Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Bottom Lug

Cargado por

Ajiri IvoviDescripción original:

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Bottom Lug

Cargado por

Ajiri IvoviCopyright:

Formatos disponibles

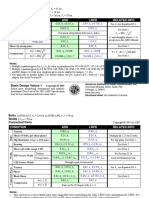

DESIGN OF BOTTOM LUG

thickness, t

Embed plate

Dia, d

kip = 1000Ib t = 1.25.in ksi = 1000 Ib'/in.in

2'' 1/2'' 3'' e

d = 1.1875 in a = 1.90625 in e = 2.40625 in fu = 58 ksi a 5'' fy = 36 ksi

Geometric Guidelines: There are some geometric guidelines to be considered as recommended in Reference 1. They will be called Rule 1 and Rule 2. Rule 1: The dimension "a" must be greater than or equal to half the hole diameter, d. i.e. a 1/2 * d For this example, a = 1.90625" and since it is greater than 1/2*d which is 0.59375". Rule 1 is satisfied. Rule_1 if ( a 0.5d "OK" "NG" ) Rule 2: The dimension "e" must be greater than or equal to 0.67 times the hole diameter, d. Thus, e 0.67*d. For this example, e = 2.40625" and since it is greater than 0.67*d which is 0.79563". Rule 2 is satisfied. Rule_2 Evaluation based on Failure Modes: Design of Top Lifting Lugs Page 1 ) Rule_2 "OK" Rule_1 "OK"

Failure Mode 1: This failure mode involves tension failure on both sides of the hole. Therefore, the ultimate tensile load is given by: Pu = 2. a. t. u = 2*1.90625*1.25*58 Pu = 276.40625 kip

A factor of safety of 5 is common for lifting components. Therefore, using a factor of safety of 5, the working load is: Pw1 = Pu/5 = 55.281 kip Failure Mode 2: This failure mode involves bearing failure at the pin/lifting lug interface. Often the pin diameter is much less than the hole diameter. Let us assume a pin diameter 1/2" less than the hole diameter. Using a bearing stress of 0.9 Fy, and a "factor" of 1.8, we have (See Note 1): dpin = Pw2 =

Pw2 = 23.3125 kip

1.125 in

Failure Mode 3: This failure mode involves shear failure as the pin tries to push out a block of steel through the edge of the lug plate. The shear area is twice the cross-sectional area beyond the hole for the pin. Thus: Pw3 = Pw3 = 48.125 kip Design of Top Lifting Lugs Page 2

Failure Mode 4: This failure mode involves tensile failure as the pin tries to push out a block of steel through the edge of the lug plate. Assuming a block of steel 0.8d in length, allowable load is given by:

Pw4 = = Pw4 = 136.398 kip

Failure Mode 5:

This failure mode involves the out-of-plane buckling failure of the lug. Per Ref. 1, this failure is prevented by ensuring a minimum thickness of lug of 0.5 inches and 0.25 times the hole diameter d. In this example, since 0.25 x 1.1875 = 0.3125" and the thickness of the lug is 1.25", this failure mode does not control. Rule_3 if ( t 0.25.d"OK" "NG") Rule_3 "OK" Rule_4 if (t 0.5 in"OK" "NG") Rule_4 "OK" AISC Code Checks per Section D3.2: The above section of AISC Code has three separate geometry checks that can be applied to the lifting lug. If these requirements are not met, a smaller value for "a" should be used for the calculation of tensile capacity, aeff. Requirement 1: This requirement states that the minimum net area beyond the pin hole, parallel to the axis of the member (A1), shall not be less than 2/3 of the net area across the pin hole(A2). A1 = t.e A2 = 2.a.t 2 A1 = 3.008in A2 = 4.766in2 Since 2/3 of A2is 3.177in2 which is more than A1, this requirement is not satisfied. Therefore, the tensile capacity of the lug must be based on a reduced "a" dimension which will Design of Top Lifting Lugs Page 3

