Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Lifting Systems For Precast Concrete Products MC Magazine Summer 1998 Concrete Publications Npca 120

Cargado por

janaaidaas0 calificaciones0% encontró este documento útil (0 votos)

73 vistas8 páginasPrecast concrete products need to be lifted and handled a number of times during production and installation. Precasters use a variety of methods and equipment, including commercially manufactured inserts, home-made devices, lifting clamps and grooves for slings. The capacity of lifting inserts should be four times the actual load.

Descripción original:

Título original

Lifting Systems for Precast Concrete Products Mc Magazine Summer 1998 Concrete Publications Npca 120

Derechos de autor

© Attribution Non-Commercial (BY-NC)

Formatos disponibles

DOC, PDF, TXT o lea en línea desde Scribd

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoPrecast concrete products need to be lifted and handled a number of times during production and installation. Precasters use a variety of methods and equipment, including commercially manufactured inserts, home-made devices, lifting clamps and grooves for slings. The capacity of lifting inserts should be four times the actual load.

Copyright:

Attribution Non-Commercial (BY-NC)

Formatos disponibles

Descargue como DOC, PDF, TXT o lea en línea desde Scribd

0 calificaciones0% encontró este documento útil (0 votos)

73 vistas8 páginasLifting Systems For Precast Concrete Products MC Magazine Summer 1998 Concrete Publications Npca 120

Cargado por

janaaidaasPrecast concrete products need to be lifted and handled a number of times during production and installation. Precasters use a variety of methods and equipment, including commercially manufactured inserts, home-made devices, lifting clamps and grooves for slings. The capacity of lifting inserts should be four times the actual load.

Copyright:

Attribution Non-Commercial (BY-NC)

Formatos disponibles

Descargue como DOC, PDF, TXT o lea en línea desde Scribd

Está en la página 1de 8

Search the Site:

Go!

2008 NPCA

MC MAGAZINE ARCHIVE

LIFTING SYSTEMS FOR PRECAST CONCRETE

PRODUCTS

Safe, effective, economical lifting and handling of precast concrete

products is essential for producers and users of these products.

Precast concrete products need to be lifted and handled a number

times during production and installation, particularly when removing

from the casting bed or form, transporting from the casting bed to

storage or from storage to point of use, lifting into installed position

or anchoring to a structural frame or other concrete members

(where required).

Precasters use a variety of methods and equipment, including

commercially manufactured inserts, home-made devices, lifting

clamps and grooves for slings. There are a number of

considerations that precasters use when selecting lifting systems.

These include safety,, ease of use by the producer and the installer,

and the impact on finished concrete product.

Safety

oncern about the safety of employees and other personnel

involved in the production and installation of precast concrete

products is paramount. There are many reasons for this, but most

importantly, prioritizing safety is just the right thing to do. There are

also good business reasons for establishing excellent safety

practices. When accidents and injuries to workers occur, potential

costs include:

O Damage to products

O Worker's compensation (actual costs and future policy

increases)

O Absence of worker

O Morale

O Adverse publicity

O Liability

Product Integrity.Precast concrete products should not be moved

until the concrete has gained sufficient compressive strength. n

some cases, the form and the product are moved at the same time

with the lifting hook connected directly to the form. Some forms are

made to remain in place while inserts, hooks, or slings are used to

remove the product.

iability.n legal cases where accidents have occurred, companies

not complying with the applicable codes and standards can be

found liable or incompetent. Attorneys rely on codes being state of

the art.

ompliance with Safety Requirements. n general, the capacity

of lifting inserts should be four times the actual load. Lifting

hardware should be five times the actual load. When wire rope is

used in a lifting system, the U.S. Occupational Safety and Health

Administration (OSHA) recommends a minimum safety factor (FS)

of five. The American National Standards nstitute (ANS), however,

recommends a minimum safety factor of seven. Because of the

differing standards, the designer needs to evaluate the situation and

choose an appropriate safety factor. f the wire rope will experience

mild "wear and tear," then an FS of five might be satisfactory. At the

other extreme, severe "wear and tear" conditions will warrant an FS

of seven.

Several organizations have related regulations or standards. OSHA

is entrusted with enforcement and can levy penalties (usually

financial) on organizations not complying with the requirements of

FR Title 29. Two organizations, ANS and the American Society

for Testing and Materials (ASTM), create and update codes and

standards. Various U.S. and anadian agencies and local

governments may have additional requirements.

