the less stable items.At temperatures from 70 to 100 F (21 C to 38 C) products tend to darken, brown, fade, and lose flavour or become stale. It is hopeful that Alfa Frozen Sdn Bhd should take this into considerations to help avoiding the lambs from producing peculiar tastes.

5.

Selection of a preservation method is influenced by the effect on quality, health hazards,

marketing, and actual cost. Flavours, varying with species and chronological age, are usually enhanced in older animals. The amount of time that carcasses are aged in coolers also influences flavour and aroma, and prolonged aging tends to impart an "aged flavour" to the meat. Quality in lamb, as in other species, refers to factors influencing acceptability and palatability. Quality lamb muscle has a firm, dry surface, modest marbling, and varies in colour from light to dark pink. Dark muscle colour and yellow fat both suggest mutton-like properties and, where lamb is preferred, may be considered detrimental. 6. Another steps that should be taken by our company is thawing. It is another critical phase

in the freezing process as it involves a change from ice crystals to melted water, which is reabsorbed, and microbial reactivation. If heat is applied to the frozen product its surface becomes warm enough to transfer heat to the inside and create conditions of temperature and humidity suitable for microbial development. Low temperature thawing, below 5C, reduces the risk of microbial growth and produces a slow thawing rate which guarantees efficient re absorption of the melted water. It is recommended that carcasses be thawed at 4 to 6C, in a hanging position and without any covering (plastic or jute is removed), inside a cold chamber with a reasonably low level of air circulation - about 0.2 m/s. Relative humidity must be kept low at the beginning (70 percent) to avoid frost forming on the meat surface, with an increase at the end of the thawing period up to 9095 percent. In these conditions thawing of beef carcasses lasts about four to five days and of smaller carcasses one to three days. It must take place in installations specifically designed for this purpose. Offal is not particularly influenced by the manner of thawing, but it is advisable to follow the same method. Thawing is considered finished when the temperature of the meat is about 0 to -1C. When frozen meats are further processed they may in some cases be used directly in the frozen state. The consumer can start cooking small prepackaged cuts without prior thawing. New quick thawing systems that satisfy hygienic requirements are now being used in the

meat industry. Rapid thawing tunnels for carcasses, microwave ovens and tunnels and vacuum steam-heated autoclaves are some of the novelties. Thawed meats deteriorate quickly and must be kept at about 0C and consumed as soon as possible. Obviously a badly conducted freezing operation and/or frozen storage period (which includes transport and distribution) with irregular storage conditions will produce disorders in meat which become immediately apparent after thawing. Exudation indicates histological damage by ice crystals; other undesirable changes have already been mentioned. 7. A meeting should be conduct with the supplier to highlight the problems in order to make

sure that it did not happened again in the future. I suggest that we terminate the contract with the supplier if they still failed to give us good service. 3.2 ON THE BEHALF OF OUR COMPANY I also suggest that we as a renowned hypermarket in Malaysia should also take into consideration to improve our cold storage department. 1. Firstly, I suggest us to install Integrated Thermometers.

Commercial freezers and some high-end consumer models have thermometers built in, so that users can tell at a glance whether the unit is operating within acceptable limits. Some are simple gauges, often with the range of safe operating temperatures identified by a band of color. Other models use digital readouts to present the temperature. Sophisticated commercial models will trigger an alarm if temperatures rise above a predetermined level. This equipment can be purchase from any local dealer with the cost RM 80,000. It will be worthy to ensure the quality of our products.

2.

Another alternative is for us to install Probe Thermometers and Internal Thermometers

These equipments also provides similar protection can be added to conventional home freezers by the use of a probe thermometer. These are electronic devices with a thermometer built into a metal probe, which relays temperature date through a wire or radio signal to a base unit with a display. Inexpensive models can be mounted on a nearby surface and monitored daily, while

costlier units transmit wirelessly to a base station and sound an alarm tone if the temperature rises. Another option is to mount a simple thermometer as what we did now permanently in the freezer, and check it regularly. Probe Thermometer is quite costly and the price range is between RM 150,000 above. 3. Another suggestions is to ensure that our employees who handle the frozen food should

have proper training in handling frozen food. This is to guarantee that all our frozen food is in good conditions.