satisfy this requirement. Thus, make 2/3*A2 =A1. 2/3* 2.a.t = 3.008 a = 1.805 in Requirement 2: This requirement states that the distance transverse to the axis of a pin-connected plate from the edge of the pin hole to the edge of the member, i.e. dimension a, shall not exceed 4 times the thickness at the pin hole. Since 4 times thickness is 4 x 1.25" = 5" and is greater than 1.90625". This requirement is satisfied. a = 1.90625 < 4t (OK). Requirement 3: This requirement states that the diameter of the pin hole shall not be less than 1.25 times distance from the edge of pin hole to the edge of plate, i.e. dimension a. Since 1.25 times "a" is 1.25 x 1.90625 = 2.383" and is greater than the diameter of hole of 1.1875". This requirement is not satisfied. Therefore, the tensile capacity of the lug must be based on a reduced "a" dimension which will satisfy this requirement. Making 1.25a = d, a = 1.1875/1.25 = 0.95 in Thus aeff = 0.95 in Combining these three requirements into a single "formula" we have: AISC min = ( ) aeff = min(AISCmin) = 0.95 in Pw5 = Pw5 = 21.375 kip Weld between Lug and Base Plate: This is typically the weak link in an overhead lifitng lug, due to off-set loading. In general, the lug is rarely directly over the item to be rigged. Conservatively, let us assume that the off-set is a maximum of 45 degrees in the plane of the lug and 20 degrees normal to the plane of the lug. The additional loads due to off-set can be determined by statics to be as follows: =

Design of Top Lifting Lugs

Page 4

Therefore, the maximum load (W) that can be applied can be calculated as follows W = 1.kip This is an initial guess for Mathcad tw = 1.25in Length of welds along lug thickness l = 2in Lever arm w = 5in Length of weld along lug width

fmax = 4123.889 Ib/in =4.124 ksi f1(W) = (0.16 +0.1075+ 0.137)W = 0.4046W

f2 (W) = 0.0291W

f3(W) = 0.0.08W Pw6 = root[(f1(W)2 + f2(W)2 + f3(W)2)0.5 - fmax,W] = root[(0.1637W2 + 0.00084W2 + 0.0064W2)0.5 - 4.124] Pw6 = 9.974kip

Lug Base Material:

The analysis is similar to the weld above except that there is no interaction between tension and Design of Top Lifting Lugs Page 5

shear. The capacity is based on the maximum tensile stress at the base of the lug:

fmax =

= 15ksi

lw =2.a + d, Lug width = 5in

f1(W) = (0.16 + 0.5591 + 0.384)W = 1.1031W Pw7 = root[f1(W) fmax,W] = root[1.1031W 15] = 13.598kip

Conclusion: Capacity = (Pw1 , Pw2 , Pw3 ,Pw4 , Pw5 , Pw6 , Pw7 ) Capallow = min(Capacity) Capallow = 9.974kip Note variation in capacities for each attribute Pw1 = 55.281 kip Pw2 = 15.469 kip Pw3 = 48.125 kip Pw4 =136.398 kip Pw5 = 21.375 kip Pw6 = 9.974 kip

Pw7 = 13.598 kip If additional capacity is desired, the angles and can be restricted as needed to increase the capacity of the lug. In the above example, if these angles are made equal to zero, the maximum capacity will increase to 15.469 kips. References: 1. David T. Ricker, "Design and Construction of Lifting Beams", Engineering Journal, 4th Quarter, 1991. Design of Top Lifting Lugs Page 6

2. AISC Manual of Steel Construction (ASD), Ninth Edition, 1989 3. Omer Blodgett, "Design of Welded Structures", 1966 4. Clement Rajendra, Design/Evaluation of Overhead lifting lugs Notes: 1. As discussed in Reference 1, using a "factor" of 1.8 on AISC allowables results in a factor of safety of 5 for A36 steel. This is in line with ASME B30.20 which requires a design factor of 3 on yield strength and ANSI N14.6 which requires a design factor of 3 on yield strength and 5 on ultimate strength. This is also in line with the load ratings for other components of the lifting assembly such as slings, shackles, etc.

Design of Top Lifting Lugs

Page 7

También podría gustarte

- Calculating Wind Load on a Dish AntennaDocumento1 páginaCalculating Wind Load on a Dish AntennadovermanAún no hay calificaciones

- Checks For CompactnessDocumento15 páginasChecks For CompactnessjologscresenciaAún no hay calificaciones

- AISC LRFD Column DesignDocumento4 páginasAISC LRFD Column Designwinlugue3059Aún no hay calificaciones

- 498 Plate Girder ShearDocumento1 página498 Plate Girder ShearAssem ElhajjAún no hay calificaciones

- KDS 41 17 00 2019Documento75 páginasKDS 41 17 00 2019Suso IglesiasAún no hay calificaciones

- BasePlate 1 Check 46.8TDocumento63 páginasBasePlate 1 Check 46.8TrustamriyadiAún no hay calificaciones