Types of Lifting Inserts

Precast concrete producers use various types of inserts. When

choosing lifting inserts, precasters are concerned with many factors,

including safety, compliance with OSHA and other requirements,

ease of installation, ease of use by rigger, angle of lift/pull, vacuum

and water testing, patching, quality, liability, and cost.

ommercially Manufactured Inserts. A variety of manufactured

lifting inserts are currently available. These products are

manufactured from several different materials, including hot-forged

high quality steel, wire coil, carbon steel roping, grade 60 rebar,

plastics (bonded impact polystyrene, thermoplastic, Hytrel

polyester, polypropylene, etc.), and ductile iron.

Generally, electo-galvanizing (per ASTM A 633) or hot-dipped

galvanizing (per ASTM A 123 or A 153) is available to protect the

inserts from external corrosion. Plastic tips or stainless tips are also

often available. Most manufacturers recommend against any

welding modification to their products.

Full-service suppliers will provide comprehensive engineering and

design information with their products. Product catalogs often

provide comprehensive information on selection, installation,

rigging, and handling.

Detailed engineering data is essential for the precast concrete

producer to properly use and install lifting inserts.

Precasters should use the appropriate hardware and inserts for

lifting their products. Occasionally, hardware and inserts are used in

situations beyond their design capacity or in applications for which

they were not designed. They may function adequately for long

periods of time, but eventually they most likely will fail. The end

result may not only be a product dropped in the yard, but a lifting

insert failure that could lead to serious accidents and injuries.

Manufacturers design inserts based on static loads, proper

installation and specific concrete design strength. f a product is

moved prior to reaching the design strength of the concrete or

subjected to a dynamic load (such as being transported at a high

rate of speed or bumped when driving over a ditch), the insert may

fail. Lifting a concrete product frozen to the ground will also exert

additional forces on the lifting system and the lift truck.

When the inserts are stressed due to forces and loadings beyond

the design capacity, the inserts may not fail, but be permanently

damaged. This is very dangerous, because the system will appear

to be intact, but may later fail at loads below the rated capacities.

Some manufactured inserts are not engineered. t can be very

difficult to evaluate the strength and capacity of such products.

Additionally, liability for failures can be complex.

%ypes:

O plastic inserts (special attachment required)

O recessed pockets with loops

O split anchors

O ring clutches

O lifting eye bolts

O coil inserts

O plates

O pulling irons

O lift pins (remain in product; special forklift attachment

required)

Advantages of commercially manufactured inserts: Load tested and

designed to meet OSHA requirements. Does not have to be

removed at the jobsite, generally no mortar patching required. May

be more economical than other inserts. Special reinforcing may be

added to increase a load capacity of an insert. Reduces spalling at

insert location. Manufacturers may be able to provide extensive

technical support to precasters using their products.

Disadvantages: Often appear to be more expensive than "home-

made" devices. May need special handling attachments or

equipment that can be costly. These items must be installed as

designed by the manufacturer, otherwise failures and pullouts may

occur. Any change in use from designed purpose should be verified

by the manufacturer's technical services department.

ome-made devices. These devices usually are not engineered

or load tested. Several types of home-made devices are routinely

used, including bent reinforcing steel bar, prestressed strand as

loops and recessed bars (countersunk with temporary blockouts).

Bent bars or loops must be carefully placed within the formwork and

rebar cage to ensure adequate concrete cover. f rebar is placed

close to the finished concrete surface, corrosion of the rebar may

occur. The rebar will expand due to this corrosion and spall the

concrete surface. Deformed bars work best, since smooth bars

require longer development lengths.

Loops are cut off after the precast concrete product is installed to

reduce corrosion. Sometimes a recessed pocket is created with a

neoprene blockout for the bent bars or loops. After the precast

product is installed the recessed pockets can be filled with grout or

other concrete patching material. The recessed pocket should be

designed such that a chain or sling will not damage the surrounding

concrete.

Advantages of home-made devices: nexpensive, simple to use, no

need for special lifting hardware or attachments, quick

connect/disconnect.