CONCLUSION

También podría gustarte

- Intensive Kitchen Training Manual (IKTM): INTENSIVE KITCHEN TRAINING MANUALDe EverandIntensive Kitchen Training Manual (IKTM): INTENSIVE KITCHEN TRAINING MANUALCalificación: 5 de 5 estrellas5/5 (1)

- Zulhairi Bin MD - Dawam 721121016501002Documento11 páginasZulhairi Bin MD - Dawam 721121016501002Zulhairi Md DawamAún no hay calificaciones

- Peculiar Taste of Frozen Lamb: To: Anuar Bin Edon, Store ManagerDocumento13 páginasPeculiar Taste of Frozen Lamb: To: Anuar Bin Edon, Store ManagerBello SyanilAún no hay calificaciones

- Oumh2203 English For Workplace Communication 730817055044002Documento12 páginasOumh2203 English For Workplace Communication 730817055044002Mariah RaniAún no hay calificaciones

- Improving Philippine Dried Fish Industry Through Modern Processing MethodsDocumento5 páginasImproving Philippine Dried Fish Industry Through Modern Processing MethodsAngelBeatZAún no hay calificaciones

- Meat Processing (Burger Patties)Documento55 páginasMeat Processing (Burger Patties)Bitter SugarAún no hay calificaciones

- Chapter 4 Surimi and Fish Protein Concentrate IsolateDocumento46 páginasChapter 4 Surimi and Fish Protein Concentrate IsolateFETRITCIA OMPOK -Aún no hay calificaciones

- ANS002 Lesson 7-1Documento13 páginasANS002 Lesson 7-1Haifa KalantunganAún no hay calificaciones

- Project Week.01 Group-.04Documento29 páginasProject Week.01 Group-.04PHỤNG HUỲNH DIỆP MỸAún no hay calificaciones

- Pasturization, Sterilizationo and FermentationDocumento36 páginasPasturization, Sterilizationo and Fermentationkwagala joshuaAún no hay calificaciones

- Storage Life of MeatDocumento3 páginasStorage Life of Meatanilstrums19670% (1)

- Home Production of Quality Meats and Sausages PDFDocumento561 páginasHome Production of Quality Meats and Sausages PDFcrepuscolarista100% (2)

- LPTDocumento15 páginasLPTShikha SharmaAún no hay calificaciones

- COOKERY 10 Quarter 4 LAS Number 4, Week 8Documento5 páginasCOOKERY 10 Quarter 4 LAS Number 4, Week 8SherivieMendonza100% (1)

- Frozen BeefDocumento15 páginasFrozen BeefFiza Meleveettil - 26Aún no hay calificaciones

- Sept 2002 Storage Life of MeatDocumento3 páginasSept 2002 Storage Life of MeatRadu ZahariaAún no hay calificaciones

- Meat, Poultry and Egg Processing Submitted To: Miss Saniya Tayyab Submitted By: Laiba KhanDocumento11 páginasMeat, Poultry and Egg Processing Submitted To: Miss Saniya Tayyab Submitted By: Laiba KhanAmmar KhanAún no hay calificaciones

- GAYODocumento5 páginasGAYOAbas S. AcmadAún no hay calificaciones

- Store Meat: Methods of Preserving Meat Evaluating The Quality of Preserved Meat Products Proper Storage of Preserved MeatDocumento9 páginasStore Meat: Methods of Preserving Meat Evaluating The Quality of Preserved Meat Products Proper Storage of Preserved MeatdanieAún no hay calificaciones

- FDA Cheese Mold ExceptionsDocumento3 páginasFDA Cheese Mold ExceptionsBernadette YurongAún no hay calificaciones

- The Very Basics of Food Preservation: MARCH 1999Documento5 páginasThe Very Basics of Food Preservation: MARCH 1999Sail Vessel J&K KatAún no hay calificaciones

- Advanced Meat Processing IndustryDocumento23 páginasAdvanced Meat Processing IndustryAl Pavillon100% (1)

- Las 3 Q4 Store MeatDocumento9 páginasLas 3 Q4 Store MeatTrei OuxAún no hay calificaciones

- 33 Im Rte Ss ProcessDocumento20 páginas33 Im Rte Ss ProcessNader SedighiAún no hay calificaciones

- SFI Meat Processor CategoriesDocumento4 páginasSFI Meat Processor CategoriesGladieJohnAlcuirezAún no hay calificaciones

- Factors Affecting Lamb Quality and ValueDocumento3 páginasFactors Affecting Lamb Quality and ValueIani ChihaiaAún no hay calificaciones

- Home Production of Quality Meats and SausagesDocumento566 páginasHome Production of Quality Meats and SausagesThalyta Cruxz100% (14)

- COOKERY 10 - LO.4 Methos of Preserving MeatDocumento34 páginasCOOKERY 10 - LO.4 Methos of Preserving MeatDianne Joy Corpuz100% (2)

- Case Study Qualifications For Receiving Staff MembersDocumento4 páginasCase Study Qualifications For Receiving Staff MembersChristian Manrique MansillaAún no hay calificaciones