- ShoringDocumento7 páginasShoringARUN RAWATAún no hay calificaciones

- Concrete Anchor Foundation Bolt Design Calculations With Example As Per ACI 318 Appendix D-Part3-Pull Out Strength in TensionDocumento4 páginasConcrete Anchor Foundation Bolt Design Calculations With Example As Per ACI 318 Appendix D-Part3-Pull Out Strength in TensionVenu GopalAún no hay calificaciones

- Stair Stringer DesignDocumento2 páginasStair Stringer DesignTerry CheukAún no hay calificaciones

- Analysis of Self-Supported Steel Chimney With The Effects of Geometrical ParametersDocumento6 páginasAnalysis of Self-Supported Steel Chimney With The Effects of Geometrical Parametersvikram413Aún no hay calificaciones

- 1.1 Design of Pipe Racks Writeup PDFDocumento5 páginas1.1 Design of Pipe Racks Writeup PDFCarlosAlbertoGrimaldoBarajasAún no hay calificaciones

- PurlinDocumento1 páginaPurlinCe WinAún no hay calificaciones

- Bs5950 Calculation Decking SheetDocumento6 páginasBs5950 Calculation Decking SheetKho C Ahl100% (1)

- TR12 PDFDocumento24 páginasTR12 PDFramorusoAún no hay calificaciones

- Duct Design With StiffenersDocumento67 páginasDuct Design With StiffenersRico CaraAún no hay calificaciones

- Appendix 1 - Scope of WorkDocumento13 páginasAppendix 1 - Scope of WorkNimra NaveedAún no hay calificaciones

- Design of Crane Runway GirdersDocumento22 páginasDesign of Crane Runway GirdersScooby DooAún no hay calificaciones

- Columns DesignDocumento60 páginasColumns DesignifsrebraAún no hay calificaciones

- 6 - CE 511 - Base Plate Design PDFDocumento33 páginas6 - CE 511 - Base Plate Design PDFJayson RamosAún no hay calificaciones

- Basic Design ValuesDocumento4 páginasBasic Design Valuesnenpatel-1Aún no hay calificaciones

- Steel ColumnDocumento8 páginasSteel ColumnvictorAún no hay calificaciones

- Underhung Monorail Beam Analysis Per AISC 9th Edition (ASD)Documento13 páginasUnderhung Monorail Beam Analysis Per AISC 9th Edition (ASD)Baran GulsayAún no hay calificaciones

- NBC 2010 - Commentaries - Section IDocumento24 páginasNBC 2010 - Commentaries - Section IRick HenbidAún no hay calificaciones

- Anchor Bolt CalculationsDocumento5 páginasAnchor Bolt Calculationssivaguruswamy thangarajAún no hay calificaciones

- Bolt-to-Rectangular HSS Wall Connections DesignDocumento1 páginaBolt-to-Rectangular HSS Wall Connections DesignronyAún no hay calificaciones

- Structural analysis and design of shedDocumento24 páginasStructural analysis and design of shedvtalexAún no hay calificaciones

- "Weldgrp" - Weld Group Analysis ProgramDocumento16 páginas"Weldgrp" - Weld Group Analysis ProgramMario BertiAún no hay calificaciones

- Wind Loads Calculations by ASCE7 05 For Any BuildingDocumento13 páginasWind Loads Calculations by ASCE7 05 For Any BuildingDaren ModestoAún no hay calificaciones

- Wind Load Calculation As Per Russia Code PDFDocumento7 páginasWind Load Calculation As Per Russia Code PDFDušan ŠebekAún no hay calificaciones

- LRFD Compression Member DesignDocumento236 páginasLRFD Compression Member DesignWayne Alegria JumawanAún no hay calificaciones

- Blast Resistant Design of Steel StructuresDocumento116 páginasBlast Resistant Design of Steel StructuresPetr KonupčíkAún no hay calificaciones

- CONNECTION: UB305X165X40BS5950 - Base Plate: AdminDocumento3 páginasCONNECTION: UB305X165X40BS5950 - Base Plate: AdminPAún no hay calificaciones

- COMPRESS Saddle DesignDocumento2 páginasCOMPRESS Saddle Designarif99pakAún no hay calificaciones

- Shear Lug Verification Example 2Documento1 páginaShear Lug Verification Example 2Nasrul AdliAún no hay calificaciones

- Code in Staad ProDocumento6 páginasCode in Staad ProZakaria ZulkifliAún no hay calificaciones

- Unistrut CatalogDocumento12 páginasUnistrut CatalogElia Nugraha AdiAún no hay calificaciones