Disadvantages: Expensive and/or inconvenient to load test or

design to meet OSHA documentation requirements. Often mortar

patching is required at the jobsite. nstallers can be sloppy about

positioning of loops and bars, which can affect performance.

ifting clamps/grapples. These products work with cranes and

forklifts. They are specialized lifting devices designed for specific

types of precast products, such as grapples for transportation

barriers, pipe handlers (clamps) for manhole sections, box culvert

handlers and lift clamps for precast concrete steps.

Advantages of lifting clamps/grapples: Fork truck/crane operators

can accomplish all handling operations without leaving the truck.

When properly operated, there is reduced damage to products.

Lower labor costs as fewer workers can move more product.

Disadvantages: No option for others to install the product unless

inserts are also installed. Specialized, sometimes expensive

equipment required. Operators need training to avoid overloading

the equipment (similar to lift truck training).

rooves for slings. Some precasters design their forms to create

a horizontal groove in end walls of box-shaped products, such as

utility vaults and septic tanks. Lifting cables are placed in the

grooves on each side of the product.

Advantages of grooves for slings: nexpensive, easy to install in

precast products. Handling equipment (slings) is standard, readily

available and uncomplicated. No problems with spalling, no holes

made through the product.

Disadvantages: rane/fork lift operator must have substantial

experience. Slings can fray and need to be regularly inspected. an

only be used for rectangular shapes, such as septic tanks and small

utility vaults.

SeIection Tips

Selection of proper anchors for lifting precast concrete products

requires consideration of a number of factors including the type of

load, type of lift, concrete thickness, reinforcement, ease of

attachment to product, compliance with safety requirements, ease

of use by rigger during final installation and cost. Precasters should

consider the following factors when determining the load per insert:

O Weight of the concrete shape.

O Weight of form, if product will be lifted before concrete

product is stripped.

O Adhesion to the form surface.

O Type of concrete (normal, light weight, etc.).

O Dynamic loads (impact due to handling, transport or

erecting conditions).

O oncrete compressive strength at time of initial lift.

O Number of lifting points and type of rigging to be used.

O Direction of pull (cable or sling angle).

O Flexural stresses of thin concrete shapes.

O Panel or product thickness.

O Edge distance (thin wall, free edge or shear loading

conditions).

Removing a precast concrete product from its form can create

additional loads that effectively increase the dead load of the item.

Forces due to adhesion will vary with different form release agents.

One insert manufacturer recommends using the following loads

when determining adhesion forces (additional dead load) for a

precast item:

O oncrete Forms 20 lbs./sq. ft.

O Steel Forms 25 lbs./sq. ft.

O Plywood Forms 50 lbs./sq. ft. (Flat Surface)

O Plywood Forms 75 lbs./sq. ft. (Ribbed Surface)

Detailed calculations should be made by an engineer to determine

the loads for each insert.

Ease of Use by Precast Concrete Producer

Lifting inserts should be simple and straightforward for the precast

concrete worker to install into a product. Secure attachment to the

steel reinforcement or to the formwork is essential. nserts must not

shift or move during concrete placement. Welding of manufactured

precast concrete accessories is not recommended. Detailed

knowledge of materials, heat treatment and welding procedures is

required for structural welding. Simple tack welding can damage

iron castings, cause carbides and extreme brittleness near the weld

point, and may destroy most of a casting's load value.

Recessed anchors can be advantageous because they are easily

grouted in after the concrete product is installed. Recessing

products provide several functions. They can fasten the anchors to

the formwork, protect the anchor head from seeping concrete, and

form a void that is shaped to receive the rigging attachment (hook,

ring clutch, etc.). Recessing products are available in steel/iron,

flexible/reusable foams, disposable plastic and reusable plastic.

Recessing products can be attached to formwork with a holding rod

or bayonet assembly, a holding plate, screws/wingnuts or nails.

They also can be suspended from temporary cross supports or tied

to reinforcing steel.

Some commercial precast concrete lifting systems use special

lifting hooks, ring clutches or other devices. These products may

add to the convenience and safety of the system. Unfortunately,

these special handling devices may be expensive. t can be a

nuisance and an additional expense if workers misplace or abuse

these items.

Impact on Finished Concrete Product

Once safety concerns are resolved, product quality is a top priority.

Lifting inserts and anchors should not create spalling problems and

should have minimal patching requirements. f watertightness or

vacuum testing is required of a precast concrete product, lifting

inserts should not adversely compromise the manhole, septic tank

or other product.