- LAS-Q4-Wk4-Cookery-10Documento8 páginasLAS-Q4-Wk4-Cookery-10Aloy GamingAún no hay calificaciones

- SausagesDocumento35 páginasSausagesFarzana100% (1)

- Meat Preservation PrinciplesDocumento7 páginasMeat Preservation PrinciplesMichiyo Sakamoto100% (1)

- Meat Cold Chain GuidelineDocumento24 páginasMeat Cold Chain GuidelinejeffotAún no hay calificaciones

- Tenderization of MeatDocumento7 páginasTenderization of MeatMohanavelu RamasamyAún no hay calificaciones

- FBPSM 222: Food Processing MethodsDocumento59 páginasFBPSM 222: Food Processing MethodsKurt Gullem PusoAún no hay calificaciones

- ETP Section - Effluent Treatment PlantDocumento9 páginasETP Section - Effluent Treatment PlantParag Manohar PatilAún no hay calificaciones

- Food Processing Week 8Documento11 páginasFood Processing Week 8Jepoy BanilaAún no hay calificaciones

- Food PreservationDocumento33 páginasFood Preservationmo_ho100% (1)

- TLE Cookery NC II Grade10 QTR4 Module 4 For ValidationDocumento19 páginasTLE Cookery NC II Grade10 QTR4 Module 4 For ValidationRonna Keith ArcillaAún no hay calificaciones

- Meat Processing GuideDocumento47 páginasMeat Processing GuideGiselle LabaganAún no hay calificaciones

- TR059 Review Properties Sol Gel PolymerDocumento70 páginasTR059 Review Properties Sol Gel PolymerSohnAún no hay calificaciones

- SHS 327 Lecture 9Documento63 páginasSHS 327 Lecture 9SABA NADEEM DARAún no hay calificaciones

- High Pressure ProcessingDocumento29 páginasHigh Pressure ProcessingZohaib ArshadAún no hay calificaciones

- Understanding Meat and GameDocumento40 páginasUnderstanding Meat and GameМария Антуанетта Кальвес100% (2)

- Tle 10 Cookery Q 4 Module 7Documento11 páginasTle 10 Cookery Q 4 Module 7Danica DaniotAún no hay calificaciones

- Contaminated That Affects The Taste of The Lamb. Raw Meat Such As Lamb Is OftenDocumento8 páginasContaminated That Affects The Taste of The Lamb. Raw Meat Such As Lamb Is OftennurAún no hay calificaciones

- Preserving Meat MethodsDocumento4 páginasPreserving Meat MethodsAngeline Cortez100% (1)

- Case Study FoodDocumento4 páginasCase Study FoodKarynne Bernardine Gerona SiclotAún no hay calificaciones

- Introduction To Milk ProcessingDocumento8 páginasIntroduction To Milk ProcessingMintesnot Bogale100% (1)

- Butchers HandbookDocumento20 páginasButchers HandbookJacqueline WongAún no hay calificaciones

- Meat, Poultry and Eggs ProcessingDocumento107 páginasMeat, Poultry and Eggs Processingaborhade100% (1)

- Food Science Unit 4Documento4 páginasFood Science Unit 4Krithi meAún no hay calificaciones

- 5th Sem Food Production NotesDocumento83 páginas5th Sem Food Production NotesRavi SomaAún no hay calificaciones

- 2 FoodDocumento27 páginas2 FoodPriyam TalukdarAún no hay calificaciones

- Meat Fish and Poultry Background InfoDocumento4 páginasMeat Fish and Poultry Background InfoChenna Mae ReyesAún no hay calificaciones

- Feng 3008-Food Technology I-Week 2Documento71 páginasFeng 3008-Food Technology I-Week 2Zülal Sıla BaştürkAún no hay calificaciones

- Manual on meat cold storage and chillingDocumento10 páginasManual on meat cold storage and chillingtanveer-azizAún no hay calificaciones

- The Complete Book of Small-Batch Preserving: Over 300 Recipes to Use Year-RoundDe EverandThe Complete Book of Small-Batch Preserving: Over 300 Recipes to Use Year-RoundCalificación: 4 de 5 estrellas4/5 (6)

- Easy Way to Can and Preserve: Simple Canning and Preserving Process for Your Food: Fermentation & Survival HacksDe EverandEasy Way to Can and Preserve: Simple Canning and Preserving Process for Your Food: Fermentation & Survival HacksAún no hay calificaciones

- STP 1560-2013Documento346 páginasSTP 1560-2013HieuHTAún no hay calificaciones

- A Medical Outreach Elective CourseDocumento11 páginasA Medical Outreach Elective CourseRobert SmithAún no hay calificaciones