- Beam Shear & Moment DiagramDocumento8 páginasBeam Shear & Moment DiagramAnantPawarAún no hay calificaciones

- Wind Load Reaction Force Due To Wind Action From Stack Acting On The Fan DeckDocumento3 páginasWind Load Reaction Force Due To Wind Action From Stack Acting On The Fan Deckikanyu79Aún no hay calificaciones

- Larsen & Toubro Limited - Ecc Division: Engineering Design and Research CentreDocumento1 páginaLarsen & Toubro Limited - Ecc Division: Engineering Design and Research CentreOuseppachan AmbookenAún no hay calificaciones

- Beam to column connection design analysisDocumento2 páginasBeam to column connection design analysisHAZIRACFS SURATAún no hay calificaciones

- Steel Members DesignDocumento195 páginasSteel Members DesignStephen JamesAún no hay calificaciones

- Lifting LugDocumento4 páginasLifting LugUmmer BavaAún no hay calificaciones

- AISC 13th Slip Critical Bolt Capacity ASDDocumento1 páginaAISC 13th Slip Critical Bolt Capacity ASDdantevariasAún no hay calificaciones

- NDS 11.3.1 Yield Limit EquationsDocumento6 páginasNDS 11.3.1 Yield Limit Equationspazz0Aún no hay calificaciones

- Civil 2019 v22 Release NoteDocumento25 páginasCivil 2019 v22 Release NoteNilay GandhiAún no hay calificaciones

- Example II.C-5 HSS Chevron Brace Connection: F F F FDocumento5 páginasExample II.C-5 HSS Chevron Brace Connection: F F F FVasilica BarbarasaAún no hay calificaciones

- SWD-CSA-A23.3-04 Shear Wall Design ManualDocumento82 páginasSWD-CSA-A23.3-04 Shear Wall Design ManualYohan LimAún no hay calificaciones

- Pin Connected Tension MemberDocumento2 páginasPin Connected Tension MemberAUNGPSAún no hay calificaciones

- Manual: Engineering Calculation TemplateDocumento8 páginasManual: Engineering Calculation TemplateHamiAún no hay calificaciones

- Crane Runway Beam Design - Crane Load CalculationDocumento6 páginasCrane Runway Beam Design - Crane Load CalculationAlex MolinaAún no hay calificaciones

- Evo Design - Structural Design: Calculation SheetDocumento4 páginasEvo Design - Structural Design: Calculation SheetVij Vaibhav VermaAún no hay calificaciones

- AD 337 - Wind Pressures For Buildings With Dominant OpeningsDocumento2 páginasAD 337 - Wind Pressures For Buildings With Dominant Openingssymon ellimacAún no hay calificaciones

- Unistrut CalcDocumento12 páginasUnistrut Calcjacs127Aún no hay calificaciones

- Combined Footing DesignDocumento1 páginaCombined Footing Designbalaji gmscAún no hay calificaciones

- AISC 9th Edition Prying Action Analysis ProgramDocumento8 páginasAISC 9th Edition Prying Action Analysis ProgramjoseherreramogollonAún no hay calificaciones

- AWWA D100 Tension TableDocumento1 páginaAWWA D100 Tension Tablejojo_323Aún no hay calificaciones

- Exhibition Stand - REV 0Documento12 páginasExhibition Stand - REV 0shibu4321Aún no hay calificaciones

- Calculation of Stresses in Footings Subjected To Uniaxial or Biaxial MomentsDocumento11 páginasCalculation of Stresses in Footings Subjected To Uniaxial or Biaxial MomentsIhab SorourAún no hay calificaciones

- Bunding of Storage Tanks and Transfer FacilitiesDocumento4 páginasBunding of Storage Tanks and Transfer FacilitiesAjiri IvoviAún no hay calificaciones

- Worship Song Lyrics Dedicated to GodDocumento1 páginaWorship Song Lyrics Dedicated to GodAjiri IvoviAún no hay calificaciones

- Table 8 - Schmidt Hammer Engr BoborDocumento1 páginaTable 8 - Schmidt Hammer Engr BoborAjiri IvoviAún no hay calificaciones

- Fund Raising LetterDocumento1 páginaFund Raising LetterAjiri IvoviAún no hay calificaciones

- Workshop 3Documento4 páginasWorkshop 3Ajiri IvoviAún no hay calificaciones

- 13 Fashion Studies Textbook XIDocumento158 páginas13 Fashion Studies Textbook XIMeeta GawriAún no hay calificaciones

- Unit 1 Writing. Exercise 1Documento316 páginasUnit 1 Writing. Exercise 1Hoài Thương NguyễnAún no hay calificaciones