Aesthetics are a primary concern for many precast products,

especially architectural wall panels. Anchors and inserts should be

installed in discrete locations and patching should be minimal.

Anchors are generally inserted into the ends of these panels.

ost is always a priority in the competitive business world.

alculating the costs of lifting inserts, anchors and systems is not

simple. Some of the many factors influencing cost include design of

the anchor and lifting system, initial cost of the anchor, labor costs

to install, costs to handle product after casting, handling costs for

final installation of the product, losses due to damage, and patching

and repair costs.

Review Your Lifting Systems

Most lifting inserts, anchors and lifting systems have been tried and

true for years. Nevertheless, it may be worthwhile to review the

systems at your facility to make certain, for example, that inserts

comply with OSHA, ANS, ASTM or equivalent anadian

requirements or to find ways to reduce damage during handling of

precast products by revamping your lifting inserts.

Call NPCA at (800) 366-7731 for the following resources:

O A list of manufacturers who produce lifting inserts.

O Detailed information on designing lifting inserts.

O $afety videos relating to material handling and cranes.

OSHA: U.S. Department of Labor (OccupationaI Safety

and HeaIth Administration)

ode of Federal Regulations (FR) Title 29 (1990 Revision)

Section 1926.704 states:

(c) Lifting inserts which are embedded or otherwise attached to

precast concrete members, other than the tilt-up members, shall be

capable of supporting at least four times the maximum intended

load applied or transmitted to them.

(d) Lifting hardware shall be capable of supporting at least five

times the maximum intended load applied or transmitted to the

lifting hardware.

(e) No employee shall be permitted under precast concrete

members being lifted or tilted into position except those employees

required for the erection of those members.

ode of Federal Regulations (FR) Title 29 (1990 Revision)

Section 1926.704 states: (a)(4) Special custom design grabs,

hooks, clamps, or other lifting accessories, for such units as

modular panels, prefabricated structures and similar materials, shall

be marked to indicate the safe working loads and shall be proof-

tested prior to use to 125 percent of their rated load.

ode of Federal Regulations (FR) Title 29 (1990 Revision)

Section 1926.251 states :

(c)(1) Tables H-3 through H-14 shall be used to determine the safe

working loads of various sizes and classifications of improved plow

steel wire rope and wire rope slings with various types of terminals.

For sizes, classifications, and grades not included in these tables,

the safe working load recommended by the manufacturer for

specific, identifiable products shall be followed, provided that a

safety factor of not less than 5 is maintained.

ANSI: American NationaI Standards Institute

Standard A10.9-1983: oncrete and Masonry Work - Safety

Requirements

9. Precast oncrete

9.3 Handling and Erection

9.3.3 Lifting hardware shall be designed to

provide sufficient strength to withstand the

imposed loads with a factor of safety of at least 5.

Embedded inserts used in precast concrete

elements or precast, prestressed concrete shall

have a minimum safety factor of 4 and shall be

used in the manner described in manufacturers'

bulletins.

Standard A10.5-1992: Safety Requirements for Material Hoists

14 MATERAL-HOST WRE ROPE AND

SHEAVES

14.1 Breaking Strength. All hoisting rope shall be

of such a breaking strength as to provide a

minimum factor of safety of 7.

ASTM: American Society for Testing and MateriaIs

ASTM 1227-97 - Standard Practice for Precast oncrete Septic

Tanks

6.1.5 nserts embedded in the concrete shall be

designed for an ultimate load that is four times

the working load (Factor of Safety = 4).

6.5 Lift equipment shall be designed for an

ultimate load that is five times the working load

(Factor of Safety = 5).