- Healy Professional DeviceDocumento1 páginaHealy Professional DeviceBramarish KadakuntlaAún no hay calificaciones

- Yoga Your Home Practice CompanionDocumento257 páginasYoga Your Home Practice Companionjohncoltrane97% (33)

- NCP - Acute Pain - FractureDocumento1 páginaNCP - Acute Pain - Fracturemawel73% (22)

- Octopi RoxDocumento29 páginasOctopi Roxlam2289Aún no hay calificaciones

- 380 Final PaperDocumento46 páginas380 Final Paperapi-538048965Aún no hay calificaciones

- NurseCorps Part 8Documento24 páginasNurseCorps Part 8smith.kevin1420344Aún no hay calificaciones

- GastroparesisDocumento10 páginasGastroparesisapi-437831510Aún no hay calificaciones

- Pain AssessmentDocumento10 páginasPain Assessmentaashika15Aún no hay calificaciones

- Week 4-Physical Fitness TestDocumento38 páginasWeek 4-Physical Fitness TestCatherine Sagario OliquinoAún no hay calificaciones

- 11 - Comfort, Rest and Sleep Copy 6Documento28 páginas11 - Comfort, Rest and Sleep Copy 6Abdallah AlasalAún no hay calificaciones

- Confidence Intervals For Ratio of Two Poisson Rates Using The Method of Variance Estimates RecoveryDocumento23 páginasConfidence Intervals For Ratio of Two Poisson Rates Using The Method of Variance Estimates RecoveryJaneAún no hay calificaciones

- Paul B. Bishop, DC, MD, PHD, Jeffrey A. Quon, DC, PHD, FCCSC, Charles G. Fisher, MD, MHSC, FRCSC, Marcel F.S. Dvorak, MD, FRCSCDocumento10 páginasPaul B. Bishop, DC, MD, PHD, Jeffrey A. Quon, DC, PHD, FCCSC, Charles G. Fisher, MD, MHSC, FRCSC, Marcel F.S. Dvorak, MD, FRCSCorlando moraAún no hay calificaciones

- Vol3issue12018 PDFDocumento58 páginasVol3issue12018 PDFpyrockerAún no hay calificaciones

- Complaints Handling: BDA AdviceDocumento8 páginasComplaints Handling: BDA Advicedruzair007Aún no hay calificaciones

- IWA Publishing - Anaerobic Reactors For Sewage Treatment - Design, Construction and Operation - 2020-01-10Documento1 páginaIWA Publishing - Anaerobic Reactors For Sewage Treatment - Design, Construction and Operation - 2020-01-10JOHNY ALEJANDRO GARCIA SEPULVEDAAún no hay calificaciones

- Birads PosterDocumento1 páginaBirads PosterGopalarathnam BalachandranAún no hay calificaciones

- 67166-Apvma Veterinary Medicines Technical Report TemplateDocumento42 páginas67166-Apvma Veterinary Medicines Technical Report Templateali aimanAún no hay calificaciones

- Newborn Care Volume 1 2020-1Documento192 páginasNewborn Care Volume 1 2020-1Shyvonne PeirisAún no hay calificaciones

- Central Adult and Pediatric in Tensive Care UnitDocumento4 páginasCentral Adult and Pediatric in Tensive Care UnitChris T NaAún no hay calificaciones

- Effect of Ointment Base Type on Percutaneous Drug AbsorptionDocumento4 páginasEffect of Ointment Base Type on Percutaneous Drug AbsorptionINDAHAún no hay calificaciones

- Post MortemDocumento4 páginasPost MortemErlinda YulyAún no hay calificaciones

- Journal Club Presentation: DR Waleed AhmadDocumento30 páginasJournal Club Presentation: DR Waleed Ahmadkaram aliAún no hay calificaciones

- NeuroQuantology Publication June 2022 Vol 20 Issue 6 AU Category B JournalDocumento7 páginasNeuroQuantology Publication June 2022 Vol 20 Issue 6 AU Category B JournalNARESHAún no hay calificaciones

- Anthrax (Woolsesters Disease, Malignant Edema) What Is Anthrax?Documento3 páginasAnthrax (Woolsesters Disease, Malignant Edema) What Is Anthrax?rvanguardiaAún no hay calificaciones

- API SM Part 1Documento7 páginasAPI SM Part 1Ronaldo JanglinAún no hay calificaciones

- Laboratory Hygiene and SafetyDocumento34 páginasLaboratory Hygiene and SafetyResmiAún no hay calificaciones

- DSM 5Documento35 páginasDSM 5Hemant KumarAún no hay calificaciones

- Posters Whofic 2020Documento107 páginasPosters Whofic 2020Kristel HurtadoAún no hay calificaciones