- IP68 Rating ExplainedDocumento12 páginasIP68 Rating ExplainedAdhi ErlanggaAún no hay calificaciones

- Obiafatimajane Chapter 3 Lesson 7Documento17 páginasObiafatimajane Chapter 3 Lesson 7Ayela Kim PiliAún no hay calificaciones

- BMS Technical ManualDocumento266 páginasBMS Technical Manualiago manziAún no hay calificaciones

- Programming Manual Magic 308/616-CLI Quick ReferenceDocumento16 páginasProgramming Manual Magic 308/616-CLI Quick ReferencekrishnamarajublrAún no hay calificaciones

- Antiquity: Middle AgesDocumento6 páginasAntiquity: Middle AgesPABLO DIAZAún no hay calificaciones

- Suband Coding in MatlabDocumento5 páginasSuband Coding in MatlabZoro Roronoa0% (1)

- Miami Police File The O'Nell Case - Clemen Gina D. BDocumento30 páginasMiami Police File The O'Nell Case - Clemen Gina D. Barda15biceAún no hay calificaciones

- Time Table For Winter 2023 Theory ExaminationDocumento1 páginaTime Table For Winter 2023 Theory ExaminationSushant kakadeAún no hay calificaciones

- Victron MultiPlus 48 1200-13-16 Datasheet enDocumento1 páginaVictron MultiPlus 48 1200-13-16 Datasheet enBAHJARI AMINEAún no hay calificaciones

- Condy LatorDocumento11 páginasCondy LatorrekabiAún no hay calificaciones

- MMW FinalsDocumento4 páginasMMW FinalsAsh LiwanagAún no hay calificaciones

- Key ssl101 Academic Skills For University Success ssl101cDocumento196 páginasKey ssl101 Academic Skills For University Success ssl101cHùng NguyễnAún no hay calificaciones

- Design and Analysis of Crankshaft ComponentsDocumento21 páginasDesign and Analysis of Crankshaft Componentssushant470% (1)

- Application of ISO/IEC 17020:2012 For The Accreditation of Inspection BodiesDocumento14 páginasApplication of ISO/IEC 17020:2012 For The Accreditation of Inspection BodiesWilson VargasAún no hay calificaciones

- USA V BRACKLEY Jan6th Criminal ComplaintDocumento11 páginasUSA V BRACKLEY Jan6th Criminal ComplaintFile 411Aún no hay calificaciones

- Tender Notice and Invitation To TenderDocumento1 páginaTender Notice and Invitation To TenderWina George MuyundaAún no hay calificaciones

- Exor EPF-1032 DatasheetDocumento2 páginasExor EPF-1032 DatasheetElectromateAún no hay calificaciones

- 5 Dec2021-AWS Command Line Interface - User GuideDocumento215 páginas5 Dec2021-AWS Command Line Interface - User GuideshikhaxohebkhanAún no hay calificaciones

- NOTE CHAPTER 3 The Mole Concept, Chemical Formula and EquationDocumento10 páginasNOTE CHAPTER 3 The Mole Concept, Chemical Formula and EquationNur AfiqahAún no hay calificaciones

- GIS Arrester PDFDocumento0 páginasGIS Arrester PDFMrC03Aún no hay calificaciones

- SWOT Analysis of Solar Energy in India: Abdul Khader.J Mohamed Idris.PDocumento4 páginasSWOT Analysis of Solar Energy in India: Abdul Khader.J Mohamed Idris.PSuhas VaishnavAún no hay calificaciones

- Spsi RDocumento2 páginasSpsi RBrandy AAún no hay calificaciones

- Corn MillingDocumento4 páginasCorn Millingonetwoone s50% (1)

- AVANTIZ 2021 LNR125 (B927) EngineDocumento16 páginasAVANTIZ 2021 LNR125 (B927) EngineNg Chor TeckAún no hay calificaciones

- Supreme Court rules stabilization fees not trust fundsDocumento8 páginasSupreme Court rules stabilization fees not trust fundsNadzlah BandilaAún no hay calificaciones

- Capacity PlanningDocumento19 páginasCapacity PlanningfarjadarshadAún no hay calificaciones

- SYNOPSIS - Impact of GST On Small Traders!Documento21 páginasSYNOPSIS - Impact of GST On Small Traders!Laxmi PriyaAún no hay calificaciones

- Standard Deviation IntroductionDocumento3 páginasStandard Deviation IntroductionShyam ShresthaAún no hay calificaciones