Back to top

Back to M Magazine Archive

También podría gustarte

- The Yellow House: A Memoir (2019 National Book Award Winner)De EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Calificación: 4 de 5 estrellas4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeCalificación: 4 de 5 estrellas4/5 (5795)

- Vertically and Crosswise: Academy of Vedic Mathematics Introductory CourseDocumento6 páginasVertically and Crosswise: Academy of Vedic Mathematics Introductory CoursejanaaidaasAún no hay calificaciones

- Welcome To Imtma: Right Click For Full ScreenDocumento18 páginasWelcome To Imtma: Right Click For Full ScreenjanaaidaasAún no hay calificaciones

- Lkikstra SW API Demystified SWW08Documento8 páginasLkikstra SW API Demystified SWW08janaaidaasAún no hay calificaciones

- Campus 45-Quickhelp eDocumento8 páginasCampus 45-Quickhelp ejanaaidaasAún no hay calificaciones

- Encyclopedia of Medical Devices and Instrumentation - Vol. 3Documento634 páginasEncyclopedia of Medical Devices and Instrumentation - Vol. 3janaaidaasAún no hay calificaciones

- Butt WeldDocumento12 páginasButt WeldjanaaidaasAún no hay calificaciones

- Ast Xiao 2008Documento24 páginasAst Xiao 2008janaaidaasAún no hay calificaciones

- PTC Creo Tips and Tricks PDFDocumento4 páginasPTC Creo Tips and Tricks PDFmsaAún no hay calificaciones

- CFRM White Paper ScreenDocumento6 páginasCFRM White Paper ScreenjanaaidaasAún no hay calificaciones

- Animation Pro eDocumento18 páginasAnimation Pro ejanaaidaasAún no hay calificaciones

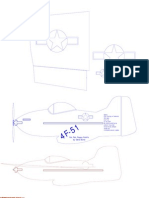

- 4F-51 FullDocumento1 página4F-51 FulljanaaidaasAún no hay calificaciones

- Korkhaus Analysis ChartDocumento3 páginasKorkhaus Analysis ChartjanaaidaasAún no hay calificaciones

- Free Book Spot - Download ListDocumento2 páginasFree Book Spot - Download ListjanaaidaasAún no hay calificaciones

- Shoe Dog: A Memoir by the Creator of NikeDe EverandShoe Dog: A Memoir by the Creator of NikeCalificación: 4.5 de 5 estrellas4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureCalificación: 4.5 de 5 estrellas4.5/5 (474)

- Grit: The Power of Passion and PerseveranceDe EverandGrit: The Power of Passion and PerseveranceCalificación: 4 de 5 estrellas4/5 (588)

- On Fire: The (Burning) Case for a Green New DealDe EverandOn Fire: The (Burning) Case for a Green New DealCalificación: 4 de 5 estrellas4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryCalificación: 3.5 de 5 estrellas3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceCalificación: 4 de 5 estrellas4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe EverandNever Split the Difference: Negotiating As If Your Life Depended On ItCalificación: 4.5 de 5 estrellas4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe EverandThe Little Book of Hygge: Danish Secrets to Happy LivingCalificación: 3.5 de 5 estrellas3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersCalificación: 4.5 de 5 estrellas4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaDe EverandThe Unwinding: An Inner History of the New AmericaCalificación: 4 de 5 estrellas4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDe EverandTeam of Rivals: The Political Genius of Abraham LincolnCalificación: 4.5 de 5 estrellas4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyCalificación: 3.5 de 5 estrellas3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaCalificación: 4.5 de 5 estrellas4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerDe EverandThe Emperor of All Maladies: A Biography of CancerCalificación: 4.5 de 5 estrellas4.5/5 (271)

- Rise of ISIS: A Threat We Can't IgnoreDe EverandRise of ISIS: A Threat We Can't IgnoreCalificación: 3.5 de 5 estrellas3.5/5 (137)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreCalificación: 4 de 5 estrellas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Calificación: 4.5 de 5 estrellas4.5/5 (121)

- The Perks of Being a WallflowerDe EverandThe Perks of Being a WallflowerCalificación: 4.5 de 5 estrellas4.5/5 (2104)

- Her Body and Other Parties: StoriesDe EverandHer Body and Other Parties: StoriesCalificación: 4 de 5 estrellas4/5 (821)

- Standard Inspection and Test Plan For API6D Valves PDFDocumento4 páginasStandard Inspection and Test Plan For API6D Valves PDFWaqas JawaidAún no hay calificaciones

- Mutu DabholkarDocumento28 páginasMutu DabholkardyaAún no hay calificaciones

- Catalogue Bron Plastic PDFDocumento54 páginasCatalogue Bron Plastic PDFpsorpAún no hay calificaciones

- Facility Decisions: Network Design in A Supply ChainDocumento35 páginasFacility Decisions: Network Design in A Supply Chainmushtaque61Aún no hay calificaciones

- CH 12Documento2 páginasCH 12onlydlonly100% (2)

- 4.1 Materials and MetallurgyDocumento16 páginas4.1 Materials and MetallurgyVijayKumarAún no hay calificaciones

- Wall Ties FormworkDocumento96 páginasWall Ties FormworkJack Jeff0% (1)

- Assignment Engineering MaterialsDocumento8 páginasAssignment Engineering MaterialsMirza HumzaAún no hay calificaciones

- ASTM D2628 (1998) - Preformed Polychloroprene Elastastomeric Joint Seals For Concrete PavingDocumento3 páginasASTM D2628 (1998) - Preformed Polychloroprene Elastastomeric Joint Seals For Concrete Pavingnoto SugiartoAún no hay calificaciones

- GTP - 12PX0.5,6PX0.75,2PX0.5,10PX0.5Documento3 páginasGTP - 12PX0.5,6PX0.75,2PX0.5,10PX0.5santhoshAún no hay calificaciones

- Project For Using Different Sizes of Coarse Aggregate For Concrete StrengthDocumento18 páginasProject For Using Different Sizes of Coarse Aggregate For Concrete StrengthZohaib Siapad100% (7)

- Aalco Metals LTD - Aluminium Alloy 5083 0 H111 Sheet and Plate - 149 PDFDocumento2 páginasAalco Metals LTD - Aluminium Alloy 5083 0 H111 Sheet and Plate - 149 PDFOvidiu ChertesAún no hay calificaciones

- Weld Profiles - AWS D1.1 D1.1M-2010Documento1 páginaWeld Profiles - AWS D1.1 D1.1M-2010gigiphiAún no hay calificaciones

- InfoSheet AUMEL23012014Documento2 páginasInfoSheet AUMEL23012014MarketinggAún no hay calificaciones

- Acid Resistant Tiles BricksDocumento6 páginasAcid Resistant Tiles BricksDeboline MitraAún no hay calificaciones

- Mix Design To Produce 1 M of Eps-Concrete: Sircontec PSBDocumento2 páginasMix Design To Produce 1 M of Eps-Concrete: Sircontec PSBmabuhamdAún no hay calificaciones

- Final Report PSDF Sports Goods Sector Skills Study PDFDocumento117 páginasFinal Report PSDF Sports Goods Sector Skills Study PDFDanish KumarAún no hay calificaciones

- Long-Run Production Function (With Diagram) : Isoquant CurveDocumento20 páginasLong-Run Production Function (With Diagram) : Isoquant Curveyazhini100% (1)

- HBCVJGKDocumento4 páginasHBCVJGKJanice FernandezAún no hay calificaciones

- Primal c-41Documento2 páginasPrimal c-41Mohammad Doost MohammadiAún no hay calificaciones

- DirectoryDocumento10 páginasDirectoryDavidAún no hay calificaciones

- 45 1014 01 Liquid Injection Molding Processing GuideDocumento24 páginas45 1014 01 Liquid Injection Molding Processing Guidezaryab khanAún no hay calificaciones

- Resume-Mayur Kasar Jan 16Documento3 páginasResume-Mayur Kasar Jan 16Mayur KasarAún no hay calificaciones

- Press Tool PDFDocumento5 páginasPress Tool PDFElaine Johnson50% (6)

- Chapter 13-Supply Chain Process Integration: Principles of Supply Chain Management: A Balanced ApproachDocumento19 páginasChapter 13-Supply Chain Process Integration: Principles of Supply Chain Management: A Balanced ApproachErum Anwer100% (1)

- Combustion Inspection Elimination KitDocumento2 páginasCombustion Inspection Elimination KitP_DaviesAún no hay calificaciones

- Marketstructure PDFDocumento15 páginasMarketstructure PDFmihir kumarAún no hay calificaciones

- DDTW Properties For High Strength Line Pipe SteelsDocumento5 páginasDDTW Properties For High Strength Line Pipe SteelsWagner Duarte FloresAún no hay calificaciones

- Management of Small Hydro Projects Developer/investor's PerspectiveDocumento0 páginasManagement of Small Hydro Projects Developer/investor's PerspectivesapkotamonishAún no hay calificaciones

- Estimating Building CostDocumento8 páginasEstimating Building CostFREDIELABRADORAún no hay calificaciones